Riello Array AR 1000 Installation And Operation Manual

Hide thumbs

Also See for Array AR 1000:

- Installation and operation manual (68 pages) ,

- Installation and operation manual (80 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Riello Array AR 1000

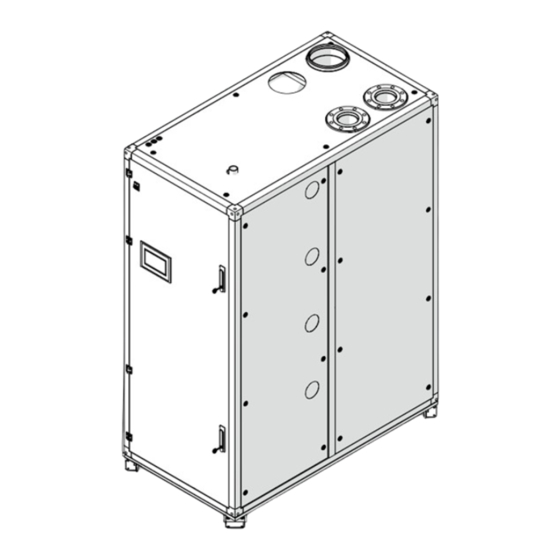

- Page 1 Array AR 1000 - AR 1500 - AR 2000 US INSTALLATION AND OPERATION MANUAL...

- Page 2 This appliance ensures maximum comfort over a long life, with high reliability, MODEL ASSEMBLY NUMBER efficiency, performance, quality and safety. Array AR 1000 20144525 This manual provides information that is essential to the installation Array AR 1500 20144524 of the appliance. Used in conjunction with your own knowledge...

-

Page 3: Table Of Contents

6.3.1 Riello Screen ....... 36 Operating Limits of the Boiler ....14 6.3.2 Cascade Screen . -

Page 4: General

GENERAL GENERAL 1.1 Warnings & Cautions Array AR 1000, AR 1500 and AR 2000 MBH Boilers are fully Installers and operating personnel MUST, at all times, observe modulating, high-efficiency condensing units. They represent all safety regulations. The following warnings and cautions a true industry advance that meets the needs of today’s energy... -

Page 5: Safety Instructions

GENERAL 1.2 Safety Instructions 1.3 General Warning Observe these instructions for your safety. The installation must conform to the requirements of the authority The burner and control must be correctly installed and adjusted to having jurisdiction or, in the absence of such requirements, to the ensure safe and economical operation of the gas boiler. -

Page 6: Product Description

PRODUCT DESCRIPTION 2 PRODUCT DESCRIPTION Component Packaging method Anchoring brackets Cardboard box on pallet 2.1 Introduction Thermowell for System Cardboard box on pallet Temperature Sensor • The gas-fired condensing Array boilers are designed to be used in central heating systems. Any other use is prohibited. 2.3 Proper Use •... -

Page 7: Prolonged Shutdown

PRODUCT DESCRIPTION 2.6 Prolonged Shutdown or equipment. The sign shall read, in print size no less than one-half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”. After prolonged shutdown, the startup procedures and the safety device test procedures of this manual shall be performed to verify 4. -

Page 8: Size And Connections

PRODUCT DESCRIPTION 2.7 Size and Connections ARRAY AR 1000, AR 1500 60.8” 11.5” 10.15” 50.8” 8.5” 11.5” 7.47” 9.48” Dimensions are in inches (*) Mounting feet may be removed during installation to reduce the overall height by 2”. Feet must be re-installed once boiler is in its... - Page 9 PRODUCT DESCRIPTION ARRAY AR 2000 60.8” 12.12” 10.3” 50.8” 8.8” 11.25” 7.47” 12.1” Dimensions are in inches (*) Mounting feet may be removed during installation to reduce the overall height by 2”. Feet must be re-installed once boiler is in its final location.

-

Page 10: Technical Data

PRODUCT DESCRIPTION 2.8 Technical Data Unit AR 1000 AR 1500 AR 2000 Boiler Category ASME Sect.IV Type of Gas Natural Gas, Propane* BTU/hr 1,000,000 1,500,000 2,000,000 Max input rate (kW) (293) (440) (586) BTU/hr 100,000 100,000 100,000 Min input rate (kW) (29) (29) -

Page 11: Structure

PRODUCT DESCRIPTION 2.9 Structure 26 25... - Page 12 PRODUCT DESCRIPTION Item Description Item Description Outer frame Burner head O-ring Burner flange (outer) Burner gasket Supply pipe Sight glass combustion Purge valve Igniter Gas pipe Burner tube Gas valve Burner flange (inner) Heat exchanger Gasket burner flange Pump Water shutoff valve Brass connection Flow meter Brass fitting...

-

Page 13: Efficiency Curves

PRODUCT DESCRIPTION 2.10 Efficiency Curves ARRAY AR 1000, AR 1500, AR 2000 100% 100% input 30% input 20% input Return water temperature (°F) @ 36 Degree Rise... -

Page 14: Regulations

4.4 Site Preparation Ensure that the site selected for installation of the Array AR 1000, AR 1500 and AR 2000 Boiler includes: − Access to AC Input Powerat 120VAC, single phase, 60Hz for AR 1000-1500 and 208VAC, three-phase, 60Hz for AR 2000 −... -

Page 15: Installation Clearances

Commonwealth of Massachusetts. In addition, the installation must comply with all requirements specified in “Warnings & Cautions” page 4Warnings & Cautions” page <?>. See pages pag. 7 and pag. 22 for additional details. Array AR 1000, AR 1500 Clearances Fig. 3... -

Page 16: Setting The Unit

Fig. 5. FRONT 31.1” 12.6” Fig. 6 Array AR 1000, AR 1500 Crane Lifting Handling Array AR 1000, AR 1500 and AR 2000 Forklift Handling Fig. 5 If a crane is required, the boiler must be lifted through bands. -

Page 17: Boiler Location

Fig. 9 and Fig. 10 for anchor locations. 0.28’’ 0.28’’ 0.75’’ Fig. 10 Array AR 1000, AR 1500 and AR 2000 Anchoring bolt detail 4.5 Boiler Location − This boiler is suitable only for indoor installations. − To operate properly and safely, this boiler requires a continuous supply of air for combustion. -

Page 18: Water Quality Guidelines

− When using oxygen permeable PEX, the system must be Fig. 11 Array AR 1000, AR 1500 and AR 2000 Connections separated from the boiler by a heat exchanger. − A correctly sized and working expansion vessel must be installed. -

Page 19: High Limit Safety Switch

INSTALLATION 4.11 Condensate Drain and Piping INSTALLATION inlet block” will appear on the screen. At this point press the Reset button. The error will turn off. The Array Boiler is designed to condense water vapor from the Module level: flue products. Each heat exchanger of the boiler is equipped A Low Water Cut Off (LWCO) sensor is installed on top of the supply with a condensate trap (see Fig. - Page 20 The maximum Plastic elbow condensate flow rate is 7.9 GPH for Array AR 1000, 13.9 GPH for Array Hose clamp AR 1500 and 15.9 GPH for Array AR 2000. The drain line must be removable for routine maintenance.

-

Page 21: Gas Supply Piping

4.12 Gas Supply Piping Array AR 1000, AR 1500 and AR 2000 boilers contain a 1.5 inch NPT gas inlet connection on the top of the unit as shown in Fig. 11. WARNING: Never use matches, candles, flames or other sources of ignition to check for gas leaks. -

Page 22: Gas Supply Specifications

INSTALLATION 4.12.4 Gas Type Conversion − A sediment trap / drip leg must be installed on the gas supply piping. − Installation of a union fitting at the appliance gas line The heating unit is factory preset for operating with natural gas. connection is required for ease of service. -

Page 23: Adjusting And Setting O Limits

Screw “A” Additional parts (such as a high voltage ignition transformer) may be required for reliable ignition of the propane. Please consult the Riello factory prior to all conversions from natural gas to propane Screw “B” 4.12.5 Adjusting and Setting O Limits −... -

Page 24: Ac Electrical Power Wiring

Module Power walls or another unit. Switch 4.13.1 Electrical Power Requirements The voltage configuration of Array AR 1000, AR 1500 and AR 2000 is as follows: Module Power Switch − AR 1000, AR 1500: 120VAC/1PH/60Hz −... - Page 25 INSTALLATION The Main Circuit two-pole switch is accessible on the front door to quickly and safely disconnect electrical service. This breaker does not remove power on the incoming power supply terminals. ⏚ Main Switch Fig. 30 AR 1000, AR 1500 120VAC Power supply connection ⏚...

-

Page 26: Field Control Wiring

INSTALLATION 4.14 Field Control Wiring connecting an air damper, the Programmable Output 3 must be set to 10 and the damper wires must be connected to terminals 3 Each unit is fully wired from the factory with an internal operating and 4, as shown in Fig. - Page 27 INSTALLATION − Do not mix components from different systems. The vent 6" Flue Gas system could fail, causing leakage of flue products into the 6" Air Intake living space. Use only approved materials. Connection − Use of cellular core PVC and CPVC for venting system is not allowed.

- Page 28 INSTALLATION VENTING CONFIGURATIONS: The following figures show the acceptable piping installation for venting and combustion air. EXHAUST EXHAUST BOILER BOILER Fig. 37 All Combustion Air from Adjacent Indoor Spaces through Fig. 39 All Combustion Air From Outdoors - Inlet Air From Ventilated Indoor Combustion Air Openings Crawl Space and Outlet Air to Ventilated Attic EXHAUST...

- Page 29 INSTALLATION EXHAUST EXHAUST BOILER BOILER Fig. 41 All Combustion Air from Outdoors through Single Fig. 43 Sealed Combustion Located on Same Side with Exhaust Combustion Air Opening (horizontal) EXHAUST EXHAUST BOILER BOILER Fig. 42 Sealed Combustion Located on Same Side with Exhaust Fig.

-

Page 30: Combustion Air

INSTALLATION Ventilation air must be provided in either case. Material Standard ANSI/ASTM D1527 PVC Schedule 40 ANSI/ASTM D1785 or D2665 CPVC Schedule 40 ANSI/ASTM F441 Polypropylene ULC S636 Single wall galvanised steel 26 gauge In cold climates it is essential to provide a motorized air inlet damper to control the supply of combustion air and prevent EXHAUST nuisance condensation. -

Page 31: Ducted Combustion Air

COMMISSIONING 4.16.3 Ducted Combustion Air pressure back to the desired value. For ducted combustion air installations, the air ductwork must be 5.4 Warnings Concerning the Gas Supply attached directly to the air inlet connection on the sheet metal enclosure. When starting up the unit for the first time the following must be In a ducted combustion air application, the combustion air ducting checked: pressure losses must be taken into account when calculating the... - Page 32 COMMISSIONING − Date and Time can be adjusted through the screen below: Ver X.X.XX Ver X.X.XX Fig. 46 Touchscreen Control Panel Stand-by screen By touching the logo, the Cascade screen will appear: Fig. 49 Date & Time screen − After the Date&Time setting, CH modes can be selected accessing the CH MODE settings screen below: Settings Ver X.X.XX...

- Page 33 COMMISSIONING Fig. 51 CH/DHW Setpoints NOTE: after selecting CH mode 4, enable it either: jumpering “Enable/Disable” pins (#11-12) on Terminal strip − − CH Mode 1 - Room Themostat & Outdoor Reset: this (see Fig. 28) mode requires an outdoor sensor, in addition to the room thermostat.

-

Page 34: Minimum Water Flow (Heat Exchanger Protection)

COMMISSIONING 5.5.1 Minimum Water Flow (Heat Exchanger (ON/OFF signal). Either a pump or a 3-way valve can be used Protection) to switch to DHW mode. When the DHW demand is on, the boiler is PID modulated to achieve the DHW store setpoint. DHW store setpoint is manually set on the CH/DHW Setpoints This unit is self-protected against low water flow. -

Page 35: Multiple Boiler Cascade Installation And Start-Up

COMMISSIONING 5.6 Multiple Boiler Cascade Installation and Start-Up Appendix L shows an example of Array boilers installed in a cascade of three units. The built-in control system is capable of managing up to 8 boilers as a single, coordinated heating system. The logical schematic is: Demand: 0-10V / OpenTherm / On-Off System sensor D2 is T outside... -

Page 36: Operation

Ver X.X.XX 6.2 Control Panel Description Fig. 63 Riello Screen All Array Series Boilers utilize the Touchscreen Control Panel shown in Fig. 62. This Touchscreen panel contains the basic controls for The R logo is the entry point of the Control System. By touching monitoring the boiler. -

Page 37: Boiler Screen

OPERATION − Home button: move back to the R screen; − Performance button: move to the Performance screen of the cascade; − Stats button: not active; − Errors button: move to the Errors screen; − Service button: move to Service screen; −... -

Page 38: Error Screen

OPERATION 6.3.6 Error Screen how long service was overdue on the system/appliance which can be useful when handling warranty claims. For each boiler, the Error screen shows the list of the last 40 errors A maximum of 15 Service moments can be logged by the 900PB, occurred on its own modules. -

Page 39: Shutdown

SHUTDOWN SHUTDOWN 8 ENVIRONMENTAL PROTECTION/DISPOSAL Environmental protection is one of the fundamental company policies of the . We regard quality of performance, economy CAUTION: Risk of system damage through frost. and environmental protection as equal objectives. When there is a frost, the heating system can freeze up if it is not Environmental protection laws and regulations are strictly adhered operational, e.g. -

Page 40: Appendix

APPENDIX SHUTDOWN APPENDIX APPENDIX A - WIRING DIAGRAM AR 1000, AR 1500 blue green 120VAC black FOR 3 PUMPS J3-4 SLAVE 3 J3-4 SLAVE 2 J3-4 MASTER J3-9 SLAVE 3 J3-9 SLAVE 2 J3-9 MASTER balck blue COIL COIL COIL COIL COIL COIL... - Page 41 APPENDIX SHUTDOWN APPENDIX WIRING DIAGRAM AR 1000, AR 1500 - MANAGING (*) ARRAY 1500 ONLY J7-2 WATER PRESSURE SWITCH CONDENSATE PRESS. SWITCH DEPENDENT 3 LWCO (Module) 11 12 J7-4 FLOWMETER J6-5 FLUE SENSOR J6-12 9 10 J9-4 J6-10 RETURN T. SENSOR J9-2 J6-3 WATER PRESSURE...

- Page 42 APPENDIX SHUTDOWN APPENDIX WIRING DIAGRAM AR 1000, AR 1500 - DEPENDENT 2 / 3 J12-2 SUPPLY TEMP. SENSOR J12-5 J12-4 SAFETY LIMIT WATER THERMOSTAT J12-1 LWCO (Module) FLOWMETER J7-8 J7-7 FLUE PRESS. SWITCH + J7-6 CONDENSATE PRESS. SWITCH J7-2 J7-3 FOR DEPENDENT 2 / 3 J6-5 FLUE TEMP.

-

Page 43: Appendix B - Wiring Diagram Ar 2000

APPENDIX SHUTDOWN APPENDIX APPENDIX B - WIRING DIAGRAM AR 2000 ... - Page 44 APPENDIX SHUTDOWN APPENDIX WIRING DIAGRAM AR 2000 - MANAGING J7-2 WATER PRESSURE SWITCH CONDENSATE PRESS. SWITCH DEPENDENT 4 LWCO (Module) 11 12 J7-4 J6-5 FLUE SENSOR FLOWMETER J6-12 9 10 J9-4 J6-10 RETURN T. SENSOR J9-2 J6-3 WATER PRESSURE J6-11 h SWITCH J6-4 SERVICE DISPLAY...

- Page 45 APPENDIX SHUTDOWN APPENDIX WIRING DIAGRAM AR 2000 - DEPENDENT 2 / 3 / 4 J12-2 SUPPLY TEMP. SENSOR J12-5 J12-4 SAFETY LIMIT WATER THERMOSTAT J12-1 LWCO (Module) FLOWMETER J7-8 J7-7 FLUE PRESS. SWITCH + J7-6 CONDENSATE PRESS. SWITCH J7-2 J7-3 FOR DEPENDENT 2 / 3 J6-5 FLUE TEMP.

-

Page 46: Appendix C - Connection Diagram

APPENDIX SHUTDOWN APPENDIX APPENDIX C - CONNECTION DIAGRAM Int. ionization CONNECTION DIAGRAM 905MN CONTROL BOARD 0...10V J9-1 Ignition 0V(GND) J9-3 BURNER J9-2 Open Thermostat interface Spark Return Room Thermostat ON/OFF J9-4 J10-1 J2 1-6 J10-2 J10-5 J10-6 J1-5 MAINS SUPPLY (120VAC, 60Hz) J1-1 COMM. - Page 47 APPENDIX SHUTDOWN APPENDIX CONNECTION DIAGRAM 905PB DISPLAY CONNECTION DIAGRAM 905PB DISPLAY 905PB05_3R Connector Function PC interface Connection to MN control/Modbus 905PB05_3R Display: RJ-11 Connector: RS485 / Mod BUS J25-1 J25-2 J25-3 1: GND/VSS J25-4 AL-BUS 2: ModBus_B (= Data -) J25-5 3: ModBus_A (= Data +) +24V...

-

Page 48: Appendix D - Maintenance

APPENDIX SHUTDOWN APPENDIX APPENDIX D - MAINTENANCE Gas Leak Inspection A qualified and adequately trained technician must perform the Inspect all gas piping to confirm there are no leaks. inspection as specified in these instructions before each heating season and at regular intervals. Servicing, inspection and adjustment must be done by a trained DANGER: To verify the gas leaks use a soap solution or a gas technician in accordance with all applicable local, state and... -

Page 49: Appendix E - Head Available For The System

APPENDIX SHUTDOWN APPENDIX APPENDIX E - HEAD AVAILABLE FOR THE SYSTEM HEAD AVAILABLE (NO GLYCOL) ∆T = 36°F ∆T = 45°F Array AR 1000 7,5 ft 16,5 ft AR 1500 7 ft 16 ft AR 2000 8 ft 16,5 ft HEAD AVAILABLE (50% MAXIMUM GLYCOL) ∆T = 36°F ∆T = 45°F... -

Page 50: Appendix F - De-Rating For Altitude Installation

(input BTU/hr) NOTE: The following chart compensates for the affects of altitude on the energy content of the gas supply. No additional de-rate required. ARRAY AR 1000 Altitude (ft) From 0% to 25%... -

Page 51: Appendix G - Troubleshooting Table

APPENDIX SHUTDOWN APPENDIX APPENDIX G - TROUBLESHOOTING TABLE LOCKOUT CODES Error no. Error Description Checks Solutions E2PROM_READ_ERROR Internal software error Replace the power control board IGNIT_ERROR Three unsuccessful ignition attempts in a- Check gas supply pressure; a- If the gas supply pressure is a row b- Check ignition spark;... - Page 52 APPENDIX SHUTDOWN APPENDIX Error no. Error Description Checks Solutions FLUE_SWITCH_NOT_CLOSING The blocked flue sensor is not closed within 10 minutes TSUPPLY_DIFF_ERROR The 2 supply sensors deviate too much for more than 60 seconds TFLUE_DIFF_ERROR The 2 flue sensors deviate too much for more than 60 seconds FILLING_TOO_MUCH Too many automated filling attempts in a...

- Page 53 APPENDIX SHUTDOWN APPENDIX Error no. Error Description Checks Solutions REFLO2_TOO_LOW Internal software error Replace the power control board Flame is detected in a state in which no FALSE_FLAME Replace the power control board flame is allowed to be seen LOW_WATER_PRESSURE_ERROR Low water pressure error LOW_WATER_PRESSURE_SENSOR Low water pressure BLOCKED_DRAIN...

- Page 54 APPENDIX SHUTDOWN APPENDIX Error no. Error Description Checks Solutions T_SELECTION3_OPEN Selection 3 sensor open T_OPTIONAL1_OPEN Optional 1 sensor open T_OPTIONAL2_OPEN Optional 2 sensor open T_AMBIENT_OPEN Ambient sensor open T_CHIMNEY_CLOSED Chimney sensor shorted T_EXCHANGE1_CLOSED Exchange 1 sensor shorted T_EXCHANGE2_CLOSED Exchange 2 sensor shorted T_SELECTION1_CLOSED Selection 1 sensor shorted T_SELECTION2_CLOSED...

- Page 55 APPENDIX SHUTDOWN APPENDIX NOTE − Disconnect both wires. In order to check if the control is functioning properly the following readings can be taken: AL Link 24VDC (with S1 Switch On and open circuit). Voltage is variable while in normal operation depending on data stream. Pressure Switches (ie: Gas Pressure, Water Pressure, Flue Pressure, etc) 3.3VDC while circuit is open.

- Page 56 (or a failure of the pressure switch itself). 2. For Array AR 1000, AR 1500 and AR 2000: “LWCO/Air inlet block” error message on TS Boiler screen. This message shows on touchscreen as a result of three possible errors: −...

-

Page 57: Appendix H - Boiler Installation (Example Drawings)

APPENDIX SHUTDOWN APPENDIX APPENDIX H - BOILER INSTALLATION (EXAMPLE DRAWINGS) ARRAY AR 1000 / AR 1500 / AR 2000 Single Unit Installation... - Page 58 APPENDIX SHUTDOWN APPENDIX ARRAY AR 1000 / AR 1500 / AR 2000 Multiple Boiler Installation...

-

Page 59: Appendix I - Venting Size Data

AR 2000 2.75 Data for Venting size T supply / return (F°) - 176 / 140 T supply / return (F°) - 104 / 86 ARRAY AR 1000 Maximum Input Minimum Input Maximum Input Minimum Input Exhaust gas mass (weight) 0.26 lb/s... -

Page 60: Appendix J - Exhaust Terminals And Air Inlet Clearances

APPENDIX SHUTDOWN APPENDIX APPENDIX J - EXHAUST TERMINALS AND AIR INLET CLEARANCES Direct vent (sealed combustion) Fan assisted appliance (Room air for combustion) Forced air inlet Forced air inlet Gravity air inlet Gravity air inlet Exhaust terminal Exhaust terminal X1 1 foot (305 mm) X1 1 foot (305 mm) X2 See Note 1) X2 See Note 1) - Page 61 APPENDIX SHUTDOWN APPENDIX Horizontal venting system (sealed combustion): Vertical venting system (sealed combustion): X ≥ 4” (102 mm); X > 12” (305 mm) Y ≥ 12” (305 mm) Y = 12” (305 mm) above maximum snow level or at least 24” whichever is greater Air intake Vent...

-

Page 62: Appendix K - Sensor Resistance

APPENDIX SHUTDOWN APPENDIX APPENDIX K - SENSOR RESISTANCE SENSOR RESISTANCE TABLE Vent terminals Temperature °F (°C) Resistance [Ω] Testing tolerance ±10% Vent terminals 32 (0) 27396 41 (5) 22140 50 (10) 17999 59 (15) 14716 68 (20) 12099 77 (25) 10000 86 (30) 8308... -

Page 63: Appendix L - List Of Parameters (With Ranges And Default Values)

APPENDIX SHUTDOWN APPENDIX APPENDIX L - LIST OF PARAMETERS (WITH RANGES AND DEFAULT VALUES) Menu item Sub item / Parameter Range Default Value Units User level Appliance Configuration 12 (Managing) (97) IO Configuration 0...99 2: Installer 13 (Dependent) 17 (NG) (98) Appliance Settings 0...99 2: Installer... - Page 64 APPENDIX SHUTDOWN APPENDIX Menu item Sub item / Parameter Range Default Value Units User level (115) DHW Store Setpoint 40...71 (104...160) 57 (135) °C (°F) 1: User (49) DHW Hysteresis Down 0...20 (0...36) 4 (7) °C (°F) 3: Factory (50) DHW Hysteresis Up 0...20 (0...36) 4 (7) °C (°F)

- Page 65 APPENDIX SHUTDOWN APPENDIX Menu item Sub item / Parameter Range Default Value Units User level 0) Disabled 1) General Pump 2) CH Pump 3) DHW Pump 4) System Pump 5) Cascade Pump 6) Alarm Relay 7) Filling Valve Managing: 2 (125) Prog.

- Page 66 APPENDIX SHUTDOWN APPENDIX Menu item Sub item / Parameter Range Default Value Units User level 0) Disabled 1) General Pump 2) CH Pump 3) DHW Pump 4) System Pump 5) Cascade Pump 6) Alarm Relay 7) Filling Valve Managing: 2 (187) Prog.

- Page 67 APPENDIX SHUTDOWN APPENDIX Menu item Sub item / Parameter Range Default Value Units User level (138) Appliance Type 50…55 2: Installer (139) Dair active Yes, No 2: Installer (140) Minimal Flow 0.0…100 l/min 2: Installer (107) Anti-legionella Day Sun…Sat. 2: Installer (108) Anti-legionella Hour 0…23 Hour...

- Page 68 APPENDIX SHUTDOWN APPENDIX Menu item Sub item / Parameter Range Default Value Units User level (80) Max Setp Offset Up 0...40 (0...72) 20 (36) °C (°F) 2: Installer (81) Start Mod Delay Fact 0…60 Min. 2: Installer (82) Next Module Start Rate 10…100 2: Installer (83) Next Module Stop Rate...

-

Page 69: Appendix M - Flowcharts

APPENDIX SHUTDOWN APPENDIX APPENDIX M - FLOWCHARTS SINGLE MODULE Module in Stop pump Stand-by Demand for Post pump module ready Start pump Supply Temp Start fan lower than Setpoint Module Blocking CH flow Start burner (*) error is above min_flow? BURN Burn: Based on delta of Supply sensor and Setpoint PID output is determined... - Page 70 APPENDIX SHUTDOWN APPENDIX BURNER IGNITION SEQUENCE Start burner Pre-Purge 0 Pre-Purge 1 Fan on ignition speed Fan on ignition Blocking error speed within time? Pre ignition on Ignite: ignition on, Gas Valve open Flame Proving, Checking flame Flame Current Ignition Tries Above Minimal less than 3? Current?

- Page 71 APPENDIX SHUTDOWN APPENDIX MODULE CASCADE (STAND-ALONE BOILER) Boiler in Stop boiler Locking error stand-by pump Boiler error Locking Present? error? Blocking error Post pump Boiler Heat ready Demand? Calculate Start boiler boiler pump setpoint Boiler Temperature Clear demand Remove all higher than active modules setpoint...

- Page 72 APPENDIX SHUTDOWN APPENDIX MODULE CASCADE (STAND-ALONE BOILER): ADD/REMOVE MODULE Add module function Delay period for starting new module is 0? Open Air damper Air damper open? Are we allowed to add another dependent? Add dependent to the cascade demand Reload delay time Update demand flags...

- Page 73 APPENDIX SHUTDOWN APPENDIX BOILER CASCADE Stop system System in pump Locking error stand-by Boiler error Locking Present? error? Blocking error System Post pump Heat completed Demand? Start system Calculate system pump setpoint System Temperature Clear demand Remove all higher than active boilers setpoint Clear demand?

- Page 74 APPENDIX SHUTDOWN APPENDIX BOILER CASCADE: ADD/REMOVE BOILER Add Boiler function Delay period Are we allowed for starting new to add another boiler is 0? dependent? Add dependent from the Reload delay time cascade demand Update demand flags Remove Boiler function Delay period for Are we allowed to removing boiler...

- Page 75 APPENDIX SHUTDOWN APPENDIX ERROR CHECKING CYCLE Stand-by Boiler Min/Max Gas pressure Locking error switches are closed? Boiler Blocked Blocking Flue pressure error switch is closed Boiler Water Blocking pressure switch is error closed? Module High limit Locking error sensor is closed? Supply/return/ Blocking Flue sensor are...

- Page 76 RIELLO S.p.A. 37045 Legnago (VR) Tel. 0442630111 - Fax 044222378 RIELLO NORTH AMERICA 35 Pond Park Road Hingham, Massachusetts U.S.A. 02043 2165 Meadowpine Blvd Mississauga, Ontario Canada L5N 6H6 Tel. (905) 542-0303 www.riello.com/north-america/ www.rielloboilers.com The manufacturer strives to continuously improve all products. Appearance, dimensions, technical specifications, standard equipment and...

Need help?

Do you have a question about the Array AR 1000 and is the answer not in the manual?

Questions and answers