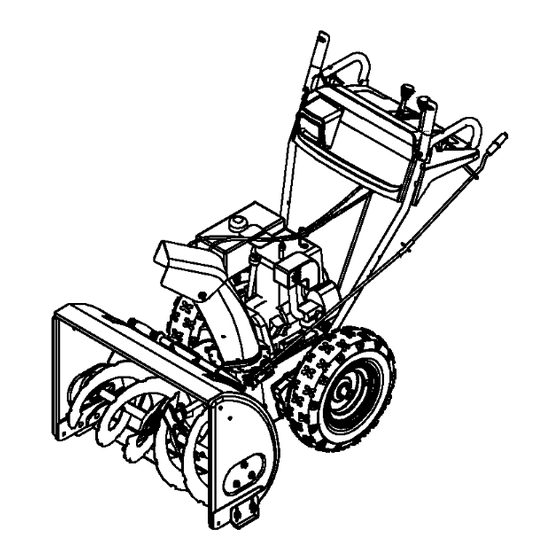

Craftsman SNOW THROWER 247.88853 Owner's Manual

9 horse power 28" two-stage wheel drive snow thrower

Hide thumbs

Also See for SNOW THROWER 247.88853:

- Owner's manual (64 pages) ,

- Owner's manual (64 pages)

Table of Contents

Advertisement

Available languages

Available languages

Owner's Manual

9 Horse Power

28" Two-Stage

Wheel

Drive

Snow Thrower

Model No.

247.888530

CAUTION:

Before

using this product,

read this manual and

follow all safety rules

and operating

instructions.

•

Safety

•

Assembly

•

Operation

•

Service

•

Maintenance

•

EspaSol

Sears, Roebuck

And Co., Hoffman

Estates,

IL 60179, U.S.A.

Visit our website:

www.sears.com/craftsman

FORM NO. 770-10057G

Prhted JnU.S.A.

(8/2002)

Advertisement

Table of Contents

Summary of Contents for Craftsman SNOW THROWER 247.88853

- Page 1 Model No. 247.888530 CAUTION: Before using this product, read this manual and follow all safety rules and operating instructions. Sears, Roebuck And Co., Hoffman Visit our website: www.sears.com/craftsman Prhted JnU.S.A. • Safety • Assembly • Operation • Service • Maintenance •...

- Page 2 Safe Operation Practices ... Assembly Operation Maintenance Two -Year Warranty on Craftsman Snow Thrower For two years from the date of purchase, when this Craftsman up according to the instructions in the owner's manual, and workmanship. If this Craftsman snow thrower is used for commercial from the date of purchase.

-

Page 3: Operation

WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. -

Page 4: Maintenance And Storage

area. Engine exhaust contains carbon monoxide, odorless and deadly gas. 6. Do not o perate machine while under the influence of alcohol ordrugs. 7. Muffler and engine become hot a nd can cause a burn. Do not t ouch. 8. Exercise extreme caution when o perating gravel surfaces. - Page 5 Lay thehardware pieces from thehardware pack o nthe figure h ere and you will h ave automatically according tothesteps o fthe assembly procedure The number in parenthesis indicates the total number of the hardware Lock Washer Hex Bolt (2) ,,,. 5/16-18 x 1.75 Hex Bolt...

-

Page 6: Loose Parts

Discharge Chute Handle & Handle Panel Assembly _, Chute Crank IMPORTANT: This unit is shipped with engine oil in the engine, but without gasoline. After assembly, OPERATION section of this manual for fuel selection and fill-up. Removing From Carton • Cut the corners of the carton and lay the sides flat on the ground. - Page 7 Discharge Figure 2 Secure bottom hole on the handle to the snow thrower frame using 5/16 x .75" hex bolt and lock washer from the hardware pack (group A on page 5 ). Do not tighten at this time. See Figure 3. Atta_ch lock washer and hex bolt here NOTE:...

- Page 8 theninsert t heendofthechute crank intotheeye hole intheplastic b ushing i nthelower c hute crank bracket. SeeFigure 6 . Hairpin CI Plastic Bushing Lower Chute Crank Bracket Figure 6 • Place the other 3/8 ID flat washer (from the same group of hardware) on the end of the chute crank and insert hairpin clip into hole at the end of the chute crank.

- Page 9 • Youwillreach correct adjustment when there is minimal slack inthecable butitisnottight. H old the flatsontheferrule withpliers andtighten thejam nutagainst theferrule. CAUTION: Cables w illbecome l oose ifyoudonot tighten t hejamnut. WARNING: There must not be any tension on either clutch cable with the drive or auger clutch grip in the disengaged These clutches are a safety feature.

- Page 10 Secure the right turn trigger cable to the right lower handle using cable tie provided in the hardware pack. Make sure not to wrap the drive cable. See Figure 13. Tie\_ Trigger Cable Cable Figure 13 Secure the left turn trigger cable to the Iower handle using the other cable tie.

- Page 11 • Ifyoufaceresistance when moving t heshiftlever orthesnow thrower w heels s top when theyshould not,loosen t helocknutonthetraction d rive cable andunthread t hecable oneturn. • Ifthewheels c anstillbeturned when youengage thetraction d rive clutch grip, l oosen thelocknuton thetraction d rive cable andthread thecable inone turn.

-

Page 12: Knowing Your Snow Thrower

Knowing Your Snow Thrower Read this owner's manual and safety rules before operating your snow thrower to familiarize yourself with the location of various controls and adjustments. future reference. Traction Auger Control Lock Discharge Chute Chute "_ Clean-Out Aug6r Skid Shoe Operating Controls (See Figure 17 .) -

Page 13: Before Starting

Shift Lever The shift lever is located in the center of the handle panel and is used to determine ground speed and direction of travel. It can be moved into any of eight positions. IMPORTANT: Always release traction the control before changing speeds. -

Page 14: To Start Engine

engine w hile instorage.To avoid engine p roblems, the fuel s ystem should b eemptied b efore s torage for 30days orlonger. Drain thegas tank, s tart t he engine and letitrununtil t he fuel l ines and carburetor are empty. -

Page 15: To Engage Drive

Disconnect thepower c ord fromthereceptacle first andthenfrom theswitch boxontheengine. Allow theengine t owarm upforafewminutes because t heengine w illnotdevelop f ullpower u ntil it reaches operating temperature. Operate t he engine atfullthrottle (FAST) when throwing s now. Warm Start • If restarting a warm engine, rotate choke to OFF instead of FULL and press the starter button. -

Page 16: Operating Tips

Operating Tips NOTE: Allow the engine to warm up for a few minutes as the engine will not develop full power until it reaches operating temperature. WARNING: The temperature surrounding areas may exceed 150 ° F. Avoid these areas. • For most efficient snow removal, remove snow immediately after it falls. -

Page 17: General Recommendations

General Recommendations • Always observe safety rules when performing maintenance. • The warranty on this snow thrower does not cover items that have been subjected or negligence. To receive full value from the warranty, operator must maintain the snow thrower as instructed in this manual. -

Page 18: Check V-Belts

Wheels • Oil or spray lubricant into bearings at wheels at least once a season. Pull klick pin, remove wheels, clean and coat axles with a multipurpose automotive grease. See Figure 23. _ .,____Klick Figure 23 Traction Control / Auger Control Lock The cams on the ends of the control rods which interlock the traction drive and auger drive clutches must be lubricated at least once a season or every 25... -

Page 19: Checking Oil Level

Refer t otheviscosity chart f orproper s election o f engine oil. Checking Oil Level CAUTION: Before operating thesnow thrower, check theengine oillevel. • Withengine onlevel g round, theoilmust b eto FULL mark ondipstick. • Stop engine andwait s everal minutes b efore checking o illevel. - Page 20 WARNING: Always stop the engine, disconnect spark plug wire and move it away from the spark plug before performing any adjustments or repairs. Adjustments Assembly Chute The distance that snow is thrown can be adjusted adjusting the angle of the chute assembly. Controls section of this manual.

-

Page 21: Replacing Belt

Carburetor WARNING: If any adjustments are made to the engine while the engine is running (e.g. carburetor), keep clear of all moving parts. Be careful of heated surfaces and mufflers. Minor carburetor adjustments may be required to compensate for differences in fuel temperature, and load. - Page 22 • Remove t hesixhexnuts endlockwashers w hich attach theauger h ousing a ssembly totheframe assembly. SeeFigure 3 0. WARNING: Do not attempt to change the auger belt without the help of an assistant. very important that one person, standing at the operating position, firmly hold the snow thrower housing to prevent it from tipping while the other person replaces the belt.

- Page 23 • Reinstall thebeltcover o nfront o ftheengine with thetwoself-tapping screws a ndflatwashers. • Reattach thechute crank tothechute assembly withthehairpin c lipandflatwasher. NOTE: M ake sure that the auger cable is routed in front of the belt. Drive Belt • Check drive belt every 50 hours of operation wear and tear.

- Page 24 Screws Friction Wheel_ Plates Figure 36 • Insert the pin from the shift arm assembly into the friction wheel assembly and hold assembly in position. See Figure 37. • Slide hex shaft through left side of the housing and the friction wheel assembly. •...

-

Page 25: Preparing The Engine

Ifthesnow thrower willnotbeused for30days or longer, orattheendofthesnow season w hen thelast possibility ofsnow isgone, t heequipment needs tobe stored properly. Follow storage i nstructions below to ensure t opperformance fromthesnow thrower for many more years. Preparing the Engine WARNING: Never store snow thrower with fuel in tank indoors or in poorly ventilated areas, where fuel fumes may reach an open flame, spark or pilot light as on a furnace, water... - Page 26 Problem Engine fails to start. Fuel tank empty, or stale fuel. Blocked fuel line. Choke not in ON position Faulty spark plug. Safety key not in ignition switch on engine Spark plug wire disconnected. Primer button nat being used properly. Engine runs erratic.

- Page 27 777D05309 777120727 777_20729 777120728 (MODELPLATECENTERED WITH TOP OF FRAME COVER) 777D00334 777120329 777120330 (CENTER MODEL PLATE 777S32065 777S32066 777D03094...

- Page 28 SEARS CRAFTSMAN 9.0 H.P. SNOW NOTE: For painted parts, please needed, to the part number to order a replacement the part number to order would be 700-xxxx-0689. Polo Green: 0689 Powder Black: 0637 THROWER MODEL " 31/23 refer to the list of color codes below. Please add the applicable part.

- Page 29 SEARS CRAFTSMAN 9.0 H.P. SNOW Key, Part No. 35931A Bearing Housing 584-0041 D Auger Housing Assy. 28" 584-0065 impeller Assy, 12" dia. 705-5226 Chute Reinforcement 710-0451 Carriage Bolt 5/16-18 x .75" Gr,2 710-0459A Hex Screw 3/8-24 x 1.5" Gr.5 710-0604A Hex Washer Screw 5/16-18 x .62"...

- Page 30 SEARS CRAFTSMAN 9.0 H.P. SNOW NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable code, wherever replacement 700-xxxx, order would be 700-xxxx-0689. \\\\\\\\ Drive Clutch Cable routed below axle and hooked here...

- Page 31 SEARS CRAFTSMAN 9.0 H.P. SNOW Key, Part No. 618-0043 Degg Assembly 618-0044 Degg Assembly 618-0575 Shift Assembly: 656-0012A Friction Wheel Disc Assy, 684-0014B Shift Rod Assembly 684-0042C Bearing Transmission 784-5731B 684-0131A Support Bracket Assembly 710-0599 TT Screw 1/4-20 x 0.5"...

- Page 32 SEARS CRAFTSMAN 9.0 H.P. SNOW THROWER MODEL 247.888530 NOTE: For painted color codes below. Please code, wherever replacement xxxx, is painted would be 700-xxxx-0689. Polo Green: Powder Black: parts, please refer to the list of add the applicable color needed, to the part number to order a part.

- Page 33 SEARS CRAFTSMAN 9.0 H.P. SNOW THROWER Part No. Description 629-0058 Harness for Headlight 684-0008A Shift Arm Assembly 684-0053B Lower Chute Crank Assembly 684-0066 Hardware Pack* 684-0102 Handle Pane{ Assembly 684-0111A Handle Assembly 684-0112 Handle Assembly 710-0262 Carriage Bolt 5/16-18 x 1.50 710-0442 Hex Bolt 5/16-18 x 1.5...

- Page 34 SEARS CRAFTSMAN 9.0 H.P. SNOW THROWER \\\\ MODEL 247.888530 Key. Part No. Description 712-0324 Hex Lock Nut: 1/4-20 732-0705 Cable Guide Craftsman Engine model 143.039001 Key, Part NO. 734-1709A- Wheel Assembly 3662 738-0994A Axle 714-0104 Klick Pin 731-04043 Spacer Description...

- Page 35 SEARS CRAFTSMAN 9.0 H.P. SNOW MODEL 247.888530 IMPORTANT: For a properly working machine, use Factory Approved Parts. V-Belts are specially designed to engage and disengage safely. A substitute (non-OEM) V-Belt can be dangerous by not disengaging completely. NOTE: For painted parts, please refer to the list of color codes below.

- Page 36 Craftsman Engine Model No. 143.039001 Snow Thrower Model 247.888530 for Craftsman 37OH >300 "60 370C '_"...

- Page 37 30588A Governor Spool 29193 Retaining Ring 650833 Screw 650832 Screw 32589 Flywheel Key 611093 Flywheel (W/Ring Gear) for Craftsman Description Qty. Belteville Washer 650880 650881 Flywheel Nut 35135 Solid State Ignition 610118 Spark Plug Cover 651024 Solid State Mounting Stud...

- Page 38 "O" Ring 35540 Fill Tube Clip 36205 Dipstick 650873 Screw 611111 Alternator Coil 611117 Connector Body 611118 Terminal Recoil Starter for Craftsman Par_ Qty. Description 29443 Wire Clip 35392 Starter Plug 35593 Ignition Key 610973 Terminal 35057A Carburetor Cover 650765...

- Page 39 Snow Thrower Model 247.888530 CARBURETOR 18,.. _*" fLOf_f_ J_/.,_,_ 48-.© _"_ 20A 29/_ '_',s7 40/t_ for Craftsman Description 640052 Carburetor (Incl. 184 of Engine Parts List) 631776A Throttle Shaft & Lever Ass'y. 631970 Throttle Return Spring 631778 Throttle Shutter 650506...

- Page 40 Reparaciones necesarias a causa deabuso o negligencia p orpartedeloperador, incluyendo cigL)eSles doblados y lafallaenmantener elequipo deacuerdo conlasinstrucciones contenidas e nelmanual delproprietario. Elservici5 degarantia estadisponible s isedevuetve e lexpulsor d enieve Craftsman a lcentro/departamento servicio deSearsmascercano enlosestados unidos. Estagarantia seaplicasolamente m ientras e steproducto e st6enusoenlosEstados U nidos.

- Page 41 ADVERTENCIA: Este simbolo respetan, podffan poner en peligro la seguridad instrucciones que aparecen en este manual antes de intentar operar esta mAquina. La falta de cumplimiento con estas instrucciones podffa resultar en lesiones personales. advertencia. ADVERTENCIA: vehfculo contienen o emiten sustancias quimicas qua de acuerdo con el Estado de California, causan cancer y El escape del motor, algunos de sus componentes, y determinados componentes del defectos de nacimiento u otros daffos reproductivos.

- Page 42 El silenciador y el motor se calientan y pueden causar quemaduras. No toque. Tenga mucho cuidado cuando utilice la m&quina sobre o a traves de super[icies con grava. Mantengase detectar riesgos ocultos o trAnsito. Tenga cuidado cuando cambie de direcci6n y cuando trabaje sobre pendientes.

- Page 43 Despliegue laferreteria deacuerdo conlailustraci6n para fines deidentificaci6n. tamaSo aproximadamente. Losnt3meros articulos adicionales quenoseusan ensuunidad.) Arandela de segurJdad (4) Perno hexagonal(2) -.,, 5/16-18 x 1.75 Perno hexagonal (2) _._ 3/16-18 x .75 Broche de cabello (1) _/_oche Arandela plana (2) Piezas de Repuesto "_ Arandela de /_ seguridad (2)

- Page 44 Panel de Mango, Mangos Manivela de la canaleta IMPORTANTE: Esta unidad ha sido despachada con aceite del motor paro sin gasolina en el motor. Despu6s del ensamblado, yea la secci6n de OPERACION de este manual para selecci6n y Ilenado de combustible. Extraccion De La Unidad De La Caja Cotte las esquinas de la caja.

- Page 45 Canaleta de Alinee orificios aquf Figura 2 Asegure el orificio inferior en el mango al bastidor del expulsor de nieve utilizando pemos hexagonales 5/16 x.75" y la arandela de seguridad del conjunto de ferreteria (grupo A en la pAgina 5). No apriete en este momento.

- Page 46 Coloque una arandela plana d e3/8 deDI(del grupo Fdel con junto deferreteria) enelextremo delamanija d ela canaleta, acontinuaciSn insette e lextremo delamanija enelorificio d elcasquillo pl_stico enelsopor_e dela manija d elacanaleta. Vea laFigura 6 . Coloque laotra arandela plana de3/8deDI(del m ismo grupo d eferreteria) alextremo delamanija d ela canaleta e inserte e lbroche d el c abello d entro d el o rificio alextremo delamanija d elacanaleta.

- Page 47 PRECAUCION: Los cables se aflojar_n si usted no ajusta la contratuerca. ADVERTENCIA: NO debe haber tensi6n en ninguno de los cables del embrague propulsor o la empufiadura espiral sin fin en la posici6n desengan-chada (up). Esos embragues sen una caracterfstica seguridad.

-

Page 48: Ajustes Finales

Asegure el cable del gatillo de giro izquierdo de la misma manera. CorSelos extremes excesivos de cada amarre de cable. NOTA: El amarre del cable del lado derecho debe usarse para evitar el contacto con el brazo m6vil de cambios de la transmisiSn. Cableado de la Ldmpara Envuelva el cable de la I_mpara hacia abajo del mango... - Page 49 Conociendo a su expulsor de nieve Por favor lea este manual del usuario y las etiquetas de seguridad anexadas a la unidad antes de operar su expulsor de nieve. Compare la ilustraci6n que figura mas abajo con su equipo para conocer la ubicaci6n y caracterfsticas de los diversos controles del mismo.

-

Page 50: Antes De Poner En Marcha El Motor

Interruptor De Encendido De Seguridad El interrupter de la Ilave de encendido debe insertarse completamente en el interrupter antes que arranque la unidad. No intente girar la Ilave. Valvula De Corte De Combustible La v_lvula de corte de combustible, ubicada debajo del tanque de combustible controla el fluje de combustible del tanque. -

Page 51: Para Poner En Marcha El Motor

Llene eltanque d ecombustible congasolina limpia, sin nueva, para autom6vil sinplome. AI f inalizar eltrabajo, vacfe eltanque d ecombustible expalser denieve n ovaasetusade d urante 3 0dfas e mAs. Vea instrucciones dealmacenamiento 25deeste manual. PRECAUCl6N: La experiencia indica que los combustibles con mezcla de alcohol (llamados gasohol) o los que utilizan etanol o metanol pueden atraer la humedad que resulta en la separaci6n y... - Page 52 mueva elregulador inmediatamente acontinuaciSn mueva g radualmente Para el arranque de tettoceao solamente prSxirnos pasos: Gire la perilla del regulador a la posiciSn FULL. Coloque el regulador en la posiciSn OFF en lugar de la posiciSn FULL, si el motor todavfa est_ caliente. Optima el botSn del cebador dos o tres veces.

-

Page 53: Consejos De Operacion

Enganche De Las Espirales Sin Fin Optima la empu_adura del embrague de la espiral sin fin contra el mango izquierdo, para enganchar las espirales sin fin y comenzar la acci6n de despedir la nieve. Suelte para detener las espirales sin fin (debe soltarse tambi6n la empuSadura del embrague del propulsor de tracci6n). - Page 54 Recomendaciones Generales Observe siempre las reglas de seguridad al efectuar el mantenimiento. La garanfia en este expulsor de nieve no cubre art{culos que han estado sujetos a abuso o negligencia pot el operador. El operador debe mantener el expulsor de nieve segL_nlas instrucciones de este manual para recibir el valor completo de la garant{a.

- Page 55 dgrasa. Puede obtenerse acceso alas levas por debajo el panel del mango. Yea la Figura 21. Varilla/de_ contro/i _ I ev s de ub "caci_alUi Figura Caja De Engranajes La caja de engranajes est& lubricada con grasa de f_brica y no requiere inspecciSn. Si se desarma pot cualquier motivo, lubrique con 2 onzas de grasa.

-

Page 56: Mantenimiento Del Motor

Mantenimiento Del Motor Aceite De Motor ° mAs frio --*'- 5w30 _ Tabla de la Viscosidad Use aceite detergente de alta calidad solamente clasificado con la clasificaci6n API de servicio SF, SG o SH. Seleccione el grado de viscosidad SAE del aceite de acuerdo con la temperatura operativa esperada. - Page 57 ADVERTENCIA: Antes de efectuar cualquier ajuste o reparaci6n, siempre apague el motor, desconecte el cable de la bujfa y al_jelo de la bujfa.Mientras el motor est& funcionando, nunca trate de limpiar la canaleta ni efectuar ajustes. Ajustes Zapata Deslizante Puede ajustarse el espacio entre la plancha raspadora y el suelo.

- Page 58 manera que los pernos hexagonales Figura 27. Si las helices no giran, inspeccione para verificar si los pernos se han cortado. Reemplace si fuera necesario. Se han provisto dos pernos hexagonales y contratuercas repuesto con el expulsor de nieve. Pernos de_orte Pemo de carro Figura 27 Plancha...

- Page 59 Par_ndose en la posici6n operativa, levante de las manijas y tire hacia atr_s el conjunto del bastidor.Se separar&n el bastidor y la armadura y saldr_ de la polea la correa de la espiral sin fin posterior. Mantenga el control del con junto del bastidor al tirar del mismo. Extraiga las dos correas de las dos poleas del motor.

- Page 60 Figura 34 Cambio De La Goma De La Rueda De Friccion Inspeccione la goma de la rueda de fricci6n despu_s de 25 horas de operaci6n y peri6dicamente hallan seSales de desgaste o grietas, reemplace Drene la gasolina de la limpiadora de nieve o coloque un trozo de plAstico debajo de la tapa de gasolina.

- Page 61 Alinee e lejehexagonal conelrodamiento ygufe cuidadosamente elrodamiento dellado izquierde delaarmadura. Reensamble lacubietta delpropulser conloscuatro tornillos queseextrajeron antes. NOTA: AsegtJrese de extraer el trozo de pl#stico colocado debajo de la tapa de gasolina, de haberlo colocado. Carburador Si usted considera que el carburador ajustado, consulte con su Servicio T_cnico autorizado Sears m_s cercano.

- Page 62 Preparaci6n del motor ADVERTENCIA: Nunca almacene el motor con combustible en el tanque, bajo techo o en adreas mal ventiladas, donde los humos del combustible pueden Ilegar a una llama expuesta, chispas o una llama piloto ni sobre una cochina, calentador de agua, secador de ropas ni otros artefactos...

- Page 63 Problema Causa(s) El motor fun- Unidad funcionando en CHOKE (REGU- ciona err_tico LADOR) Tuberia de gasolina bloqueada o combusti- ble rancio. Agua o suciedad en el sistema de combus- tible. Carburador mal ajustado. Perdida de Cable de la bujfa flojo. )otencia Orificio de ventilaci6n de la tapa de gaso- lina taponado.

- Page 64 Get it fixed, at your home or ours! For repair-in your home-of lawn and garden equipment, no matter who made it, no matter who sold it! For the replacement owner's manuals that you need to do-it-yourself. For Sears professional and items like garage door openers and water heaters. 1-800-4-MY-HOME Call anytime, day or night (U.S.A.

Need help?

Do you have a question about the SNOW THROWER 247.88853 and is the answer not in the manual?

Questions and answers