Table of Contents

Advertisement

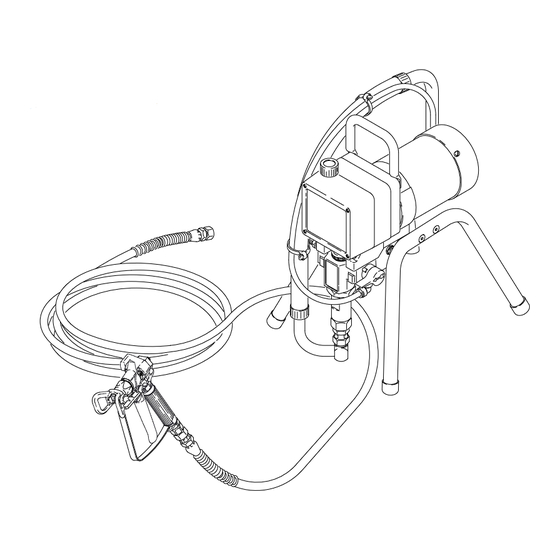

Nova spx

ELECTRIC, AIRLESS PAINT SPRAYER

2750 psi (195 bar) Maximum Working Pressure

Model 820–226, Series A

Complete sprayer with hoses, gun, RAC IV DripLess

Tip Guard and SwitchTip

The SHERWIN-WILLIAMS COMPANY, CLEVELAND, OHIO 44115

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

OWNER'S MANUAL

820–228

Rev D

Supercedes Rev C

Advertisement

Table of Contents

Summary of Contents for Graco Nova spx

- Page 1 Supercedes Rev C This manual contains important warnings and information. READ AND RETAIN FOR REFERENCE Nova spx ELECTRIC, AIRLESS PAINT SPRAYER 2750 psi (195 bar) Maximum Working Pressure Model 820–226, Series A Complete sprayer with hoses, gun, RAC IV DripLess...

-

Page 2: Table Of Contents

Table of Contents Warnings ........Power Supply Cord . -

Page 3: Warnings

WARNING WARNING INJECTION HAZARD Spray from the gun, leaks or ruptured components can inject fluid into your body and cause ex- tremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury. Fluid injected into the skin is a serious injury. - Page 4 This equipment is for professional use only. Read all instruction manuals, tags, and labels before operating the equipment. Use the equipment only for its intended purpose. If you are not sure, call Graco Technical Assis- tance at 1–800–543–0339. Do not alter or modify this equipment.

-

Page 5: Major Components

Major Components Fig. 1 Motor DC motor, 120 Vac, 15A, 1 phase Drive Assembly Transfers power from DC motor to the displacement pump Pressure Adjusting Knob Controls fluid outlet pressure ON/OFF Switch Power switch that controls 120 Vac power to sprayer Fluid Outlet Hose and spray gun is connected here Displacement Pump... -

Page 6: Setup

Setup 2. Fill the wet–cup (102). Pry off the wet-cup seal. WARNING Fill the cup 1/3 full with Throat Seal Liquid (TSL), supplied. Install the wet-cup seal. If you supply your own hoses and spray gun, be sure the hoses are electrically conductive, that the 3. -

Page 7: Operation

Operation How to Use the Gun Trigger Safety Open or drain, position Closed, or spray position WARNING INJECTION HAZARD If the gun still sprays when the gun trig- ger safety is locked, repair the gun. See manual 308–645, supplied. 1. To engage the gun trigger safety, turn the latch counterclockwise toward the handle until the detent of the latch locks on and the pin is at a right angle with the gun body. - Page 8 Operation How to use the RAC IV tip guard. WARNING INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve pressure, follow the Pressure Relief Procedure on page 9. The tip guard alerts you to the risk and helps prevent placing any part of the body close to the spray tip.

-

Page 9: Startup

Startup NOTE: If this is a first-time startup, flush the sprayer. WARNING See page 13. INJECTION HAZARD NOTE: Refer to Fig. 9 and the other figures referenced The system pressure must be manually in the text as you start the sprayer. relieved to prevent the system from starting or spraying accidentally. - Page 10 Startup b. If more coverage is needed, use a larger tip WARNING rather than increasing the pressure. FIRE AND EXPLOSION HAZARD To reduce the risk of static sparking and c. Adjust the direction of the spray pattern. See splashing when priming or flushing the Fig.

- Page 11 Startup 1/4 npsm(m) fluid outlet Do not install any shutoff device here Rotate clockwise to increase pressure Shown in closed or spray position Fill 1/3 full with TSL Fig. 9...

-

Page 12: Shutdown And Care

Shutdown and Care WARNING WARNING INJECTION HAZARD INJECTION HAZARD See the warning section INJECTION To reduce the risk of serious injury, HAZARD on page 3 for information on whenever you are instructed to relieve the hazard of using damaged hoses. pressure, follow the Pressure Relief Procedure on page 9. -

Page 13: Flushing

Flushing When to Flush 3. Pour one-half gallon (2 liters) of compatible solvent into a grounded metal flushing pail. Put the suction 1. Before using a new sprayer: flush out the oil hose in the pail. which was left in to protect pump parts. 4. -

Page 14: Troubleshooting

Troubleshooting WARNING INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve pressure, follow the Pressure Relief Procedure on page 9. Basic Problem Solving Check everything in the troubleshooting table before disassembling the sprayer. TYPE OF PROBLEM WHAT TO CHECK WHAT TO DO If check is OK, go to next check... - Page 15 Basic Problem Solving TYPE OF PROBLEM WHAT TO CHECK WHAT TO DO If check is OK, go to next check When check is not OK, refer to this column Electrical 5. Check motor armature commutator for burn 5. Remove motor and have motor shop (continued) spots, gouges and extreme roughness.

- Page 16 Intermediate Problem Solving TYPE OF PROBLEM WHAT TO CHECK WHAT TO DO If check is OK, go to next check When check is not OK, refer to this column Low output 3. Release gun trigger. Observe resting position of 3. If pump consistently comes to rest with (continued) pump rod (107).

- Page 17 Intermediate Problem Solving TYPE OF PROBLEM WHAT TO CHECK WHAT TO DO When check is not OK, refer to this column If check is OK, go to next check 1. Spray tip worn beyond sprayer pressure capa- 1. Replace spray tip. Spray Pattern Variations bility.

-

Page 18: Motor Test

Motor Test WARNING INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve pressure, follow the Pressure Relief Procedure on page 9. For checking armature, motor winding and brush elec- trical continuity. Setup Remove the drive housing. See page 28. This is to ensure that any resistance you notice in the armature test is due to the motor and not to worn gears in the drive housing. -

Page 19: General Repair Information

General Repair Information WARNING WARNING INJECTION HAZARD HOT SURFACE HAZARD During operation, the motor and drive To reduce the risk of serious injury, housing become very hot and could burn whenever you are instructed to relieve your skin if touched. Flammable materi- pressure, follow the Pressure Relief als spilled on the hot, bare motor could cause a fire Procedure on page 9. -

Page 20: Motor Brush

Motor Brushes NOTE: Replace brushes when worn to about 0.5 in. Motor lead; do not disconnect (12.5 mm). Always check both brushes. Brush Repair Minimum 0.5” (12.5 mm) Kit 821–022, which includes spring clip 821–061, is available for motors manufactured by Pacific Scientific. Included in Brush Repair Kit 821–022 NOTE: Replacement brushes may last only half as... - Page 21 Motor Brushes 9. Test the brushes. WARNING a. Remove the pump connecting rod pin (17). MOVING PARTS HAZARD See Fig. 19, page 22. Do not touch the brushes, leads, springs or brush holders while the sprayer is b. With the sprayer OFF, turn the pressure con- plugged in to reduce the risk of electric trol knob fully counterclockwise to minimum shock and serious injury.

-

Page 22: Displacement Pump Repair

Displacement Pump Repair 2. Align the hole in the rod (107) with the connecting WARNING rod assembly (15). Use a screwdriver to push the retaining spring (18) up and push in the pin (17). INJECTION HAZARD Push the retaining spring (18) into place around To reduce the risk of serious injury, the connecting rod. - Page 23 Displacement Pump Repair Intake valve repair 1. Check the outside of the piston rod (107) and the (See Fig. 17) inside of the cylinder (115) for wear. Replace worn 1. Remove the suction hose. See Step 2, Removing parts to ensure a good seal with the new packings. the pump.

- Page 24 Displacement Pump Repair 3. Tighten the nut (110) onto the piston valve (108) to Torque to 2 in-lb (0.23 N.m). See Fig. 20. 5 in–lb (0.57 N.m) Apply one strip of NOTE: Note the alignment of the piston (108) to the sealant to these *109 nut (110).

- Page 25 Displacement Pump Repair 11. Place a new o-ring (116*) firmly in the cylinder 15. Torque the cylinder jam nut (117) to 73 ft-lb groove. See Fig. 22. (98 N.m). See Fig. 22. 12. Coat the piston rod and packings with oil. Carefully 16.

-

Page 26: Motor

Motor 8. Remove the two screws (46) and lift the motor off WARNING the base (66). INJECTION HAZARD 9. Align the new motor with the base and reinstall the screws (46). To reduce the risk of serious injury, whenever you are instructed to relieve 10. -

Page 27: Motor Start Board

Motor Start Board 5. Install the new cord (50) in the reverse order of disassembly. 6. Install the junction box. Be sure no leads are WARNING pinched against the motor or by the motor start board. Also be sure the gasket (89) is installed. INJECTION HAZARD To reduce the risk of serious injury, On/Off Switch... -

Page 28: Drive Housing, Connecting Rod, Crankshaft

Drive Housing, Connecting Rod, Crankshaft WARNING CAUTION INJECTION HAZARD Do not allow the gear (16) to fall; it may stay attached to the drive housing or to the motor. To reduce the risk of serious injury, whenever you are instructed to relieve Do not lose the thrust balls (11a or 4a) or let them pressure, follow the Pressure Relief fall between the gears, which will damage the drive... - Page 29 Drive Housing, Connecting Rod, Crankshaft REF A Torque to 80 in–lb (9 N.m) Quantity of three Quantity of one Apply a total of 3 fl. oz.(29 cc) of grease to gears. Fig. 29...

-

Page 30: Pressure Control

Pressure Control 7. Loosely install the screws (63) and then torque WARNING them to 21 in–lb (2.4 N.m). INJECTION HAZARD 8. Install the front cover (13). Connect the harness To reduce the risk of serious injury, (A) to the motor start board (47). whenever you are instructed to relieve pressure, follow the Pressure Relief 9. -

Page 31: Pressure Transducer

Pressure Transducer WARNING INJECTION HAZARD To reduce the risk of serious injury, whenever you are instructed to relieve pressure, follow the Pressure Relief Procedure on page 9. NOTE: See Fig. 31 for this procedure. 1. Remove the displacement pump. See page 22. 2. -

Page 32: Drain Valve

Drain Valve Repair WARNING 1. Unscrew the spring retainer from the valve body. Remove the spring, washers and stem/ball. Clean INJECTION HAZARD any debris from the ball or seat area. To reduce the risk of serious injury, whenever you are instructed to relieve 2. -

Page 33: Displacement Pump Parts Drawing And List

Displacement Pump Parts Drawing and List Model 820–877, Series A Includes items 101 to 127 Part No. Description 820–970 MANIFOLD, pump 820–287 PACKING NUT 103* 820–286 GLAND, female, throat *103 104* 820–285 V–PACKING, plastic, throat 105* 820–284 V–PACKING, leather, throat 106* 820–283 GLAND,... -

Page 34: Sprayer Parts Drawing

Sprayer Parts Drawing Model 820–226, Series A HOSE AND GUN NOT SHOWN IN PROPORTION TO SPRAYER Label See detail on page 31 REF 33 REF 32 OUT- SIDE LABEL INSIDE LABEL... -

Page 35: Sprayer Parts List

Sprayer Parts List Model 820–226, Series A Includes items 3 to 89 as listed below Ref. Ref. Part No. Description Qty. Part No. Description Qty. 820–880 MOTOR KIT 820–911 PIN, grooved, 3/32 x 1” 820–912 HANDLE, Includes items 4a to 4g drain valve 820–457 .BALL, sst,... -

Page 36: Technical Data

......0.33 gpm (1.25 lpm) Order the labels directly from Graco, free of Tip Size . - Page 37 ....PTFE UHMW polyethylene, leather TO PLACE AN ORDER , call SHERWIN-WILLIAMS COMPANY 1–800–367–4023 Toll Free CLEVELAND, OHIO 44115 FOR TECHNICAL ASSIST ANCE , call COPYRIGHT 1995, GRACO INC. 1–800–543–0339 Toll Free PRINTED IN U.S.A. 82Z–228 August 1995...

- Page 38 82Z–228 Rev A Supplement to instruction manual 820–228 Nova spx WARNING INJECTION HAZARD This form is only a quick reference to the features and frequently ordered parts of INSTRUCTIONS this sprayer. To reduce the risk of seri- ous injury, including fluid injection, while operating or repairing this sprayer, follow the warnings and instructions in manual 820–228.

Need help?

Do you have a question about the Nova spx and is the answer not in the manual?

Questions and answers