Endress+Hauser Cerabar M PMC51 Operating Instructions Manual

Process pressure measurement

Hide thumbs

Also See for Cerabar M PMC51:

- Technical information (134 pages) ,

- Operating instructions manual (134 pages) ,

- Brief operating instructions (32 pages)

Summary of Contents for Endress+Hauser Cerabar M PMC51

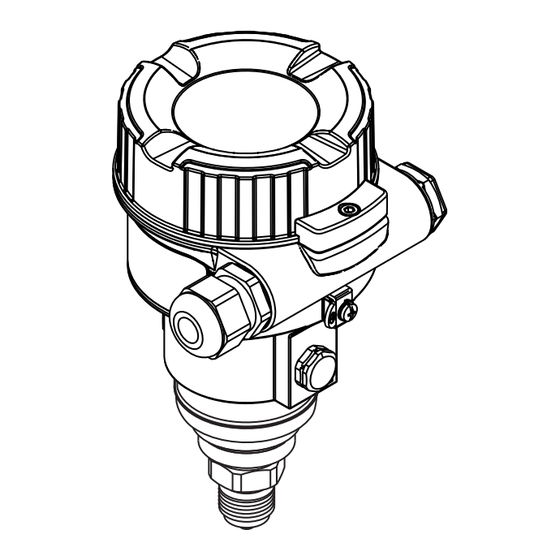

- Page 1 Operating Instructions Cerabar M PMC51, PMP51, PMP55 Process pressure measurement BA385P/00/EN/10.09 71102503 Valid from software version: 01.00.zz...

- Page 2 – The documentation is supplied with the device. Instructions – Wiring – The documentation can also be found on the – Local operation documentation CD supplied. – Commissioning – The documentation is also available on the Internet. See: www.endress.com Download Endress+Hauser...

-

Page 3: Table Of Contents

Disposal ....... . 31 Software history ......31 Endress+Hauser... -

Page 4: Safety Instructions

Operating Instructions. Pay particular attention to the technical data and information on the nameplate. Operational and process safety Alternative monitoring measures have to be taken while configuring, testing or servicing the device to ensure the operational and process safety. Warning! Dismantle device only when depressurized! Endress+Hauser... -

Page 5: Notes On Safety Conventions And Icons

Connecting cable immunity to temperature change Indicates that the connecting cables have to withstand a temperature of 85°C at least. > t 85°C Safety instructions Observe the safety instructions in the associated Operating Instructions. Endress+Hauser... -

Page 6: Identification

10 Unit of length 11 No entry 12 ID number of notified body with regard to Pressure Equipment Directive (optional) 13 Approvals 14 Degree of protection 15 Wetted materials 16 No entry 17 Approval-specific information 18 Software version 19 Device version Endress+Hauser... -

Page 7: Scope Of Delivery

• The Operating Instructions BA385P, the Technical Information TI436P and the Brief Operating Instructions can be found on the documentation CD supplied. ä 2, "Overview of documentation" section. • Brief Operating Instructions: KA1036P • Final inspection report • Optional: factory calibration form, test certificates Endress+Hauser... -

Page 8: Ce Mark, Declaration Of Conformity

The devices comply with the applicable standards and regulations as listed in the EC Declaration of Conformity and thus comply with the statutory requirements of the EC Directives. Endress+Hauser confirms the conformity of the device by affixing to it the CE mark. -

Page 9: Installation

• Local display: –40 to +85°C (–40 to +185°F) • Separate housing: –40 to +60°C (–40 to +140°F) Installation conditions 3.2.1 Dimensions For dimensions, please refer to the Technical Information for Cerabar M TI436P, "Mechanical construction" section. See also ä 2, "Overview of documentation". Endress+Hauser... -

Page 10: Installation Instructions

• For PMP55, please refer to Section 3.3.2 "Installation instructions for devices with diaphragm seals – PMP55", ä 12. • Endress+Hauser offers a mounting bracket for installing on pipes or walls. ä 15, Section 3.3.5 "Wall and pipe mounting (optional)". - Page 11 The siphon reduces the temperature to almost the ambient temperature. Pressure measurement in liquids ➀ ➁ P01-PMx5xxxx-11-xx-xx-xx-005 Fig. 6: Measuring arrangement for pressure measurement in liquids Cerabar M Shutoff device • Mount Cerabar M with shutoff device below or at the same level as the tapping point. Endress+Hauser...

- Page 12 • Vibration-free (in order to avoid additional pressure fluctuations) • Not in the vicinity of heating or cooling lines • Insulate if the ambient temperature is below or above the reference temperature • With a bending radius of 100 mm (3.94 in). Endress+Hauser...

- Page 13 115 P01-PMx5xxxx-11-xx-xx-xx-008 Endress+Hauser recommends the use of temperature isolators in the event of constant extreme medium temperatures which lead to the maximum permissible electronics temperature of +85°C (+185°F) being exceeded. To minimize the influence of rising heat, Endress+Hauser recommends the device be mounted horizontally or with the housing pointing downwards.

- Page 14 £ • P01-PMx5xxxx-11-xx-xx-xx-010 Fig. 11: Maximum permitted insulation height, here indicated on a PMP55 with a flange PMP55 70°C (158°F) Ambient temperature (T Process temperature (T Max. 400°C (752°F), depending on the diaphragm seal filling oil used (see TI436PDE) Endress+Hauser...

- Page 15 Installation 3.3.5 Wall and pipe mounting (optional) Endress+Hauser offers a mounting bracket for installing on pipes or walls. P01-xMx5xxxx-06-xx-xx-xx-001 Please note the following when mounting: • Devices with capillary tubes: mount capillaries with a bending radius 100 mm (3.94 in).

- Page 16 Mount the housing on a wall or pipe using the mounting bracket (item 7). When mounting on a pipe, tighten the nuts on the bracket uniformly with a torque of at least 5 Nm (3.69 lbs ft). Mount the cable with a bending radius (r) 120 mm (4.72 in). Endress+Hauser...

-

Page 17: Closing The Cover

Setscrew See the "Welding recommendation" table below Endress+Hauser recommends welding on the diaphragm seal as follows for the "XSJ - Prepared for diaphragm seal mount" version in feature 110 "Process connections" in the order code up to, and including, 40 bar (600 psi) sensors: the total welding depth of the fillet weld is 1 mm (0.04 in) with an outer diameter of 16 mm (0.63 in). -

Page 18: Wiring

Switch on the supply voltage. 4…20 mA 11.5 V DC P01-PMD55xxx-04-xx-xx-xx-010 Electrical connection 4 to 20 mA Terminals for supply and signal Test terminals Ground terminal Supply voltage: 11.5 to 45 VDC (versions with plug-in connectors: 35 V DC) External ground terminal Endress+Hauser... - Page 19 Left: electrical connection for devices with an M12 connector Right: view of the connector at the device For devices with an M12 connector, Endress+Hauser offers the following accessories: Plug-in jack M 12x1, straight • Material: Body PA; coupling nut CuZn, nickel-plated •...

-

Page 20: Connecting The Measuring Unit

< 0.7 . 4.2.2 Cable specification • Endress+Hauser recommends using twisted, shielded two-wire cables. • Terminals for wire cross-sections 0.5 to 2.5 mm (20 to 14 AWG) • Cable outer diameter: 5 to 9 mm (0.2 to 0.35 in) -

Page 21: Potential Equalization

The overvoltage protection is mounted at the factory on the housing thread for the cable gland and is approx. 70 mm (2.76 in) in length (take additional length into account when installing). The device is connected as specified in the following graphic. For details, see TI103R/09/en, XA036R/09/a3 and KA161R/09/a6. Endress+Hauser... - Page 22 1.5 mm² max. 2.5 mm² max. 3.75 Nm min. 1.5 mm² ➀ Screw coupling glued at the factory: hold in place with a wrench when loosening/tightening the coupling nut ➁ black Shield grounding ➁ without ➂ direct ➂ black P01-xMx5xxxx-04-xx-xx-en-007 Endress+Hauser...

-

Page 23: Post-Connection Check

• Are all screws firmly tightened? • Is the housing cover screwed down tight? As soon as voltage is applied to the device, the green LED on the electronic insert lights up for a few seconds or the connected local display lights up. Endress+Hauser... -

Page 24: Operation

Damping is switched off. Damping is switched on. The output signal follows measured value The output signal follows measured value changes with the delay time Factory changes without any delay. setting: = 2 s or as per order specifications). Endress+Hauser... -

Page 25: Using The Device Display (Optional)

Depending on the orientation of the device, this makes it easy to read the measured values. P01-Mxxxxxxx-19-xx-xx-xx-011 Functions: • 8-digit measured value display including sign and decimal point, bar graph for 4 to 20 mA as current display. • Diagnostic functions (fault and warning message etc.) Endress+Hauser... - Page 26 The device is in the service mode (during a simulation, for example). Error message "Maintenance required" Maintenance is required. The measured value remains valid. Error message "Failure detected" An operating error has occurred. The measured value is no longer valid. Endress+Hauser...

-

Page 27: Commissioning

Observe the input Observe the input Observe the input limits. limits. limits. Endress+Hauser... -

Page 28: Maintenance

• The cleaning agents used should not corrode the surface and the seals. • Mechanical damage to the diaphragm, e.g. due to sharp objects, must be avoided. • Observe the degree of protection of the device. See the nameplate if necessary ( ä 6 ff). Endress+Hauser... -

Page 29: Troubleshooting

In the event of an error, the current output assumes a value of 3.6mA. Repair The Endress+Hauser repair concept provides for measuring devices to have a modular design and that the customer can also carry out repairs (see ä 30, on Section 8.5 "Spare Parts"). -

Page 30: Spare Parts

Select the required spare parts (You may also use the overview drawing on the right side of the screen.) When ordering spare parts, always quote the serial number indicated on the nameplate. As far as necessary, the spare parts also include replacement instructions. Endress+Hauser... -

Page 31: Return

• The duly completed and signed "Declaration of Hazardous Material and Decontamination" (see penultimate page). Only then is it possible for Endress+Hauser to inspect or repair the returned device. • The chemical and physical properties of the medium. • A description of the application. - Page 32 Technical data Cerabar M Analog Technical data For the technical data, please refer to the Technical Information TI436P. ä 2, "Overview of documentation" section. Endress+Hauser...

- Page 33 • US 5,050,034 A1 i EP 0 445 382 B1 • US 5,005,421 A1 i EP 0 351 701 B1 • EP 0 414 871 B1 • EP 1 061 351 B1 • US 5,334,344 A1 i EP 0 490 807 B1 • US 6,703,943 A1 Endress+Hauser...

- Page 34 Supply voltage ....... . . 20 Temperature isolator, installation instructions ..13 Endress+Hauser...

- Page 35 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 36 www.endress.com/worldwide BA385P/00/EN/10.09 71102503 CCS/FM+SGML6.0 71102503...

Need help?

Do you have a question about the Cerabar M PMC51 and is the answer not in the manual?

Questions and answers