Summary of Contents for Inficon TC3000L

- Page 1 Translation of the original operating instructions TC3000L Large rigid test chamber for ELT3000 Catalog No. 600-101 From software version mimc95en1-01-(2112)

- Page 2 INFICON GmbH Bonner Strasse 498 50968 Cologne, Germany...

-

Page 3: Table Of Contents

4.2 Markings on the device........................... 13 4.3 Technical data ............................ 14 5 Installation.............................. 15 6 Operation............................... 18 6.1 Carrying out leak testing ......................... 20 7 Cleaning and maintenance .......................... 21 8 Sending in the device........................... 23 8.1 Disposal .............................. 23 9 Declaration of Contamination ........................ 24 10 Declarations of Conformity ......................... 25 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 4: About This Manual

Imminent hazard resulting in death or serious injuries WARNING Hazardous situation resulting in potential death or serious injuries CAUTION Hazardous situation resulting in minor injuries NOTICE Hazardous situation resulting in damage to property or the environment 4 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 5: Definition Of Terms

* Helium equivalent leak rate for DMC with a pressure difference of 1000 mbar versus 0 mbar. Gas Control Unit (basic unit, operating unit) Gas Detection Unit Dimethyl carbonate, typical solvent in battery electrolyte. CAS No. 616-38-6 MSDS Material Safety Data Sheet TC3000L-Operating-instructions-mimc95en1-01-(2112) 5 / 28... -

Page 6: Safety

Avoid the following unintended uses: • Testing of partially or fully charged cells and batteries without further safety measures. • Use outside the technical specifications, see "Technical Data". • Testing of non-vacuum Li-ion cells, batteries or other test objects. 6 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) - Page 7 • Use of unauthorized accessories or spare parts. • Mounting by untrained or unauthorized personnel. Only trained personnel or INFICON employees are permitted to carry out the assembly. • Interchanging the exhaust air ("INLET") and supply air ("VENT") lines on the ELT3000.

-

Page 8: Duties Of The Operator

Personnel qualifications • Only allow instructed personnel to work with the test chamber and the battery leak detector. The instructed personnel must have received appropriate training. This includes knowledge of the dangers posed by leaking electrolyte/solvent. 8 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 9: Dangers

► When nitrogen or argon is used as a purge gas, it can cause asphyxiation at dangerous room concentrations. Suitable measures must be taken. The pressure in the gas line to the purge gas connection must not exceed 100 mbar over atmospheric pressure. An exhaust gas line must be connected. TC3000L-Operating-instructions-mimc95en1-01-(2112) 9 / 28... - Page 10 ► Remove coarse soiling with a dust-free cloth. This soiling can falsify the measurement results. The device features a purging function which can be carried out in case of minor soiling, see ELT3000 instructions "Purging the device". Use personal protective equipment. 10 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

-

Page 11: Scope Of Delivery, Transport

INFICON Scope of delivery, transport | 3 3 Scope of delivery, transport Scope of delivery Item Quantity Test chamber TC3000L Operating instructions Insulator Inline Filter "VENT" hose "INLET" hose Angle clips ► Check the scope of delivery after receipt of the product to make sure it is complete and it has no visible damage. -

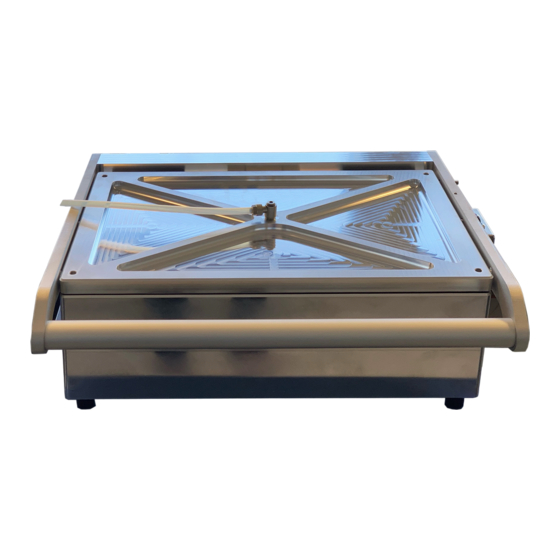

Page 12: Description

4 | Description INFICON 4 Description TC3000L overview Fig. 1: TC3000L "INLET" connection Connection for optional auxiliary pump "VENT" connection Hinge (spring-mounted) Proximity switch with red-green display Hinge (dampened) (for automatic measurement start) Insulator Hinge (spring-mounted) 12 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 13: Function

The markings on the device have the following meanings: Device cannot be disposed of as normal domestic waste. Note: Only put objects that are obviously undamaged and vacuum-tight in the device. Warning about hand injuries Read operating instructions TC3000L-Operating-instructions-mimc95en1-01-(2112) 13 / 28... -

Page 14: Technical Data

1080 hPa to 1 hPa Ambient conditions Temperature range (°C) 10 °C to 40 °C Relative humidity (%) 80 % at 30 °C, linear decrease to 50 % at 40 °C Height above sea level (m) 2000 m Degree of contamination 14 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 15: Installation

► Do not place the test chamber on the gas control unit. ► Use non-slip rubber bumpers for the device feet. NOTICE Property damage due to improper installation It is recommended to have the installation carried out by INFICON or by trained personnel. TC3000L-Operating-instructions-mimc95en1-01-(2112) 15 / 28... - Page 16 ELT3000, the valve can be switched via one of the PLC outputs. Please note that the valve is switched with 24V, with a maximum current consumption of 0.75 A. You can connect a suitable pump to the valve via a corrugated hose and adapter. For this 16 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

- Page 17 40 L/min (up to 1000 L/min). The external pump is not operated via the ELT3000, but must be permanently operated externally. TC3000L-Operating-instructions-mimc95en1-01-(2112) 17 / 28...

-

Page 18: Operation

► Make sure that the test chamber is always free of pointed foreign bodies. CAUTION Warning about hand injuries ► Only open and close the test chamber when your fingers are outside the pivoting range of the test chamber. 18 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) - Page 19 Property damage due to accumulation or blockage in detachable parts with solvents Accumulation or blockage in detachable parts due to solvents lead to functional problems. ► Replace the particle filter as needed or annually. ► Replace all gaskets and hoses as necessary, otherwise annually. TC3000L-Operating-instructions-mimc95en1-01-(2112) 19 / 28...

-

Page 20: Carrying Out Leak Testing

ð The green LED lights up when a leak less than the configured setpoint has been detected. You can now open the lid and remove the test object. Skin contact with electrolytes when cleaning the test chamber or removing leak-tested test objects should be avoided. 20 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 21: Cleaning And Maintenance

► Carefully remove minor, visible contamination of the test chamber with alcohol. ► Avoid contact with the electrolyte. ► Before sending the test chamber to INFICON Service, fill in a contamination declaration, also see "Sending in the device [} 23]". INFICON Service then decides whether the test chamber must be sent to a decontamination center beforehand. - Page 22 ► Replace the particle filter annually or as needed, e.g. noticeable solvent accumulation or blockage. O ring ► Replace the O-ring of the test chamber in case of functional problems and external damage. Insulator ► Replace the insulator in case of mechanical damage and wear. 22 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

-

Page 23: Sending In The Device

The test chamber consists of materials that can be recycled. This option should be exercised to prevent waste and also to protect the environment. During disposal, observe the environmental and safety regulations of your country. The test chamber cannot be disposed of as normal domestic waste. TC3000L-Operating-instructions-mimc95en1-01-(2112) 23 / 28... -

Page 24: Declaration Of Contamination

9 | Declaration of Contamination INFICON 9 Declaration of Contamination 24 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112) -

Page 25: Declarations Of Conformity

INFICON Declarations of Conformity | 10 10 Declarations of Conformity TC3000L-Operating-instructions-mimc95en1-01-(2112) 25 / 28... - Page 26 10 | Declarations of Conformity INFICON 26 / 28 TC3000L-Operating-instructions-mimc95en1-01-(2112)

Need help?

Do you have a question about the TC3000L and is the answer not in the manual?

Questions and answers