Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to "Model Description Chart" to match the pump material options.

637118-C for air section repair (see page 6).

637119-XX-C for fluid section repair (see page 4).

637167 abrasion resistant conversion kit is available for use in heavy

and abrasive material applications (see page 4).

PUMP DATA

Models

. . . . . . . . . . . .

see "Model Description Chart" for "-XXX".

Pump Type

. . . . . . . . .

Metallic Air Operated Double Diaphragm.

Material

. . . . . . . . . . . .

see "Model Description Chart".

Weight

. . . .

Aluminum

. . . . . . . . . . . .

Cast Iron

. . . . . . . . . . . . .

Stainless Steel

[add 8 lbs (3.63 kg) for cast iron air motor section]

Maximum Air Inlet Pressure

Maximum Material Inlet Pressure

Maximum Outlet Pressure

. . . . . . . . . .

Maximum Flow Rate (flooded inlet)

Maximum Particle Size

. . . . . . . . . . . .

Maximum Temperature Limits (diaphragm / ball / seal material)

Acetal

. . . . . . . . . . . . . . . . .

E.P.R. / EPDM

. . . . . . . . . . .

R

Hytrel

. . . . . . . . . . . . . . . .

Neoprene

. . . . . . . . . . . . . .

Nitrile

. . . . . . . . . . . . . . . . .

Polypropylene

. . . . . . . . . . .

Polyurethane

. . . . . . . . . . . .

R

Kynar

PVDF

. . . . . . . . . . .

R

Santoprene

. . . . . . . . . . .

PTFE

. . . . . . . . . . .

. . . . . . . . . . . . . . . . .

R

Viton

. . . . . . . . . . . . . . . .

Dimensional Data

. . . . . . . . . . . . . . . .

Noise Level @ 70 p.s.i., 60 c.p.m.

* The pump sound pressure levels published here have been updated to an Equivalent Continuous

Sound Level (L

) to meet the intent of ANSI S1.13-1971, CAGI-PNEUROP S5.1 using four micro-

Aeq

phone locations.

NOTICE: All possible options are shown in the chart. However, certain

combinations may not be recommended, consult a representative or the

factory if you have questions concerning availability.

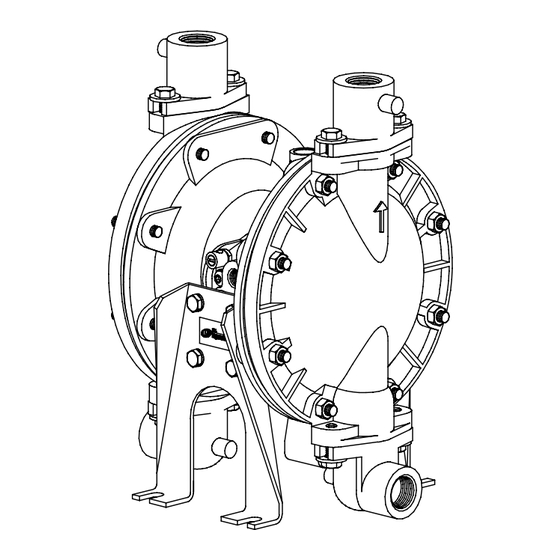

1" DIAPHRAGM PUMP

1:1 RATIO (METALLIC)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

19 lbs (8.62 kg)

31 lbs (14.06 kg)

. . . . . . . . .

36 lbs (16.33 kg)

. . . . . . . . .

120 p.s.i. (8.3 bar)

. . . . .

10 p.s.i. (0.69 bar)

120 p.s.i. (8.3 bar)

. . .

35 g.p.m. (133 l.p.m.)

1/8" dia. (3.2 mm)

10_ to 180_ F (-12_ to 82_ C)

-60_ to 280_ F (-51_ to 138_ C)

-20_ to 150_ F (-29_ to 66_ C)

0_ to 200_ F (-18_ to 93_ C)

10_ to 180_ F (-12_ to 82_ C)

35_ to 175_ F (2_ to 79_ C)

10_ to 150_ F (-12_ to 66_ C)

10_ to 200_ F (-12_ to 93_ C)

-40_ to 225_ F (-40_ to 107_ C)

40_ to 225_ F (4_ to 107_ C)

-40_ to 350_ F (-40_ to 177_ C)

see page 8.

. . . . .

64.5 db(A)*

CCN 81376642

DUAL MANIFOLD

6661XX-XXX-C

1'' DIAPHRAGM PUMP

MODEL DESCRIPTION CHART

Center Body Material, Threads

0 - Aluminum, N.P.T.F.

2 - Aluminum, BSP

1 - Cast Iron, N.P.T.F.

3 - Cast Iron, BSP

Fluid Cap / Manifold Material, Inlet / Outlet

(Steel Hardware)

(Stainless Steel Hardware)

0 - Aluminum, Single

A - Aluminum, Single

1 - Stainless Steel, Single

B - Stainless Steel, Single

2 - Cast Iron, Single

C - Cast Iron, Single

9 - Stainless Steel, Dual

D - Stainless Steel, Dual

Seat Material

1 - Aluminum

4 - Kynar PVDF

2 - 316 Stainless Steel

5 - Carbon Steel

3 - Polypropylene

8 - Hard 440 Stainless Steel

Ball Material

1 - Neoprene

6 - Acetal

2 - Nitrile

8 - Polyurethane

3 - Viton

A - Stainless Steel

4 - PTFE

C - Hytrel

5 - E.P.R.

E - Santoprene

Diaphragm Material

1 - Neoprene

3 - Viton

2 - Nitrile

5 - E.P.R.

4 - PTFE / Santoprene

FLUID SECTION SERVICE KIT SELECTION

EXAMPLE: Model # 666100-361-C

Fluid Section Service Kit # 637119-61-C

66610X-X-C

RELEASED:

REVISED:

10-15-10

(REV. AB)

SINGLE MANIFOLD

Figure 1

6661 X X - X X X - C

9 - Hytrel

B - Santoprene

6661XX - X X X - C

637119 - X X - C

Ball

Diaphragm

8-24-89

Advertisement

Table of Contents

Summary of Contents for ARO 66610 C Series

- Page 1 66610X-X-C OPERATOR’S MANUAL INCLUDING: OPERATION, INSTALLATION & MAINTENANCE RELEASED: 8-24-89 REVISED: 10-15-10 1” DIAPHRAGM PUMP (REV. AB) 1:1 RATIO (METALLIC) READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT. It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference. SERVICE KITS Refer to “Model Description Chart”...

-

Page 2: Operating And Safety Precautions

Certain chemicals will significantly reduce Use the pump grounding screw terminal provided. Use ARO maximum safe operating temperature. Consult the chemical part no. 66885-1 ground kit or connect a suitable ground wire manufacturer for chemical compatibility and temperature lim- (12 ga. -

Page 3: General Description

Lubricate (1) diaphragm rod and (2) “O” ring with Key-Lube grease. situation, it is recommended that a “Check Valve” be installed at the Use ARO pn / 98930-T bullet (installation tool) to aid in installation of air inlet. (2) “O” ring on (1) diaphragm rod. - Page 4 PARTS LIST / 66610X-X-C FLUID SECTION L 637119-XX-C Fluid Section Service Kits include: Balls (see BALL Option, refer to -XX in chart below), Diaphragms (see DIAPHRAGM Option, refer to -XX in chart below), plus items: 2, 3, 19 and 93706-1 Key-Lube grease. SEAT OPTIONS BALL OPTIONS 6661XX-XXX-C MATERIAL CODE...

- Page 5 PARTS LIST / 66610X-X-C FLUID SECTION . TORQUE REQUIREMENTS , COLOR CODE DIAPHRAGM BALL NOTE: DO NOT OVERTIGHTEN FASTENERS MATERIAL COLOR COLOR (14) Bolt, 25 - 30 ft lbs (33.9 - 40.7 Nm). OPTIONAL Acetal Orange 26 , (26) Bolts and (29) nuts, 120 - 140 in. lbs (13.6 - 15.8 Nm). 1/2 - 14 N.P.T.

- Page 6 Indicates parts included in 637118-C Air Section Service Kit. SERVICE KIT NOTE: Service Kit 637118-C is a general repair kit for all 1” and larger ARO diaphragm pump air motors. It contains extra “O” rings and extra parts that may not be needed to service this model.

-

Page 7: Pilot Valve

PARTS LIST / 66610X-X-C AIR MOTOR SECTION IMPORTANT BE CERTAIN TO ORIENT (115) SPACER LEGS AWAY FROM BLOCKING INTERNAL PORTS WHEN REASSEMBLING AIR SECTION. 105 , k 114 k 113 MAJOR VALVE See cross section detail, figure 4. Figure 3 102 k 103 k . -

Page 8: Troubleshooting

TROUBLE SHOOTING Product discharged from exhaust outlet. Low output volume, erratic flow, or no flow. Check for diaphragm rupture. Check air supply. Check tightness of (14) diaphragm screw. Check for plugged outlet hose. Check for kinked (restrictive) outlet material hose. Air bubbles in product discharge.

Need help?

Do you have a question about the 66610 C Series and is the answer not in the manual?

Questions and answers