Table of Contents

Advertisement

Quick Links

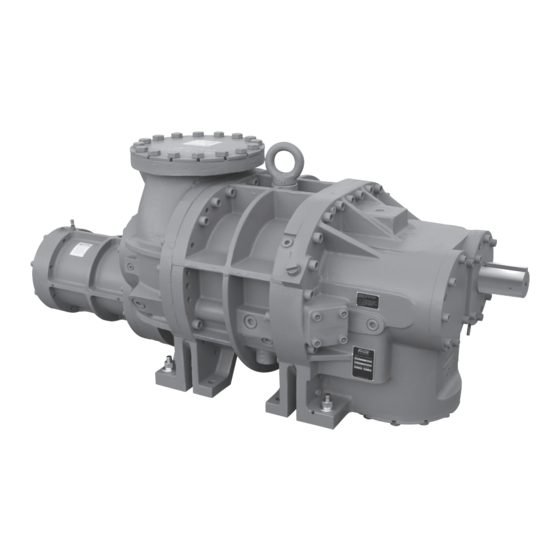

Rotary Screw Compressor

Models TDS_163 - TDS_355

This manual contains installation, operation, and maintenance

instructions. Read thoroughly before beginning installation. Failure

to follow these instructions may result in personal injury or death,

damage to the unit, or incorrect operation.

Check www.FrickCold.com for the latest version of this publication.

Form 070.250-IOM1 (NOV 2013)

Installation – Operation – Maintenance

File:

Service Manual – Section 070

Replaces:

Nothing

Distribution: 3, 3a, 3b, 3c

Revised:

April 2016, p. 2, 8, 16

October 31, 2022

TDS_

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the TDS Series and is the answer not in the manual?

Questions and answers