Table of Contents

Advertisement

Quick Links

Models

ADPB40PPT

Read this manual carefully before installing, operating or servicing this equipment. It's the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

This document is issued with Product Serial No

Operation and Maintenance Guide

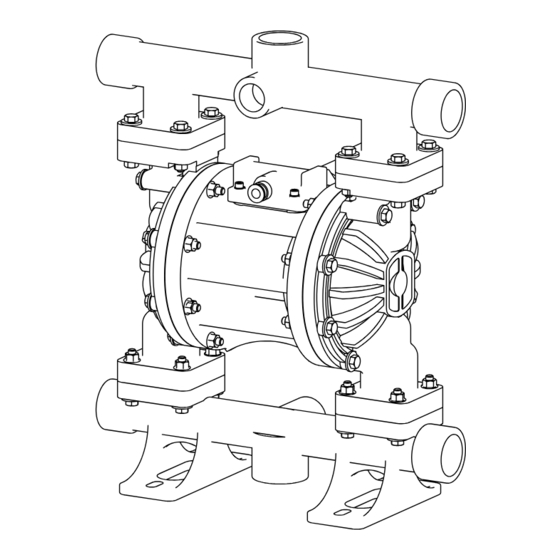

ADPB40PPT

Descriptions

Polypropylene with PTFE fitments

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Teryair ADPB40PPT

- Page 1 Operation and Maintenance Guide ADPB40PPT Models Descriptions ADPB40PPT Polypropylene with PTFE fitments Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi- bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

-

Page 2: Table Of Contents

Table of Contents Pump Nomenclature Operating and Safety Instructions Suggested Lubricants Suggested site selection and installation recommendations Troubleshooting Maintenance Bill of Materials for ADPB40PPT Pumps Exploded View for ADPB40PPT Pump Dimensional Data Eu Declaration Of Conformity Warranty Certificate FF-MM-379-REV - 01... -

Page 3: Pump Nomenclature

Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 3 Pump Nomenclature Air Valve Type Pump Size Material of Construction Material of Bolted or Threading on Inlet Diaphragm Clamped and Outlet 06 - 1/4” 12 - 1/2” 15 - 1/2” DP - Classic AL - Aluminium R- NPT... - Page 4 Operating Instructions The Teryair diaphragm pump generates a alternate stroking of the diaphragms against the fluid in the liquid chambers of the Pump. This reciprocatory action is responsible for the fluid being pumped.

-

Page 5: Suggested Lubricants

Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 5 Caution: Temperature limitations and diaphragm options Excellent choice when pumping highly aggressive fluids such as aromatic or chlorinated hydrocarbons, PTFE acids, caustics, ketones and acetates. Temperature range +4°C to +104°C (+40°F to +220°F) Suggested Lubricants Brand Above 27 Deg C (... - Page 6 Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 6 Location selection Suction Pump location must be easily accessible with reasonable Ensure that the suction head after installation is well space around for maintenance operations. within the pumps suction capabilities Pump dimensional data for each variant is available in section showing exploded views Muffler...

-

Page 7: Troubleshooting

Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 7 Troubleshooting Serial No Description Causes Remedial Action Pump stops and Insufficient Air Pressure Check air pressure is as recommended will not start at the pump air inlet Air Filter Blocked Check if debris has clogged the inlet fil- ter on the FRL unit/pump inlet air valve ( some models have air filter on the air... -

Page 8: Maintenance

Follow the instructions clearly in “Disassembly and Reassembly” of the pump and in the troubleshooting section. Use genuine Teryair spares and if possible mention the serial number of the pump when ordering spares. Always replace elastomers as a set, eg diaphragms, balls and seats. -

Page 9: Exploded View For Adpb40Ppt Pump

Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 9 Exploded View for ADPB40PPT Pump FF-MM-379-REV - 01... -

Page 10: Dimensional Data

Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 10 Dimensional Data ADPB40PPT FF-MM-379-REV - 01... -

Page 11: Eu Declaration Of Conformity

CE certification registration no – C E 16831 Issued by – BMQR Certifications Pvt Ltd. www.cemarking-india.com Valid Till – 03/11/2025 Signed for and on behalf of TERYAIR EQUIPMENT PVT. LTD. Place of Issue : Vasai Date : FF-MM-379-REV - 01... -

Page 12: Warranty Certificate

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, compliance with any design, specification or other specific requirement of Dealer/End User;... - Page 13 Operation and Maintenance Guide ADPB 40 Plastic Pump Series Page 13 This page is intentionally Left blank. FF-MM-379-REV - 01...

Need help?

Do you have a question about the ADPB40PPT and is the answer not in the manual?

Questions and answers