Summary of Contents for THORLABS XM-ORC Series

- Page 1 User Manual Optical Reference Cavity with Crystalline Mirrors XM-ORC Series Important Document Please keep for your records...

- Page 3 Thorlabs, a vertically integrated photonics products manufacturer, was founded in 1989 to serve the laser and electro-optics research market. As that market has spawned a multitude of technical innovations, Thorlabs has extended its core competencies in an effort to play an ever-increasing role to serve the Photonics Industry at the research end, as well as the industrial, life science, medical, and defense segments.

-

Page 4: Imprint

User Manual – Optical Reference Cavity with Crystalline Mirrors – XM-ORC Manufacturer: Menlo Systems GmbH, Munich, Germany Thorlabs Inc., Newton, New Jersey, USA Copyright: © 2023 Menlo Systems GmbH. All rights reserved. Reproduction by any means of any image in this user manual is prohibited without the prior consent of Menlo Systems GmbH. -

Page 5: Table Of Contents

TABLE OF CONTENTS IMPRINT ..............................4 TABLE OF CONTENTS ..........................5 III. SAFETY INSTRUCTIONS ......................... 7 III.1 Laser Safety ..........................7 Intended Use of the Laser ..................... 7 Laser Hazard Classification ....................7 Laser Safety Precautions ....................... 8 Protective Eyewear ....................... 9 Safety Features of Your Laser.................... -

Page 7: Safety Instructions

III. SAFETY INSTRUCTIONS Please follow the directions given in this manual; otherwise the safety level the laser has been designed to provide might be affected. III.1 LASER SAFETY INTENDED USE OF THE LASER Your laser is a versatile light source for research and industry applications. The laser is designed for indoor use only (IP21, NEMA Type 1). -

Page 8: Laser Safety Precautions

LASER SAFETY PRECAUTIONS The laser system may constitute a serious potential threat for eye injury resulting from intrabeam viewing. It generally does not represent a diffuse reflection hazard, and therefore only minor potential skin or a fire hazards. ▪ Areas where a laser with accessible radiation is operated should be marked with warning symbols according to local regulations ▪... -

Page 9: Protective Eyewear

▪ Eliminate unnecessary specular (mirror-like) surfaces from the vicinity of the laser beam path, or avoid aiming at such surfaces ▪ Avoid looking with the unprotected eye along or near the beam axis. Some alignment procedures may place personnel at risk by requiring close proximity to the beam where the chance of hazardous specular reflections is the greatest ▪... - Page 10 ▪ Light-tight encapsulation of the laser sources and robust individual housings. ▪ Protective grounding (electrical class I equipment) and fine fuses on individual units. ▪ Operating instructions (this document).

-

Page 11: Iii.2 Electrical Safety Precautions

III.2 ELECTRICAL SAFETY PRECAUTIONS Part of the system contains hazardous voltage (mains voltage 230V / 240V). The Ion Pump Power Supply and Ion Pump work with high voltage of 7000V, for details refer to the separate manuals (900026_Small-pump-Controller-SPCe- _EN_manual; 900013_ION-Pump_EN_manual). You should make sure that electrical equipment used for work is safe. -

Page 13: Principle Of Operation

PRINCIPLE OF OPERATION Thank you for choosing our Optical Reference Cavity with Crystalline Mirrors XM-ORC – a high finesse cavity serving as a reference for a continuous wave (CW) laser. The combination of high vacuum, temperature stabilization, ultra-low expansion (ULE) glass and high-reflectivity crystalline (xtal stable™) coated mirrors on fused silica substrates leads to unprecedented performance in a commercial system. -

Page 14: System Description

SYSTEM DESCRIPTION The XM-ORC Series optical reference cavity with crystalline coated (xtal stable™) mirrors comes supplied with the components and specifications as detailed in Table 2.1. SPECIFICATIONS XM-ORC Series Wavelength 1550, 1397, 1156 or 1064 nm 1064 nm – XM15P8 / XM15R8 1156 nm –... -

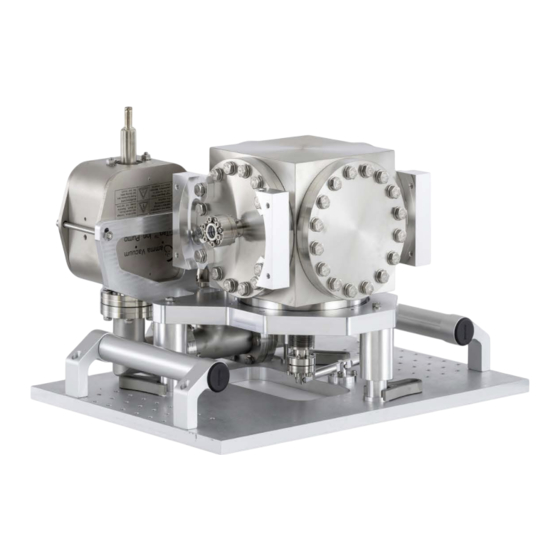

Page 15: Vacuum Chamber

VACUUM CHAMBER The vacuum chamber is made out of stainless steel and CF flange components with small leaking rates. It is continuously pumped by a 10 l/s IGP. This pumping technology works only up to maximum pressures of 10 mbar, which may cause problems if the pump is accidentally shut down or a power blackout occurs for a longer time interval. -

Page 16: Temperature Stabilization

Figure 3: Optically contacted cylindrical cavity The cavity is mounted in the vacuum chamber such that there is a small angle between the chamber’s viewports and the cavity in order to avoid etalons. There is a 7.4 cm distance between the mirrors and the viewports on both sides. - Page 17 TED200C-SP3 to the underside of the vacuum chamber (adjacent to the transport lock). Note: the TED200C-SP3 is a modified version of the Thorlabs standard TED200C and incorporates a non-standard integrator time constant. For full operational instructions of the TED200C-SP3 please refer to the document downloads on the Thorlabs website (https://www.thorlabs.com/thorproduct.cfm?partnumber=TED200C).

-

Page 18: Setting Up The Xm-Orc

SETTING UP THE XM-ORC UNPACKING AND ESTABLISHING VACUUM Due to the system weight and form factor, it is recommended to have 2 persons perform the unpacking and installation procedure. ▪ Open the top of the wooden box and lift the system out. ▪... - Page 19 ▪ Open the hexagonal screw of the gate valve slowly and carefully, monitoring the effect on the turbo pump thereby ensuring the chamber does not flood during the process. Evacuate at least to ≈ 7x10 mbar. ▪ Connect the IGP to power and to the XM-ORC. ▪...

-

Page 20: Warranty

During this warranty period Menlo Systems or Thorlabs will see to defaults by repair or by exchange if these are entitled to warranty. In the instance a warranty claim is to be made, contact should be first arranged through the original point-of-sale of the goods. -

Page 21: Customer Service

CUSTOMER SERVICE Your system is designed to be maintenance free. Opening the chassis of the system voids the warranty and exposes the user to hazardous voltage. FACTORY SERVICE & REPAIR For factory service or repair please call the Menlo Systems customer service. Together with the product specialist they will determine if the equipment requires service, repair, calibration or replacement. -

Page 22: Regulatory

REGULATORY As required by the WEEE (Waste Electrical and Electronic Equipment) Directive of the European Community and the corresponding national laws, Menlo Systems offers all end users in the EC the possibility to return "end-of-life" units without incurring disposal charges. This offer is valid for Menlo Systems electrical and electronic equipment: ▪... -

Page 23: Contacts

CONTACTS Menlo Systems GmbH Thorlabs Inc. Bunsenstraße 5 43 Sparta Avenue D-82152 Martinsried, Germany Newton, NJ 07860, USA service@menlosystems.com TCS@thorlabs.com sales@menlosystems.com sales@thorlabs.com Phone: +49 89 189 166 0 Phone: +1 973 300 3000 Fax: +49 89 189 166 111...

Need help?

Do you have a question about the XM-ORC Series and is the answer not in the manual?

Questions and answers