Blue Diamond Severe Duty 2 Series Operation And Maintenance Manual

Angle broom

Hide thumbs

Also See for Severe Duty 2 Series:

- Owner's manual (54 pages) ,

- Operation and maintenance manual (18 pages)

Summary of Contents for Blue Diamond Severe Duty 2 Series

- Page 1 Severe Duty Series 2 Angle Broom Operation and Maintenance Manual Register your WARRANTY within 30 days of purchase 888-376-7027 | BlueDiamondAttachments.com...

- Page 2 Serial Number: _____________________________ Blue Diamond is continually working to improve its Dealer Name: ______________________________ products. Blue Diamond reserves the right to make any improvements or changes as deemed practical and pos- Dealer Number: _____________________________ sible without incurring any responsibility or obligation...

-

Page 3: Table Of Contents

5. Parts ..................18-28 5.1 Angle Broom Parts Breakdown ..........18 5.2 Hardware ................23 5.3 Hydraulic Angle Kit ...............26 6. Specifications .................29-31 6.1 Attachment Specifications ...........29 6.2 Performance Specifications..........30 6.3 Torque Specifications............31 7. Warranty ..................33 Blue Diamond® Attachments... -

Page 4: Introduction

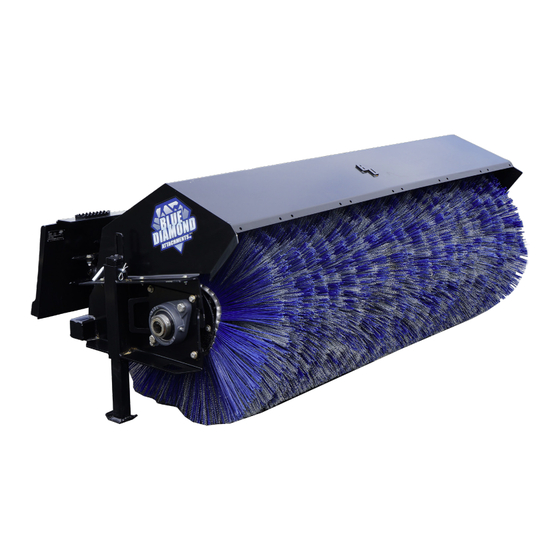

1. Introduction 1.1 Attachment Identification Broom Hood Pivot Pin Attachment Mount Broom Wafer (Poly / Wire) Support Leg Blue Diamond® Attachments... -

Page 5: Safety

The signal word CAUTION on the machine and in the manuals indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices. Blue Diamond® Attachments... -

Page 6: Important Safety Guidelines

Use caution on slopes and near banks and • DO NOT modify the equipment in any way. ditches to prevent overturn. Unauthorized modification may impair the function and/or safety and could affect the life of the equipment. Blue Diamond® Attachments... - Page 7 Tighten or replace any parts that show leakage • Always clean fluid spills. Do not use gasoline or diesel fuel for cleaning parts. Use commercial nonflammable solvents. Blue Diamond® Attachments...

-

Page 8: Set Up

Repair as needed before operation. • Check that broom wafers are in good condition. Replace them as necessary. • Check that all shields and guards are in place. • Check for loose bolts and tighten them if necessary. Blue Diamond® Attachments... -

Page 9: Attachment Inspection

Engage the park brake. • Wait for all moving parts to stop. • Stop the engine and remove the key. Check all bolts for tightness. SEE MACHINE OPERATOR’S MANUAL FOR ADDITIONAL INFORMATION. Inspect the frame for cracks, bends, or damage. Blue Diamond® Attachments... -

Page 10: Attachment Installation

Leave the operator’s position. The locking pins / wedges must extend through the holes in the attachment mounting frame. Failure to secure locking pins / wedges can allow attachment to come off. SEE MACHINE’S OPERATOR’S MANUAL FOR ADDITIONAL INFORMATION. Blue Diamond® Attachments... - Page 11 Hydraulic fluid, tubes, fittings, and quick couplers can get hot during operation. Be careful when connecting and disconnecting hydraulic hoses. Relieve auxiliary hydraulic pressure. (See the machine’s Operator’s Manual for correct procedure.) Disconnect attachment hydraulic hoses from the machine. Blue Diamond® Attachments...

-

Page 12: Operating The Attachment

WARNING ANGLE BROOM WEIGHT MODEL AVOID SERIOUS INJURY OR DEATH Never allow riders on the angle broom. 60” 995 lbs (451 kg) 72” 1125 lbs (510 kg) 84” 1300 lbs (590 kg) 96” 1450 lbs (658 kg) Blue Diamond® Attachments... - Page 13 Adjust brush using loader tilt to give a 2”– 4” wide pattern. Excessive down force will prematurely Drive the machine slowly backward, away from the wear wafers. attachment. Slow down in heavy material. Allow time for the broom to sweep. Blue Diamond® Attachments...

- Page 14 Changing Sweeping Direction on Manual Angle plugged nozzles. Units Lower machine RPM to just above idle. Stop hydraulic flow, and restart in the opposite direction. Slowly raise the machine’s engine RPM to the correct and desired broom speed. Blue Diamond® Attachments...

-

Page 15: Maintenance

Broom wafers for excessive wear or genuine factor replacement parts must be damage. used to restore your equipment to original specifications. Blue Diamond® will not be Hydraulic hoses and fittings for wear, responsible for injuries or damaged caused by damage, or leaks. -

Page 16: Lubrication

Apply 3-4 pumps of grease to the grease zerk. Figure 1 6. Measure pattern width left by broom. Pattern should be 2”-4” wide and even across the width of the broom [Figure 1]. Blue Diamond® Attachments... -

Page 17: Removal And Installation

5. Remove broom drum retaining plate from end of broom core. 6. Stand broom core on end with assembled retaining plate and remove broom wafers. 7. Install new wafer making sure wafer retention pins are trapped on broom drum bar. Blue Diamond® Attachments... -

Page 18: Cleaning The Attachment

See “Leaving The Operator’s Position” on page 10. Use water or air pressure to clean debris from under the angle broom frame/shields. Be careful when removing any obstructions that are wrapped around broom core or broom wafers. Blue Diamond® Attachments... -

Page 19: Parts

5. Parts 5.1 Angle Broom Parts Breakdown Blue Diamond® Attachments... - Page 20 5. Parts 5.1 Angle Broom Parts Breakdown Blue Diamond® Attachments...

- Page 21 Motor Mount Weldment 216750-60 Frame Weldment 60" — — — 216750-72 Frame Weldment 72" — — — 216750-84 Frame Weldment 84" — — — 216750-96 Frame Weldment 96" — — — 216752 Support Leg 270505 Support Leg Pin Blue Diamond® Attachments...

- Page 22 SEVERE DUTY SERIES 2 WIRING HARNESSES 103884 Wire Harness Attachment Side 103885 Wire Harness Machine Side Universal Control 103887 Wire Harness Machine Side 14-Pin 103888 Wire Harness Machine Side bobcat 7-Pin 103889 Wire Harness Machine Side 8-Pin Blue Diamond® Attachments...

-

Page 23: Hardware

5. Parts 5.2 Hardware 6 13 18 16 11 8 13 18 10 20 7 13 18 11 16 Blue Diamond® Attachments... - Page 24 5. Parts 5.2 Hardware Blue Diamond® Attachments...

- Page 25 Pivot/Spring Mount to Hinge Weldment Washer 1/2" Washer 299732 Bearing Mount Plate Washer 1/2" Washer 299732 Motor to Motor Coupler Washer 1/2" Washer 299732 Motor Coupler Mount Washer 1/2" Washer 223178 Hinge Spring Washer 1" Washer (2.5" OD) Blue Diamond® Attachments...

-

Page 26: Hydraulic Angle Kit

5. Parts 5.3 Hydraulic Angle Kit Blue Diamond® Attachments... - Page 27 5. Parts 5.3 Hydraulic Angle Kit Cont’d Blue Diamond® Attachments...

- Page 28 Cylinder Hose 90 degree fittings 206052 Cylinder Base End Straight Restrictor Fitting 295020-M08JIC-F08JIC Motor 45 Degree Fittings 205010-M08JIC-M10ORB Motor Straight Fittings 224010 Male Coupler 224009 Female Coupler 295010-M12JIC-M08ORB Supply Line Coupler Fitting 216353 Return Line Check Valve Coupler Fitting Blue Diamond® Attachments...

-

Page 29: Specifications

Overall Depth (C) 1,737 mm 37.8 in Overall Height (D) 960 mm Pivot Angle - Left & Right (E) 30° 995 lbs 1,125 lbs 1,300 lbs 1,450 lbs Weight 451 kg 510 kg 590 kg 658 kg Blue Diamond® Attachments... -

Page 30: Performance Specifications

89 lbs Optional Water Kit Weight (Empty) 40 kg 25 Gal Optional Water Kit Capacity 95 L 43 lbs 49 lbs 56 lbs 63 lbs Optional Front Cover Weight 20 kg 22 kg 25 kg 29 kg Blue Diamond® Attachments... -

Page 31: Torque Specifications

547 ft / lb 708 ft / lb 773 ft / lb 1000 ft / lb 386 ft / lb 545 ft / lb (289 N•m) (373 N•m) (742 N•m) (960 N•m) (1048 N•m) (1356 N•m) (523 N•m) (739 N•m) Blue Diamond® Attachments... - Page 32 This page intentionally left blank Blue Diamond® Attachments...

-

Page 33: Warranty

ATTACHMENTS before work is performed. ® The BLUE DIAMOND® PRODUCT SUPPORT TEAM will advise repairs and applicable parts exchanges. Tampering with the failed part may void the warranty. This warranty does not include freight or delivery charges incurred when returning machinery for servicing. Dealer mileage, service calls, and pickup/delivery charges are the customers’... - Page 34 QUALITY | DEPENDABILITY | INTEGRITY Blue Diamond® Attachments 4512 Anderson Road, Knoxville, TN 37918 888-376-7027...

Need help?

Do you have a question about the Severe Duty 2 Series and is the answer not in the manual?

Questions and answers