Table of Contents

Advertisement

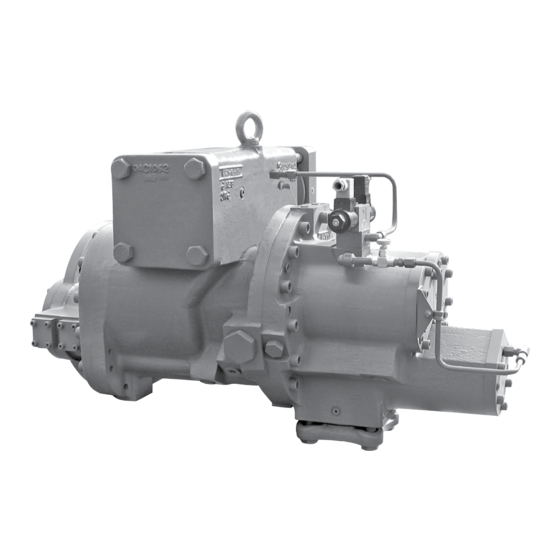

ROTARY SCREW COMPRESSOR

THIS MANUAL CONTAINS RIGGING, ASSEMBLY, START-UP,

AND MAINTENANCE INSTRUCTIONS. READ THOROUGHLY

BEFORE BEGINNING INSTALLATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN PERSONAL INJURY OR DEATH,

DAMAGE TO THE UNIT, OR IMPROPER OPERATION.

Please check www.jci.com/frick for the latest version of this publication.

XJF

MODELS XJF 95, 120, 151

Form 070.450-IOM (NOV 2013)

INSTALLATION - OPERATION - MAINTENANCE

File:

EQUIPMENT MANUAL - Section 070

Replaces:

NOTHING

Dist:

3, 3a, 3b, 3c

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Frick XJS 95M

- Page 1 THIS MANUAL CONTAINS RIGGING, ASSEMBLY, START-UP, AND MAINTENANCE INSTRUCTIONS. READ THOROUGHLY BEFORE BEGINNING INSTALLATION. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY OR DEATH, DAMAGE TO THE UNIT, OR IMPROPER OPERATION. Please check www.jci.com/frick for the latest version of this publication.

-

Page 2: Table Of Contents

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 2 INSTALLATION - OPERATION - MAINTENANCE Contents GENERAL INFORMATION OIL HEATER(S) ..............16 OIL FILTER(S) ..............17 PREFACE ................3 OIL COOLING REQUIREMENTS..........17 DESIGN LIMITATIONS ............3 ECONOMIZER - HIGH STAGE ..........17 JOB INSPECTION .............. 3 DEHYDRATION / EVACUATION TEST .........18 STANDARD BARE COMPRESSOR ........ -

Page 3: General Information

PLANT DECADE MONTH YEAR SEQ NO. REMARKS to protect the compressor. Contact Johnson Controls - Frick 1024 0000015 Compressor Engineering for application details. Month: A = JAN, B = FEB, C = MAR, D = APR, E = MAY, F = JOB INSPECTION JUN, G = JUL, H = AUG, K = SEP, L = OCT, M = NOV, N = DEC. -

Page 4: Long Term Storage

The standard Johnson Controls-Frick Warranty for an XJF screw compressor covers twelve (12) months from start-up or 18 months from shipment, whichever comes first. It is... -

Page 5: Preparing Compressor For Storage

4. Fills gas leakage paths between or around the rotors with XJF COMPRESSOR oil, thus greatly reducing gas leakage and main tain ing good The Frick XJF rotary screw compressor utilizes mating compressor per formance even at high compres sion ratios. asymmetrical profile helical rotors to provide a continuous 5. -

Page 6: Construction Details

400 psig. During operation it is vented to low pressure to provide extended life. VOLUMIZER II ADJUSTABLE VOLUME RATIO CONTROL: The Frick XJF compressor adjusts to the most efficient of three volume ratios (2.2, 3.5 or 5.0) depending upon system... -

Page 7: Installation

Frick Selection Program, CoolWare). Pressure and tem- Solenoid control valves for Capacity Control Slide Valve perature limits are shown in Frick publication 070.410- (SV) are NOT included in delivery. Internal piping is SED. Refer to Johnson Controls-Frick Compressor Control included. -

Page 8: Xjf 95 Dimensions

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 8 INSTALLATION XJF 95 DIMENSIONS C L SUCTION 4.82 10.88 SUCTION FLANGE (122.4) (276.3) FABRICATED SQUARE FLANGE 2.50 (63.5) 2½" (95S & 95M), 3" (95L) C L COMPRESSOR 8.45 0.94 (214.5) (23.9) 6.94 18.75... -

Page 9: Xjf 120 Dimensions

XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) INSTALLATION Page 9 XJF 120 DIMENSIONS C L SUCTION 4.25 SUCTION FLANGE 11.76 6.75 (108) FABRICATED SQUARE FLANGE (171.5) (298.8) 2.00 (50.8) 3" (1750 RPM COMPRESSORS) 4" (3550 RPM COMPRESSORS) C L COMPRESSOR IMPORTANT REMOVE SEALING DISC FROM SUCTION FLANGE BEFORE... -

Page 10: Xjf 151 Dimensions

SEE DETAIL A 13.17 ( 334.5 SEE NOTE 3 Ø1.999/2.000 15.73 ( 399.5 (Ø50.77/50.80) DETAIL A 19.04 ( 483.6 LIFTING HOLE FRICK FABRICATED M20 X 2.5-6H SUCTION FLANGE 5" 1.56 DP 15.73 (399.5) 4.57 DRIVE SHAFT (116.1) 1.25 (31.8) COMPRESSOR 1.25... -

Page 11: Xjf 95 Compressor Port Locations

XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) INSTALLATION Page 11 XJF 95 COMPRESSOR PORT LOCATIONS PORT CONNECTION SIZE 3/4 - 14 NPTF 1/8 - 27 NPTF 3/8 - 18 NPTF 3/8 - 18 NPTF 3/4 - 14 NPTF 1/4 - 18 NPTF 3/8 - 18 NPTF 1/4 - 18 NPTF 1/4 - 18 NPTF... -

Page 12: Xjf 120 Compressor Port Locations

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 12 INSTALLATION XJF 120 COMPRESSOR PORT LOCATIONS PORT CONNECTION SIZE 1 - 11½ NPTF 1/4 - 18 NPTF 3/8 - 18 NPTF 3/8 - 18 NPTF 1 - 11½ NPTF 1/2 - 14 NPTF 1/4 - 18 NPTF 1/4 - 18 NPTF 1/4 - 18 NPTF... -

Page 13: Xjf 151 Compressor Port Locations

XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) INSTALLATION Page 13 XJF 151 COMPRESSOR PORT LOCATIONS PORT CONNECTION SIZE O-RING 1Z\zn - 12 UN-2B 980A0012K66 7/16 - 20 UNF-2B 980A0012K58 1Z\zn - 12 UN-2B 980A0012K66 1Z\zn - 12 UN-2B 980A0012K66 1M\, - 12 UN-2B 980A0012K72 9/16 - 18 UNF-2B... -

Page 14: Sae Straight Thread O-Ring Fittings - Assembly Procedure For Rxf 58 - 101

Access valves are bronze and they must be replaced with steel plugs when package is assembled. Every XJF compressor is pressure and leak tested at the Johnson Controls–Frick factory and then thoroughly evacu- WARNING ated and charged with dry nitrogen to ensure its integrity during shipping and short term storage prior to installation. -

Page 15: Rigging And Handling

CoolWare will select a specific Frick oil for the refrigerant being The best insurance for a trouble-free installation is to firmly used. Depending on the application, a different oil can be... -

Page 16: Compressor

CAUTION If you are using the Johnson Controls – Frick motor mount, To prevent injury or damage to components, and for the mount is machined to ensure that motor to compressor complete details regarding pressurized refrigerant vapor alignment is in specification (see the above “MOTOR... -

Page 17: Oil Filter(S)

In cases where wide swings in pressure are anticipated in 16/14/11 according to ISO 4406. Frick SuperFilters ™ can be the flash econo mizer vessel, it may be necessary to add an ordered separately. -

Page 18: Dehydration / Evacuation Test

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 18 INSTALLATION run at partial load, exposing the economizer port to suction LIQ. LINE SIZE* 5 MIN LIQUID pressure. In the case of a flash vessel, there is no need for REFRIG SUPPLY VOLUME... -

Page 19: Electrical Installation

Observe the maximum power input and ensure design limitations are not exceeded. Connect to +/- and signal as shown in the wiring diagram, Figure 10. Refer to Frick compressor panel instructions for calibration procedure 090.040-O. Figure 11 - Hydraulic Schematic... -

Page 20: Low Ambient Operation

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 20 INSTALLATION 3. Set the compressor Vi to 3.5, then record the voltage that is shown on the Slide Valve calibration screen for the cur- rent Slide Valve and 0% Slide Valve positions. The difference between these voltages must be in the 0.95 - 1.15 Vdc range. -

Page 21: Operation

OPERATION MAINTENANCE OPERATION AND START-UP INSTRUCTIONS GENERAL INFORMATION The Frick XJF Rotary Screw Compressor will be a component This section provides instructions for normal maintenance, in an integrated system. As such the compressor requires a recommended maintenance program, and troubleshooting some specific operation and conditions to ensure trouble- and correction guides. -

Page 22: Changing Oil

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 22 MAINTENANCE 5. Protect the compressor during long periods of 3. Close the suction and discharge service valves shutdown. If the compressor will be sitting for long periods 4. Using appropriate equipment, lower the compressor without running, it is advisable to evacuate to low pressure pressure to 0 psig. -

Page 23: Vibration Analysis

Use the list as a guide to further investigate compressor unit: the problem. 1. Only use Frick oil or high quality oils approved by Johnson Controls - Frick for your application. The second step in problem solving is to decide which items on the list are possible causes and which items are 2. - Page 24 Refrigerant flood-back. Correct system problem. NOTICE Unless the Service Technician has been certified by Johnson Controls – Frick to rebuild our compressors, troubleshooting the compressor is limited to identifying the probable cause. If a mechanical problem is suspected contact Johnson Controls –...

-

Page 25: P And I Drawings

XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) MAINTENANCE Page 25 P AND I DRAWINGS XJF MODELS 95 and 120 without OIL PUMP (See OIL COOLING ADDITIONS) LEGEND* PUMP HIGH TEMPERATURE ALARM AIR SUPPLY HIGH PRESSURE ALARM TAHH HIGH TEMP. SHUTDOWN COMPRESSOR PAHH HIGH PRESSURE SHUTDOWN... - Page 26 070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 26 MAINTENANCE XJF MODELS 95 and 120 with OIL PUMP (See OIL COOLING ADDITIONS) LEGEND (Cont.) CONNECTIONS VENT - UNLOADING NOTES: THERMOWELL MAIN OIL SUPPLY 1. PRESSURE TRANSDUCERS INDICATE: SUCTION PRESSURE SLIDE VALVE PISTON PE-1 OIL PRESSURE LOW VI LIQUID INJECTION...

- Page 27 XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) MAINTENANCE Page 27 XJF MODEL 151 without OIL PUMP (See OIL COOLING ADDITIONS) LEGEND* PUMP HIGH TEMPERATURE ALARM AIR SUPPLY HIGH PRESSURE ALARM TAHH HIGH TEMP. SHUTDOWN COMPRESSOR PAHH HIGH PRESSURE SHUTDOWN LOW TEMPERATURE ALARM CHECK VALVE LOW PRESSURE ALARM...

- Page 28 070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 28 MAINTENANCE XJF MODEL 151 with OIL PUMP and DUAL OIL FILTERS ( See OIL COOLING ADDITIONS) LEGEND (Cont.) NOTES: CONNECTIONS MAIN OIL INJECTION MAIN OIL SUPPLY 1. PRESSURE TRANSDUCERS INDICATE: SUCTION PRESSURE SLIDE VALVE PISTON PE-1 OIL PRESSURE...

-

Page 29: Forms

XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) MAINTENANCE Page 29 FORMS ROTARY SCREW COMPRESSOR OPERATING LOG SHEET... - Page 30 READ THIS FIRST: COMPRESSOR PRESTART CHECKLIST The following items MUST be checked and completed by the installer prior to the arrival of the Frick Field Service Supervisor. Details on the checklist can be found in this manual. Certain items on this checklist will be reverified by the Frick Field Service Supervisor prior to the actual start-up.

- Page 31 XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) MAINTENANCE Page 31 DRIVE TRAIN ALIGNMENT Ambient Temperature at Time of Alignment _______ Oil Separator Temperature at Time of Alignment_________ Motor Coupling Type ___________ Size ___________ Distance Between Coupling Hub Faces __________ Soft Foot Check OK as Found Shimming Required...

-

Page 32: Vibration Data Sheet

070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 32 MAINTENANCE VIBRATION DATA SHEET Date: __________________________________________ Sales Order Number: ________________________________ End User: _______________________________________ Installing Contractor: ________________________________ Address: __________________________________________ Service Technician: __________________________________ Equipment ID (As in Microlog): ____________________ Compressor Serial Number: __________________________ Unit Serial Number: _________________________________ National Board Number: _____________________________ Running Hours: _____________________________________... - Page 33 XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) INSTALLATION - OPERATION - MAINTENANCE Page 33 Index accumulator, 3 High capacity roller bearings, 5 Allowable Flange Loads, 15 high-stage operation, 6 Antifriction bearings, 6 Holding Charge, 14 ASHRAE, 3 hydraulic cylinder, 5 Assembly Torque Table, 14 hydraulic system, 19 hydraulic tubing, 14...

- Page 34 070-450 IOM (NOV 13) XJF ROTARY SCREW COMPRESSOR Page 34 INSTALLATION - OPERATION - MAINTENANCE Operating Log Sheet, 29 O-ring, 14 thermal stability, 6 O-ring compression, 14 traps, 3 over-compression, 6 troubleshooting, 21 Troubleshooting, 24 Excessive Noise And Vibration, 24 pipe hangers, 15 Slide Valve, 24 piping layouts, 3...

- Page 35 XJF ROTARY SCREW COMPRESSOR 070-450 IOM (NOV 13) INSTALLATION - OPERATION - MAINTENANCE Page 35...

- Page 36 Form 070.450-IOM (2013-11) JOHNSON CONTROLS Supersedes: NOTHING 100 CV Avenue Subject to change without notice Waynesboro, PA 17268-1206 USA Published in USA • PDF 11/13 Phone: 717-762-2121 • FAX: 717-762-8624 www.jci.com/frick © 2013 Johnson Controls Inc. - ALL RIGHTS RESERVED...

Need help?

Do you have a question about the XJS 95M and is the answer not in the manual?

Questions and answers