Table of Contents

Advertisement

Available languages

Available languages

Owner's Manual

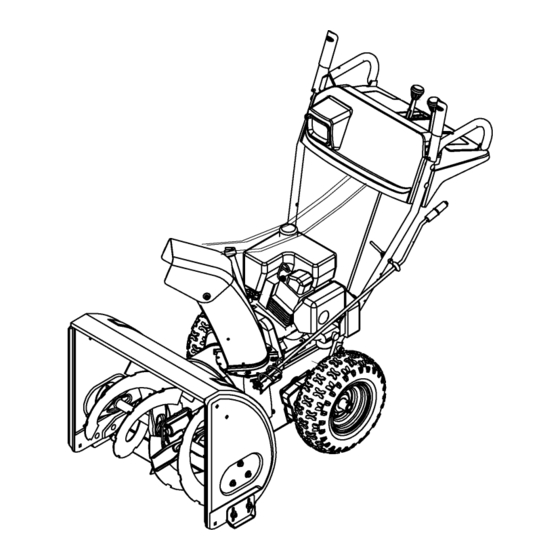

CRRFTSMR

6.5 Horse Power

24" Two-Stage Wheel Drive

Snow Thrower

Model No.

247.888160

CAUTION:

Before

using this product,

read this manual and

follow all safety rules

and operating

instructions.

Safety

Assembly

Service

Maintenance

EspaSol

Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.sears.com/craftsman

FORM NO. 770-10559

Printed in U.S.A.

(7/2001)

Advertisement

Table of Contents

Summary of Contents for Craftsman 247.888160

- Page 1 Before Safety using this product, Assembly read this manual and Service follow all safety rules Maintenance and operating instructions. EspaSol Sears, Roebuck And Co., Hoffman Estates, IL 60179, U.S.A. Visit our website: www.sears.com/craftsman FORM NO. 770-10559 Printed in U.S.A. (7/2001)

- Page 2 Sears will repair, free of charge, any defect in material and workmanship. If this Craftsman snow thrower is used for commercial or rental purposes, this warranty applies for only 30 days from the date of purchase.

- Page 3 SECTION 1: IMPORTANT SAFEOPERATION P RACTICES This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury.

- Page 4 5. Never runanengine i ndoors orinapoorly v entilated Maintenance And Storage area. E ngine exhaust contains carbon m onoxide, an Never tamper with safety devices. Check their proper odorless and deadly gas. 6. Donotoperate m achine while under theinfluence of operation regularly.

- Page 5 Lay the hardware pieces on the figure here to sort them according to the assembly procedure described later in the manual. Only one unit of each hardware piece is shown although the total number of units per group is listed in parenthesis. Cupped Wyher {4) Hex Bolt (2)

- Page 6 IMPORTANT: This unit is shipped with engine oil in the Assembly Tips: For easier assembly purposes, engine, but without gasoline. After assembly, see remove the chute from the carton and lay it on top of OPERATION section of this manual for fuel selection the engine.

- Page 7 handles g othrough theslotsinthehandle panel. route chute and chute cable between the handles While placing thehandle panel, m a kesureto _\_\TChut underneath the panel keeping the cable on top of Align the holes in the handle with the holes on two sides of the handle panel.

- Page 8 Tighten all loose hardware on the handle assembly in the following order-- first the four hex bolts at the bottom of the handle, then the carriage bolts and Carriage lastly any other bolt that may have been left loose. Attaching Clutch Cables The clutch control cables are attached to the snow thrower.

- Page 9 Attaching Shift Rod • Place the shift lever in the sixth (6) speed. Trigge% • Place the bent end of the shift rod into the hole in Inner Cable the shift arm assembly. See Figure 10. Secure with Trigger us,ng flat washer and hairpin clip from group E of the hardware pack.

- Page 10 NOTE: The right side cable tie must be used to keep • If you face resistance when moving the shift lever cable from coming in contact with the moving shift arm or the snow thrower wheels stop when they should from the transmission.

- Page 11 Read this owner's manual and safety rules before • Turn clockwise to discharge to the left; operating your snow thrower. Compare illustration • Turn counterclockwise to discharge to the right. below with your snow thrower to familiarize yourself Throttle Control with the location of various controls and adjustments.

- Page 12 A. Electric Starter Before Starting Engine • For location of all the engine controls referred to in Fill Gas this section, see Figure 16. • Before starting, make sure that the engine has sufficient oil. The snow thrower engine is equipped caution must be used when handling or WARNING: Gasoline is flammable...

- Page 13 restarted only when it has cooled to a safe • Allow the engine to warm up for a few minutes temperature (a wait of about 5 to 10 minutes). because the engine will not develop full power until • When the engine starts, release the starter button it reaches operating temperature.

- Page 14 WARNING: • While the auger control is engaged, squeeze the The temperature of muffler and traction drive control to move, release to stop. Do the surrounding areas may exceed 150 ° F. not shift speeds while the drive is engaged. Avoid these areas.

- Page 15 General Recommendations Always observe safety rules when performing any Shear Bolt maintenance. The warranty on this snow thrower does not cover items that have been subjected to operator abuse or negligence. To receive full value from the warranty, operator must maintain the snow thrower as instructed in this manual.

- Page 16 Shifting Mechanism • Stop engine and wait several minutes before checking oil level. Remove oil fill cap and dipstick. • Lubricate the shifting mechanism and pivot points • Wipe dipstick clean, insert it into oil fill hole and on the shift rod with engine oil at least once a tighten securely.

- Page 17 WARNING: snow thrower, disconnect spark plug wire and Always stop the engine of the • the discharge chute by removing the hairpin clip Disconnect chute directional control assembly at move it away from the spark plug before and thetwoflatwashers. See Figure20. performing any adjustments or repairs.

- Page 18 the rear auger belt will come off the pulley. Maintain control of the frame assembly while pulling it. Remove the two belts from the two engine pulleys. For location of the pulleys, see Figure 22. Auger Be_ PUSH Frame ERe;rn_ Assembly Pulley _ Figure 24...

- Page 19 Friction Friction Wheel Disc Cover Figure 25 Figure 26 Insert the pin from the shift arm assembly into the Friction Wheel Rubber friction wheel assembly and hold assembly in • Check the rubber on the friction wheel after 25 position. See Figure 27. hours of operation, and periodically thereafter.

- Page 20 • Make certain the entire bottom surface of skid • Align the hex shaft with the right hand bearing and carefully guide the left hand bearing into the left shoe is against the ground to avoid uneven wear on the skid shoes. side of the housing.

- Page 21 Shift Rod hole in the shift lever. See Figure 29. Insert ferrule from the left side of the snowthrower To adjust the shift rod, proceed as follows. into the upper hole in shift lever. • Remove the hairpin clip and flat washer from the Reinstall the hairpin clip and the washer.

- Page 22 Corrective Action Trouble Possible Cause(s) Enginefails to start Fueltank empty,or stale fuel. Fill tank with clean, fresh gasoline. Fuel will not last over thirty days unless a fuel stabilizer is used. Blocked fuel line. Clean fuel line. Choke not in ON position Move switch to ON position Faulty spark plug.

- Page 23 Safety & Decorative Labels 777120729 777120728 777120727 777D00334 777120329 777120330 777S30511 777S30514 777D05306 777D05314 (MODEL PLATE CENTERED WITH TOP OF FRAME COVER) Engine Labels: FAST SLOW STOP CHOKE IGNITION KEY INSERT REMOVE TO RUN TO STOP PRIMER...

- Page 24 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 23 31 NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed, to the part number to order a replacement part. For instance, if a part, numbered 700- xxxx, is painted polo green, the part number to order would be 700-xxxx-0689.

- Page 25 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 Part No. Key. Part No. Description Key. Description 05931A 736-0167 Flat Washer Bearing Housing 684-0039C 736-0188 Flat Washer Auger Housing Assy. 24" 684-0065 736-0242 Belleville Washer Impeller Assy. 12" dia. 705-5226 Chute Reinforcement...

- Page 26 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed, to the part number to order a replacement part. For instance, if a part, numbered 700- xxxx, is painted polo green, the part number to order would be 700-xxxx-0689.

- Page 27 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 Key No. Part No. Key No. Part No. Description Description 618-0043 736-0142 Flat Washer Dogg Assembly: RH 618-O044 736-0160 Flat Washer Dogg Assembly: LH 736-0169 Lock Washer 618-0575 Drive Shaft Assembly 656-0012A 736-0351...

-

Page 28: Parts Diagram

Craftsman 6.5 H.P. Snow Thrower Model 247.888160 NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed, to the part number to order a replacement part. For instance, if a part, numbered 700- xxxx, is painted polo green, the part number to order would be 700-xxxx-0689. - Page 29 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 Key. Part No. Description 712-0324 Hex Lock Nut: 1/4-20 736-0173 Flat Washer 732-0705 Cable Guide Craftsman Engine model 143.026503 Key. Part No. Description 734-1714- Wheel Assembly: 13.0 x 5.0 Steerable 0662 738-0993 Axle: 0.75" dia. x 12.201" Lg.

- Page 30 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 NOTE: For painted parts, please refer to the list of color codes below. Please add the applicable color code, wherever needed, to the part number to order a replacement part. For instance, if a part, numbered 700- xxxx, is painted polo green, the part number to order would be 700-xxxx-0689.

- Page 31 Craftsman 6.5 H.P. Snow Thrower Model 247.888160 Part No. Part No. Description Description 629-0058 736-0509 Special Washer Harness for Headlight 684-0008A 737-0133 Grease Shift Arm Assembly 705-5204A Chute Directional Control 746-0896 Chute Deflector Control Cable 684-0066 Hardware Pack* 746-0901 Chute Deflector Cable w/Clip...

- Page 32 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 /155 //157 A/!35 186B /'_/...

- Page 33 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 /287 Part No. Description Description Part No. 37120B Cylinder (Incl. 2 & 20) 36070 Piston & Pin Ass'y (Std.) (Incl. 43) 26727 Dowel Pin 36071 Piston & Pin Ass'y (.010" OS) (Incl.

- Page 34 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 Part No. Part No. Description Description 30590A Washer 36702 Compression Release Spring 30591 36901 Governor Gear Ass'y (Incl. 81) Blower Housing 36057 651008 Governor Spool Screw, 1/4-20 x 31/64" 650488...

- Page 35 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 Part No. Description 590733 Rewind Starter 590599A Spring Pin 590600 Washer 590696 Retainer 590601 Washer 590697 Brake Spring 590698 Starter Dog 590699 Dog Spring 590709 Pulley & Rewind Assembly 590734A...

- Page 36 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 Part No. Description 590749 Rewind Starter 590599A Spring Pin 590600 Washer 590679 Retainer 590601 Washer 590678 Brake Spring 590680 Starter Dog 590412 Dog Spring 590682 Pulley & Rewind Spring Assembly...

- Page 37 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 Part No. Description 33290E Electric Starter (110 Volt) 31749 Retainer Ring 33522 Spring Retainer 33769 Anti-drift Spring 37332 Nut & Gear (Incl. 2) 35461 Drive End Cap Ass'y. (Incl. 7) 35450 "O"...

- Page 38 Craftsman Engine Model 143.026503 for Craftsman Snow Thrower Model 247.888160 Part No. Description 640058A Carburetor (Incl. 184 of Engine Parts List) 631615 Throttle Shaft & Lever Assembly 631767 Throttle Return Spring 631184 Dust Seal Washer 631183 Dust Seal (Throttle) 631036...

- Page 39 Por un afio desde la fecha de compra cuando este expulsor de nieve Craftsman sea mantenido, lubricado y puesto a punto de acuerdo con las instrucciones de operaciSn y mantenimiento en el manual del proprietario, Sears reparara libre de costo cualquier defecto de material o de mano de obra.

- Page 40 Este simbolo senala instrucciones importantes de seguridad las cuales, si no se observan, podrian poner en peligro la seguridad personal y/o la propiedad suya y de otras personas. Lea y observe todas las instrucciones de este manual antes de intentar operar su expulsor de nieve motorizada, no cumplir con estas instrucciones puede resultar en lesiones...

- Page 41 velocidades de transporte sobre superficies Despues de golpear un objeto, apague el motor, resbalosas. Mire hacia atrAs y sea precavido al extraiga el cable de la bujfa, e inspeccione retroceder. completamente el expulsor de nieve por averfas. Nunca dirija la descarga hacia los observadores Antes de volver a arrancar y operar el expulsor de permita que nadie se pare delante de la unidad.

- Page 42 Despliegue laferreteria deacuerdo conlailustraci6n para fines deidentificati6n. Laspiezas e stAn i lustradas a lamitad desu tamaSo aproximadamente. Los nt_meros depieza s emuestran entre parentesis. r-Tqq Arandela Perno Hexagonal (2), Perno del Carro(4) 5/16-18 x 1.50" uerca exagona ( ) Aleta del Perno Hexagonal (2) Arandela (2) Tuerca...

- Page 43 Sugerencias de ensamblado: Para facilitar el IMPORTANTE: Esta unidad ha sido despachada ensamblado, extraiga la canaleta de la caja y col6quela aceite del motor pero sin gasolina en el motor. Despues sobre el motor. No desenvuelva la canaleta hasta del ensamblado, vea la secci6n de OPERACION de este despues de instalar el panel del mango, los cables del...

- Page 44 Coloque e lpanel delmango enposici6n entre los mangos d emanera q uelosextremos delaparte Canaleta curvada d elosmangos atraviesen lasranuras e nel panel delmango. Alinee losorificios e nelmango conlosorificios e nlosdoslados delpanel d el "l'uel_a mango. VealaFigura 3 . hexagonal de la brida Mango Panel del Derecho...

- Page 45 Ajuste toda la ferreteria floja en el conjunto del mango en el siguiente orden-primero los pernos hexagonales al fondo del mango, a continuaci6n los pernos del carro y finalmente los pernos hexagonales en el reverso del panel del mango. Perno Fijacion De Los Cables Del Embrague Carro _...

- Page 46 Fijacion De La Vara De Cambios Fijacion De Los Gatillos De Giro • Coloque la palanca de cambios en la posici6n de • Alimente el cable del gatillo a traves del lado exterior de la ranura en el panel del mango. No alimente el sexta (6) velocidad.

- Page 47 Asegure el cable del gatillo de giro a la derecha al • Si es necesario ajustar, afloje la tuerca de seguridad mango derecho inferior, usando el amarre de cable hexagonal y enrosque el cable hacia adentro (para provisto en el conjunto de ferreteria. Vea la Figura 13. menos exceso) o hacia afuera (para ma.s exceso).

- Page 48 Presi6n De Las Ruedas (Ruedas Neumdticas) ADVERTENCIA: Para fines de transporte las ruedas estAn infladas en exceso. neumAtico bajo cualquier circunstancia es 30 psi. La presi6n maxima Debe mantenerse en todo momento una presi6n • Inspeccionar la presi6n de la rueda, mantener la presi6n igual.

- Page 49 ANTES D EHACER F UNCIONAR SUEXPULSOR DENIEVE L EA ESTE MANUAL DEL PROPIETARIO Compare lasilustraciones eneste Figura 1 6consuexpulsor denieve para familiarizarse conlaubicaci6n devarios c ontroles yajustes. Guarde este manual para referencia futura. Laoperaci6n deunexpulsor denieve puede r esultar enobjetos despedidos contra losojos, I oquepuede resultar enlesiones graves d elosojos.

- Page 50 Propulsor De Traccion/Seguro Del Embrague De ADVERTENCIA: Nunca Ilene el tanque bajo techo, con el motor funcionando o mientras el La Espiral Sin Fin motor estA caliente. No fume al Ilenar el tanque El embrague del propulsor de tracci6n estA ubicado en el de combustible.

- Page 51 • Enelcaso de Arrancador a retroceso: Con el motor arranque el_ctrico solamente siga los tres pr6ximos pasos. funcionando, tire de la soga del arrancador con una pasada rApida y continua con todo el brazo, tres o • Gire la perilla del regulador a la posici6n OFF. •...

- Page 52 • Oprima ambos gatillos para transportar la unidad cuando el motor no esta.funcionando. silenciador y de las Areas circundantes puede Advertencia: temperatura exceder 150°F. Evite esas Areas. NOTA: Esos controles deben usarse mientras opera su limpiadora nieve areas abiertas, hasta familiarizarse con su operaciSn.

- Page 53 Recomendaciones Generales IMPORTANTE: Mantenga toda la grasa y aceite fuera de la rueda de fricci6n y de la placa propulsora. • Observe siempre las reglas de seguridad al efectuar Mecanismo De Cambios el mantenimiento. • La garantfa en este expulsor de nieve no cubre •...

- Page 54 Cambio De Aceite Cambie el aceite del motor despues de las primeras dos horas de operaci6n y cada 25 horas posteriormente. Pernos de corte • Apague el motor y espere varios minutos antes de inspeccionar el nivel de aceite. Extraiga el tap6n de Ilenado de aceite y a varilla medidora.

- Page 55 Vara De Cambios Para ajustar la vara de cambios, proceda como sigue. Advertencia: ajuste o reparaci6n, siempre apague el motor, Antes de efectuar cualquier • Extraiga el broche del cabello y la arandela plana del desconecte el cable de la bujia y al_jelo de la casquillo debajo del panel de cambios.

- Page 56 Service Helices Las helices est_n aseguradas al eje de la espiral mediante dos pernos de corte y contratuercas hexagonales. Si usted golpea un objeto extraSo o se atasca con hielo, el expulsor de nieve estA diseSado de manera que los pernos hexagonales se cortarAn.

- Page 57 Arandela segurida tuerca hexa¢ \Freno de la polea Figura 25 • Coloque nuevas correas en las dos poleas de las espirales sin fin asegura.ndose que la correa de la espiral sin fin delantera este debajo del freno de la Figura 23 polea.

- Page 58 lospernos p risioneros. Estas piezas d eferreterfa Cambio De La Goma De La Rueda fueron extraidas antes. Ajuste bienlastuercas. De Friccion • Vuelva a instalar lacubierta d elacorrea en laparte delantera delmotor c onlosdostornillos Inspeccione la goma de la rueda de fricci6n despues autoroscantes y lasarandelas planas.

- Page 59 Inserte laclavija delconjunto delbrazo de • Deslice el eje hexagonal a traves del lado izquierdo cambios d entro delconjunto delarueda de de la armadura y a traves del conjunto de la rueda fricci6n y mantenga e lconjunto enposici6n. Vea de fricci6n. la Figura 29.

- Page 60 Preparacibn Del Motor NOTA: El estabilizador de combustible (tal como STA- BIL) es una altemativa aceptable para minimizar Si la unidad va a almacenarse por mas de 30 dias, formaciSn depSsitos goma combustible prepare para almacenamiento como sigue: durante el almacenamiento. Siga siempre la relaciSn de mezcla indicada en el recipiente...

- Page 61 Problema Causa(s) posible Accion correctora El motor fun- Unidad funcionando en CHOKE (REGU- Mueva la palanca del regulador a la posici6n OFE ciona errAtico LADOR) Limpie la tuberia de combustible, Ilene el tanque con gasolina Tuberia de gasolina bloqueada o combusti- limpia y fresca.

- Page 64 In U.S.A. or Canada for in-home major brand repair service: Call 24 hours a day, 7 days a week 1-800-4-MY-HOME sM (1-800-469-4663) Para pedir servicio de reparaci6n a domicillio -- 1-800-676-5811 Au Canada pour tout le service ou les pi_ces -- 1-800-469-4663 For the repair or replacement parts you need: Call 6 a.m.

Need help?

Do you have a question about the 247.888160 and is the answer not in the manual?

Questions and answers