Table of Contents

Advertisement

Quick Links

INSTALLATION AND MAINTENANCE INSTRUCTIONS

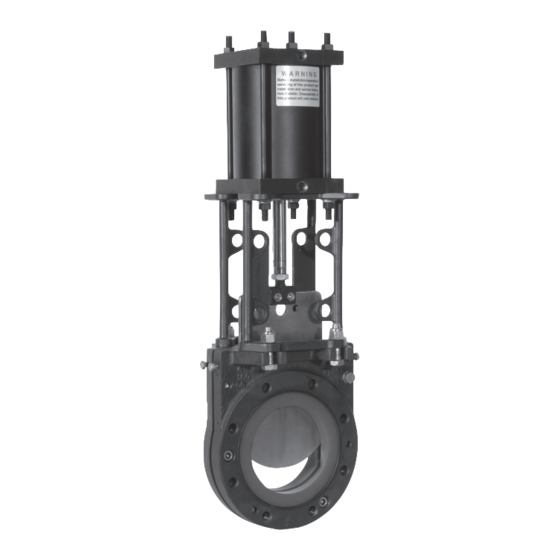

Figure XS150 - ULV (Urethane Lined Valve)

®

FABRI-VALVE

TABLE OF CONTENTS

0.0 GENERAL ................................................................................................................... 2

1.0 INSTALLATION ........................................................................................................... 3

2.0 OPERATION AND ADJUSTMENT .............................................................................. 6

3.0 MAINTENANCE ........................................................................................................... 6

3.1 Periodic Inspection................................................................................................. 6

3.2 General .................................................................................................................. 7

3.3 Lifting ..................................................................................................................... 8

3.4 Packing Adjustment ............................................................................................... 9

3.5 Lubrication (Stem & Stem nut) .............................................................................. 10

3.6 Electric Actuators ................................................................................................... 10

3.7 Seal Replacement.................................................................................................. 10

3.8 Setting of Valve Stroke........................................................................................... 11

3.9 Transport and Storage ........................................................................................... 11

4. SERVICE / SPARE PARTS ........................................................................................... 12

4.1 Recommended Mating Flange Fasteners .............................................................. 12

5. EXPLODED VIEW ......................................................................................................... 13

http://www.engvalves.com/

BI-DIRECTIONAL HIGH PERFORMANCE KNIFE GATE VALVE

Page 1 of 13

Engineered Valves

1110 Bankhead Avenue

Amory, MS 38821

Tel: (662) 256-7185

Fax: (662) 256-7932

Rev. 5 05/16/08

Advertisement

Table of Contents

Summary of Contents for ITT FABRI-VALVE XS150

-

Page 1: Table Of Contents

Engineered Valves 1110 Bankhead Avenue Amory, MS 38821 Tel: (662) 256-7185 Fax: (662) 256-7932 INSTALLATION AND MAINTENANCE INSTRUCTIONS Figure XS150 - ULV (Urethane Lined Valve) ® FABRI-VALVE BI-DIRECTIONAL HIGH PERFORMANCE KNIFE GATE VALVE TABLE OF CONTENTS 0.0 GENERAL ........................2 1.0 INSTALLATION ...................... -

Page 2: General

0.0 GENERAL The latest edition of this manual can be found on the website listed on page 1 or the back page. 0.1 Safety The safety precautions in these operating instructions are specially marked with the standard symbol for danger when non-observance could result in personal injury, loss of life or property damage. -

Page 3: Installation

0.1.5 Unauthorized reconstruction and manufacture of spare parts Reconstruction or modification of the valve or any component is only permissible after consulting the manufacturer. Genuine spare parts and accessories authorized by the manufacturer serve to maintain safety. The use of other parts can annul all liability for the consequences. 0.1.6 Inadmissible modes of operation The operating limits given on the identification tag and in the data sheet may not be exceeded under any circumstances. - Page 4 Fabri-Valve XS150 ULV Recommended Flange Gaskets Note: The XS150 includes an integrated O-ring seal. Flange Gaskets are not required. In some cases a gasket may be used if the o-ring is damaged or missing.

- Page 5 FOR A SPECIFIED PRESSURE. EXCESSIVE PRESSURE COULD RESULT IN SERIOUS PERSONAL INJURY OR MAY CAUSE DAMAGE TO THE VALVE AND/OR CYLINDER. AIR REGULATORS AND AIR FILTERS ARE AVAILABLE FROM YOUR ITT DISTRIBUTOR. Page 5 of 13 http://www.engvalves.com/ Rev. 5 05/16/08...

-

Page 6: Operation And Adjustment

2.0 OPERATION AND ADJUSTMENT 2.1 All valves are pressure and seat tested before shipment and an inspection tag is attached. The Packing may require some adjusting after line pressure is up to normal. Tighten the packing bolts just enough to stop leakage. All four packing screws must be adjusted equally to maximize the life of the valve. -

Page 7: General

3.2 General 3.2.1 Maintenance on the XS150-ULV is a straightforward procedure. To assist in the proper assembly of the valve after maintenance, it is recommended that the user NOT make adjustments to the stem clamp (on actuated valves) or the upper stop collar (on manually operated valves.) This will help insure that the valve stroke is correctly set upon re- assembly. -

Page 8: Lifting

3.3 Lifting - General DO NOT LIFT VALVES BY THE HAND WHEEL USE LIFTING EQUIPMENT RATED FOR THE WEIGHT OF THE VALVE ASSEMBLY Route lifting strap under yoke Attach lifting eyes here DO NOT remove or adjust retaining nuts Page 8 of 13 http://www.engvalves.com/ Rev. -

Page 9: Packing Adjustment

3.4 PACKING ADJUSTMENT (Injectable) SPECIAL PRECAUTIONS MUST BE TAKEN BEFORE REMOVING THE PACKING BOLTS. WEAR PROTECTIVE CLOTHING AND EQUIPMENT NORMALLY REQUIRED TO AVOID INJURY FROM THE PARTICULAR FLUID IN THE LINE. WEAR PROTECTIVE CLOTHING AND PROTECTIVE EQUIPMENT THAT SAFEGUARDS EYES, FACE, HANDS, ALL SKIN AND LUNGS. -

Page 10: Lubrication (Stem & Stemnut)

3.5 LUBRICATION (STEM & STEMNUT) The stem and stemnut are lubricated at the factory before shipment. However, these parts should be lubricated periodically to prevent wear and to minimize operating forces. Some recommended lubricants are: CHEVRON INDUSTRIAL GREASE-MEDIUM TEXACO MOLYTEX GREASE #2 MOLY XL 47-F2-75 FEL-PRO C5-A COMPOUND 3.6 VALVES WITH ELECTRIC ACTUATORS... -

Page 11: Setting Of Valve Stroke

If the valve is to be stored for an extended period of time before installation, the valve should be stored in accordance with ITT’s Long Term Storage Procedure. Contact the manufacturer using the information on page 1 to obtain this procedure. -

Page 12: Service / Spare Parts

4.0 SERVICE / SPARE PARTS Size Seal Material Packing Liner One Piece Perimeter & Chest Seal Inches Aflas Viton EPDM Urethane 155512 155524 155500 137375 159800 155513 155525 155501 “ 159801 155514 155526 155502 “ 159802 155515 155527 155503 “ 159803 155516 155528... -

Page 13: Exploded View

5. EXPLODED VIEW Page 13 of 13 http://www.engvalves.com/ Rev. 5 05/16/08...

Need help?

Do you have a question about the FABRI-VALVE XS150 and is the answer not in the manual?

Questions and answers