Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

637118-C for air section repair (see page 6).

637138-63 for fl uid section repair (see page 4).

PUMP DATA

Models . . . . . . . . . . . . . . . . . . . 650718-C

Application . . . . . . . . . . . . . . Diesel Fuel, Kerosene, Aviation

Pump Type . . . . . . . . . . . . . . . U.L. Listed Metallic Air Operated

Material . . . . . . . . . . . . . . . . . . see Model Description Chart

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60.44 lbs (27.4 kgs)

Maximum Air Inlet Pressure . . . . . . . . 50 p.s.i.g. (3.4 bar)

Maximum Outlet Pressure . . . . . . . . . . 50 p.s.i.g. (3.4 bar)

Maximum Flow Rate

(fl ooded inlet)

Displacement / Cycle @ 100 p.s.i.g. . 0.64 gal. (2.42 lit.)

Maximum Particle Size . . . . . . . . . . . . . 1/4" dia. (6.4 mm)

Maximum Temperature Limits (diaphragm / ball / seal /

seat material)

Acetal . . . . . . . . . . . . . . . . . . . . 10° to 180° F (-12° to 82° C)

Kynar® PVDF . . . . . . . . . . . . . . 10° to 200° F (-12° to 93° C)

Viton® . . . . . . . . . . . . . . . . . . . . -40° to 350° F (-40° to 177° C)

Dimensional Data . . . . . . . . . . . . . . . . . . . see page 8

Noise Level @ 70 p.s.i., 60 c.p.m. . . . . . . 77.7 db(A)

The pump sound pressure levels published here have been updated to

an Equivalent Continuous Sound Level (L

S1.13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

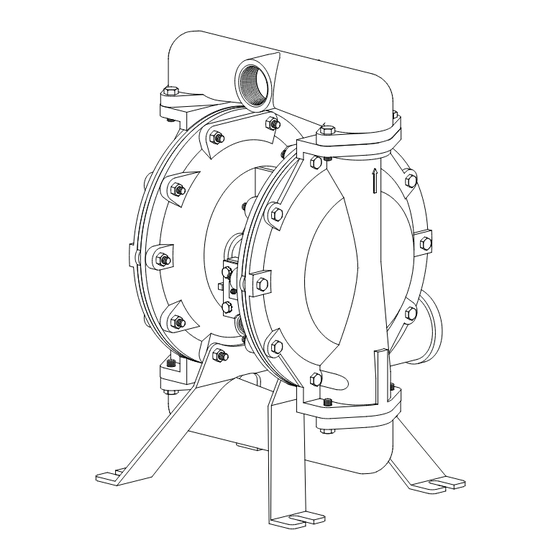

1-1/2" DIAPHRAGM PUMP

U.L. LISTED, 1:1 RATIO, METALLIC

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

Fuel, Fuel Oil and Unleaded Fuel

Double Diaphragm for use with

Petroleum Product Dispensing

Systems

. . . 75 g.p.m. (283.9 l.p.m.)

) to meet the intent of ANSI

Aeq

© 2010

CCN 15201429

MODEL DESCRIPTION CHART

Diaphragm Material

8 - Viton

Center Body Material

Aluminum

Fluid Connection

1-1/2 - 11-1/2 N.P.T.F. - 1

Fluid Cap / Manifold Material, Hardware

Aluminum / Aluminum, Steel hardware

Seat Material

Kynar PVDF

Ball Material

Acetal

650718-C

RELEASED:

8-11-03

12-2-10

REVISED:

(REV. 08)

Figure 1

65071 8 - C

Advertisement

Table of Contents

Summary of Contents for ARO ARO 650718-C

- Page 1 OPERATOR’S MANUAL INCLUDING: OPERATION, INSTALLATION & MAINTENANCE 1-1/2" DIAPHRAGM PUMP It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference. SERVICE KITS 637118-C for air section repair (see page 6). 637138-63 for fl uid section repair (see page 4).

-

Page 2: Operating And Safety Precautions

OPERATING AND SAFETY PRECAUTIONS READ, UNDERSTAND AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE. EXCESSIVE AIR PRESSURE HAZARDOUS MATERIALS STATIC SPARK HAZARDOUS PRESSURE EXCESSIVE AIR PRESSURE. Can cause per- WARNING sonal injury, pump damage or property damage. Do not exceed the maximum inlet air pressure as stated on the pump model plate. -

Page 3: General Description

Loctite® is a registered trademark of Henkel Loctite Corporation ARO® is a registered trademark of Ingersoll-Rand Company 262™, 271™ and 572™ are trademarks of Henkel Loctite Corporation Kynar® is a registered trademark of Arkema Inc. Viton® is a registered trademark of the DuPont Company... -

Page 4: Fluid Section Disassembly

PARTS LIST / 650718-C FLUID SECTION 637138-63 fl uid section service kits include: Balls (item 22), diaphragms (item 7) plus items 2, 3, 19 and 93706-1 Key-Lube grease (page 6). Item Description Qty Part No. (size) 1 Rod (1) 98720-1 2 “O”... - Page 5 PARTS LIST / 650718-C FLUID SECTION FOR THE AIR MO- TOR SECTION, SEE Fluid side Air side Cross section view of diaphragm. 650718-C (en) PAGES 6 & 7. ASSEMBLY TORQUE REQUIREMENTS NOTE: DO NOT OVERTIGHTEN FASTENERS. (14) Diaphragm screw, 65 - 70 ft. lbs (88.1 - 94.9 Nm). (26) Bolt, 240 - 280 in.

- Page 6 PARTS LIST / 650718-C AIR MOTOR SECTION Indicates parts included in 637118-C air section repair kit. Item Description (Qty) Part No. (size) 101 Motor Body (1) 93161 (includes items 195) 102 “O” Ring (2) 92960 (0.07” x 1.25” o.d.) 103 Sleeve (1) 94528 104 Retaining Ring (2) Y145-26...

- Page 7 PARTS LIST / 650718-C AIR MOTOR SECTION IMPORTANT BE CERTAIN TO ORIENT (115) SPACER LEGS AWAY FROM BLOCKING INTERNAL PORTS WHEN REASSEMBLING AIR SECTION. MAJOR VALVE CROSS SECTION DETAIL Figure 4 650718-C (en) MAJOR VALVE See cross section detail, fi gure 4. ASSEMBLY TORQUE REQUIREMENTS NOTE: DO NOT OVERTIGHTEN FASTENERS.

-

Page 8: Troubleshooting

Product discharged from exhaust outlet. Check for diaphragm rupture. Check tightness of (14) diaphragm screw. Air bubbles in product discharge. Check connections of suction plumbing. Check “O” rings between intake manifolds and fl uid caps. Check tightness of (14) diaphragm screw. Dimensions shown are for reference only, they are displayed in inches and millimeters (mm).

Need help?

Do you have a question about the ARO 650718-C and is the answer not in the manual?

Questions and answers