Summary of Contents for Bentone LME21.130C2

- Page 1 178 066 25-4 P 93783 2022-11-23 Providing sustainable energy solutions worldwide Installation- and maintenance instruction STG 120/2 LME21.130C2 MB-DLE 407 Translation of the original instructions.

- Page 2 1~230V 1,0A 50Hz IP 20 Motor supply MADE IN SWEDEN BY 1. Manualer på övriga språk 1. Manuals in other languages 1. Manualer på andre sprog 2. www.bentone.com\ 2. www.bentone.com\ 2. www.bentone.com\ nedladdning eller scanna download or scan QR-code. download eller scan QR-koden.

-

Page 3: Table Of Contents

Control of flame monitoring and ionization current ... 35 Gas supply ..................15 Electric connection ..............15 Handing over of the installation ........37 Mounting ................16 Troubleshooting ..............38 Gas nozzle..................17 Service- and inspection protocol ........40 Tightness control ................ 18 De-aerating ................... 18 5.4 Calculation of gas flow .............. 19 Bentone... -

Page 4: General Information

Make sure that the burner is suitable for the application (see Technical • Data). All components must be installed without being bent, twisted or • subjected to mechanical or thermal forces that affect components. 172 515 01-2 2021-10-05 Bentone... -

Page 5: What To Do If You Smell Gas

Prevent open fl ames or sparking, e.g. do not turn lights on or off, do • not use any electrical appliances or mobile phones. • Evacuate the building. Notify the installer or gas supplier of the problem so that it can be • rectifi ed. Bentone... -

Page 6: Technical Data

LPG, Butane and Propane. • Dimensions STG 120/2 Ø B Flame tube Flame tube Length of fl ame tube Measure A Measure B Ø 89 Ø 89 * Dimensions may vary depending on the components used. 172 525 12-4 2023-04-12 Bentone... -

Page 7: Output Range

HR, HU, IE, IS, IT, LT, LU, LV, MK, MT, NL, NO, PL, PT, RO, 20 mbar RS, SE, SI, SK, TR AT, CH, CY, DK, FI, LT, RO, SE, SK 20 mbar 2H3B/P GB, IE 20 mbar 2H3P NL, RO 20 mbar 2L3B/P 20 mbar 2E3B/P 20 mbar 2E(R)B 20 mbar Bentone... -

Page 8: Working Field

Installation must be done so it does not prevent air supply to the burner. Working field G20,G25 15-50 kW G30,G31 18-70 kW mbar Do not exceed working field -0,2 Bentone... -

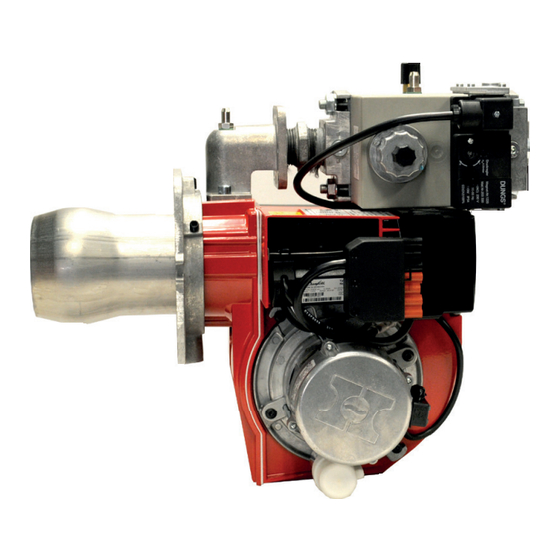

Page 9: Components

Air damper Transformer Motor Fixing fl ange Fan housing, front Electrical connection Gas valve (MultiBloc) Connection, gas valve Fan housing, rear Air pressure switch Gas pressure switch, min Ionisation electrode Gas nozzle Shielding wall, fan housing Brake plate Fan wheel Bentone... -

Page 10: Skeleton Diagram Cpi

Gas pressure switch, maxi Main valve Safety valve Valve proving system Air pressure switch Electrical connection Solenoid V3 Pos. 5b, 7: Components not required according to EN 676. Required over 1200 kW according to EN 676. 172 525 13 2020-10-08 Bentone... -

Page 11: Electric Equipment

The cables of the safety system must be separated so that the outgoing signal is not placed in the same cable as the incoming signal. Wiring diagram Brown Blue Green Yellow Gn/Ye Green/Yellow Black Grey White Orange Violet 172 615 76-4 2022-11-16 Bentone... -

Page 12: Function Lme

If the gas burner control is blocked Red light in the gas burner control is lit. The burner is restarted by pushing the reset button. 3.2.2 Technical data LME21.130C2 LME21.550C2 Preiginition time Prepurge time 50 s Postignition time 2.5 s 4.5 s... -

Page 13: Control Program When Disruption

(waiting time 10 s) Paus c:a 3 s Limiting of starting repetitions LME11 ... has a function with start repetition if the flame is not created at start ord disappears during operation.. LME11 ... allows max. three repetitions during coninuous starting cycle Bentone... - Page 14 To change to interface mode, press and hold the reset button longer than 3 s. To go back to the normal position, press and hold the reset button longer than 3 s. If the gas burner control is in the alarm position, it is reset by pressing the reset button 0.5...3 s. Bentone...

-

Page 15: Installation

Connection must be done in accordance with the applicable • regulations. • Connection must conform to the wiring diagram. If any electrical connection other than that recommended by Enertech is used, there is a risk of property damage and personal injury. 172 535 09-2 Bentone... -

Page 16: Mounting

Mount the fixing flange and the supplied gasket on the boiler. If new mounting holes must be drilled, use the fixing flange as a template and fasten with M8-M10 screws. Before obtaining access to electrical and fuel line components all supply circuits must be disconnected. 172 515 20-2 2022-09-07 Bentone... -

Page 17: Gas Nozzle

Gas nozzle Check that the ignition and ionization electrodes are correctly set before mounting on the boiler. Natural gas, LPG Natural gas Bentone... -

Page 18: Tightness Control

If leaks are found during measurement, locate the source using soapy water or leak detection spray. After sealing: check the tightness of the gas fixture again. Check the gas tightness. Bentone... -

Page 19: Calculation Of Gas Flow

Natural gas 34.02 Butan 32.25 116.09 Natural gas 29.25 Propan 24.44 88.00 Lower calorific value H at normal conditions 15 °C and 1013 mbar, EN 676. For exact calorific value of the gas, contact the gas distributor. 172 535 28 Bentone... -

Page 20: Settings

Turn the screw in the desired direction with an allen key. Turn screw to the left to reduce opening. • Turn screw to the right to increase opening. • Nozzle assembly Air setting adjustment 172 515 22-2 Bentone... -

Page 21: Startup

Max % CO Gas quality % CO Lambda 1.2 ≈10 Natural gas 3 - 5 11.9 ≈11.5 Propane 3 - 5 13.9 ≈11.5 Butane 3 - 5 14.1 Liquefied ≈11 3 - 5 13.8 petroleum gas Biogas 3 - 5 Bentone... -

Page 22: Setting The Air Pressure Switch

Measure and note the lowest air pressure in the entire work area. Set the air pressure switch to about 10-15% lower than the lowest noted pressure. Test run the burner and check the function in the entire work area. Refi t protective cover. Bentone... -

Page 23: Setting The Gas Pressure Switch, Min

When the gas pressure switch stops the burner, the measured value must approximately correspond to the setting on the gas pressure switch. Open ball valve. Remove manometer and close measuring socket. Refi t protective cover. Check gas tightness. Bentone... -

Page 24: Gas Valve

Electrical connection for pressure switch possible on both sides (DIN EN 175 301-803 connector) (option) Outlet flange Test point connection G 1/8 upstream of V1, possible on both sides Test point connection M4 downstream of valve 2 Gas flow direction 172 525 14 2020-10-16 Bentone... -

Page 25: Mounting Closed Position Indicator (Cpi)

Rotate setting screw C to ” + ” until switching point is reached. Then rotate the setting screw by another scale division. Check function by activating the valve. Re-set switching point Turn setting screw C back in arrow direction ”–” to the stop; proceed as described in 7. Bentone... -

Page 26: Adjustment Of Governor

The flow adjustment can also be made by means of the governor. Adjust the outlet pressure to a value giving the desired gas flow on the fully open valve. At small capacities (gas flows) it is also necessary to adjust as above. Flow adjustment e:under cap Adjustment of V2 damper Bentone... -

Page 27: Skeleton Diagrams

Skeleton diagrams 7.6.1 MultiBloc MB-DLE..B07 p Br Filter cover 1,3,4,6 G 1/8 screw plug Test nipple (option) M4 screwed sealing plug p Br 5 3 4 7.6.2 Electritrical connection MB-DLE..B07 MB-D(LE) B07 S22 / S52 Bentone... - Page 28 19 at the hydraulic brake under the cover. 7.6.7 Closing function When the supply voltage to the main valve solenoid coils is interrupted, valves V1, V3 and V2 are closed within < 1 s by the compression springs. Bentone...

-

Page 29: Service

Replacement upon fault detection Gas pressure switch 10 years 250,000 starts Safety blow-off system 10 years Damper motor 500,000 starts Contactor 10 years 500,000 starts The burner and its components must be recycled according to applicable regulations. 172 615 88-2 2022-09-08 Bentone... -

Page 30: Combustion Device

Turn on the main power and open the fuel supply. Start burner and check/adjust combustion. Check for leaks in the gas line. When servicing/replacing components that aff ect combustion, fl ue gas analysis and soot test shall be carried out on the installation. 172 615 90-2 Bentone... -

Page 31: Fan Motor And Fan Wheel

Turn on the main power and open the fuel supply. Start burner and check/adjust combustion. When servicing/replacing components that aff ect combustion, fl ue gas analysis and soot test shall be carried out on the installation. 172 615 96-2 Bentone... -

Page 32: Air Intake And Suction Cone

Turn on the main power and open the fuel supply. Start burner and check/adjust combustion. Check for leaks in the gas line. When servicing/replacing components that aff ect combustion, fl ue gas analysis and soot test shall be carried out on the installation. 172 615 97 Bentone... -

Page 33: Replacement Of Electrical Components

Switch on the main power and check the operation of the new component. Start burner and check/adjust combustion. When servicing/replacing components that affect combustion, flue gas analysis and soot test must be carried out following installation. 165 105 11-3 Bentone... -

Page 34: Vibrations

• Check tightness of fasteners. Check fan wheel for damage and contamination (replace if necessary). • Check motor shaft and bearings. If they are worn, replace the motor. • Use screw to attach the vibration sensor. 172 615 98 Bentone... -

Page 35: Control Of Flame Monitoring And Ionization Current

Required current to ensure detection Min. DC 3 µA Possible detection current Max. DC 20 µA Operational indicator lamp flashes green <5 µA DC >5 µA DC Operational indicator lamp shines green 8.8.1 Flame monitoring ionisation 172 615 02-3 Bentone... - Page 36 Max. current for flame detection Max. DC 5.5 µA Required current to ensure detection Min. DC 40 µA Possible detection current Max. DC 60 µA Operational indicator lamp flashes green <45 µA DC >45 µA DC Operational indicator lamp shines green Bentone...

-

Page 37: Handing Over Of The Installation

Instruct the persons in charge of the operation on the service and • maintenance of the installation and what to do should any troubles occur. Inspection and service must be carried out by authorized personnel. • Review and service should be performed by authorised personnel only. 172 615 04-2 Bentone... -

Page 38: 10. Troubleshooting

Voltage lower than 185V. Contact an electrician. Ignition electrodes disrupting ionisation current. Adjust ignition electrodes. Re-polarise the transformer. Poor earth connection. Ensure adequate earth connection. Phase and neutral swapped around. Check wiring diagram and change accordingly. 172 615 06 2018-01-10 Bentone... - Page 39 Flame at incorrect angle due to combustion head out of Check the combustion head and readjust. position. Condensation build up in boiler and chimney: Raise the flue gas temperature by increasing gas volume Insulate Flue gas temperature too low or gas volume too low. the chimney. Bentone...

-

Page 40: 11. Service- And Inspection Protocol

11. Service- and inspection protocol Installation Boiler Efficiency kW: Name: Type: Address: Burner Efficiency kW: Type: Installed by: Date: Date gas/h Efficiency Governor Fluegas Ionisation Pressure temp current Fire Chimney room Measure- °C µ A ment Before After mbar mbar Small Flame Large Flame... - Page 44 Enertech AB. P.O Box 309, SE-341 26 Ljungby www.bentone.com...

Need help?

Do you have a question about the LME21.130C2 and is the answer not in the manual?

Questions and answers