Table of Contents

Advertisement

Quick Links

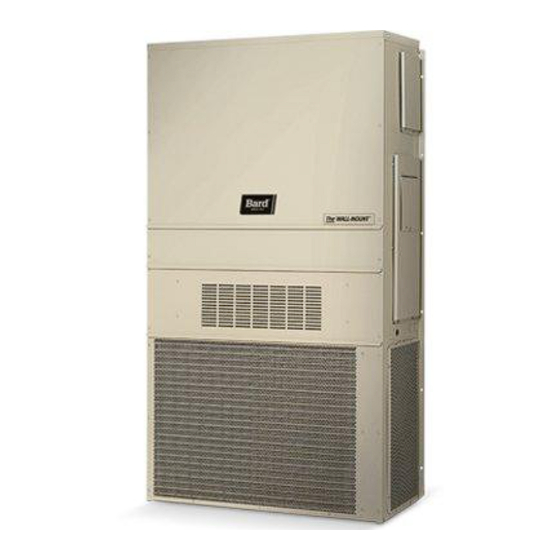

INSTALLATION INSTRUCTIONS

Wall Mounted Package

W18HB-A

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Heat Pump

Models:

W24HB-A

W24HB-B

W24HB-C

W30HB-A

W30HB-B

W30HB-C

W36HB-A

W36HB-B

W36HB-C

W24HBDA

W24HBDB

W24HBDC

W30HBDA

W30HBDB

W30HBDC

W36HBDA

W36HBDB

W36HBDC

Manual:

2100-703H

Supersedes: 2100-703G

Date:

3-1-21

Page

1 of 42

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Bard W30HB Series

- Page 1 Heat Pump Models: W18HB-A W24HB-A W24HBDA W24HB-B W24HBDB W24HB-C W24HBDC W30HB-A W30HBDA W30HB-B W30HBDB W30HB-C W30HBDC W36HB-A W36HBDA W36HB-B W36HBDB W36HB-C W36HBDC Bard Manufacturing Company, Inc. Manual: 2100-703H Bryan, Ohio 43506 Supersedes: 2100-703G Date: 3-1-21 www.bardhvac.com Page 1 of 42...

-

Page 2: Table Of Contents

CONTENTS Getting Other Information and Publications ..3 Pressure Service Ports ........23 Wall Mount General Information ......4 Service Hints ............. 23 Heat Pump Wall Mount Model Nomenclature ..4 Service ..............25 Shipping Damage ..........4 Solid State Heat Pump Control Troubleshooting General ............... -

Page 3: Getting Other Information And Publications

FIGURES GRAPHS Figure 1 Fresh Air Damper ........5 Graph 1 W18HB FAD-NE2, 3 W/O Exhaust Figure 2 Unit Dimensions ........9 Ventilation Delivery ......41 Figure 3A Mounting Instructions – W18H, W24H .. 10 Graph 2 W24HB FAD-NE2, 3 W/O Exhaust Figure 3B Mounting Instructions –... -

Page 4: Wall Mount General Information

WALL MOUNT GENERAL INFORMATION Heat Pump Wall Mount Model Nomenclature – CONTROL MODULES REVISIONS MODEL NUMBER (See Spec. Sheet S3592) CAPACITY 18 - 1½ Ton VOLTS & PHASE COIL OPTIONS H - Heat Pump 24 - 2 Ton A - 230/208/60/1 X - Standard COLOR &... -

Page 5: Filters

Any grille that meets with 5/8" louver criteria may be in place and is recommended for maximum energy efficiency. used. It is recommended that Bard Return Air Grille Kit RG-2W through RG-3W or RFG-2W through RFG- The blank-off plate is available upon request from the 3W be installed when no return duct is used. -

Page 6: Installation

INSTALLATION Basic Installation Design and contact with the base of the unit. If allowed, this could cause damage to the coil and other Application Planning base components. Also, be sure there are no Successful unit installations require proper planning air obstructions to the sides or front of the and site inspection before installation begins. -

Page 7: Ducted Applications

5/8". It is recommended that a Maximum External Static Pressure (ESP) of Operation Bard Return Air Grille Kit be installed that is designed Table 17 on page 38. Design the duct work according specifically for the wall mount product. Contact the to methods given by the Air Conditioning Contractors local Bard distributor or visit www.bardhvac.com for... -

Page 8: Unit Installation

Unit Installation flashing is supplied for field use and is mounted to the back of the unit for shipping. Remove rain Make sure to have the proper tools at the work site that flashing before locating the unit against wall. Top are needed for unit installation. -

Page 9: Table 1 Clearance Required For Service Access And Adequate Condenser Airflow

2. Field ventilation installation with the unit installed requires 40" on the left or right side of the unit. 3. Bard recommends a minimum of 10' between the unit front condenser air outlet and solid objects including fences, walls, bushes and other airflow obstructions. -

Page 10: Figure 3A Mounting Instructions - W18H, W24H

Manual 2100-703H Page 10 of 42... -

Page 11: Figure 3B Mounting Instructions - W30H, W36H

Manual 2100-703H Page 11 of 42... -

Page 12: Figure 4 Electric Heat Clearance

FIGURE 4 Electric Heat Clearance W30H and W36H SIDE SECTION VIEW OF SUPPLY AIR DUCT FOR WALL-MOUNTED UNIT SHOWING 1/4" CLEARANCE TO COMBUSTIBLE SURFACES. WARNING Fire hazard. Maintain minimum 1/4" clearance between the supply air duct and combustible materials in the first 3' of ducting. -

Page 13: Figure 5 Wall Mounting Instructions

FIGURE 5 Wall Mounting Instructions WALL STRUCTURE SEE FIGURES 3A-B – MOUNTING INSTRUCTIONS FACTORY SUPPLIED RAIN FLASHING. MOUNT ON UNIT BEFORE INSTALLATION SUPPLY AIR SUPPLY AIR SUPPLY AIR DUCT OPENING OPENING RETURN AIR RETURN AIR RETURN AIR OPENING OPENING OPENING BOTTOM MOUNTING WOOD OR STEEL SIDING BRACKET. -

Page 14: Figure 7 Common Wall Mounting Installations

FIGURE 7 Common Wall Mounting Installations SUPPLY DUCT MAY BE LOCATED IN AN ATTIC OR BELOW CEILING RAFTERS AS SHOWN RAIN RAIN FLASHING RAFTERS FLASHING RAFTERS FINISHED CEILING SURFACE SUPPLY AIR DUCT SUPPLY AIR DUCT FINISHED CEILING SURFACE W/ GRILLE RETURN AIR RETURN AIR OPENING W/ GRILLE... -

Page 15: Wiring - Main Power

Wiring – Main Power the factory wired on 240V tap. For 208V operation, reconnect from 240V to 208V tap. The acceptable operating voltage range for the 240 and 208V taps are: WARNING RANGE 253 – 216 220 – 187 Electrical shock hazard. NOTE: The voltage should be measured at the field power connection point in the unit and while Do not operate this equipment without an... -

Page 16: Dehumidification Feature

Balanced Climate™ Feature (Standard on All Models) changes. On/Off LAC operation cycles the condenser fan on/off to maintain desired liquid pressure while All units are equipped with the capability of running modulating LAC operation is factory adjusted and slows in Balanced Climate mode. This mode is designed to the condenser fan speed (rpm). -

Page 17: Table 4 Wall Thermostats

TABLE 4 Wall Thermostats Part Number Predominate Features 8403-060 3 stage Cool; 3 stage Heat; Electronic Programmable/Non-Programmable; HP or Conventional; Auto or Manual (1120-445) changeover; Dehumidification Output 3 stage Cool, 3 stage Heat; Programmable/Non-Programmable; HP or Conventional; Auto or Manual Changeover; CS9B-THOA Humidity Sensor w/ dehumidification;... -

Page 18: Figure 8 Thermostat Connections

FIGURE 8 Thermostat Connections Completestat Model #CS9B-THOA or Model #CS9BE-THOA W1/E Thermostat W1/E YO/D Bard #8403-060 Optional CO2 Controller Bard Part #8403-096 24VAC CO2 OUT TEMP-OUT Unit Low B/W1 Voltage Term. Strip 12-Pin Vent Plug ALL VENT OPTIONS PLUG IN HERE If not equipped with a ventilation option to plug in, a jumper plug must be installed. -

Page 19: Figure 9 Thermostat Connections

Thermostat Connections Units With Dehumidification 8403-038 Mechanical Humidistat T4 Pro 8403-095 T6 Pro 8403-090 or 8403-092 8403-047 Electronic Humidistat Optional CO2 Controller Bard Part #8403-096 24VAC CO2 OUT TEMP-OUT Unit Low B/W1 Voltage Term. Strip 12-Pin Vent Plug ALL VENT OPTIONS PLUG IN HERE If not equipped with a ventilation option to plug in, a jumper plug must be installed. -

Page 20: Start Up

Topping Off System Charge 10. Never trap liquid R-410A in manifold sets, gauge lines or cylinders. R-410A expands significantly If a leak has occurred in the system, Bard at warmer temperatures. Once a cylinder or line is Manufacturing recommends reclaiming, evacuating... -

Page 21: High And Low Pressure Switch

If the Bard air conditioning system is being set up If a fault condition occurs, reverse two of the supply in a typical environment where 72°F is the lowest leads to the unit. -

Page 22: Defrost Cycle

1/4" QC, to short between the SPEEDUP If the unit is being installed with any ventilation terminals to accelerate the HPC timer and initiate package, a Bard LAC kit must be installed. Failure to defrost. utilize an LAC with any air conditioner can cause coil Be careful not to touch any other terminals with the freeze up. -

Page 23: High Pressure Switch Operation

There is also a 5-minute compressor time delay To change a Coremax valve without first removing the function built into the HPC. This is to protect the refrigerant, a special tool is required which can be obtained at www.fastestinc.com/en/SCCA07H. See the compressor from short cycling conditions. -

Page 24: Figure 10 Defrost Control Board

FIGURE 10 Defrost Control Board TIME (SEC) LOW PRESSURE BYPASS TIMER SWITCH 120* *(FACTORY SETTING 120 SECONDS) ACCUMULATED DEFROST TIME TIMER (FACTORY SETTING 60 MIN.) MIS-2668 A Model Setting W18HB W24HB W30HB W36HB Manual 2100-703H Page 24 of 42... -

Page 25: Service

SERVICE Solid State Heat Pump Control NOTE: If there was no power to 24 volt transformer, Troubleshooting Procedure the compressor and outdoor fan motor will not start for 5 minutes. This is because of the 1. NOTE: A thorough understanding of the defrost compressor short cycle protection. -

Page 26: Checking Temperature Sensor Outside Unit Circuit

Checking Temperature Sensor Outside 3. Check resistance reading to chart of resistance. Use sensor ambient temperature. (Tolerance of part Unit Circuit is ± 10%.) 1. Disconnect temperature sensor from board and 4. If sensor resistance reads very low, sensor is from outdoor coil. -

Page 27: Troubleshooting Nidec Selectech Series Ecm Motors

“Continuous Fan” only problem identified. on the “G” terminal. NOTE: Bard Models PA13242; PA13302; PA13362-A, -B; PA13422-A, -B, -C; PA13482-A, -B, -C; PA13602-A, -B, -C 2. If the system is excessively noisy, does not appear contain the X13-Series Motors. -

Page 28: Model Selectech Communication Diagnostics

TROUBLESHOOTING GE X13-SERIES ECM2.3 ™ MOTORS CONT’D. Model SelecTech Communication Diagnostics B. If the motor has proper high voltage as identified above (If the Motor Is Not Running 2. Initiate a demand from the thermostat and check the The SelecTech motor is communicated through 24 VAC Model X13 Communication Diagnostics #1 on page 27), proper low voltage to a voltage between the common and the appropriate motor... -

Page 29: Fan Blade Setting Dimensions

Fan Blade Setting Dimensions Removal of Fan Shroud The correct fan blade setting for proper air delivery 1. Disconnect all power to the unit. across the outdoor coil is shown in Figure 13. Refer to 2. Remove the screws holding both grilles, one on Table 10 for unit specific dimension. -

Page 30: Table 11A Cooling Pressure

TABLE 11A Cooling Pressure Air Temperature Entering Outdoor Coil °F Return Air Temp Model Pressure (DB/WB) Low Side 75/62 High Side Low Side W18HB 80/67 High Side Low Side 85/72 High Side Low Side 75/62 High Side Low Side W24HB 80/67 High Side Low Side... -

Page 31: Table 12 Cooling Pressure - Balanced Climate Airflow

TABLE 12 Cooling Pressure – Balanced Climate Airflow Air Temperature Entering Outdoor Coil °F Return Air Temp Model Pressure (DB/WB) Low Side 75/62 High Side Low Side W18HB 80/67 High Side Low Side 85/72 High Side Low Side 75/62 High Side Low Side W24HB 80/67... -

Page 32: Table 13 Electrical Specifications

TABLE 13 Electrical Specifications Single Circuit Dual Circuit Maximum Rated Minimum Field External Fuse Field Power Ground Maximum Field Model Volts Circuit Minimum Power or Ckt. Wire Size Wire Size External Power Ground &... -

Page 33: Setting Unit Airflow

24VAC signals from the low voltage terminal block located inside the control panel by a thermostat or other controlling device. Each speed tap is programmed by Bard at the factory to different motor torque settings (see Figure 14). Manual 2100-703H... -

Page 34: Speed Tap 1 - Vent/Blower Only

TABLE 15 Blower Speeds for Unit Operational Modes Thermostat Inputs – 24VAC Speed Taps Unit Compressor Blower Speed Operation Operation B/W1 W2 W3 3-4-5 Blower Only Vent/Blower Only Balanced Climate Cooling Balanced Climate Full Load Cool Lo/Med/Hi Balanced Climate Balanced Climate Heat Pump Heating Full Load Heat Pump Lo/Med/Hi... -

Page 35: Dirty Filter Switch

Dirty Filter Switch 3. With air filters installed and switch initially set at 0.4" W.C. (see Step 2 under Dirty Filter 1. Disconnect all power to the unit. Remove control Switch), begin restricting the air filter of the unit panel outer cover and upper front panel. using a piece of cardboard under the filters until 2. -

Page 36: Figure 17 Adjusting Dirty Filter Switch

FIGURE 17 Adjusting Dirty Filter Switch TURN CLOCKWISE TO INCREASE RESTRICTION AMOUNT REQUIRED TO ACTIVATE THE SWITCH AND COUNTER-CLOCKWISE TO DECREASE RESTRICTION AMOUNT MIS-4086 B Manual 2100-703H Page 36 of 42... -

Page 37: Table 16 Indoor Blower Performance

TABLE 16 Indoor Blower Performance Default LO Optional MED Balanced Climate Optional HI Cooling Cooling & Heating/ Cooling & Heating E.S.P. Speed & Heating Speed Ventilation Speed Speed (In. H Dry Coil Wet Coil Dry Coil Wet Coil Dry Coil Wet Coil Dry Coil Wet Coil... -

Page 38: Electric Heat Only

TABLE 17 Maximum ESP of Operation Electric Heat Only Front Outlet Model Model High A00/0Z Speed Speed W18H W24H A00/0Z W30H B00/0Z W36H W24H C00/0Z B00/0Z W24H W30H W36H C00/0Z W30H W36H TABLE 18 Electric Heat Models 240V-1 208V-1 240V-3 208V-3 460V-3 Amps... -

Page 39: Table 19 Optional Accessories

TABLE 19 Optional Accessories Part Number EHW18H-A04 EHW18H-A08 EHW2HB-A04 EHW2HB-A08 EHW2HB-B05 EHW2HB-C05 EHW3HB-A05 EHW3HB-A10 Heater Kits EHW3HB-A15 EHW3HB-B05 EHW3HB-B09 EHW3HB-C05 EHW3HB-C09 EHW30HB-A05 EHW30HB-A10 EHW30HB-B05 WMCB-02A WMCB-02B WMCB-03A Circuit Breaker (WMCB) & WMCB-03B Pull Disconnect (WMPD) WMCB-05A WMCB-06A WMPD-01C Manual 2100-703H Page 39 of 42... -

Page 40: Table 20 Vent And Control Options

TABLE 20 Vent and Control Options Part Number Description CMC-15 Start Relay (PTCR based) CMC-31 Dirty Filter Sensor Kit CMC-34 Alarm Relay Crankcase Heater – 230V CMC-36 CMC-37 Crankcase Heater – 460V CMH-28 Outdoor Thermostat – Heat Pump (ODT) CMH-33 Low Ambient Control Modulating –... - Page 41 GRAPH 1 W18HB FAD-NE2, 3 W/O Exhaust Ventilation Delivery GRAPH 2 W24HB FAD-NE2, 3 W/O Exhaust Ventilation Delivery Manual 2100-703H Page 41 of 42...

- Page 42 GRAPH 3 W30HB FAD-NE2, 3 W/O Exhaust Ventilation Delivery GRAPH 4 W36HB FAD-NE2, 3 W/O Exhaust Ventilation Delivery Manual 2100-703H Page 42 of 42...

Need help?

Do you have a question about the W30HB Series and is the answer not in the manual?

Questions and answers