Summary of Contents for Winco DR400V4 1 Series

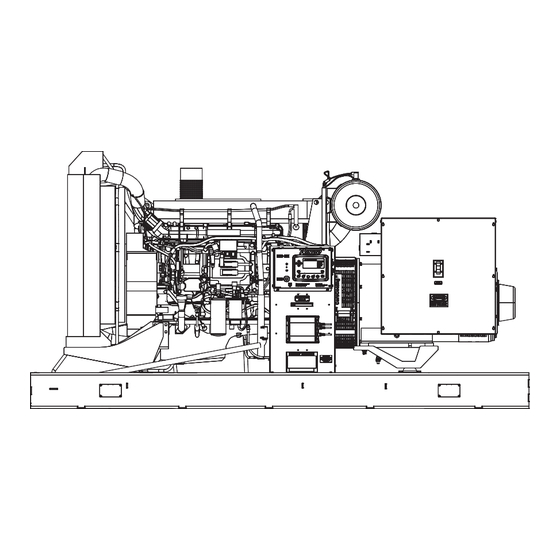

- Page 1 DR400V4-XX / 1 DR400V4-XX / 2 GENERATORS INSTALLATION AND OPERATORS MANUAL 16200-037 www.wincogen.com...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAVE THESE INSTRUCTIONS SAFETY INFORMATION SPECIFICATIONS DR400V4 INTRODUCTION TESTING POLICY PRODUCT DESCRIPTION PREPARING THE UNIT START-UP CHECK LIST UNPACKING LIFTING THE GENERATOR SET INSTALLATION GENERAL INFORMATION ENGINE GENERATOR SET MOUNTING VENTILATION REQUIREMENTS EXHAUST INSTALLATION INSTALLING THE FUEL LINE LUBRICATION INSTALLING THE BATTERY CONNECTING BATTERY CHARGER &... -

Page 3: Save These Instructions

COPY YOUR MODEL AND SERIAL NUMBER HERE No other WINCO generator has the same serial number as yours. If you should ever need to contact us on this unit, it will help us to respond to your needs faster. -

Page 4: Safety Information

SAFETY INFORMATION This engine generator set has been designed and WARNING: FIRE HAZARD manufactured to allow safe, reliable performance. Poor Gasoline and other fuels present a hazard of possible maintenance, improper or careless use can result in explosion and/or fire. potentially deadly hazards;... -

Page 5: Specifications

SPECIFICATIONS DR400V4 Generator Wattage 400,000 400,000 400,000 400,000 Volts 120/208 120/240 277/480 346/600 Phase Three Three Three Three Amps 1,388 1,201 CB Size 2,000 1,200 Hertz Engine Model Volvo TAD1353GE Starting System 24 Volt Muffler Standard Fuel Consumption (full load) 29.1 Gal/Hr Engine Fluid Specifications Fuel... -

Page 6: Introduction

M-Spec (i.e. M-10372) number which can be found off, and 5 minute cool-down delay. The cool-down delay on the WINCO data tag. When the M-Spec is present, can be changed in the field from 0 to 30 minutes by your supplemental inserts will accompany this standard manual installer. -

Page 7: Preparing The Unit

This must be completed and lifting points are only for the use during the manufacturing returned to WINCO Inc. within 180 days of the factory process and are designed for lifting of the individual invoice date. -

Page 8: Installation

INSTALLATION The factory weather enclosures are acoustical housing This unit should be installed in a well ventilated area, intended for outdoor installation only. Factory weather ensuring the exhaust air cannot be recirculated back into enclosed units are not intended to be used indoors and the engine. -

Page 9: Exhaust Installation

We have partnered with a national lubrication oil manufacturer to give you access to Winco private branded installation. Ensure proper alignment with the generator. premium oil available at comparable prices to conventional The flex can be eliminated if it is pushed to one side to make a connection. -

Page 10: Installing The Battery

INSTALLING THE BATTERY WARNING CAUTION The electrolyte is diluted sulfuric acid that is harmful to the In the following battery installation procedure, check to skin and eyes. It is electrically conductive and corrosive. be sure the DSE 7310 MKII is in the “stop” position. This The following precautions must always be taken. - Page 11 will be on constantly. This charger is mounted under the customer connection on the control side of the generator and plugged into the receptacle mounted in the AC connection cabinet. The battery charger receptacle is to be powered by a GFCI circuit and installed in accordance with the United States National Electric Code.

-

Page 12: A.c. Connections

When installing a three-phase 240 Volt system, be sure WINCO uses an adjustable breaker, which allows us to you know which lead is the high voltage “wild” leg (208 use the same breakers in reconnectable units. These Volt line to neutral). -

Page 13: D.c. Connections

D.C. CONNECTIONS B. ESTOP - & ESTOP +. These two terminals are shipped with a jumper installed. CAUTION If your application requires the installation of a Remote Never run the AC and DC wiring on the same conduit. Emergency Stop switch, remove the jumper and wire your switch to these terminals. -

Page 14: Mounting The Automatic Transfer Switch

Engine start and auxiliary circuit terminal block TB located on 3ATS &3NTS transfer switch. MOUNTING THE AUTOMATIC TRANSFER SWITCH WARNING: FIRE HAZARD All wiring must be done by a licensed electrician, and must conform to the National Electrical Code and comply with all the local codes and regulations. -

Page 15: Starting Procedure

STARTING PROCEDURE CONTROL LAYOUT Warning alarms are self-resetting when the fault condition is removed. The icon will appear steady in the display. SHUTDOWN Shutdowns are critical alarm conditions that stop the engine and draw the operator’s attention to an undesirable condition. - Page 16 3. During manual operation, the load will not normally be applied to the generator. But caution must be used, if the line power should fail or be turned off the transfer switch during manual operation the load may be applied to the generator.

-

Page 17: Maintenance

See your dealer for additional information. Outside Long-Life Coolant WINCO has plumbed an oil drain valve to the outside of the Usage Region Temperature Concentration unit. Attach a customer supplied 5/8” hose to conveniently... -

Page 18: Changing Air Filter

CHANGING THE FUEL FILTERS 3. Bleed the system at the bleeding nipple. 4. Start the engine when the coolant system is completely The fuel system has a fine filter (A) and a pre-filter (B) filled and vented. Open any bleeding nipples a short while after starting, to allow trapped air to escape. -

Page 19: Bringing Out Of Storage

2. Drain the engine oil and fill up with conservation 10. Check that no oil, fuel or coolant leakage occurs. oil to just over the MIN marking on the dipstick. 11. Fill the AdBlue/DEF tank. The solution must fulfill ISO 22241 standards. -

Page 20: Troubleshooting Table

TROUBLESHOOTING TABLE Problem Possible Causes Unit will not crank when power fails Digital genset not in AUTO Transfer control switch not in AUTOMATIC position Incorrect wiring between ATS and genset Defective control relay in ATS Fuse(s) blown in the DSE 7310 MKII Defective DSE 7310 MKII Loose or dirty battery terminals Defective starter... -

Page 21: Avr Wiring

VOLTAGE REGULATOR WIRING AVR WIRING MX341 Automatic Voltage Regulator MX341 Automatic Voltage Regulator Under normal conditions only two adjustments are made to the voltage regulator. K1 K2 P2 P3 P4 XX X 3 2 2 1 VOLTS - To adjust generator output voltage. REFER Clockwise to increase voltage. -

Page 22: Wiring Size Table

WIRING SIZE TABLE The table below is based on Table 310.15 (B) (16) un the National Electric Code 2014 edition. Allowable ampacitier of insulated conductrs rated 0 through 2000V, 75°C through 90°C. Not more than three current-carrying conductors in Raceway, Cable, or Earth (direct buried). Adjust for 40°C (104°F) ambient temperature. -

Page 23: Engine Schematic

ENGINE SCHEMATIC OPM-157/B... -

Page 24: Dse 7310 Mkii Wiring Diagram

DSE 7310 MKII WIRING DIAGRAM OPM-157/B... -

Page 25: Ac Wiring

THREE PHASE AC WIRING THREE PHASE AC WIRING HIGH AND LOW WYE HIGH AND LOW WYE AC WIRING THREE PHASE-HIGH WYE THREE PHASE-LOW WYE 277/480 VOLTS 120/208 VOLTS THREE PHASE-HIGH WYE THREE PHASE-LOW WYE 277/480 VOLTS 120/208 VOLTS THREE PHASE - HIGH WYE 277/480V THREE PHASE - LOW WYE 120/208V LE PHASE AC THREE PHASE AC... -

Page 26: Warranty Statement

Air cooled units purchased for stock have 1 year to be sold. The warranty to the original retail customer commences on the date of sale of the product to them. All liquid cooled units have 180 days from the Winco invoice to submit a start up date. If no startup form is submitted, then warranty period starts on the Winco invoice date unit was sold. - Page 27 Note 2: 3rd Year warranty coverage is parts only/no labor. Note 3: Round trip mileage is limited to 200 miles per trip and a total of 2 trips per repair unless authorized in writing by the WINCO Service Dept.

- Page 28 225 S. CORDOVA AVE • LE CENTER, MN 56057 Sales: 507-357-6821• sales@wincogen.com Service: 507-357-6831 • service@wincogen.com www.wincogen.com OPM-157/B...

Need help?

Do you have a question about the DR400V4 1 Series and is the answer not in the manual?

Questions and answers