Summary of Contents for MEDAP FINA VAC P 350

- Page 1 OPERATING INSTRUCTIONS TAPPING UNIT PAEDIATRICS MEDAP-FINA VAC P 350 GA 5752 2133 GB 21...

- Page 2 Subject to technical modification! Illustrations and technical specifications may vary slightly from those in these operating instructions as a result of ongoing product development. V21 2020-07 GA 5752 2133 GB 21...

-

Page 3: Table Of Contents

ATMOS products .......................... 7 Overview ..............................8 1.5.1 FINA VAC P 350 ........................... 8 1.5.2 Versions of the FINA VAC P 350 ....................9 Basic requirements ............................. 9 1.6.1 Use in accordance with the intended purpose ................9 1.6.2 Applicable standards ........................10 1.6.3... - Page 4 Table of contents 3.2.2.1 General ........................17 3.2.2.2 Version A ........................17 3.2.2.3 Version B ......................... 17 3.2.3 Assembly of the septic fluid jar and accessories ............... 18 Operation ..............................20 Function test ............................. 20 Working with the product .......................... 20 Taking the unit out of operation ......................

-

Page 5: Introduction

Introduction Foreword Introduction Foreword Your facility has selected the leading-edge medical technology made by ATMOS. We sincerely appreciate the trust you have placed in us. How to use these operating instructions These operating instructions are provided to familiarise you with the features of this ATMOS product. -

Page 6: Definitions

Introduction Symbols used 1.2.3 Definitions 1.2.3.1 Design of safety notes Pictogram Descriptor Text The text for the safety note DANGER! describes the type of risk and Indicates a direct and immediate risk to how to avert it. persons which may be fatal or result in most serious injury. -

Page 7: Disposal

Introduction Disposal Symbols Identification Labelling in compliance with the ISO 15223-1 standard. Symbol for ‘Name and address of the manufacturer as well as date of manufacture’. Packaging label. Symbol for ‘Keep dry’. Packaging label. Symbol for ‘Caution! Do not overturn’. Packaging label. -

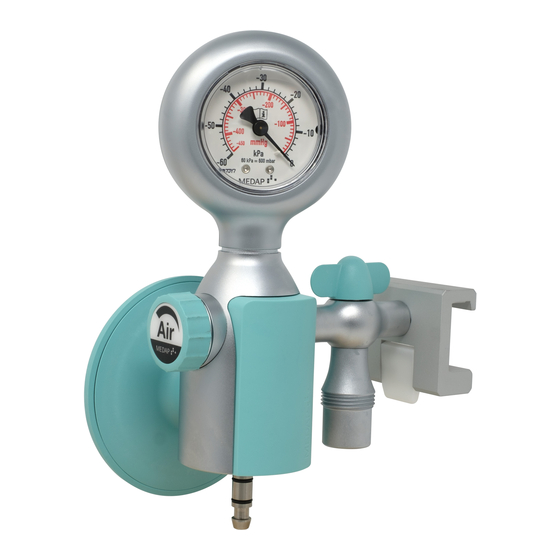

Page 8: Overview

Overview Overview 1.5.1 FINA VAC P 350 1 1 0 0 Fig. 1: Overview of the FINA VAC P 350 1 Vacuum gauge 7 Tube connector of mechanical overflow protection 2 Housing 8 Mechanical overflow protection 3 Control valve 9 NIST connection... -

Page 9: Versions Of The Fina Vac P 350

Introduction Basic requirements 1.5.2 Versions of the FINA VAC P 350 Fig. 2: Overview of the FINA VAC P 350 versions 1 Version A 6 NIST screw connection Tapping unit with integrated gas pin 7 Connection tube 2 Plug 8 Locking lever... -

Page 10: Applicable Standards

Aspiration of secretion, blood, serous fluids and vomit along with any contained particles Medical indications / The FINA VAC P 350 is used to ensure the precise adjustment of application: the vacuum and is particularly well suited for bronchial aspiration in paediatrics and neonatology. -

Page 11: Versions Of The Fina Vac P 350

Version B: Tapping unit with rail clamp and NIST connection • FINA VAC P 350 is designed for mounting onto a 25 x 10 mm equipment rail and is supplied via a NIST connection with vacuum from a terminal unit connected using a connection tube with gas probe. -

Page 12: Hydrophobic Bacterial And Viral Filter

Introduction Basic requirements 1.6.5.2 Hydrophobic bacterial and viral filter In its function as overflow protection device, the hydrophobic bacterial and viral filter protects the product against the ingress of particles, fluid and foam. In its function as bacterial and viral filter, it protects the product against the ingress of bacteria and viruses. -

Page 13: Mechanical Overflow Protection

Introduction Basic requirements Prerequisites • The inner diameter of the utensil's connector must match the outer diameter of the fingertip. • The utensil must be sterilisable or a sterile single-use item. • Biocompatibility • For endobronchial extraction, a utensil with side openings must be used. 1.6.5.7 Mechanical overflow protection The mechanical overflow protection device protects the product against the ingress of fluids. -

Page 14: Safety Notes

Safety notes General safety notes Safety notes General safety notes WARNING! Risk of injury! Hazard resulting from incorrect handling. Be absolutely sure to observe the operating instructions for all the products used in the configuration. WARNING! Risk of injury! ATMOS products may be used only when fully functional . Ensure that this ATMOS product is fully func tional and in good working order prior to use. - Page 15 Safety notes Product safety notes WARNING! Measuring accuracy / oversuction! The product may only be operated in a vertical position. WARNING! Backflow of aspirated secretion! In the event of oversuction, the aspirated secretion may flow back to the patient if there is secretion still left in the suction tube.

-

Page 16: Initial Operation

Initial operation Equipment inspection Initial operation Equipment inspection DANGER! Product inspection! Only product parts which are in perfect condition can ensure proper functioning of the product. The product parts will thus have to be carefully inspected before mounting. DANGER! Infection hazard! Contaminated components may be hazardous to the patient's health. -

Page 17: Connection To The Terminal Unit

Initial operation Mounting 3.2.2 Connection to the terminal unit 3.2.2.1 General NOTE Please refer to the manufacturer’s instructions for the particular terminal unit for information on connecting the gas probe to the terminal unit. 3.2.2.2 Version A Tapping unit with integrated gas pin ... -

Page 18: Assembly Of The Septic Fluid Jar And Accessories

Initial operation Mounting 3.2.3 Assembly of the septic fluid jar and accessories WARNING! Tensile forces! The connected accessories must not exert any mechanical forces which could adversely affect the secure fit of the product. WARNING! Tensile forces! Hold the basic unit with one hand when installing or removing accessories in order to compensate for the tensile forces which are created. - Page 19 Initial operation Mounting Connection of the hydrophobic bacterial and viral filter The connection tubes (1) and (2) are plugged onto the tube connectors of the hydrophobic bacterial and viral filter (3). Check the flow direction of the bacterial and viral filter.

-

Page 20: Operation

Operation Function test Operation Function test DANGER! Function check! The product is used in the treatment of patients. Any restriction in the unit's performance can result in serious complications in treatment. Perform a complete function check every time before using the unit. Prior to use, the following function check must be performed: Version A: Tapping unit with integrated gas pin •... - Page 21 Operation Working with the product Setting the vacuum for treatment Open the shut-off valve (1) completely for operation. For this purpose, turn the valve by 90° so that it is in line with the gas supply. Close the control valve (2) until it stops. Turn in a clockwise direction.

-

Page 22: Taking The Unit Out Of Operation

Taking the unit out of operation Completing the aspiration process Taking the unit out of operation Completing the aspiration process NOTE Please refer to the manufacturer’s instructions for the particular terminal unit for information on detaching the gas probe from the terminal unit. ... -

Page 23: Cleaning And Disinfection

Cleaning and disinfection General Cleaning and disinfection General The product must be wipe or spray disinfected after every use. DANGER! Risk due to incorrect use of detergents and disinfectants! It is strictly advised to observe the manufacturer’s instructions regarding how to use the detergents and disinfectants as well as to observe the valid hospital hygiene rules. -

Page 24: Cleaning

Cleaning and disinfection Cleaning Cleaning 6.2.1 General NOTE Use only all-purpose cleaners which are slightly alkaline (soap solution) and contain surfactants and phosphates as the active cleaning agents. In the event of heavily contaminated surfaces, use concentrated all-purpose detergent. CAUTION! Improper cleaning can cause property damage! Residues of physiological saline solutions (e.g. -

Page 25: Suitable Disinfectants

Cleaning and disinfection Product-specific safety notes CAUTION! Material damage due to excessive exposure times! Exceeding the specified exposure time of the disinfectant may damage the surfaces. Observe the exposure time specified by the disinfectant manufacturer. 6.3.2 Suitable disinfectants Only surface disinfectants based on the following combinations of active ingredients may be used for disinfection: •... - Page 26 Cleaning and disinfection Product-specific safety notes DANGER! Risk to patient! Oversuction of products results in them no longer being functional. There is considerable risk to the patient if the tapping unit is not cleaned properly after being exposed to oversuction, as safety equipment could be clogged. After oversuction, products must be dismantled and cleaned thoroughly by authorised service staff.

-

Page 27: Maintenance

Maintenance General Maintenance General Maintenance, repairs and periodic tests may only be carried out by persons who have the appropriate technical knowledge and are familiar with the product. To carry out these measures, the person must have the necessary test devices and original spare parts. ATMOS recommends: Work should be carried out by an authorised ATMOS service partner. -

Page 28: Repairs

Maintenance Repairs Defect Source of malfunction Corrective actions Vacuum gauge does not fit An attempt has been made to Always insert vacuum gauge connect the vacuum gauge to with a 90° twist and then turn it the tapping unit with the scale to the front pointing forwards Vacuum gauge for the... - Page 29 Maintenance Sending in the device The device must be well padded and packed in suitable packaging. Place form QD 434 ‘Delivery complaint / return shipment’ and the respective decontamination certificate in an envelope. Affix the envelope to the outside of the package. ...

-

Page 30: Technical Specifications

Technical specifications General Technical specifications General Classification as per Annex IX to Directive 93/42/EEC Class IIa Ambient conditions Temperature: Shipping / storage −15 °C to +50 °C Temperature: Operation +10 °C to +40 °C Relative humidity: Shipping / storage 10% to 95% Relative humidity: Operation 30% to 75% Atmospheric pressure: Shipping / storage 700 hPa to 1060 hPa... -

Page 31: Approved Accessories

Mechanical overflow protection 5752 3330 Aspiration set for equipment rail / 1 l 5752.5669 Aspiration set for wall mount / 1 l 5750 8021 Tube holder VAC connection tube with NIST screw connection (see MEDAP tube list) Tab. 7: Accessories Consumables 5750 0630 Hydrophobic bacterial and viral filter 006.0009.0 Suction tube, silicone, Ø 6 mm, 1 m 000.0347.0... - Page 32 Manufacturer: ATMOS MedizinTechnik GmbH & Co. KG Ludwig-Kegel-Str. 16 79853 Lenzkirch GERMANY Telephone: +49 7653 689-0 www.atmosmed.com...

Need help?

Do you have a question about the FINA VAC P 350 and is the answer not in the manual?

Questions and answers