Summary of Contents for Kärcher 500 PSI

- Page 1 500 PSI English Register 8.634-336.0-V 12/13/22 your product www.kaercher.com/welcome...

-

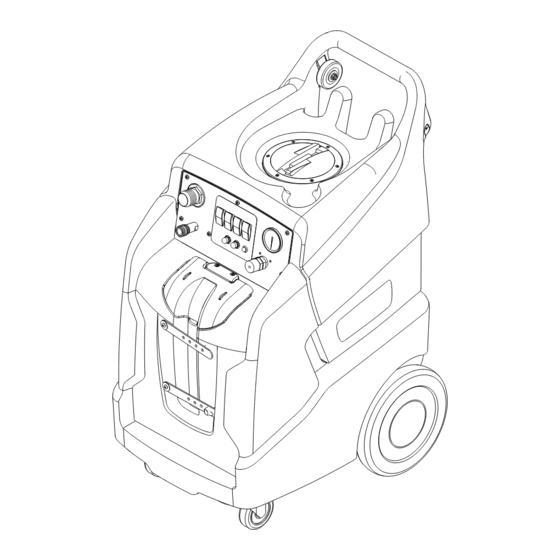

Page 2: Machine Data Log / Overview

Machine Data Log / Overview Model: Date of Purchase: Serial Number: Dealer: Address: Phone Number: Sales Representative: OVERVIEW This machine is an electric powered carpet extractor intended for commercial use. This appliance applies a cleaning solution to the carpet and then vacuums the soiled water back into the recovery tank. MODEL: PUZZI 64/35E 1.006-674.0 Warranty Registration Thank you for purchasing a Kärcher North America product. -

Page 3: Table Of Contents

Table of Contents Machine Data Log / Overview....2 PARTS Control Panel ......20 Table of Contents . -

Page 4: How To Use This Manual

How to Use This Manual This manual contains the following sections: The SAFETY section contains important information regarding hazardous or unsafe practices of the • How to Use This Manual machine. Levels of hazards are identified that could • Safety result in product damage, personal injury, or severe •... -

Page 5: Safety

Safety IMPORTANT SAFETY INSTRUCTIONS When using an electrical appliance, basic precaution must always be followed, including the following: READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE. This machine is for commercial use. To reduce the risk of fire, electric shock, or injury: Connect to a . -

Page 6: Hazard Intensity Level

Safety The following symbols are used throughout this guide as indicated in their descriptions: HAZARD INTENSITY LEVEL There are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FOR SAFETY. The level of hazard intensity is determined by the following definitions: WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death. -

Page 7: Safety Labels

Safety Safety Labels NOTE: These drawings indicate the location of safety labels on the machine. If at any time the labels become illegible, promptly replace them. Label Warning 86244300 PRV # 500955 WARNING! FOR YOUR PROTECTION USE A GROUND FAULT CIRCUIT INTERRUPTER Label Circuit Interrupter 86200570 PRV # 170-41... -

Page 8: Grounding Instructions

Safety Grounding Instructions THIS PRODUCT IS FOR COMMERCIAL USE ONLY. ELECTRICAL: In the USA this machine operates on a standard 15 amp 115V, 60 hz, A.C. power circuit. The amp, hertz, and voltage are listed on the data label found on each machine. -

Page 9: Operations

Operations Technical Specifications ITEM MEASURE Electrical 115 Volt, 60 hz, 15A Solution Pump 500 psi Solution Capacity 17 Gal Recovery Capacity 14 Gal Height 43 inches Length 32.5 inches Width 22.5 inches Vacuum Motor Dual 2 Stage Weight- Empty 139 lbs... -

Page 10: Controls

Operations Controls 7. Adjustable Pressure Relief Valve 1. Vacuum Accessory Tool Hook-up 8. Heater Temperature Light (Units w/Heat Only) 2. Solution Pump Switch 9. Breaker for Vacuum 2 3. Vacuum 1 Switch 10. Breaker for Vacuum 1 4. Vacuum 2 Switch 11. -

Page 11: Machine Operation

Operations Machine Operation Only use chemicals approved for use with this machine. Use of non-compatible chemicals may cause machine damage and will not be covered under the Care must be exercised in the use of all chemicals. warranty. Carefully read ingredients on manufacturer’s Chemicals are poisonous and can pose a health risk. -

Page 12: Pre-Run Inspection

Operations Pre-Run Inspection Heater Operation 1. Check all fittings and connectors for proper assembly. The solution fittings on the machine will become 2. Check all hoses for leaks. Repair or replace any extremely hot during operation. Allow sufficient damaged hoses. time to cool, or run solution through the machine 3. -

Page 13: Cleaning

Operations Cleaning Always use defoamer if foaming occurs. Foam will suspend large particles that may damage vacuum(s) as well as allow liquid into the vacuum motor(s) without activating the float shutoff. 1. Prior to cleaning, make certain that the nozzle is functioning properly. -

Page 14: Maintenance

Maintenance Periodic Maintenance Daily/Regular Maintenance Twice a month, flush a white vinegar solution (one quart vinegar to two gallons of water) or anti-browning solution (mixed as directed) through the machine. This Before making any repairs or adjustments to the will prevent build-up of alkaline residue in the system. machine, disconnect the power cords from the electrical source. -

Page 15: Vacuum Motor Replacement

Maintenance Vacuum Motor Carbon Brushes Replacement Only qualified maintenance personnel are to perform the following repairs. End Cap Vacuum Motor Replacement Carbon 1. Turn off all switches and unplug machine. Brushes 2. Remove hardware under front of machine to access component compartment. WARNING: The green ground wire 3. -

Page 16: Solution Pump Replacement

Maintenance Solution Pump Replacement Only qualified maintenance personnel are to perform the following repairs. Seal and O-Ring Kit 8.756-049.0 8.756-049.0 8.756-049.0 86343360 PUZZI 64/35E... -

Page 17: Pressure Regulator

4. Wipe piston and u-cup clean of any film or scale. 5. Lubricate the piston and u-cup with Superlube. 6. Reassemble regulator. 7. With pump ON, re-adjust pressure regulator for normal operation. Lubricate U-Cup with Superlube Monthly. REBUILD KIT (GREEN 500 PSI) 8.619-924.0 86343360 PUZZI 64/35E... -

Page 18: Troubleshooting

Maintenance Troubleshooting PROBLEM CAUSE SOLUTION Unit not plugged in Connect unit to 3 prong grounded outlet. Loss of Power Dead electrical circuit Check building circuit breaker or fuse box. Faulty power cord Replace Receptacle not grounded Contact an electrician to check building's wiring Electrical shock Have a trained service technician check Internal wiring problem... -

Page 19: Parts

PARTS 86343360 PUZZI 64/35E... -

Page 20: Control Panel

Control Panel 86343360 PUZZI 64/35E... - Page 21 Control Panel SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 86180350 12-800035 ELL, 1/4FP X 1/4T BR 86202230 390-09A WASHER 9/16 S/S USS THICK 86002370 20035 CLAMP, 7/16 DIA NYLON UL 86002450 22015 COUPLER, 1/4 QD 86197390 31021 ELBOW, 1/4NPT 45D STREET 86005700 57104 NUT, 10-32 HEX W/STAR...

-

Page 22: Electrical

Electrical 86343360 PUZZI 64/35E... - Page 23 Electrical SERIAL NO. REF PART NO. PRV NO. QTY DESCRIPTION NOTES FROM 86201510 390-26 SPACER NYLON 1/4ID X 1/2 OD 86005670 57040 NUT, 1/2 NPT CONDUIT 86005700 57104 NUT, 10-32 W/STAR WASHER PLTD 86273830 70020 SCR, 1/4-20 X 1/2 HHCS SS 86006850 70393 SET SCR, 1/4-20 X 1.25L...

-

Page 24: Frame

Frame 86343360 PUZZI 64/35E... - Page 25 Frame SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 86199430 040-03 CASTER, SWIVEL 4" 250# CPCTY 86001660 41236 HUBCAP, 5/8 SHAFT 86005810 57245 NUT, 1/4-20 HEX NYLOCK SS 86276080 70595 SCR, 10-32 X 1” PPHMS GRN 86010630 87013 WASHER, 1/4 X 5/8 FLAT SS 86005700 57104 NUT, 10-32 HEX W/STAR...

-

Page 26: Heater

Heater TO CONSOLE SOLUTION FROM PUMP 86343360 PUZZI 64/35E... - Page 27 Heater SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 86200260 151-50C HOSE,PULSE 47.0 1/4MPTX1/4MPT 86197360 31016 ELBOW, 1/4 NPT STREET 86005810 57245 NUT, 1/4-20 HEX NYLOCK SS 86273830 70020 SCR, 1/4-20 X 1/2 HHCS SS 86233410 81270 CLAMP, 3/4 DIA CUSHION .406 DIA 86010630 87013 WASHER, 1/4 X 5/8 FLAT SS...

-

Page 28: Labels

Labels 86343360 PUZZI 64/35E... - Page 29 Labels SERIAL NO. REF PART NO. PRV NO. DESCRIPTION NOTES FROM 86343010 LABEL, RECOVERY, AKW, LH 86342640 LABEL, RECOVERY, AKW, RH 86318280 LABEL, NINJA, WARRIOR, W/ HEAT 87581720 LABEL QR CODE PUZZI 64/35 86343360 PUZZI 64/35E...

-

Page 30: Pump

Pump TO PRESSURE GAUGE TO SOLUTION TANK FROM SOLUTION TANK 86343360 PUZZI 64/35E... - Page 31 Pump SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 86190520 11-800224 PLUG, 3/8 SOCHD BR 86364360 HOSE, PULSE 19.5” 1/4MPT X 1/4MPT 89247270 PUMP ASSY, 500PSI 120V CA 86197270 04008 ADPTR, 1/4MPT X 1/4FPT BR 86374840 BUSHING, 3/8 MPT X 1/4 FPT 86233150 20042 CLAMP, 3/8 WORM GEAR...

-

Page 32: Recovery

Recovery 86343360 PUZZI 64/35E... - Page 33 Recovery SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 86161460 15-808123 DUMP VALVE, 1 1/2 86334490 COVER PLATE COMPLETE 86197820 31002 ELBOW, 1.5 FPT X FS PVC 86004000 35255 GASKET, TANK LID 86197040 57264 NUT, 5/16-18 HEX ACORN PLTD 86273740 70010 SCR, 1/4-20 X 1.50 HHCS SS...

-

Page 34: Solution

Solution 86343360 PUZZI 64/35E... - Page 35 Solution SERIAL NO. REF PART NO. PRV NO. DESCRIPTION NOTES FROM 86173640 11-800437 ADPT,3/8 BLKHD COMPLETE 86233150 20042 CLAMP, 3/8 WORM GEAR 86238460 36259 HOOK, STRAP 86317550 HOSEBARB, 3/8 MPT X 1/2 90 BR 86001550 40043 HOSEBARB, 3/8 MPT X 3/8 HOSE 90° 86273740 70010 SCR, 1/4-20 X 1.50 HHCS SS...

-

Page 36: Vacuum, 2-Stage

Vacuum, 2-Stage 86343360 PUZZI 64/35E... - Page 37 Vacuum, 2-Stage SERIAL NO. REF PART NO. PRV NO. DESCRIPTION NOTES FROM 86005810 57245 NUT, 1/4-20 HEX NYLOCK SS 86274090 70092 SCR, 10-32 X 1.5 PPHMS 86233430 81431 CLAMP, 2.50 WORM GEAR 86010630 87013 WASHER, 1/4 X 5/8 FLAT SS 86278990 87017 WASHER, #8 X 3/8 FLAT...

-

Page 38: Wiring

Wiring -PUMP MOTOR 86343360 PUZZI 64/35E... - Page 39 Wiring SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 98407920 HARNESS KIT, HEATED 86343360 PUZZI 64/35E...

-

Page 40: Suggested Spare Parts

Suggested Spare Parts SERIAL NO. PART NO. PRV NO. DESCRIPTION NOTES FROM 89247270 PUMP ASSY, 500PSI 120V CA 86317510 THERMOSTAT W/ VERT SPADE 86201790 130-14C THERMOSTAT RESET 302 86135320 140687 BRUSH SET, 120V VAC 86199430 040-03 CASTER SWIVEL 4” 250# CAPACITY 86002620 260-64A ACCESS COVER CLEAR 6”... -

Page 41: Serial Numbers

Serial Numbers REF. MODEL: SERIAL # 1.006-674.0 - 10066740000017 86343360 PUZZI 64/35E... - Page 42 THANK YOU! MERCI! DANKE! GRACIAS! Registrieren Sie Ihr Produkt und profitieren Sie von vielen Vorteilen. Register your product and benefit from many advantages. Enregistrez votre produit et bénéficier de nombreux avantages. Registre su producto y aproveche de muchas ventajas. www.kaercher.com/welcome Bewerten Sie Ihr Produkt und sagen Sie uns ihre Meinung.

Need help?

Do you have a question about the 500 PSI and is the answer not in the manual?

Questions and answers