Table of Contents

Advertisement

Quick Links

Visit our website at

www.MillerWelds.com

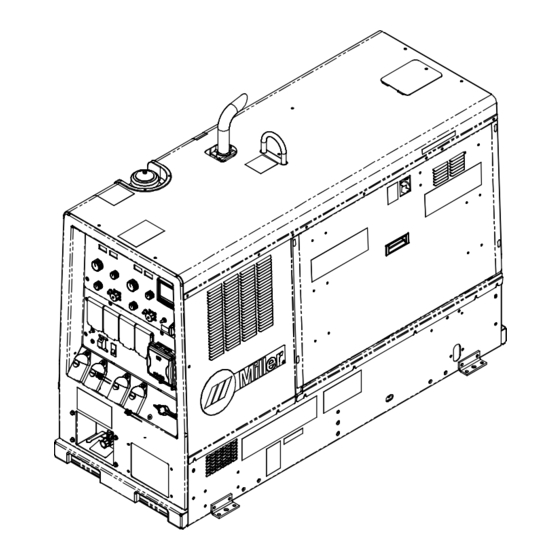

Big Blue 800X / 800CA

Duo Air Pak

OM-267603G

Processes

Processes

Description

Engine Driven Welder/Generator And

Air Compressor

)

2016−01

MIG (GMAW) Welding

Flux Cored (FCAW) Welding

Stick (SMAW) Welding

TIG (GTAW) Welding

Air Carbon Arc (CAC-A)

Cutting and Gouging

)

File: Engine Drive

Advertisement

Table of Contents

Summary of Contents for Miller Big Blue Duo Air Pak 800X

- Page 1 OM-267603G 2016−01 Processes Processes MIG (GMAW) Welding Flux Cored (FCAW) Welding Stick (SMAW) Welding TIG (GTAW) Welding Air Carbon Arc (CAC-A) Cutting and Gouging Description Engine Driven Welder/Generator And Air Compressor Big Blue 800X / 800CA Duo Air Pak File: Engine Drive Visit our website at www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING ....... . . 1-1. - Page 4 TABLE OF CONTENTS 6-4. Process/Contactor Switch ............. 6-5.

-

Page 5: Section 1 − Safety Precautions − Read Before Using

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING rom_2015−09 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. not avoided, will result in death or serious injury. - Page 6 D Be alert that welding sparks and hot materials from welding can FLYING METAL or DIRT can injure easily go through small cracks and openings to adjacent areas. eyes. D Watch for fire, and keep a fire extinguisher nearby. D Welding, chipping, wire brushing, and grinding D Be aware that welding on a ceiling, floor, bulkhead, or partition can cause sparks and flying metal.

-

Page 7: Engine Hazards

1-3. Engine Hazards EXHAUST SPARKS can cause fire. BATTERY EXPLOSION can injure. D Do not let engine exhaust sparks cause fire. D Always wear a face shield, rubber gloves, and D Use approved engine exhaust spark arrestor in protective clothing when working on a battery. required areas —... -

Page 8: Additional Symbols For Installation, Operation, And Maintenance

HOT METAL from air arc cutting and MOVING PARTS can injure. gouging can cause fire or explosion. D Keep away from moving parts such as fans, D Do not cut or gouge near flammables. belts and rotors. D Watch for fire; keep extinguisher nearby. D Keep all doors, panels, covers, and guards closed and securely in place. - Page 9 BATTERY CHARGING OUTPUT and BATTERY STATIC (ESD) can damage PC boards. EXPLOSION can injure. D Put on grounded wrist strap BEFORE handling Battery charging not present on all models. boards or parts. D Use proper static-proof bags and boxes to D Always wear a face shield, rubber gloves, and store, move, or ship PC boards.

-

Page 10: California Proposition 65 Warnings

1-6. California Proposition 65 Warnings For Gasoline Engines: Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to Engine exhaust contains chemicals known to the State of cause birth defects and, in some cases, cancer. (California California to cause cancer, birth defects, or other reproduc- Health &... -

Page 11: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 CONSIGNES DE SÉCURITÉ − LIRE AVANT − UTILISATION fre_rom_2015−09 Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 12 D Utiliser une protection différentielle lors de l’utilisation d’un équi- LES ACCUMULATIONS DE GAZ pement auxiliaire. Ne pas tester ni réarmer les prises femelles risquent de provoquer des blessures avec différentiel au régime de ralenti/en basse tension: cela ou même la mort. endommagerait le disjoncteur différentiel, qui ne remplirait plus son rôle de protection contre une électrocution causée par un D Fermer l’alimentation du gaz comprimé...

-

Page 13: Dangers Existant En Relation Avec Le Moteur

D Porter un équipement de protection pour le corps fait d’un matériau Si des BOUTEILLES sont endomma- résistant et ignifuge (cuir, coton robuste, laine). La protection du gées, elles pourront exploser. corps comporte des vêtements sans huile comme par ex. des gants de cuir, une chemise solide, des pantalons sans revers, des chaussures hautes et une casquette. -

Page 14: Dangers Liés À L'air Comprimé

D Pour empêcher tout démarrage accidentel pendant les travaux D Toujours vérifier le niveau de liquide de refroidissement dans le d’entretien, débrancher le câble négatif (−) de batterie de la borne. vase d’expansion (si présent), et non dans le radiateur (sauf si pré- cisé... -

Page 15: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

D Pour rechercher des fuites, utiliser de l’eau savonneuse ou D Ne pas approcher les mains, cheveux, vêtements lâches et outils un détecteur à ultrasons, jamais les mains nues. En cas des organes mobiles. de détection de fuite, ne pas utiliser l’équipement. D Avant d’intervenir sur le circuit d’air comprimé, couper l’alimentation électrique, verrouiller et étiqueter l’appareil, D Remettre les portes, panneaux, recouvrements ou dispositifs... - Page 16 D Réduire le courant ou le facteur de marche avant de poursuivre le LA SORTIE DE RECHARGE et L’EXP- soudage. LOSION DE LA BATTERIE peuvent D Ne pas obstruer les passages d’air du poste. provoquer des blessures. LES CHARGES ÉLECTROSTATI- La recharge de batterie n’existe pas sur tous les QUES peuvent endommager les modèles.

-

Page 17: Proposition Californienne 65 Avertissements

2-6. Proposition californienne 65 Avertissements Pour les moteurs à essence : Les équipements de soudage et de coupage produisent des fumées et des gaz qui contiennent des produits chimiques Les gaz d’échappement des moteurs contiennent des pro- dont l’État de Californie reconnaît qu’ils provoquent des mal- duits chimiques dont l’État de Californie reconnaît qu’ils formations congénitales et, dans certains cas, des cancers. -

Page 18: Section 3 − Definitions

Complete Parts List available at www.MillerWelds.com SECTION 3 − DEFINITIONS 3-1. Additional Safety Symbols And Definitions Some symbols are found only on CE products. Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Wear dry insulating gloves. Do not touch electrode with bare hand. Do not wear wet or damaged gloves. Safe2 2012−05 Protect yourself from electric shock by insulating yourself from work and ground. - Page 19 Complete Parts List available at www.MillerWelds.com Do not work on unit if engine is running. Stop engine first. Safe21 2012−05 Do not smoke while fueling or if near fuel. Safe22 2012−05 Stop engine before fueling. Safe23 2012−05 Do not fuel a hot engine. Safe24 2012−05 Use lift eye to lift unit and properly installed accessories only, not gas cylinders.

-

Page 20: Miscellaneous Symbols And Definitions

Complete Parts List available at www.MillerWelds.com Engine fuel plus flames or sparks can cause fire. Safe45 2012−05 Remove unit from shipping crate. Remove Owner’s Manual from unit. Follow instructions to install muffler. Safe46 2012−05 Read Owner’s Manual. Read labels on unit. Safe47 2012−05 <12.4 V Read Owner’s Manual for battery maintenance information. - Page 21 Complete Parts List available at www.MillerWelds.com Three Phase Engine Current Suitable For Rated Welding Welding In An Engine Current Environment With Increased Risk Of Electric Shock Rated Load Engine RPM Speed Rated No−Load Engine Stop Speed Slow Rated Idle Speed Increase/ Decrease of Quantity...

-

Page 22: Section 4 − Specifications

Complete Parts List available at www.MillerWelds.com SECTION 4 − SPECIFICATIONS 4-1. Serial Number And Rating Label Locations The serial number and rating information for this product is located on the right side. Use rating label to determine input power requirements and/or rated output. -

Page 23: Dimensions, Weights, And Operating Angles

Complete Parts List available at www.MillerWelds.com 4-5. Dimensions, Weights, And Operating Angles Dimensions 53.75 in. (1365 mm) Height (to top of exhaust) 28-1/2 in. (724 mm) (mtg. brackets turned in) Width 30-3/4 in. (781 mm) (mtg. brackets turned out) Depth 69.5 in. -

Page 24: Volt-Ampere Curves

Complete Parts List available at www.MillerWelds.com 4-7. Volt-Ampere Curves The volt-ampere curves show the A. Stick Mode minimum and maximum voltage and amperage output capabilities of the welder/generator. Curves of all other settings fall between the curves shown. Parallel Mode Dual Operator DC AMPERES B. -

Page 25: Ac Generator Power Curves

Complete Parts List available at www.MillerWelds.com 4-8. AC Generator Power Curves The AC power curve shows the generator power in amperes. A. Single Phase 4 kW 2 8 0 2 6 0 2 4 0 2 2 0 2 0 0 1 8 0 AC AMPERES B. -

Page 26: Fuel Consumption

Complete Parts List available at www.MillerWelds.com 4-9. Fuel Consumption The curve shows typical fuel use under weld or power loads. 4.00 3.75 3.50 No Air Output 3.25 3.00 With Air Output 2.75 2.50 2.25 2.00 Dual Weld Mode 1.75 1.50 1.25 1.00 0.75... -

Page 27: Section 5 − Installation

Complete Parts List available at www.MillerWelds.com SECTION 5 − INSTALLATION 5-1. Installing Welder/Generator Airflow Clearance 18 in. Movement (460 mm) 18 in. (460 mm) 18 in. (460 mm) 18 in. 18 in. (460 mm) (460 mm) Location/Mounting Bolting Welding Unit In Unit In Place Place... -

Page 28: Installing Exhaust Pipe

Complete Parts List available at www.MillerWelds.com 5-2. Grounding Generator To Truck Or Trailer Frame GND/PE rot_grnd2 2014−11 − 800 652-D Always ground generator frame to frame. Always connect a ground Equipment Grounding Terminal (On vehicle frame to prevent electric wire from the generator equipment Front Panel) shock and static electricity hazards. -

Page 29: Connecting The Battery

Complete Parts List available at www.MillerWelds.com 5-4. Connecting The Battery − Tools Needed: 1/2 in. Conn_batt1 2014−11 802 168-E / S-0756-C NOTICE − Lead acid batteries discharge Battery is most easily accessed through Never start the engine when the when stored in any temperature. Units that the rear panel. -

Page 30: Engine Prestart Checks

Full Diesel Full 907535−1 / 907 634−2 NOTICE − Diesel engines in MILLER equip- Check all engine fluids daily. ment are meant to operate optimally at mod- After fueling, check oil with unit on level sur- erate to rated load. Using light or no load for Automatic warning and shutdown indi- face. -

Page 31: Connecting To Weld Output Terminals

Complete Parts List available at www.MillerWelds.com 5-7. Connecting To Weld Output Terminals Stop engine. Failure to properly connect weld cables may cause excessive heat and start a fire, or damage your ma- chine. Tools Needed: Do not place anything between weld 3/4 in. -

Page 32: Making Dual Operator Cc Weld Connections W/ Separate Work Cables

Complete Parts List available at www.MillerWelds.com 5-8. Making Dual Operator CC Weld Connections w/ Separate Work Cables Tools Needed: 3/4 in. Direct Current Electrode Positive (DCEP) connections are shown. Welder A (Left) Side Welder B (Right) Side 258 836 Stop engine. Electrode Holder Cables For Stick/TIG Direct Current Electrode Negative (DCEN), connect work cables to... -

Page 33: Making Dual Operator Mode Cc Weld Connections W/ Common Work Cable

Complete Parts List available at www.MillerWelds.com 5-9. Making Dual Operator Mode CC Weld Connections w/ Common Work Cable Tools Needed: 3/4 in. Direct Current Electrode Positive (DCEP) connections are shown. Welder A (Left) Side Welder B (Right) Side 258 836 Stop engine. -

Page 34: Making Dual Operator Cv Weld Connections W/ Separate Work Cables

Complete Parts List available at www.MillerWelds.com 5-10. Making Dual Operator CV Weld Connections w/ Separate Work Cables Tools Needed: 3/4 in. Direct Current Electrode Positive (DCEP) connections are shown. Welder A (Left) Side Welder B (Right) Side 258 836 Stop engine. Wire Feeder Cables For MIG and FCAW Direct Current Elec- trode Negative (DCEN), connect work... -

Page 35: Making Dual Operator Cv Weld Connections W/ Common Work Cable

Complete Parts List available at www.MillerWelds.com 5-11. Making Dual Operator CV Weld Connections w/ Common Work Cable Tools Needed: 3/4 in. Direct Current Electrode Positive (DCEP) connections are shown. Welder A (Left) Side Welder B (Right) Side 258 836 Stop engine. weld output of both modules (see Section mon work cable and work jumper cable to 5-15 for proper cable size). -

Page 36: Making Dual Operator Cc And Cv Weld Connections W/ Separate Work Cables

Complete Parts List available at www.MillerWelds.com 5-12. Making Dual Operator CC And CV Weld Connections w/ Separate Work Cables Tools Needed: 3/4 in. Direct Current Electrode Positive (DCEP) connections are shown. Welder A (Left) Side Welder B (Right) Side 258 836 Stop engine. -

Page 37: Making Dual Operator Cc And Cv Weld Connections W/ Common Work Cable

Complete Parts List available at www.MillerWelds.com 5-13. Making Dual Operator CC And CV Weld Connections w/ Common Work Cable Tools Needed: 3/4 in. Direct Current Electrode Positive (DCEP) connections are shown. Welder A (Left) Side Welder B (Right) Side Ref. 251 340-A / Ref. 802 292-A Stop engine. -

Page 38: Making Single Operator Cc Weld Connections

Complete Parts List available at www.MillerWelds.com 5-14. Making Single Operator CC Weld Connections Direct Current Electrode Positive (DCEP) connections are shown. Welder B (right) Terminals Inactive In Single Operator Mode Welder A (Left) Side Tools Needed: 3/4 in. 258 836 Stop engine. -

Page 39: Weld Output Terminals And Selecting Cable Sizes

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. ( ) = mm for metric use ***For distances longer than those shown in this guide, call a factory applications rep. at 920-735-4505 (Miller) or 1-800-332-3281 (Hobart). Ref. S-0007-L 2015−02 5-16. Weld Output Terminals Turn off power before connecting to weld output terminals. -

Page 40: Connecting To Remote 14 Receptacle

Complete Parts List available at www.MillerWelds.com 5-17. Connecting To Remote 14 Receptacle Socket* Socket Information Not all models have contactor control. See description of front panel controls and circuit diagram. 24 volts AC. Protected by supplementary protector. 24 VOLTS AC Contact closure to A completes 24 volt AC contactor control circuit. -

Page 41: Connecting To The Air Compressor

Complete Parts List available at www.MillerWelds.com 5-18. Connecting To The Air Compressor Stop engine and release air pres- sure before servicing compressor. Open Position Closed Position 907 535−1 Air pressure is present at air shutoff Be sure valve is in open position when us- The air compressor will not start if still under valve whenever Engine Display on ing air compressor. -

Page 42: Section 6 − Operating Welder/Generator

Complete Parts List available at www.MillerWelds.com SECTION 6 − OPERATING WELDER/GENERATOR 6-1. Front Panel Controls (See Section 6-2) 258 833 -E/ 907 535−1 OM-267603 Page 38... -

Page 43: Description Of Front Panel Controls (See Section 6-1)

CC and CV output from See Section 6-5 for Arc Control information. Welder A (left) and Welder B (right) weld out- NOTICE − Diesel engines in MILLER equip- put terminals. Control the weld output from the ment are meant to operate optimally at mod-... -

Page 44: Engine Starting Sequence

Complete Parts List available at www.MillerWelds.com 6-3. Engine Starting Sequence Wait to Start/Preheating Service Reminder Remaining Remaining Service Reminder Engine Oil Engine Oil Compressor Oil Compressor Oil NOTICE − Do not use ether or other start- The Wait to Start display appears when the Once this message clears, the engine can ing fluids. - Page 45 Complete Parts List available at www.MillerWelds.com Switch Setting Typical Process Applications (DC Only) MIG solid wire uses a voltage sensing (VS) feeder that does not require a control cable Electrode Hot – MIG VS back to the welder/generator. FCAW (Flux Cored Arc Welding) uses a voltage sensing (VS) feeder that does not re- Electrode Hot –...

-

Page 46: Arc Control

Complete Parts List available at www.MillerWelds.com 6-5. Arc Control Arc Control Stick Control adjusts Dig when Stick is se- lected on mode switch. When control is set toward minimum, short-circuit amperage at low arc voltage is the same as normal weld- ing amperage. -

Page 47: Low Open-Circuit Voltage (Vrd) Switch Mode

Complete Parts List available at www.MillerWelds.com 6-6. Low Open-Circuit Voltage (VRD) Switch Mode Voltage Reducing Device (VRD) Switch The VRD switch can be set for low open-circuit voltage operation in Stick mode. When the unit is con- figured for low open-circuit voltage operation only a low sensing voltage (approximately 15 volts DC) is present between the elec-... -

Page 48: Lift-Arct Tig With Auto-Stopt

Complete Parts List available at www.MillerWelds.com 6-8. Lift-Arct TIG With Auto-Stopt Arc Start With Lift-Arc TIG Lift-Arc is used for the DCEN GTAW process when HF Start method is not permitted. Arc Start With Lift-Arc Select Lift-Arc TIG at Process/ Contactor switch. -

Page 49: Remote Voltage/Amperage Control

Complete Parts List available at www.MillerWelds.com 6-9. Remote Voltage/Amperage Control Remote 14 Receptacle Connect optional remote control to receptacle (see Section 5-17). When a remote control is connected to the Remote receptacle, the Auto Sense Re- mote feature automatically switches volt- age/amperage control to the remote con- trol. -

Page 50: Engine Block Heater Operation

Complete Parts List available at www.MillerWelds.com 6-10. Engine Block Heater Operation Engine Block Heater Plug Use heater to maintain a constant engine coolant temperature. To turn on heater, connect heater Coolant Heater plug to 120 volts AC receptacle. Specifications Do not run engine while en- ±... -

Page 51: Optional Air Dryer Operation

Complete Parts List available at www.MillerWelds.com 6-11. Optional Air Dryer Operation The air dryers blow out (purge) mois- ture and debris when the air compres- sor is being used. The air dryer heaters operate whenever the welder/genera- tor is running. See the supplied air dryer Owner’s Manual for air dryer maintenance and service information. -

Page 52: Section 7 − Operating Auxiliary Equipment

Complete Parts List available at www.MillerWelds.com SECTION 7 − OPERATING AUXILIARY EQUIPMENT 7-1. North American Auxiliary Power Receptacles 271 858-A Single-Phase Generator Power erator winding from overload. If CB6 (240 V x 13 A) + (120 V x 7 A) = opens, RC1, RC2, GFCI1 and GFCI2 do 4.0 kVA/kW Use GFCI protection when operat-... -

Page 53: Export Auxiliary Power Receptacles

Complete Parts List available at www.MillerWelds.com 7-2. Export Auxiliary Power Receptacles Ref. 251 252-A / 251 965-A 110 V 16 A AC Receptacle RC1 Supplementary Protector CB1 10 Supplementary Protector CB8 (Deluxe Model) 220 V 16 A AC Receptacle RC3 CB8 protects GFCI2 and RC2 from over- load. -

Page 54: Gfci Receptacle Information, Resetting And Testing

Complete Parts List available at www.MillerWelds.com 7-3. GFCI Receptacle Information, Resetting And Testing Test and reset GFCI only at Run speed. RotGFCI1 2014−09 Use GFCI protection when operating If a ground fault is detected, the GFCI Reset Resetting GFCI Receptacles button pops out, and the circuit opens to dis- auxiliary equipment. -

Page 55: Section 8 − Maintenance

Complete Parts List available at www.MillerWelds.com SECTION 8 − MAINTENANCE 8-1. Maintenance Label OM-267603 Page 51... -

Page 56: Cleaning Unit

Complete Parts List available at www.MillerWelds.com DEUTZ Service: http://www.deutzamericas.com To ensure rapid, efficient service support, you should initially contact your nearest DEUTZ service distributor or dealer: http://www.deutzamericas.- com/deutznew/distributors/index.htm. They are staffed with highly qualified parts, service and engine specialists to handle your different needs. The DEUTZ Service Desk enhances this support and can be contacted by completing and submitting the Service Support Form. -

Page 57: Checking Generator Brushes

Complete Parts List available at www.MillerWelds.com 8-4. Checking Generator Brushes Stop engine and let cool. Generator Brush Mark and disconnect leads at brush hold- er cap. Remove brushes. Minimum Length: Replace brushes if damaged or if brush 5/8 in. (16 mm) material is at or near minimum length. -

Page 58: Servicing Air Cleaner

Complete Parts List available at www.MillerWelds.com 8-7. Servicing Air Cleaner Stop engine. NOTICE − Do not run engine without air cleaner or with dirty element. Engine damage caused by using a damaged ele- ment is not covered by the warranty. The air cleaner primary element can be cleaned but the dirt holding capac- ity of the filter is reduced with each... -

Page 59: Servicing Fuel And Lubrication Systems

Complete Parts List available at www.MillerWelds.com 8-9. Servicing Fuel And Lubrication Systems Tools Needed: 907 634−2 Stop engine and let cool. To replace fuel filters: To drain sludge from fuel tank: After servicing, start engine and Turn filter counterclockwise. Remove filter. Beware of fire. -

Page 60: Engine/Generator Overload Protection

Complete Parts List available at www.MillerWelds.com 8-10. Engine/Generator Overload Protection 907 634−2 Stop engine. Fuse F1 See Section 6-6 for VRD switch informa- tion. Fuse F2 When a supplementary protector, cir- Supplementary Protector CB14 F1 and F2 protect the stator exciter winding cuit breaker or fuse opens, it usually in- Air dryer overload protection, see Section from overload. -

Page 61: Voltmeter/Ammeter Help Displays

Complete Parts List available at www.MillerWelds.com 8-11. Voltmeter/Ammeter Help Displays HL.P HL.P HL.P HL.P HL.P Use the Voltmeter/Ammeter help displays side) on the heat sink has failed. If this dis- and then disconnected. Clear fault by stop- to diagnose and correct fault conditions. play is shown, have Factory Authorized ping and restarting the unit or by turning Service Agent check TH1 (each side), and... -

Page 62: Removing Optional Air Dryer For Service

Complete Parts List available at www.MillerWelds.com 8-12. Removing Optional Air Dryer For Service Follow this procedure whenev- er the air dryer must be re- moved to gain access to the battery. Air Line Timer Control Cable Air Dryer Heater Plug Solenoid LED Disconnect air line from dryer as- sembly bottom inlet. -

Page 63: Section 9 − Air Compressor Maintenance

Complete Parts List available at www.MillerWelds.com SECTION 9 − AIR COMPRESSOR MAINTENANCE 9-1. Air Compressor Maintenance Label The air compressor normally requires service at the intervals listed in the maintenance schedule if used in a clean, dry environment. The compressor will require service more often if used in dirty, humid conditions. Notes OM-267603 Page 59... -

Page 64: Routine Air Compressor Maintenance

Complete Parts List available at www.MillerWelds.com 9-2. Routine Air Compressor Maintenance See Section 8 for engine/generator maintenance information. Recycle air compressor fluids. Stop engine before maintaining. Service air compressor more often if used in severe conditions. n = Check Z = Change ~ = Clean l = Replace Reference... -

Page 65: Servicing Compressor Air Cleaner

Complete Parts List available at www.MillerWelds.com 9-3. Servicing Compressor Air Cleaner Stop engine. NOTICE − Do not run air compressor without air cleaner or with dirty element. Compressor damage caused by using a damaged element is not covered by the warranty. -

Page 66: Compressor Overload Protection

Complete Parts List available at www.MillerWelds.com 9-4. Compressor Overload Protection Stop engine. When a circuit breaker or fuse opens, it usually indicates a more serious problem exists. Contact Factory Authorized Service Agent. See Section 8-10 for engine/gener- ator overload protection. Circuit Breaker CB15 Circuit breaker CB15 protects the air compressor clutch. -

Page 67: Servicing Air Compressor

Complete Parts List available at www.MillerWelds.com 9-5. Servicing Air Compressor Tools Needed: 7/8, 15/16 in. Air Compressor Assembly Right Side High Full Full 907 634−2 / 255 862-A Stop engine and let cool. Wait 20 sec- To change compressor oil and filter: Add recommended oil until oil level indicator onds for system pressure to drop be- shows system is full (see compressor mainte-... -

Page 68: Adjusting Compressor Air Pressure

Complete Parts List available at www.MillerWelds.com 9-6. Adjusting Compressor Air Pressure Check compressor air pressure using air pressure gauge known to be accu- rate. If necessary, adjust air pressure as follows: Tools Needed: Screw 5/16, 3/8 in. Loosen jam nut securing screw. Turn screw clockwise (increase pressure) or counterclockwise (decrease) until pressure is 125 psi (862 kPa). -

Page 69: Section 10 − Troubleshooting

Complete Parts List available at www.MillerWelds.com SECTION 10 − TROUBLESHOOTING 10-1. Troubleshooting Also see Voltmeter/Ammeter help displays to assist in troubleshooting weld problems (see Section 8-11). Also see Engine Information Display to assist in troubleshooting engine related problems (see Section 13). A. - Page 70 Complete Parts List available at www.MillerWelds.com Trouble Remedy No remote fine amperage or voltage Repair or replace remote control device. control (Continued). Have Factory Authorized Service Agent check current sensing devices, and connections. Constant speed wire feeder does not Reset supplementary protector CB9 or CB29 (see Section 8-10). work.

- Page 71 Complete Parts List available at www.MillerWelds.com D. Engine Trouble Remedy Engine will not crank. Supplementary protector CB2 open. Reset CB2. Check battery connections and tighten if necessary. Check battery, and replace if necessary. Circuit breaker CB10 may be open. CB10 automatically resets when fault is corrected (see Section 8-10). Have Factory Authorized Service Agent check engine wiring harness and components.

-

Page 72: Section 11 − Parts List

Complete Parts List available at www.MillerWelds.com Trouble Remedy Air compressor stops after short period Check compressor oil level (see Section 9-5). Automatic shutdown stops compressor if compressor tem- of operation. perature is too high. Clean debris from radiator. Automatic shutdown stops compressor if compressor temperature is too high. Low air pressure. - Page 73 Complete Parts List available at www.MillerWelds.com Notes OM-267603 Page 69...

-

Page 74: Section 12 − Electrical Diagrams

SECTION 12 − ELECTRICAL DIAGRAMS Figure 12-1. Circuit Diagram For CA Model Welder/Generator OM-267603 Page 70... - Page 75 266 206-D OM-267603 Page 71...

- Page 76 Figure 12-2. Circuit Diagram For Export Model Welder/Generator OM-267603 Page 72...

- Page 77 266 207-D OM-267603 Page 73...

-

Page 78: Section 13 − Engine Information Display

SECTION 13 − ENGINE INFORMATION DISPLAY The views in this section are intended to be representative of all engine-driven welding generators. Your unit may differ from those shown. 13-1. Display Layout And Controls Engine Information Display Engine Control Switch Function Buttons Yellow LED Red LED The Engine Information Display... - Page 79 13-3. RPM Signal Failed Display RPM Signal Failed Display If the operator places the Engine Control switch in the Run/Idle or Run position and does not start the engine, a timer starts. If this condi- tion exists for 5 minutes or longer, the RPM signal failed message ap- pears.

- Page 80 13-5. 6-Up Display n/min 6-Up Display With Engine RPM 6-Up Display With Air Compressor Engine Coolant Temperature Pressure (Models With Air Engine RPM Compressor) This is the default screen configuration. If Compressor Air Pressure The air compressor must be on and air the operator wants to toggle to the 1-Up Battery Voltage pressure must be available for this display...

- Page 81 13-7. 1-Up Displays 1-Up Machine Hours Display To increment to the next display, press the Next function button. To return to previous display, press the Previous function button. To return to the 6-Up Display, press the View function button. Machine Hours 15 18 Battery Potential Coolant Temperature...

- Page 82 13-8. 1-Up Compressor Displays (Models With Compressor Only) Air Compressor Pressure 1-Up Display To increment to the next display, press the Next function button. To return to previous display, press the Previous function button. To return to the 6-Up Display, press the View function button.

- Page 83 13-9. Fuel Level Warnings Fuel level warnings are generat- ed by sensors at the fuel tank. All engine warnings that are dis- played are generated by the en- gine controller (see Sections 13-10 and 13-11). 6-Up Display 1-Up Fuel Level Display Low Fuel Warning The low fuel warning indicator ap- pears and begins to flash when fuel...

- Page 84 13-10. Warning or Shutdown Display Oil Pressure Display Fault Warning Indicator The warning symbol appears on the display when an engine condition approaches a shutdown condition. 45 60 Fault Shutdown Indicator The shutdown symbol appears on the display when a severe engine fault can cause shutdown.

- Page 85 Table 13-1. Fault Descriptions This is an abbreviated list of faults. These faults can commonly be remedied by the operator. If other faults appear, contact Factory Authorized Service Agent. Description of Fault Tier 3 or Tier 4 Interim Engines Low oil pressure; warning threshold exceeded High coolant temperature;...

- Page 86 13-12. Main Menu Access Code Access Code Display An access code is required to gain access to the main menu. This dis- play appears whenever the Menu/ Cancel function button is pressed while in the 1-Up or 6-Up display ENTER PASSWORD Access Code (Password) The factory set access code is 1000.

- Page 87 13-14. Main Menu Options: Brightness, Contrast, And Units Main Menu Cursor Scroll Function Buttons Use scroll function buttons to move cursor. Select Function Button When the cursor is in desired posi- Brightness " tion, press Select function button to go to sub-menu. Contrast Brightness Menu Display Units...

- Page 88 13-15. Main Menu Options − Reminders Main Menu Cursor Scroll Function Buttons Use scroll function buttons to move cursor. Select Function Button When the cursor is in desired posi- tion, press Select function button to Brightness go to sub-menu. Contrast Service Reminders Display Units English...

- Page 89 13-16. Main Menu Options − OEM, Version, Stored Codes, And Language Main Menu Cursor Scroll Function Buttons Use scroll function buttons to move cursor. Select Function Button When the cursor is in desired posi- tion, press Select function button to go to sub-menu.

-

Page 90: Section 14 − Run-In Procedure

2014−10 NOTICE − Diesel engines in MILLER equipment are meant to operate optimally at moderate to rated load. Using light or no load for extended periods of time may cause wetstacking or other engine damage. Do not idle engine longer than necessary. -

Page 91: Run-In Procedure Using Load Bank Or Resistance Grid

14-2. Run-In Procedure Using Load Bank Or Resistance Grid S-0683 / S-0684 Stop engine. Connect load bank or resistor grid to For Resistance Grid generator Side A weld output terminals Set grid switches and then adjust gen- Do not touch hot exhaust pipe, en- using proper size weld cables with correct erator A/V control so load equals rated gine parts, or load bank/grid. -

Page 92: Section 15 − Air Compressor Tables

SECTION 15 − AIR COMPRESSOR TABLES 15-1. Flow Of Free Air (CFM) Through Orifices Of Various Diameters Orifice Diameter (in) And Free Air Flow (CFM) Gauge Pressure (psi) 1/64 1/32 3/64 1/16 3/32 3/16 0.027 0.107 0.242 0.430 0.97 1.72 3.86 6.85 0.038... -

Page 93: Approximate Air Consumption (Cubic Feet) To Operate Pneumatic Equipment At 70-90 P.s.i.g

15-2. Approximate Air Consumption (Cubic Feet) To Operate Pneumatic Equipment At 70-90 P.S.I.G. Percent Use Factor And Percent Use Factor And MISCELLANEOUS MISCELLANEOUS Compressed Air Consumption (CF) Compressed Air Consumption (CF) PORTABLE PORTABLE TOOLS TOOLS 9 sec 15 sec 21 sec 1 min 9 sec 15 sec... -

Page 94: Section 16 − Generator Power Guidelines

SECTION 16 − GENERATOR POWER GUIDELINES The views in this section are intended to be representative of all engine-driven welder/generators. Your unit may differ from those shown. 16-1. Selecting Equipment Generator Power Receptacles − Neutral Bonded To Frame 3-Prong Plug From Case Grounded Equipment 2-Prong Plug From Double Insulated Equipment... - Page 95 16-3. Grounding When Supplying Building Systems Equipment Grounding Terminal Grounding Cable Use #8 AWG or larger insulated copper wire. GND/PE Ground Device Use ground device as stated in electrical codes. Ground generator to system earth ground if supplying power to a premises (home, shop, farm) wiring system.

- Page 96 16-5. Approximate Power Requirements For Industrial Motors Industrial Motors Rating Starting Watts Running Watts Split Phase 1/8 HP 1/6 HP 1225 1/4 HP 1600 1/3 HP 2100 1/2 HP 3175 Capacitor Start-Induction Run 1/3 HP 2020 1/2 HP 3075 3/4 HP 4500 1400 1 HP...

- Page 97 16-7. Approximate Power Requirements For Contractor Equipment Contractor Rating Starting Watts Running Watts Hand Drill 1/4 in. 3/8 in. 1/2 in. Circular Saw 6-1/2 in. 7-1/4 in. 8-1/4 in. 1400 1400 Table Saw 9 in. 4500 1500 10 in. 6300 1800 Band Saw 14 in.

- Page 98 16-8. Power Required To Start Motor Single-Phase Induction Motor Starting Requirements Motor Start Code KVA/HP 10.0 11.2 12.5 14.0 Motor Start Code Running Amperage Motor HP Motor Voltage To find starting amperage: Step 1: Find code and use table to find kVA/HP.

- Page 99 16-10. Typical Connections To Supply Standby Power Have only qualified persons perform these connections according to all applicable codes and safety practices. Properly install, ground, and operate this equipment ac- cording to its Owner’s Manu- al and national, state, and lo- cal codes.

- Page 100 16-11. Selecting Extension Cord (Use Shortest Cord Possible) Cord Lengths for 120 Volt Loads Use GFCI protection when operating auxiliary equipment. Do not use GFCI receptacles to power life support equipment. Maximum Allowable Cord Length in ft (m) for Conductor Size (AWG)* Current Load (Watts) (Amperes)

- Page 101 Effective January 1, 2016 (Equipment with a serial number preface of MG or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions below, 6 Months —...

- Page 102 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2016 Miller Electric Mfg. Co. 2016−01...

Need help?

Do you have a question about the Big Blue Duo Air Pak 800X and is the answer not in the manual?

Questions and answers