Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Custom Audio Electronics VKP80II-SX

- Page 1 USER MANUAL VKP80II-SX...

- Page 3 CUSTOM S.p.A. GENERAL SAFETY INFORMATION THE CE MARK AFFIXED TO THE PRODUCT CERTIFY THAT THE Via Berettine 2/B Your attention is drawn to the following actions PRODUCT SATISFIES THE BA- that could compromise the characteristics of the 43010 Fontevivo (PARMA) - Italy SIC SAFETY REQUIREMENTS.

- Page 5 MANUAL For details on the commands, refer to the manual with code 77200000001600 For further information about the use of “PrinterSet” tool refer to the manual with code 78200000001800...

-

Page 7: Table Of Contents

TABLE OF CONTENTS 1 INTRODUCTION ............. 9 2 DESCRIPTION . - Page 8 6 ALIGNMENT ..............55 6.1 Enable alignment .

-

Page 9: Introduction

1 INTRODUCTION This document is divided into sections and chapters. Each chapter can be reached by the index at the beginning of this document. The index can be reached by the button on each page as shown in the diagram below. Link to table of contents Notes reference Numbered title... -

Page 11: Description

2 DESCRIPTION 2.1 Box content Remove the device from its carton being careful not to damage the packing material so that it may be re-used if the printer is to be transported in the future. Make sure that all the components illustrated below are present and that there are no signs of damage. If there are, contact Customer Service. -

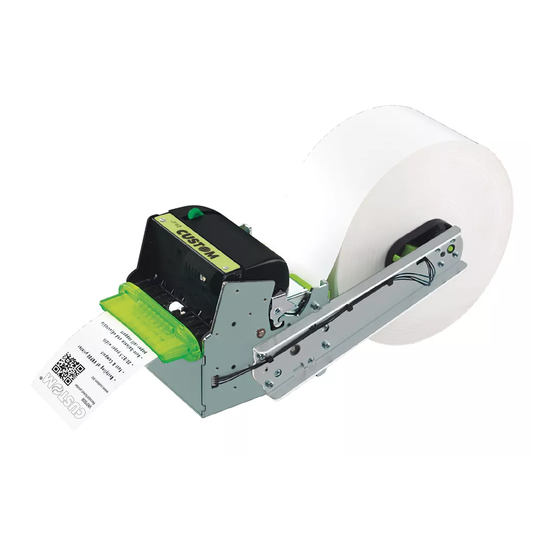

Page 12: Device Components: External Views

2.2 Device components: external views 1. Opening lever 8. Power supply port 2. Autocutter 9. USB port 3. Paper output 10. RS232 serial port 4. Right cursor for paper input 11. FORM FEED key 5. Paper input 12. LINE FEED key 6. -

Page 13: Device Components: Internal Views

2.3 Device components: internal views 1. Printing head 2. Paper out presence sensor 3. Ejector roller 4. Sensor for paper in presence 5. Sensor for black mark 6. Autocutter... -

Page 14: Product Label

2.4 Product label The main data used to identify the machine are shown on the label attached to the bottom of the device. In particular, it shows the electrical data for the connection to a power source. It also shows the product code, the serial number and the hardware revision (R). -

Page 15: Key Functions: Power Up

2.5 Key functions: power up POWER UP Hold down Hold down printing printing SETUP report FONT TEST Fast push Fast push skip the enter the SETUP PROCEDURE SETUP PROCEDURE Fast push Fast push next modify parameter selected parameter... -

Page 16: Key Functions: Standby

2.6 Key functions: standby STANDBY Fast push Fast push advance the paper advance the paper (manual insertion) (preset length) -

Page 17: Status Messages

2.7 Status messages The Status LED indicates hardware status of device. Given in the table below are the various LED signals and the cor- responding device status. STATUS LED DESCRIPTION DEVICE OFF GREEN DEVICE ON: NO ERROR RECEIVE DATA RECEPTION ERROR GREEN (PARITY, FRAME ERROR, OVERRUN ERROR) COMMUNICATION... -

Page 19: Installation

3 INSTALLATION 3.1 Fastening NOTE: All the dimensions shown in following igures are in millimetres. The device is provided with three ixing holes on the bottom of device (see following igure). To fasten the device on a panel, use three M4 screws. M4; n°3 bottom fixing point +0.5 +0.5 85.5 − 0.5 − 0.5 It’s very important to consider the screws length not to damage the internal components placed near the ixing holes (see following igure). Section E-E Device chassis Fixing panel Fixing screw The screw length (L) will be calculated according to the thickness of the panel (Sp) on which the device is ixed, as follows: L ≤ 8 mm + Sp For example, if panel thickness is 10mm (Sp = 10 mm), the maximum length for screws will be 18 mm. - Page 20 Furthermore, the panel must provide an opening for the paper handling that respects the measures shown below: 85.5 19.5 min. 36...

-

Page 21: Connections

3.2 Connections The following igure show the possible connections for the device. When the RS232 and USB communication cables are connected to the device at the same time, communication takes place via the USB port. Power supply Power supply cable (supplied) USB device Standard USB cable serial device Standard serial cable ATTENTION: In some using conditions, we recommend the installation of a ferrite core on the power supply cable. -

Page 22: Pinout

3.3 Pinout POWER SUPPLY Male Molex connector series 5569 vertical (n° 39-30-1020) 1 +24 Vdc 2 GND The following igure shows the connector pinout of the power supply cable for device: Female Molex connector Power supply cable series 5557 (n.39-01-3022) Cable Signal color +24V Black ATTENTION: Respect power supply polarity. USB INTERFACE Female USB type B connector 1 USB-VBUS (in) 2 D -... - Page 23 SERIAL INTERFACE Female DB9 connector 1 DTR (out) When “1”, printer is fed 2 TX (out) During transmission, oscillates between “0” and “1” depending on data 3 RX (in) During reception, oscillates between “0” and “1” depending on data 4 n.c. 5 GND 6 DTR (out)

-

Page 24: Driver And Sdk

3.4 Driver and SDK In the website www.custom4u.it are available the drivers for the following operating system: OPERATING DESCRIPTION INSTALLATION PROCEDURE SYSTEM Driver for Windows XP From the Start menu, press Run Driver for Windows VISTA (32/64bit) and type-in the path where the SW Windows was saved on PC, then click OK. -

Page 25: Paper Reduction Guides Kit (Optional)

3.5 Paper width reduction guides kit (optional) The printer includes a kit for the reduction of paper width up to 45mm. The kit includes the reductions for both the left paper guide and the right paper guide. With both the guides assembled, do not go below 45mm wide paper: below this value, the sensor can not detect the paper presence. -

Page 27: Operation

4 OPERATION 4.1 Cover opening To open the device cover proceed as follows: Push the release lever in the direction shown in the figure. Open the device cover to the lock position. -

Page 28: Adjusting Paper Width

4.2 Adjusting paper width Paper width may be adjusted from 60mm to 82.5mm using the right (Dx) and Left (Sx) slides located at the paper infeed opening. Move the right and left slides to adjust the paper width (see following igure). Below the right slide there are four point of reference for paper width (60, 70, 80 and 82.5mm). NOTE: To use the paper reduction kit (optional) see previous paragraph. -

Page 29: Adjusting Paper Width With The Paper Roll Holder

4.3 Adjusting paper width with the paper roll holder code 974DW010000001 (optional) This accessory allows the use of paper roll width from 60 mm to 82.5 mm. To adjust the width of the paper roll case, rotate the knob as shown in the following igure. -

Page 30: Adjusting The Paper Stock With The Paper Roll Holder

4.4 Adjusting the paper stock with the paper roll holder code 974DW010000001 (optional) This accessory allows the move the position of the low paper sensor to adjust the amount of paper on the roll under which report the low paper. Use the lever shown in igure to move the low paper sensor: move the lever up to increase the paper stock, move the lever ... -

Page 31: Low Paper Sensor

4.5 Low paper sensor The device provides as an accessory (see chapter 10) a low paper sensor with the cable (see following igure). To ix the sensor, use an M3 screw not supplied. All the dimensions shown in following igures are in millimetres. MATERIAL NOT MATERIAL INCLUDED INCLUDED Low paper sensor Fixing screw M3 Low paper wiring Connector Low paper sensor board 18.2 For the assembly procedure, proceed as follows: Low paper wiring... - Page 32 Low paper wiring Connect the wiring coming from the low paper sensor board at the connector shown in figure.

-

Page 33: Switch The Device On

4.6 Switch the device ON Power supply cable ALIMENTATORE ESTERNO (OPZIONALE) Connect the power supply cable to an external power supply unit. IN DC 24V Power supply cable Connect the power supply cable to the device. Use the type of electrical power supply indicated on the label. The green status LED turns on and the device is ready. -

Page 34: Loading The Paper Roll

4.7 Loading the paper roll At every change of paper, check inside the device. To change the paper proceed as follows. ATTENTION !!! Open the device cover Open the device cover (see paragraph 4.1). Do not load the paper with the device cover open. (see paragraph 4.1). - Page 35 Insert the paper into the input mouth so that it unrolls correctly. Be sure that the paper is correctly positioned into paper guides. ROOM Wait until the paper is automatically loaded.

- Page 36 The following igure gives the limit positions of the paper roll related to the printer for a correct paper loading without a paper roll holder support. The direction of the paper will always form a maximum angle of 90 ° or -90 ° with the insertion plane of paper inside the printer. 90° 90° -90° -90°...

-

Page 37: Issuing Ticket

4.8 Issuing ticket The device allows you to choose between diferent operating modes for the issuance of printed tickets. The operating modes shown in the following images, depend on the settings of the coniguration parameters and com- mands sent to the device. NOTE: To enable this issuing mode, you need to correctly set the operation mode of the ejector with the command 0x1D 0x65 (see Commands Manual) and the setup parameter “Automatic Ejecting” (see chapter 5 of this manual). “PRESENT/EJECT”... - Page 38 Ejector rollers Cutter Ejector duct The ticket advances ahead to the ejector and is caught between the ejector rollers. The printed part of ticket is collected into the ejection canal while the device continues printing. Ejector rollers Cutter Ejection duct When printing ends, the device cuts the ticket printed.

- Page 39 Paper output Ejector rollers Ticket presented The device presents a portion of the ticket printed on the paper mouth. The ticket is waiting on the paper mouth for a preset period of time.

- Page 40 Paper output Ejector rollers Ticket ejector The device directly ejects the ticket.

- Page 41 “PRESENT/RETRACT” mode NOTE: To enable this issuing mode, you need to correctly set the operation mode of the ejector with the command 0x1D 0x65 (see Commands Manual) and the setup parameter "Paper Retracting" (see chapter 5 of this manual). For the minimum and maximum length of the ticket refer to"Paper specifications". The ticket presentation will be performed in this way: TICKET LENGTH PRESENTATION...

- Page 42 Ejector rollers Cutter Ejector duct The ticket advances ahead to the ejector and is caught between the ejector rollers. The printed part of ticket is collected into the ejection canal while the device continues printing. Ejector rollers Cutter Ejection duct When printing ends, the device cuts the ticket printed.

- Page 43 Paper output Ejector rollers Ticket presented The device presents a portion of the ticket printed on the paper mouth. The ticket is waiting on the paper mouth for a preset period of time.

- Page 44 Ejector rollers Ticket Ejector withdrew duct The device retracts and collects the ticket from the mouth paper...

-

Page 45: Configuration

5 CONFIGURATION 5.1 Coniguration by keys To enter the coniguration mode and print a SETUP report with the operating parameters of the device, proceed as follows. LINE FEED KEY POWER SUPPLY (hold down) During power-up, hold down the LINE FEED key while the wiring is plugged into the power supply connector of the device. The device prints the report with settings parameters. Enter setup Press the FORM FEED key to enter the configuration mode. - Page 46 The following igure shows the setup report of the device. The shown values for parameters are sample values; for the list and the description of device parameters see the following paragraphs. < device name > DEVICE NAME AND SCODE. <code> rel 1.00 FIRMWARE MODULES RELEASE FCODE. <code> rel 1.00 PRINTER SETUP INTERFACE ........RS232 PROGRAM MEMORY TEST..OK DYNAMIC RAM TEST....OK EEPROM TEST......OK CUTTER TEST.......OK HEAD VOLTAGE [V] = 24.01...

-

Page 47: Coniguration By Software

5.2 Coniguration by software The setup parameters can be set by using the “PrinterSet” software tool available on www.custom4u.it. For a detailed description of the device operating parameters see the following paragraphs. To conigure the device by software, proceed as follows: Connect the device to a PC directly (see paragraph 3.2), Connect the device to a PC directly (see paragraph 4.5),... -

Page 48: Device Status

5.3 Device status The printer operating status is indicated in the coniguration print-out in which, next to the name of the components dis- played, the following information is given: INTERFACE interface present PROGRAM MEMORY TEST OK appears if functioning and NOT OK if faulty DYNAMIC RAM TEST OK appears if functioning and NOT OK if faulty OK appears if functioning and NOT OK if faulty EEPROM TEST CUTTER TEST OK appears if functioning and NOT OK if faulty... -

Page 49: Communication Parameters

5.4 Communication parameters The device allows the coniguration of the parameters listed in the following table. The parameters marked with the symbol are the default values. Settings remain active even after the device has been turned of and they are stored in non-volatile memory. RS232 BAUD RATE Communication speed of the serial interface: 1200 9600 57600 2400 19200 115200 4800 38400 This parameter is valid only for with serial interface. RS232 DATA LENGTH Number of bit used for characters encoding: 7 bits/char... - Page 50 Numerical address code for the univocal identiication of the USB device (in case of more USB ADDRESS NUMBER than a USB device connected with the same PC):...

-

Page 51: Operating Parameters

5.5 Operating parameters The device allows the coniguration of the parameters listed in the following table. The parameters marked with the symbol are the default values. Settings remain active even after the device has been turned of and they are stored in non-volatile memory. AUTOFEED Setting of the Carriage Return character: CR disabled = Carriage Return disabled CR enabled = Carriage Return enabled Printing mode: PRINT MODE Normal = enables printing in normal writing way Reverse = enables printing rotated 180 degrees CHARS / INCH Font selection:... - Page 52 Setting of the Font Type: FONT TYPE International Enables the use of font tables to 256 characters Chinese GB18030 Enables the use of the Chinese extended font GB18030-2000 Korean PC949 Enables the use of the Korean extended font PC949 When the Chinese and Korean font is enabled, the selection of the character code table is suspended (parameter “Code Table”).

-

Page 53: Alignment Parameters

5.6 Alignment parameters This printer allows the coniguration of the parameters listed in the following table. The parameters marked with the symbol are the default values. Settings remain active even after the printer has been turned of and they are stored in non-volatile memory. BLACK MARK ALIGNMENT Alignment management (see chapter Disabled the black mark alignment is not performed Enabled = the black mark alignment is performed BLACK MARK THRESHOLD Threshold value (in percent) for the recognition of the presence of black mark by the black mark sensor: 0.33V 1.32V... -

Page 54: Hexadecimal Dump

5.7 Hexadecimal dump This function is used for the diagnosis of the characters received from the communications port. Characters are printed as hexadecimal code and the corresponding ASCII code (see below). Each line is preceded by a counter in hexadecimal that indicates the number of bytes received. -

Page 55: Alignment

6 ALIGNMENT The device is provided with sensors for the use of alignment black mark in order to handle rolls of tickets with pre-printed ields and a ixed length. All alignment sensors are “relection” sensors: this kind of sensor emits a band of light and detects the quantity of light relected to it. The presence of the black mark is therefore detected by the amount of light that returns to the sensor, con- sidering that the light is relected by the white paper and absorbed by the black mark. The following paragraphs show how to correctly set the coniguration parameters of device in order to assure the alignment. -

Page 56: Enable Alignment

6.1 Enable alignment Device is provided with one ixed sensor facing the non-thermal side of paper. To guarantee the alignment, you must enable the parameter “Black Mark Alignment” during the Setup procedure (see chapter SENSOR VALUE OF THE USED USING MODE “BLACK MARK ALIGNMENT” BLACK MARK TYPE (see following OF SENSOR PARAMETER igures) Disabled Alignment disabled... - Page 57 The following igure show the usable format of paper and the corresponding sensors used for alignment: Paper with black mark on the non thermal side In standard model, the detection of black mark is performed on the non-thermal side of paper by the ixed sensor. direction of paper feed BLACK MARK NON THERMAL SIDE...

-

Page 58: Calibration

6.2 Calibration The sensor calibration occurs automatically and consists in adjusting the quantity of light emitted to match the degree of whiteness of the paper used and the degree of black of the mark printed on paper. The device automatically performs the self-calibration during the Setup procedure only if the “Black Mark Alignment” pa- rameter is set to “Enabled”... - Page 59 The following igure shows an example of paper with the non-thermal paper printed with black marks and other graphics (for example, a barcode): the outgoing voltage is constant while passing the white paper between two black marks, presents a peak at each black mark and presents some “noise” at each barcode. In this case, the optimal value for the “Black Mark Threshold” parameter is located about halfway between the peak value and the maximum value of the “noise”.

-

Page 60: Alignment Parameters

6.3 Alignment parameters The “alignment point” is deined as the position inside the ticket to use for the black mark alignment. The distance between the black mark edge and the alignment point is deined as “Black Mark Distance”. “Black Mark/Distance” value varies from 0 mm minimum and 32 mm maximum. If the “Black Mark Distance” value is set to 0, the alignment point is set at the beginning of the black mark. Alignment Alignment point: point... - Page 61 The following igure shows a section of the device with the paper path and the distances between the alignment sensors, the printing head and the autocutter (cutting line), where: A = 11.9 mm = distance between the cutting line and the printing line on paper B = 28.5 mm = distance between the printing line and the alignment sensor. To deine the alignment point you need to set the device parameters that compose the numerical value of the “Black Mark ...

-

Page 62: Printing Area

6.4 Printing area In order to print ticket containing only one black mark and to not overlay printing to a black mark (that will make it useless for the next alignment), it is important to well calibrate: the length of the printing area of ticket according to the inter-black mark distance; • • the value for the paper recovery after a cut (if present). -

Page 63: Maintenance

7 MAINTENANCE 7.1 Planning of cleaning operations The regular cleaning of the device keeps the print quality and extends its life. The following table shows the recommended planning for the cleaning operations. If you use the device in dusty environments, you must reduce the intervals between the cleaning operations. -

Page 64: Cleaning

7.2 Cleaning For periodic cleaning of the device, see the instructions below Sensors Paper path Disconnect the power supply cable and Disconnect the power supply cable and Disconnect the power supply cable and Disconnect the power supply cable and open the device cover (see paragraph 4.1). - Page 65 Printhead Rollers Disconnect the power supply cable and Disconnect the power supply cable and Disconnect the power supply cable and Disconnect the power supply cable and open open the device cover (see paragraph 4.1). open the device cover (see paragraph 4.1).

- Page 66 Case Cutter Disconnect Disconnect the power supply cable and Disconnect the power supply cable and the power supply cable open the device cover (see paragraph 4.1). open the device cover (see par. 4.3) ATTENTION: ATTENTION: Do not use alcohol, solvents, or hard brushes. Do not use alcohol, solvents, or hard brushes.

-

Page 67: Upgrade Irmware

7.3 Upgrade irmware Firmware upgrade can be performed by using the “PrinterSet” software tool available on www.custom4u.it. To upgrade irmware, proceed as follows: Login to the website www.custom4u.it, type in the product code of the device Login to the website www.custom4u.it, type in the product code of the device and download the latest irmware release available. - Page 68 LOAD SAVE PORT EXTRA HELP From Device From File Select a configuration file as follows: Click on LOAD > From device and select a device connected with the PC Click on LOAD > From file and select a .psc file on your PC Drag and drop a .psc file Click on LOAD >...

-

Page 69: Specification

8 SPECIFICATION 8.1 Hardware speciications GENERAL Printing head temperature, black mark presence, paper presence, Sensor paper presence on output, printing unit open, (near paper end on external paper roll holder optional) Emulation CUSTOM/POS Windows XP VISTA (32/64bit) Windows 7 (32/64bit) Opos Printing driver Linux... - Page 70 Printing format height/width from 1 to 8, bold, reverse, underlined, italic 54 character code tables (see paragraph 8.9) Character fonts Extended chinese GB18030-2000, Korean PC949 UPCA, UPCE, EAN13, EAN8, CODE39, ITF, CODABAR, CODE93, Printable barcode formats CODE128, CODE32, PDF417, QRCODE High quality = 80 mm/s Printing speed Normal = 180 mm/s...

- Page 71 Stand-by consumption 0.04 A ELECTRICAL SPECIFICATIONS POWER SUPPLY code 963GE020000071 (OPTIONAL) Power supply voltage from 90 Vac to 264 Vac Frequence from 47 Hz to 63 Hz Output 24 V, 2.5 A Power 60 W ENVIRONMENTAL CONDITIONS (11) Operating temperature from -20 °C to +70 °C Relative humidity (RH) from 10% to 80% (without condensation)

-

Page 72: Character Speciications

8.2 Character speciications Character set Character density 11 cpi 15 cpi 20 cpi Number of columns Chars / s 2251 2895 4053 Lines / s Characters (L x H mm)-Normal 2.25 x 3 1.75 x 3 1.25 x 3 NOTE: Theoretical values. 8.3 Ejector speciications Ticket length Ticket presentation... -

Page 73: Device Dimensions

8.4 Device dimensions Length 149.5 mm Height 121.2 mm Width 123.5 mm Weight 1600 g All the dimensions shown in following igures are in millimetres and referred to the devices without paper roll. 123.5 125.5 149.5... -

Page 74: Device Dimensions With Adjustable Paper Roll Holder

8.5 Device dimensions with adjustable paper roll holder code 974DW010000001 (optional) Upper position: 160.7 mm Length Rear position: 306.2 mm Lower position: 160.7 mm Upper position: 292.1 mm Height Rear position: 189.4 mm Lower position: 313.2 mm Width 123.5 mm Weight 1874 g All the dimensions shown in following igures are in millimetres. -

Page 75: Device Dimensions With Shutter Device

8.6 Device dimensions with shutter device code 976DX010000008 (optional) Length 163.5 mm Height 121.2 mm Width 123.5 mm Weight 1600 g All the dimensions shown in following igures are in millimetres. 123.5 114.5 19.5 125.5... -

Page 76: Dimensions Of Power Supply, Power Cord And Adapter Cable

8.7 Dimensions of power supply, power cord and adapter cable (optionals) The following table shows the dimensions of the power supply, the power cord and the adapter for power supply optionals for the device: POWER CORD code 26100000000311 Length 2000 mm ADAPTER FOR POWER SUPPLY code 26900000000005 Length 200 mm... - Page 77 POWER SUPPLY code 963GE020000071 AC INLET DC OUTPUT WIRE 30 ± 5 130 ± 1 1500 n.c. +24V...

-

Page 78: Paper Speciication

8.8 Paper speciication Paper with black mark on the non-thermal side The following image shows the placement of the black mark on the non-thermal side of paper. For more information about the use of paper with black mark see chapter All the dimensions shown in following igures are in millimetres. -

Page 79: Character Sets

8.9 Character sets The device has 3 fonts of varying width (11, 15 and 20 cpi) which may be related one of the coding tables provided on the device. To know the coding tables actually present on the device, you need to print the font test (see paragraph 2.5). - Page 80 <CodeTable> Coding table PC861 - Icelandic on request PC862 - Hebrew PC864 - Arabic PC869 - Greek on request ISO8859-2 - Latin 2 on request ISO8859-15 - Latin 9 on request PC1098 - Farsi on request PC1118 - Lithuanian on request PC1119 - Lithuanian on request PC1125 - Ukranian...

-

Page 81: Consumables

9 CONSUMABLES The following table shows the list of available consumables for device: 67300000000401 THERMAL PAPER ROLL weight = 74 g/m width = 80 mm Ø external = 80 mm Ø core = 25 mm 67300000000388 THERMAL PAPER ROLL weight = 74 g/m width = 80 mm Ø... -

Page 83: Accessories

10 ACCESSORIES The following table shows the list of available accessories for device: 963GE020000071 POWER SUPPLY (for technical speciications, see paragraph 8.1) 26100000000311 POWER CORD SCHUKO PLUG length = 2 m (see paragraph 8.7) 26300000000579 POWER SUPPLY CABLE length = 1 m 26500000000352 SERIAL CABLE DB9M-DB9F length = 1.8 m 26500000000060 USB CABLE TYPE A-B with two ferrite cores... - Page 84 974DW010000001 PAPER ROLL HOLDER WITH LOW PAPER SENSOR to assemble on the right side of the device 976DX010000008 “SHUTTER” DEVICE KIT...

-

Page 85: Technical Service

11 TECHNICAL SERVICE In case of failure, contact the technical service accessing the website www.custom4u.it and using the support tools on the homepage. It is advisable to keep the identiication data of the product at hand. The product code, the serial number and the hardware release number can be found on the product label (see paragraph 2.4). - Page 88 CUSTOM S.p.A. World Headquarters Via Berettine, 2/B - 43010 Fontevivo, Parma ITALY Tel. +39 0521 680111 - Fax +39 0521 610701 info@custom.biz - www.custom.biz All rights reserved www.custom.biz...

Need help?

Do you have a question about the VKP80II-SX and is the answer not in the manual?

Questions and answers