Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

INGERSOLL RAND COMPANY INC

34800 BENNETT DR, FRASER, MI 48026

www.gardnerdenver.com/en-us/mppumps

CHEMFLO® 3

(2" X 1-1/2")

OPERATING OR SERVICING THIS EQUIPMENT.

56C

CC Models

Hydraulic Models

Pedestal Models

© 2021

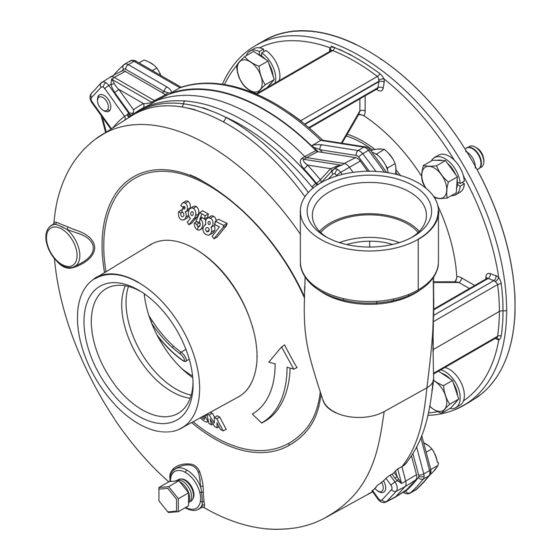

Figure 1

CHEMFLO 3

RELEASED:

(REV: A)

145TC

8-27-21

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ingersoll-Rand MP CHEMFLO 3 CC

- Page 1 OPERATOR’S MANUAL CHEMFLO 3 RELEASED: 8-27-21 INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE (REV: A) CHEMFLO® 3 (2” X 1-1/2”) READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT. It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference. 145TC CC Models Hydraulic Models...

-

Page 2: General Description

GENERAL DESCRIPTION CHEMFLO 3: ChemFlo®3 pumps utilize a semi-open impeller design to al- 2” x 1-1/2” End Suction Centrifugal Pump low for passage of larger solid sizes and a totally enclosed im- Made with high quality investment cast 316 stainless steel peller to meet high efficiency standards. -

Page 3: Operating And Safety Precautions

OPERATING AND SAFETY PRECAUTIONS READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE. Maximum temperatures are based on CAUTION EXCESSIVE AIR PRESSURE HAZARDOUS MATERIALS mechanical stress of seals and elastomers only. Cer- STATIC SPARK HAZARDOUS PRESSURE tain chemicals will significantly reduce maximum safe operating temperature. -

Page 4: Storage Precautions

STORAGE PRECAUTIONS BEARING INSTALLATION (PEDESTAL MODELS): Check the shaft to insure that it rotates freely. Shafts should Do not store filled with fluid at or below freezing temp of be aligned in accordance with the instructions of the cou- process fluid. pling manufacturer. -

Page 5: Motor Mounting

MOTOR MOUNTING TO ADJUST IMPELLER CLEARANCE: 1. Loosen the impeller drive sleeve Check rotation of the driver to be sure it coincides with the 2. Use a tool such as a screwdriver to push the impeller required rotation of the pump. When viewed from the driver back then reinsert the Assembly Shim. - Page 6 WORKING OF CENTRIFUGAL PUMP Hd = DISHCARGE HEAD DISCHARGE PIPE DISCHARGE Hs = SUCTION HEAD (NPSHr) OVER HEAD WATER TANK VALVE CASING SUCTION UNION PIPE FLANGE UNION FLANGE EYE OF IMPELLER SUCTION VALVE MINIMIZE LENGTH & AVOID SHARP BENDS NEAR INLET Figure 3 OPERATING INSTRUCTIONS WEAR AND INSPECTION POINTS...

-

Page 7: Seal Replacement Instructions

SEAL REPLACEMENT INSTRUCTIONS Make sure the shim is installed between the impeller and the wear plate. Do not remove the shim material before the drive DISASSEMBLE THE PUMP: sleeve clamp has been tightened to the motor drive shaft. INSTRUCTIONS FOR SET SCREW TYPE SEAL: Drain the system of liquid, break suction and discharge pipe unions, and, if necessary, remove all piping from the suction Do not remove the seal retaining clips. - Page 8 PARTS LIST / CHEMFLO 3 CC (56C AND 145TC) For 145 TC Motors Figure 4 PARTS LIST / CHEMFLO 3 CC (56C AND 145TC) Item Description Qty Part No. Item Description Qty Part No. (size) (size) Drive Sleeve 29785 316 SS Pipe Plug 316 SS (56C)

- Page 9 PARTS LIST / CHEMFLO 3 HYDRAULIC (0.22 AND 0.37) Figure 5 PARTS LIST / CHEMFLO 3 HYDRAULIC (0.22 AND 0.37) Item Description Qty Part No. Item Description Qty Part No. (size) (size) Pipe Plug 21255 316 SS Lockwasher 21266 304 SS (3/8 X 1/8) (1/8"...

- Page 10 PARTS LIST / CHEMFLO 3 PEDESTAL Figure 6 PARTS LIST / CHEMFLO 3 PEDESTAL Item Description Qty Part No. Item Description Qty Part No. (size) (size) Lockwasher 21238 304 SS Pipe Plug 21255 316 SS (1/8" NPT) (5/16 X 18) Flat Washer 50914 Housing...

-

Page 11: Service Kits

SERVICE KITS PUMP MODEL PUMP DESCRIPTION SEAL KIT BEARING KIT IMPELLER MP39346 CF3PMP SS:1.5-1 1750 56C MB 5.25T-2100HF MP51271 #N/A MP33005 MP39626 CF3PMP SS:1.5-1 56C MB 3.75 T-2100 MP51271 #N/A MP30239 MP31208 CF3PMP SS:1.5-3 56C MB 3.75 T-2100 MP51271 #N/A MP30239 MP39257 CF3PMP SS:1.5-3 56C MB 4.00 T-2100... -

Page 12: Dimensional Data

SEAL TYPE OPTIONS Material Seal PN Seal Type Shaft Dia. Mating Ring Primary Ring Elastomer Components 29168 0.75” (19.05 mm) Silicon Carbide Carbon Viton 316 SS 30061 2100 0.75” (19.05 mm) Ceramic Carbon Viton 316 SS 30358 0.75” (19.05 mm) Ceramic Carbon 316 SS 30745... - Page 13 DIMENSIONAL DATA CF3 0.22 DISP MOTOR Figure 9 CF3 0.37 DISP MOTOR Figure 10 CHEMFLO 3 (en) Page 13 of 16...

- Page 14 DIMENSIONAL DATA CF3 PED Figure 11 Page 14 of 16 CHEMFLO 3 (en)

-

Page 15: Troubleshooting

TROUBLESHOOTING PROBLEM PROBABLE CAUSE REMEDY 1. Reprime pump, check that pump and 1. Pump not primed. there are no obstructions in the suc- tion line. 2. Discharge valve closed 2. Check discharge valve. 3. Suction line clogged. 3. Remove obstructions. 4. - Page 16 PROBLEM PROBABLE CAUSE REMEDY 1. Improper pump/driver alignment. 1. Align shafts. 2. Partly clogged impeller causing 2. Back-flush pump to clean impeller. imbalance. 3. Broken or bent impeller or shaft. 3. Replace as required. 4. Tighten bolts of pump and motor or 4.

Need help?

Do you have a question about the MP CHEMFLO 3 CC and is the answer not in the manual?

Questions and answers