Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Grunbeck BOXER KX

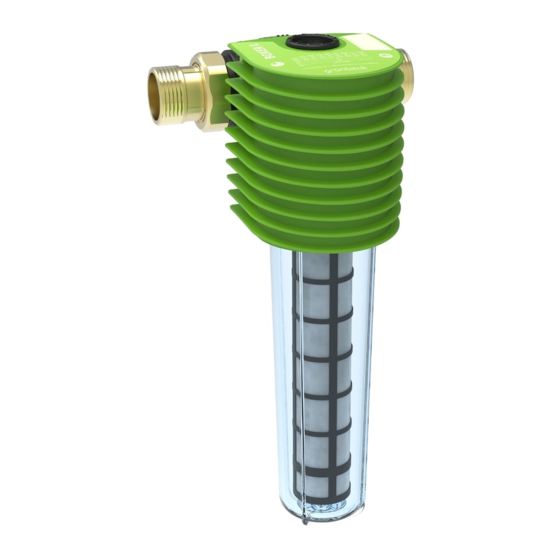

- Page 1 We understand water. Fine filter | BOXER KX/KDX ¾", 1", 1¼" Operation manual...

- Page 2 General Contact Germany International Sales +49 9074 41-145 Service +49 9074 41-333 service@gruenbeck.de Availability Monday to Thursday 7:00 am - 6:00 pm Friday 7:00 am - 4:00 pm We reserve the right to technical modifications. © by Grünbeck Wasseraufbereitung GmbH Original operation manual Edition: February 2022 Order no.: TD3-AK001_en_025...

-

Page 3: Table Of Contents

Table of contents Table of contents Checking the product ..... 24 Introduction ........5 Setting the month indicator .... 25 Setting the pressure reducer Validity of the manual ...... 5 (BOXER KDX) ....... 26 Product identification ....... 6 Handing over the product to the Symbols used ........ - Page 4 Table of contents 12.1 BOXER KX ........45 12.2 Pressure loss curves BOXER KX .. 46 12.3 BOXER KDX ........47 Operation log ......... 49 13.1 Start-up/Commissioning log ... 49 13.2 Maintenance ........50 4 | 52...

-

Page 5: Introduction

1.1 Validity of the manual This manual applies to the products below: ● Fine filter BOXER KX/KDX ¾" (DN 20) ● Fine filter BOXER KX/KDX 1" (DN 25) ● Fine filter BOXER KX/KDX 1¼" (DN 32) -

Page 6: Product Identification

Introduction 1.2 Product identification You can identify your product based on the product designation and the order no. indicated on the type plate. ► Check whether the products indicated in chapter 1.1 corre- spond to your product. The type plate is located on the filter head. Designation Designation Nominal connection diameter... -

Page 7: Symbols Used

Introduction 1.3 Symbols used Symbol Meaning Danger and risk Important information or requirement Useful information or tip Written documentation required Reference to further documents Work that must be carried out by qualified specialists only Work that must be carried out by technical service personnel only 1.4 Depiction of warnings This manual contains information and instructions that you must obey for your personal safety. -

Page 8: Demands On Personnel

Introduction Warning symbol and Consequences if the information/ signal word instructions are ignored DANGER Death or serious injuries Personal WARNING Possible death or serious injuries injury CAUTION Possible moderate or minor injuries Possible damage to components, the Damage to NOTE product and/or its functions, or an ob- property ject in its vicinity... - Page 9 Introduction Personnel Requirements • Professional training Qualified specialist • Electrical engineering • Knowledge of relevant standards and regulations • Sanitary engineering • Knowledge of detection and prevention of potential (HVAC and plumbing) hazards • Transport • Knowledge of statutory regulations on accident pre- vention •...

- Page 10 Introduction 1.5.3 Personal protective equipment You do not need any protective equipment to operate the product. ► Recommendation: Use hygienic gloves when replacing the filter element and cleaning the support mesh in order to pre- vent bacterial growth. Protective gloves 10 | 52...

-

Page 11: Safety

Safety Safety 2.1 Safety measures ● Only operate your product if all components are installed properly. ● Obey the local regulations on drinking water protection, acci- dent prevention and occupational safety. ● Do not make any changes, alterations or extensions on your product. -

Page 12: Product-Specific Safety Instructions

Safety 2.1.2 Groups of persons requiring protection ● Children must not play with the product. ● This product is not designed to be used by persons (including children) with reduced capabilities, lack of experience or lack of knowledge. Unless they are supervised, have been in- structed on the safe use of the product and understand the re- sulting hazards. -

Page 13: Product Description

Product description Product description 3.1 Intended use ● The fine filters BOXER KX and BOXER KDX are designed for filtering drinking water. ● The fine filter BOXER KDX with pressure reducer in addition is suitable for the adjustment of the outlet pressure on the withdrawal side in order to maintain the max. -

Page 14: Product Components

Product description 3.2 Product components Designation Designation Water meter screw Filter element connection O-ring of filter cylinder Seal Filter cylinder Connection flange Pressure reducer cartridge Flange seal Maintenance ring Screw connection kit Pressure gauge Filter head Support mesh 14 | 52... -

Page 15: Functional Description

Product description 3.3 Functional description The unfiltered drinking water flows into the filter through the inlet side and from the outside in through the filter element and to the pure water outlet. Thus, foreign particles of a size > 100 µm are re- tained. -

Page 16: Transport And Storage

Transport and storage Transport and storage 4.1 Transport ► Transport the product in its original packaging only. 4.2 Storage ► Protect the product from the impacts below when storing it: • Dampness, moisture • Environmental impacts such as wind, rain, snow, etc. •... -

Page 17: Installation

Installation Installation The installation of the product represents a major intervention into the drinking water system and must be carried out by a qualified specialist only. In accordance with DIN EN 806-2 and DIN EN 1717, the product is installed in the cold water pipe downstream of the water meter and upstream of distribution pipes and the appliances to be protected. - Page 18 Installation Installation example in vertical pipe Designation Designation Inlet shut-off valve Outlet shut-off valve 18 | 52...

-

Page 19: Requirements For The Installation Site

Installation 5.1 Requirements for the installation site ● The installation site must be frost-proof and ensure the filter's protection from chemicals, dyes, solvents and their vapours as well as from direct sunlight. ● The installation site must be away from heat sources (e.g. -

Page 20: Checking The Scope Of Supply

5.2 Checking the scope of supply Designation Designation Water meter screw connection Screw connection kit Seal Flange seal Connection flange Quick reference manual Fine filter BOXER KX or BOXER KDX ► Check the scope of supply for completeness and damage. 20 | 52... -

Page 21: Water Installation

Installation 5.3 Water installation The filter can be installed in a horizontal or vertical water pipe. 5.3.1 Preparing the pipe ► Install the water meter screw connection in the pipe. » The distance between the two seals must be 100 mm. 21 | 52... - Page 22 Installation 5.3.2 Installing the connection flange ► Check the flow direction given on site. 1. Rotate the connection flange into the position matching your flow direction (refer to the marking on the connection flange). » The arrow must correspond to the flow direction of the water. 2.

- Page 23 Installation 5.3.3 Mounting the filter Do not grease the flange seal. Greased flange seals can cause leaks and malfunctions. 1. Insert the hexagonal screws with washers into the recesses on the filter head. 2. Slide on the flange seal. 3. Screw the filter onto the connection flange. Tighten the 4 nuts crosswise.

-

Page 24: Start-Up/Commissioning

Start-up/Commissioning Start-up/Commissioning The initial start-up/commissioning of the product must be carried out by technical service personnel only. 6.1 Checking the product 1. Open the shut-off valves. 2. Open the closest water withdrawal point downstream of the filter to the maximum. »... -

Page 25: Setting The Month Indicator

Start-up/Commissioning 6.2 Setting the month indicator Via Grünbeck’s myProduct app, you will receive a message about the timely replacement of the filter element (refer to chapter 7.1). ► Set the maintenance ring to the month of the next mainte- nance (alternatively, to the month of the next replacement of the filter element –... -

Page 26: Setting The Pressure Reducer (Boxer Kdx)

Start-up/Commissioning 6.3 Setting the pressure reducer (BOXER KDX) The factory setting for the pressure reducer is 4 bar. You can change this value as follows: 1. Set the required outlet pressure on the pressure reducer handwheel (turn clockwise = pressure increase, turn counter- clockwise = pressure reduction). -

Page 27: Handing Over The Product To The Owner/Operating Company

Start-up/Commissioning The screw of the pressure reducer cartridge can come loose. ► Tighten the screw during annual maintenance (refer to chapter 8.4.2) and whenever required. 6.4 Handing over the product to the owner/ operating company ► Explain to the owner/operating company how the product works. -

Page 28: Operation

Operation Operation The filter is operated automatically and does not require any manual operation. ► Inspect the filter at regular intervals (refer to chapter 8.3). ► Replace the filter element at regular intervals (refer to chapter 8.4.1). ► Flush the filter after a temporary downtime (refer to chapter 10.1). -

Page 29: Maintenance And Repair

Maintenance and repair Maintenance and repair Maintenance and repair includes cleaning, inspection and mainte- nance of the product. The responsibility for inspection and maintenance is subject to local and national requirements. The owner/operating company is re- sponsible for compliance with the prescribed maintenance and re- pair work. -

Page 30: Intervals

Maintenance and repair 8.2 Intervals By way of regular inspections and maintenance, malfunctions can be detected in time and product failures might be prevented. ► As owner/operating company determine which components must be inspected and maintained at which intervals (load- dependent). -

Page 31: Inspection

Maintenance and repair 8.3 Inspection You as owner/operating company can carry out the regular inspec- tions yourself. ► Carry out an inspection at least every 2 months and proceed as follows to do so: 1. Check the installation for leaks and function. 2. -

Page 32: Maintenance

Maintenance and repair 8.4 Maintenance Regular work is required in order to ensure the proper functioning of the product in the long term. DIN EN 806-5 recommends regular maintenance to ensure trouble-free and hygienic operation of the product. Irregularly replaced filter element and contaminated WARNING support mesh ●... - Page 33 Maintenance and repair 8.4.1 Semi-annual maintenance Proceed as follows to carry out the semi-annual maintenance: 8.4.1.1 Preparing the replacement of the filter element 1. Place a bucket (min. 10 l) under the filter. 2. Close the shut-off valves on the inlet and on the outlet. 3.

- Page 34 Maintenance and repair 8.4.1.2 Replacing the filter element hygienically 1. Unscrew the filter cylinder by hand. Use a strap wrench, if needed. 2. Pull off the O-ring with the filter cylinder. 3. Pull off the used filter element from the support mesh. 4.

- Page 35 Maintenance and repair 5. Clean the support mesh in case of major impurities. a Pull the support mesh off downwards. b Rinse the support mesh with water. c Insert the support mesh into the filter head as far as it will go.

- Page 36 Maintenance and repair 9. Clean the filter cylinder with clear water. 10. Screw in the filter cylinder by hand as far as it will go – do not use a strap wrench. 11. Put the filter into operation (refer to chapter 6.1). 12.

-

Page 37: Consumables

Maintenance and repair 8.5 Consumables NOTE The filter element must not be cleaned. ● Risk of hygienic contamination. ► Dispose of the used filter element. Illustration Product Quantity Order no. 100 µm filter element 2 pieces 101 272 8.6 Spare parts For an overview of the spare parts, refer to our spare parts cata- logue at www.gruenbeck.com. - Page 38 Maintenance and repair Wearing parts are listed below: ● Seals (O-rings) Designation Designation O-ring of filter cylinder Filter cylinder O-ring of support mesh Pressure reducer cartridge Support mesh 38 | 52...

- Page 39 Maintenance and repair Tools required Order no. 105 805 Strap wrench (to remove the filter cylinder) 104 805 Pipe socket wrench (for pressure reducer cartridge) ► Have the seals replaced in the event of leaks, damage or deformations. ► Have defective or worn components replaced. 39 | 52...

-

Page 40: Troubleshooting

Troubleshooting Troubleshooting Contaminated drinking water due to stagnation WARNING ● Infectious diseases ► Have malfunctions eliminated immediately. 9.1 Observations Observation Explanation Remedy ► Fully open the shut-off Water pressure at the The shut-off valves are withdrawal point too not fully open valves low (pressure loss too ►... - Page 41 Troubleshooting Observation Explanation Remedy ► Check O-rings and Water loss in the Faulty joint system (leaks) seals for deformations or wear and tear ► Check filter head for damage ► Have leaky components replaced by a qualified specialist If a malfunction cannot be eliminated, the technical service person- nel can take further measures.

-

Page 42: Decommissioning

Decommissioning 10 Decommissioning It is not necessary to put your product out of operation. In case of longer absences, e.g. holidays, precautionary hygiene measures according to VDI 3810-2 and VDI 6023-2 must be taken in order to maintain drinking water hygiene after downtimes. 10.1 Temporary downtime ►... -

Page 43: Dismantling And Disposal

Dismantling and disposal 11 Dismantling and disposal 11.1 Dismantling The work described herein represents an intervention into your drinking water system. ► Have this work carried out by qualified specialists only. 1. Close the shut-off valves upstream and downstream of the filter. -

Page 44: Disposal

Dismantling and disposal 11.2 Disposal ► Obey the applicable national regulations. Packaging Danger to the environment due to incorrect dis- NOTE posal ● Packaging materials are valuable raw materials that can be reused in many cases. ● Incorrect disposal can cause hazards to the environment. ►... -

Page 45: Technical Specifications

Technical specifications 12 Technical specifications 12.1 BOXER KX Dimensions and weights BOXER KX Nominal connection diameter DN 20 DN 25 DN 32 Connection diameter ¾" 1" 1¼" Installation height up to centre of connection Installation length with/without 185/100 182/100 191/100 screw connection ≥... -

Page 46: Pressure Loss Curves Boxer Kx

ÜA registration number The Office of the Vienna Provincial R-15.2.3-21-17496 Government – City of Vienna Order no. 101 830 101 835 101 840 12.2 Pressure loss curves BOXER KX Designation Designation Pressure loss in bar Flow rate in m 46 | 52... -

Page 47: Boxer Kdx

Technical specifications 12.3 BOXER KDX Dimensions and weights BOXER KDX Nominal connection diameter DN 20 DN 25 DN 32 Connection diameter ¾" 1" 1¼" Installation height up to centre of connection Installation length with/without 185/100 182/100 191/100 screw connection ≥ 60 Distance to wall Installation depth up to centre of connection... - Page 48 Technical specifications Performance data ¾" 1" 1¼" Flow rate as per DIN EN 1567 m³/h Pore size µm Largest/smallest pore size µm 120/80 2 – 16 Operating pressure Nominal pressure PN 16 General data ¾" 1" 1¼" 5 – 30 Water temperature °C 5 –...

-

Page 49: Operation Log

Operation log 13 Operation log ► Document the initial start-up/commissioning and all maintenance activities. Fine filter BOXER ________ Serial no.: ______________ 13.1 Start-up/Commissioning log Customer Name Address Installation/Accessories Floor drain present Safety device Operating values Water pressure at raw water inlet Water pressure at water outlet Residential water meter reading m³... -

Page 50: Maintenance

Operation log 13.2 Maintenance Date Work performed Signature 50 | 52... - Page 52 Grünbeck Wasseraufbereitung GmbH Josef-Grünbeck-Str. 1 89420 Hoechstaedt/Germany +49 9074 41-0 +49 9074 41-100 info@gruenbeck.com For more information go to www.gruenbeck.com www.gruenbeck.com...

Need help?

Do you have a question about the BOXER KX and is the answer not in the manual?

Questions and answers