Summary of Contents for Unverferth PARKER 1042

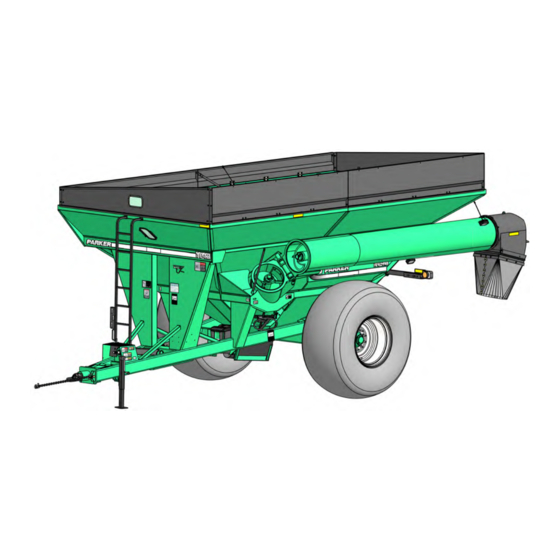

- Page 1 Grain Handling CORNER AUGER GRAIN CART MODELS 1042 Model 1042 - Serial Number D64600100 & Higher Part No. 2007593...

- Page 2 — Introduction Parker 1042 Foreward This symbol identifies important safety messages. When you see it, read the message that follows and be alert to the possibility of personal injury. Remember, safety instructions stated in this manual are for your protection. Read them care- fully and follow them closely when working around or using this machine.

- Page 3 The information, specifications, and illustrations in the manual are based on information available at the time it was written. Due to continuing improvements in the design and manufacture of Unverferth products, all specifications and information contained herein are subject to change without notice.

-

Page 4: Table Of Contents

— Introduction Parker 1042 Table of Contents Section I Safety General Hazard Information ......................1-2 Safety Decals ..........................1-3 Following Safety Instructions ......................1-5 Before Servicing..........................1-6 Before Operating ..........................1-6 During Operation ..........................1-7 Before Transporting ......................... 1-7 During Transport..........................1-7 Drive Line Safety .......................... - Page 5 — Introduction Parker 1042 Table of Contents Section II Set Up Set Up Checklist ..........................2-2 Basic Cart Set Up - Folding Side Extension ................. 2-3 Basic Cart Set Up - Transport Lighting and Markings ..............2-4 Basic Cart Set Up - SMV Emblem ....................2-4 Basic Cart Set Up - Auger Rest Retainer Removal ..............

- Page 6 — Introduction Parker 1042 Table of Contents Section III Operation Operating Checklist ......................... 3-2 Preparing Tractor..........................3-2 Preparing Cart - Hardware ......................3-3 Preparing Cart - Pivot Pins......................3-3 Preparing Cart - Hitch........................3-3 Preparing Cart - Auger........................3-3 Preparing Cart - Soft Start System ....................3-4 Preparing Cart - Hydraulic System ....................

- Page 7 — Introduction Parker 1042 Table of Contents Section IV Maintenance Lubrication............................4-2 Gearbox Lubrication ........................4-3 Seasonal Storage ..........................4-3 Adjusting Cleanout Door ......................... 4-4 Auger Driveline..........................4-6 Bearings............................ 4-6 Driveline Replacement ......................4-6 Auger System - Lower Auger Disassembly ................... 4-9 Auger System - Lower Auger Assembly ..................

- Page 8 — Introduction Parker 1042 Table of Contents Section V Parts Final Assembly ........................... 5-2 Touch-Up Paint........................... 5-3 Rigid Axle Single Wheel ......................5-4 Adjustable Axle Single Wheel ....................5-6 Adjustable Axle - Dual Wheels....................5-8 Track Bundle Components ....................... 5-10 Track Axle Components ......................

- Page 9 — Safety Parker 1042 Section I Safety General Hazard Information ......................1-2 Safety Decals ..........................1-3 Following Safety Instructions ......................1-5 Before Servicing..........................1-6 Before Operating ..........................1-6 During Operation ..........................1-7 Before Transporting ......................... 1-7 During Transport..........................1-7 Drive Line Safety ..........................1-8 Pressurized Oil ..........................

-

Page 10: Safety

It is true that the designer, the manufacturer, and the safety engineer can help; and they will help, but their combined efforts can be wiped out by a single careless act of the operator. It is said that, “the best kind of a safety device is a careful operator.” We, at Unverferth Mfg. -

Page 11: Safety Decals

— Safety Parker 1042 Safety Decals • REPLACE LOST, DAMAGED, PAINTED, OR UNREADABLE DECALS IMMEDIATELY. IF PARTS THAT HAVE DECALS ARE REPLACED, ALSO MAKE SURE TO INSTALL NEW DECALS. THESE DECALS INFORM AND REMIND THE OPERATOR WITH OPERATIONAL INFORMATION AND SAFETY MESSAGES. - Page 12 — Safety Parker 1042 Safety Decals (continued) 95445 95839 REFLECTORS 9003125 (Fluorescent) 9003126 (Red) 9003127 (Amber) 9003475 TA510514 95046 94754...

-

Page 13: Following Safety Instructions

— Safety Parker 1042 Following Safety Instructions • Read and understand this operator’s manual before operating. • All machinery should be operated only by trained and authorized personnel. • To prevent machine damage, use only attachments and service parts approved by the manufac- turer. -

Page 14: Before Servicing

— Safety Parker 1042 Before Servicing • Avoid working under an implement; however, if it becomes absolutely unavoidable, make sure the implement is safely blocked. • Ensure that all applicable safety decals are installed and legible. • When working around the implement, be careful not to be cut by sharp edges. -

Page 15: During Operation

— Safety Parker 1042 During Operation • Regulate speed to field conditions. Maintain complete control at all times. • Never service or lubricate equipment when in operation. • Keep away from overhead power lines. Electrical shock can cause serious injury or death. -

Page 16: Driveline Safety

— Safety Parker 1042 Driveline Safety • Do not allow children near equipment that is running or engaged. • Do not exceed 1000 rpm PTO speed. • Disengage the PTO, stop the tractor engine, and remove key from ignition before making inspec- tions, or performing maintenance and repairs. -

Page 17: Pressurized Oil

— Safety Parker 1042 Pressurized Oil • Relieve pressure before disconnecting hydraulic lines from tractor, loosening any hydraulic fittings or servicing hydraulic system. See hydraulic power unit manual for procedure to relieve pressure. • High-pressure fluids can penetrate the skin and cause serious injury or death. Use cardboard or wood to detect leaks in the hydraulic system. -

Page 18: Preparing For Emergencies

— Safety Parker 1042 Preparing for Emergencies • Keep a first aid kit and properly rated fire extinguisher nearby. • Keep emergency numbers for fire, rescue, and poison control personnel near the phone. Wearing Protective Equipment • Wear clothing and personal protective equipment appropriate for the job. -

Page 19: Set Up

— Set Up Parker 1042 Section II Set Up Set Up Checklist ..........................2-2 Basic Cart Set Up - Folding Side Extension ................. 2-3 Basic Cart Set Up - Transport Lighting and Markings ..............2-4 Basic Cart Set Up - SMV Emblem ....................2-4 Basic Cart Set Up - Auger Rest Retainer Removal .............. -

Page 20: Set Up Checklist

— Set Up Parker 1042 Set Up Checklist After the cart has been completely assembled, use the following checklist and inspect the cart. Check off each item as it is found satisfactory or after proper adjustment is made. o Torque wheel nuts and check tire pressure as specified in MAINTENANCE section. - Page 21 — Set Up Parker 1042 Basic Set Up Folding Side Extensions Downspout FIG. 2-1 Sideboards Wheels/Tires Jack Due to shipping requirements and various dealer-installed options, some initial cart set up will be required after it arrives from the factory. Use the following procedures as needed for initial cart set up.

- Page 22 Basic Set Up (continued) Transport Lighting and Markings NOTE: Unverferth Manufacturing has designed the transport lighting and marking kit to meet United States federal law and ASABE standards at the time of manufacture. Machine modifi- cations, including additional features or changes to the intended configurations, may require updates to the lighting and marking as well.

- Page 23 — Set Up Parker 1042 Basic Set Up (continued) Auger Rest Retainer Removal Remove the retainer located on the upper auger rest at the back of the cart, before folding out the upper auger tube. • Upper auger retainer must be removed before operating upper auger tube.

- Page 24 — Set Up Parker 1042 Basic Set Up (continued) Wheel/Tire Set Up Tire Pressure Tire pressure must be verified before first use and adjusted as necessary. Refer to maintenance section of this manual for information on tire pressure. Wheel Nuts •...

-

Page 25: Basic Cart Set Up - Adjustable Axle (Optional)

— Set Up Parker 1042 Basic Set Up (continued) Adjustable Axle (Optional) • FALLING OBJECTS CAN CAUSE SERIOUS INJURY OR DEATH. DO NOT WORK UNDER THE MACHINE AT ANY TIME WHILE BEING HOISTED. BE SURE ALL LIFTING DEVICES AND SUPPORTS ARE RATED FOR THE LOADS BEING HOISTED. THESE ASSEMBLY INSTRUCTIONS WILL REQUIRE SAFE LIFTING DEVICES UP TO 16,000 LBS. - Page 26 — Set Up Parker 1042 Basic Set Up (continued) Adjustable Axle (Optional) 4. Slide extensions to desired tire gauge spacing. Axle extensions should be extended equally. Refer to chart below and FIG. 2-10. Slide Out Distance Distance Hub Flange Distance...

-

Page 27: For Track Information, Please Refer To Your Track Manual

— Operation Parker 1042 Section III Operation Operating Checklist ......................... 3-2 Preparing Tractor..........................3-2 Preparing Cart - Hardware ......................3-3 Preparing Cart - Pivot Pins......................3-3 Preparing Cart - Hitch........................3-3 Preparing Cart - Auger........................3-3 Preparing Cart - Soft Start System ....................3-4 Preparing Cart - Hydraulic System .................... -

Page 28: Operating Checklist

— Operation Parker 1042 Operating Checklist o Read and understand all safety precautions before operating cart. Check axle spacing to be sure axle is adjusted from shipping position to desired operating width. (If Applicable) Check to be sure all the reflective decals and the SMV sign are clearly visible with the cart attached to the tractor. -

Page 29: Preparing Cart - Hardware

— Operation Parker 1042 Preparing Cart Perform the service checks as outlined below. Repair or replace any damaged or worn parts before operating. Hardware Check for loose bolts and nuts, and tighten as needed. Check again after the first half-day of operation. -

Page 30: Preparing Cart - Hitch

— Operation Parker 1042 Preparing Cart (continued) Soft Start System Check for wear or damage. Lubricate as recommended. Do not over lubricate. Hydraulic System Check all hoses and cylinders for signs of leakage. Hoses should not be kinked, twisted or rubbing against sharp edges. -

Page 31: Hitching To Tractor - Drawbar Connection

— Operation Parker 1042 Hitching to Tractor Drawbar Connection This cart is intended to be hitched to a tractor drawbar. Do not attempt to hitch to any other location on the tractor other than the drawbar. The cart is equipped standard with a single tang hitch. - Page 32 — Operation Parker 1042 Hitching to Tractor (continued) Transport Chain Connection • ALWAYS USE TRANSPORT CHAIN WHEN TRANSPORTING IMPLEMENTS. FAILURE TO USE A TRANSPORT CHAIN COULD CAUSE PERSONAL INJURY IF CART BECOMES DISENGAGED. Always use intermediate chain support when connecting the grain cart directly to a tractor.

- Page 33 — Operation Parker 1042 Hitching to Tractor (continued) Clean hydraulic hose couplers before connecting to the tractor. For convenience, it is recom- mended to connect the flow door circuit hoses to tractor implement coupler #1, auger spout circuit hoses to coupler #2, and attach auger fold circuit to coupler #3.

- Page 34 If your tractor does not have this type of receptacle, an SAE J-560 seven-point socket can be purchased from your Unverferth dealer (Part number 92824). FIG. 3-5 The wiring schematic for this cart, shown in the MAINTENANCE section, complies with ASABE Standards.

-

Page 35: Towing

— Operation Parker 1042 Towing This cart is not equipped with brakes. Ensure that the towing vehicle has adequate weight and braking capacity to tow this implement. See towing vehicle’s operators manual for tow- ing capacity. Never tow a loaded grain cart over public roads. -

Page 36: Auger Operation Pto Driven Auger

— Operation Parker 1042 Auger Operation PTO Driven Auger • ELECTROCUTION WILL CAUSE SERIOUS INJURY OR DEATH. THE GRAIN CART IS NOT INSULATED. KEEP AWAY FROM ALL ELECTRI- CAL LINES AND DEVICES. ELECTROCUTION CAN OCCUR WITHOUT DIRECT CONTACT. • ENTANGLEMENT WITH THE DRIVELINE WILL CAUSE SERIOUS INJURY OR DEATH. -

Page 37: Optional Equipment Hydraulic Drive

— Operation Parker 1042 Optional Equipment Hydraulic Drive The optional hydraulically-driven auger permits cart operation using tractors that are not equipped with a PTO. However, due to the power requirements of a grain cart, it should be expected that a hydraulically-driven grain cart will not unload as quickly as a PTO driven cart. - Page 38 — Operation Parker 1042 Optional Equipment (continued) Hydraulic Drive (continued) NOTE: For complete assembly and operation details for the Hydraulic Drive, please refer to the Hydraulic Drive manual (282894). 1. Before loading cart or operating auger, verify that the flow control door is closed.

-

Page 39: For Track Information, Please Refer To Your Track Manual

— Maintenance Parker 1042 Section IV Maintenance Lubrication............................4-2 Gearbox Lubrication ........................4-3 Seasonal Storage ..........................4-3 Adjusting Cleanout Door ......................... 4-4 Auger Driveline..........................4-6 Bearings............................ 4-6 Driveline Replacement ......................4-6 Auger System - Lower Auger Disassembly ................... 4-9 Auger System - Lower Auger Assembly ..................4-10 Auger System - Upper Auger Disassembly.................. -

Page 40: Lubrication

— Maintenance Parker 1042 Lubrication To keep your grain cart in top operating condition and to assure its proper performance and reliability for a long period of time, periodic inspection and lubrication is a must. Refer to Gearbox Lubrication Hydraulic Motor Shaft... -

Page 41: Gearbox Lubrication

— Maintenance Parker 1042 Gearbox Lubrication Gear box check/fill plug is located on the right hand front side of the housing. To check oil fluid level, place cart on a level surface with the tongue elevated to hitch height and remove the plug. -

Page 42: Adjusting Cleanout Door

— Maintenance Parker 1042 Adjusting Cleanout Door MOVING PARTS CAN CRUSH AND CUT. KEEP AWAY FROM MOVING PARTS. • KEEP HANDS CLEAR OF PINCH POINT AREAS. • EYE PROTECTION AND OTHER APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT • MUST BE WORN WHILE SERVICING THE IMPLEMENT. - Page 43 — Maintenance Parker 1042 Adjusting Cleanout Door (continued) 5. Push the gear assembly toward bottom of au- ger to remove excess movement and prevent the door from moving upward when unloading Push Gear Assembly Toward Bottom of Auger the cart. (FIG. 4-3) FIG.

-

Page 44: Auger Driveline

— Maintenance Parker 1042 Auger Driveline Bearings It is important to periodically check setscrews in all bearings of the driveline for tightness. Driveline Replacement Flangette Bearings FIG. 4-1 1. Park the empty cart on a firm, level surface. Block the wheels or tracks on the cart to keep it from moving. - Page 45 — Maintenance Parker 1042 Auger Driveline (continued) Driveline Replacement (continued) 6. Remove bearings, bearing mounts, universal joint cover, PVC driveshaft covers, and driveline cover, located behind the ladder, off the current driveshaft. 7. When installing new bearings (9003920) onto new driveshaft (9007718), assemble new 25” PVC driveshaft cover (291555) between bearings near the gearbox, and new 36”...

- Page 46 — Maintenance Parker 1042 Auger Driveline (continued) Driveline Replacement (continued) 11. Tighten all flangette mounting hardware. Universal Joint Drill Dimple 12. With bearing mounting hardware loosely tight- In-Line Orientation on Driveshaft ened, drill a setscrew dimple in the driveshaft by going through the bearing setscrew thread- ed hole to dimple the driveshaft being careful to not damage threads.

- Page 47 — Maintenance Parker 1042 Auger System • TO PREVENT PERSONAL INJURY OR DEATH, ALWAYS ENSURE THAT THERE ARE PEOPLE WHO REMAIN OUTSIDE THE CART TO ASSIST THE PERSON WORKING INSIDE, AND THAT ALL SAFE WORKPLACE PRACTICES ARE FOLLOWED. THERE IS RESTRICTED MOBILITY AND LIMITED EXIT PATHS WHEN WORKING INSIDE THE IMPLEMENT.

- Page 48 — Maintenance Parker 1042 Auger System (continued) Lower Auger Assembly 1. When installing the coupler into the auger pipe, the lower auger flighting should be set with the Upper Auger Fig. 4-3 driving surface of the drive lobe at a 11:00 po-...

- Page 49 — Maintenance Parker 1042 Auger System (continued) Lower Auger Assembly (continued) 4. 5-Pin Drive Bushing Weldment: Fig. 4-4 Rotate auger 360 degrees to ensure it is cen- tered on the drive bushing weldment (286436) and the five pins are engaged with auger end.

- Page 50 — Maintenance Parker 1042 Auger System (continued) Upper Auger Disassembly 1. Support the upper auger assembly using a 2-ton hoist and two straps rated for 2000 lbs. 2. Remove auger tube cylinder pin and carefully swing cylinder down without breaking hose connec- tions.

- Page 51 — Maintenance Parker 1042 Auger System (continued) Upper Auger Assembly 1. Install upper bearing and spring assembly if previously removed. 2. Insert auger in auger tube. Back out bearing setscrews and insert auger stub shaft through bearing. Retain auger with 5/16” x 2” machine screw and nut.

- Page 52 — Maintenance Parker 1042 Auger System (continued) Auger Flow Door Cylinder Replacement • TO PREVENT PERSONAL INJURY OR DEATH ALWAYS ENSURE THAT THERE ARE PEOPLE WHO REMAIN OUTSIDE THE CART TO ASSIST THE PERSON WORKING INSIDE, AND THAT ALL SAFE WORKPLACE PRACTICES ARE FOLLOWED. THERE IS RESTRICTED MOBILITY AND LIMITED EXIT PATHS WHEN WORKING INSIDE THE IMPLEMENT.

- Page 53 — Maintenance Parker 1042 Auger System (continued) Auger Flow Door Cylinder Replacement (continued) 2. On the inside of the cart, open the screen ser- Fig. 4-9 vice access panel shown in Fig. 4-9. Screen Service Access Panel 3. Remove the cotter pins from the lower cylinder pin then remove the pin.

- Page 54 — Maintenance Parker 1042 Auger System (continued) Auger Flow Door Cylinder Replacement (continued) 6. Label the hydraulic hoses to indicate upper and lower. Disconnect them from the cylinder, Remove Lower along with the lower hydraulic fitting (Fig. 4-11). Hose & Fitting...

-

Page 55: Verify Telescoping Pto Shaft Length

— Maintenance Parker 1042 Verify Telescoping PTO Shaft Length • PROPERLY EXTENDED AND COLLAPSED LENGTHS OF THE TELESCOPING PTO SHAFT MUST BE VERIFIED BEFORE FIRST OPERATION WITH EACH AND EVERY DIFFERENT TRACTOR. IF THE EXTENDED LENGTH OF THE PTO SHAFT IS NOT SUFFICIENT, IT... - Page 56 — Maintenance Parker 1042 Verify Telescoping PTO Shaft Length (continued) 4. Hitch tractor drawbar to cart, ensuring that tractor and cart are on level ground and coupled as straight as practical. 5. Connect PTO shaft to tractor, and measure length “L” from same points as used in step 1. Ensure that this measurement does not exceed the maximum recommended extended length calculated in step 3 above.

-

Page 57: Pto Shaft And Clutch

— Maintenance Parker 1042 PTO Shaft and Clutch Lubrication (Figs. D1 - D6) Lubricate with quality grease before starting work and every 8 operating hours. Clean and grease PTO driveshaft before each prolonged period of non-use. Molded nipples on the... - Page 58 — Maintenance Parker 1042 PTO Shaft and Clutch (continued) Coupling the PTO Driveshaft (Figs. E1 - E2) Clean and grease the PTO and implement input connection (IIC) AS-Lock 1. Pull locking collar and simultaneously push PTO driveshaft onto PTO shaft until the locking device engages.

- Page 59 — Maintenance Parker 1042 PTO Shaft and Clutch (continued) Chains (Figs. G1 - G3) NOTE: The chain is intended to prevent the shield from rotating against non-moving parts and there- by preventing shield damage. A properly installed chain will increase the service life of the shield.

- Page 60 — Maintenance Parker 1042 PTO Shaft and Clutch (continued) To Dismantle Guard (Figs. J1 - J4) 1. Remove locking screw. 2. Align bearing tabs with cone pockets. 3. Remove half-guard. 4. Remove bearing ring. To Assemble Guard (Figs. K1 - K5) 1.

-

Page 61: Pto Quick Disconnect

— Maintenance Parker 1042 PTO Shaft and Clutch (continued) To Assemble Cone (Figs. L1 - L3) 1. Dismantle guard (Figs. J1 - J3). Remove old cone (e.g. cut open with knife). Take off chain. Place neck of new cone in hot water (approx... - Page 62 — Maintenance Parker 1042 PTO Quick Disconnect (continued) Quick Disconnect Disassembly 1. Compression Spring 2. Ball 3. Lock Collar 4. Back-up ring 5. Snap ring * Back-up ring * (For some clutch types, place additional back up ring first). Compress lock collar (#3) and remove snap right (#5).

- Page 63 — Maintenance Parker 1042 PTO Quick Disconnect (continued) Clutch Disassembly Tighten the four hex nuts (12) uniformly until the clutch pack and hub are loose. Use special tool 9002007 to bend all four retaining lugs back on the edge of the clutch housing. Remove the thrust plate with Belleville springs to get at the friction disks, drive plates and hub for inspection and service.

- Page 64 — Maintenance Parker 1042 Electrical Schematic - Rear Wiring Harness #9003050 Electrical Schematic - Front Wiring Harness #9003981 4-26...

- Page 65 — Maintenance Parker 1042 Electrical Schematic - Coupler #92450 GRAIN CART WIRES White -- Ground Green -- Right amber flashing lamp Yellow -- Left amber flashing lamp Brown -- Tail light Black -- Interior & Auger Lights Red -- Brake Lights...

-

Page 66: Hydraulic System Schematic

— Maintenance Parker 1042 MAINTENANCE HYDRAULIC SYSTEM Hydraulic System Schematic 4-28 3-16... -

Page 67: Um520 Auto Unload Manifold Schematic

— Maintenance Parker 1042 UM 520 Auto Unload Manifold Schematic Hydraulic pressure from tractor Hydraulic return to tractor tank Flow door cylinder end that closes flow door when pressurized Flow door cylinder end that opens flow door when pressurized Pressure switch... - Page 68 — Maintenance Parker 1042 Wheels and Tires Wheel Nut Torque Requirements • IMPROPERLY TORQUED WHEEL NUTS/BOLTS CAN CAUSE A LOSS OF IMPLEMENT CONTROL AND MACHINE DAMAGE. TORQUE WHEEL NUTS/BOLTS TO VALUES IN TABLE. CHECK TORQUE BEFORE USE, AFTER ONE HOUR OF UNLOADED USE OR AFTER FIRST LOAD, AND EACH LOAD UNTIL WHEEL NUTS/BOLTS MAINTAIN TORQUE VALUE.

- Page 69 — Maintenance Parker 1042 Wheels and Tires (continued) Tire Pressure The following is to be used as a general guide for tire inflation and figures can vary depend- It is important that tires are inspected after ing on specific brand of tire used.

- Page 70 — Maintenance Parker 1042 Wheels and Tires (continued) Tire Pressure (continued) Tire Pressure for Grain Carts Load Index / Ply Max. PSI Tire Make Part Number Tire Size Rating Titan/Goodyear 94286 23.1x26 R-3 99364 23.1x26 R-1 99307 24.5R32 R-1 169A8/B (5-Star) 94289 24.5x32 R-3...

- Page 71 — Maintenance Parker 1042 Complete Torque Chart Capscrews - Grade 5 NOTE: • Grade 5 capscrews can be identified by three radial dashes on the head. • For wheel torque requirements, refer to Wheels and Tires. • Tighten U-bolts evenly and equally to have the same number of threads exposed on each end.

- Page 72 — Maintenance Parker 1042 Complete Torque Chart Capscrews - Grade 8 NOTE: • Grade 8 capscrews can be identified by six radial dashes on the head. • For wheel torque requirements, refer to Wheels and Tires. • Tighten U-bolts evenly and equally to have the same number of threads exposed on each end.

- Page 73 — Maintenance Parker 1042 Hydraulic Fittings – Torque and Installation SAE Flare Connection (J. I. C.) 1. Tighten nut with finger until it bottoms the seat. 2. Using a wrench, rotate nut to tighten. Turn nut 1/3 turn to apply proper torque.

- Page 74 — Maintenance Parker 1042 Notes 4-36...

- Page 75 — Parts Parker 1042 Section V Parts Please visit www.unverferth.com/parts/ for the most current parts listing. Please visit www.unverferth.com/parts/ for the most current parts listing. Final Assembly ........................... 5-2 Touch-Up Paint........................... 5-3 Rigid Axle Single Wheel ......................5-4 Adjustable Axle Single Wheel ....................5-6 Adjustable Axle - Dual Wheels....................

-

Page 76: Final Assembly

— Parts Parker 1042 Final Assembly Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Refer to “PTO Assembly” in Parts PTO Assembly Section for Items Window 92403 Window Molding 271951 Bracket, Window Retainer... -

Page 77: Touch-Up Paint

— Parts Parker 1042 Final Assembly Please visit www.unverferth.com/parts/ for the most current parts listing. Split Tension Bushing 2 OD x 1 3/4 ID x 2 9002130 Transport Chain 9003278 Storage Box 9005850 Nut/Large Flange 3/8-16UNC 91263 Grade 5 Capscrew 1-8UNC x 3 1/2... -

Page 78: Rigid Axle Single Wheel

— Parts Parker 1042 Rigid Axle — Single Wheel Please visit www.unverferth.com/parts/ for the most current parts listing. - Page 79 — Parts Parker 1042 Rigid Axle — Single Wheel Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Rigid Axle Bundle, Scale =Green= 2006246G Rigid Axle Bundle, Scale =Red= 2006246R Items 1-7 Rigid Axle Bundle, Non-Scale =Green=...

-

Page 80: Adjustable Axle Single Wheel

— Parts Parker 1042 Adjustable Axle — Single Wheel Please visit www.unverferth.com/parts/ for the most current parts listing. Note bending arrow direction. DETAIL A... - Page 81 — Parts Parker 1042 Adjustable Axle — Single Wheel Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Adjustable Axle Bundle, Scale =Green= 280489G Includes Items 2-7, 8A, 9-19 Adjustable Axle Bundle, Scale =Red= 280489R...

-

Page 82: Adjustable Axle - Dual Wheels

— Parts Parker 1042 Adjustable Axle — Dual Wheels Please visit www.unverferth.com/parts/ for the most current parts listing. Note bending arrow direction. - Page 83 — Parts Parker 1042 Adjustable Axle — Dual Wheels Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Adjustable Axle Bundle, Scale =Green= 2006452G Includes Items 2-7, 8A, 9-19 Adjustable Axle Bundle, Scale =Red= 2006452R...

-

Page 84: Track Bundle Components

— Parts Parker 1042 Track Bundle Components Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Washer, 7 1/2" 268619 Cover Plate =Black= 268121B Lock Washer, 3/4" 9404-033 Capscrew, 3/4-10UNC x 2 Gr.5 9390-145... -

Page 85: Track Axle Components

— Parts Parker 1042 Track Axle Components Please visit www.unverferth.com/parts/ for the most current parts listing. Note bending arrow direction. ITEM DESCRIPTION PART NO. NOTES Track Axle Bundle, Scale =Green= 287906G Includes Items 1-5, 6A, 7-10 Track Axle Bundle, Scale =Red=... - Page 86 — Parts Parker 1042 Hub — Rigid Axle — Single Wheels Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Hub & Spindle Asy (Green), Scale 267280G Includes Items 1 through 17 Hub & Spindle Asy (Red), Scale 267280R Hub &...

-

Page 87: Hub - Adjustable Axle - Single Wheels

— Parts Parker 1042 Hub — Adjustable Axle — Single Wheels Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Hub & Spindle Asy (Green) 267284G Includes Items 1 through 17 Hub & Spindle Asy (Red) -

Page 88: Hub - Adjustable Axle - Dual Wheels

— Parts Parker 1042 Hub — Adjustable Axle — Dual Wheels Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM ITEM DESCRIPTION PART NO. QTY. NOTES Hub & Spindle Assembly (Green) 284269G Hub & Spindle Assembly (Red) 284269R Hub (Green) 266455G Includes Items 2 &... -

Page 89: Dual Wheels & Tires

— Parts Parker 1042 Dual Wheels & Tires Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Wheel & Tire Assembly 14565 18 x 42 / TL520/85R42F R-1 / Firestone Tire Wheel Only 14562... -

Page 90: Single Wheels & Tires

— Parts Parker 1042 Single Wheels & Tires Please visit www.unverferth.com/parts/ for the most current parts listing. TIRES For questions regarding new tire warranty, please contact your local original equipment tire dealer. Used tires carry no warranty. 5-16... - Page 91 — Parts Parker 1042 Single Wheels & Tires Please visit www.unverferth.com/parts/ for the most current parts listing. STRAIGHT PLATE WHEELS QTY. NOTES ITEM DESCRIPTION PART NO. RIGID ADJUSTABLE AXLES AXLES Wheel & Tire Assembly 18519 30 x 32 / TL900/60R32 R1W / Mitas Tire...

-

Page 92: Decals

— Parts Parker 1042 Decals Please visit www.unverferth.com/parts/ for the most current parts listing. 5-18... - Page 93 — Parts Parker 1042 Decals Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Fluorescent Strip 9003125 2 x 9" Red Reflector 9003126 2 x 9" Amber Reflector 9003127 2 x 9" Decal, Reflective Checker Tape...

-

Page 94: Sideboards

— Parts Parker 1042 Sideboards Please visit www.unverferth.com/parts/ for the most current parts listing. 5-20... - Page 95 — Parts Parker 1042 Sideboards Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Sideboard, Rear RH 2007876B Sideboard, Front RH 2007880B Sideboard, Rear LH 2007911B Sideboard, Front LH 2007923B Plate 4 1/2” x 12” with 4 Slots 2007927B Plate 4 1/2”...

-

Page 96: Electrical

— Parts Parker 1042 Electrical Please visit www.unverferth.com/parts/ for the most current parts listing. Auger Lights Rear View of Cart Front View of Lamp Bracket Asy Rear View of Lamp Bracket Asy 5-22... - Page 97 — Parts Parker 1042 Electrical Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Wiring Harness, Rear 190" 9003050 Wiring Harness, Front 184" 9003981 Wiring Harness - Auger Light 297" 9004350 Electrical Coupler 92450...

-

Page 98: Drive Components

— Parts Parker 1042 " 2 " 1 " 2 " 2 Drive Components Please visit www.unverferth.com/parts/ for the most current parts listing. To Tractor Check/Fill Plug 5-17 5-24... - Page 99 — Parts Parker 1042 Drive Components Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES 1 1/2 Flangette Bearing 9003920 Carriage Bolt 1/2-13 x 1 1/4 9388-103 Lock Washer 1/2 9404-025 Hex Nut 1/2-13UNC 9394-010 Driveshaft 1 1/2 x 125.5...

-

Page 100: Auger Components

— Parts Parker 1042 Auger Components Please visit www.unverferth.com/parts/ for the most current parts listing. 5-26... - Page 101 — Parts Parker 1042 Auger Components Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Drive Dog Weldment 288811 Pillow Block Bearing 2 1/2 Bore 9004731 Locknut 5/8-11UNC 9801 Lower Auger Kit 281578-SER Includes Items 14, 22 & 25...

- Page 102 — Parts Parker 1042 Auger Components (continued) Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Capscrew 5/8-11UNC x 6 1/2 9390-137 Auger Rest Weldment =Green= 268646G Auger Rest Weldment =Red= 268646R Rubber Stop Pad 3/8 x 2 x 5...

-

Page 103: Auger Fold Indicator

— Parts Parker 1042 Auger Fold Indicator Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Auger Indicator Weldment 280168B Decal, Auger Indicator 9005335 Decal, Cart Profile 9004288 Indicator Retainer Weldment 268671B Cable, Push/Pull 180"... -

Page 104: Cleanout Door Assembly

— Parts Parker 1042 Cleanout Door Assembly Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Door Wheel Weldment 220060B Shaft & Gear Weldment 281062 Door Weldment 281015B Plate, Back Door Lift 281059B Plate, Front Door Lift... -

Page 105: Flow Door Seals

— Parts Parker 1042 Flow Door Seals Please visit www.unverferth.com/parts/ for the most current parts listing. OM04229 Revised 031805-4 5-22 ITEM DESCRIPTION PART NO. QTY. NOTES Capscrew, 1/4”-20UNCx7/8” G5 9390-004 Capscrew, 3/8”-16UNCx1 1/2” G5 9390-057 Spring Bracket =Green=... -

Page 106: Cylinders

— Parts Parker 1042 Cylinders — 3” x 24” (Auger Fold) Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Cylinder Kit 280920 Seal Kit 9004382 Cylinders — 2 1/2” x 36” (Flow Door) - Page 107 — Parts Parker 1042 Notes Please visit www.unverferth.com/parts/ for the most current parts listing. 5-33...

-

Page 108: Hydraulics

— Parts Parker 1042 Hydraulics Please visit www.unverferth.com/parts/ for the most current parts listing. 5-34... - Page 109 — Parts Parker 1042 Hydraulics Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES Hydraulic Cylinder, 3 x 24 - 3000 PSI 9004378 Fold Cylinder 3 x 24 Seal Kit 9004382 90° Elbow (9/16-18 JIC Male x 9/16-18 O-Ring Male) 9004379 w/.055 Restrictor...

-

Page 110: Directional Spout

— Parts Parker 1042 Directional Spout Please visit www.unverferth.com/parts/ for the most current parts listing. 5-36... - Page 111 — Parts Parker 1042 Directional Spout Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Adapter 9/16-18 JIC Female x 9/16-18 JIC Male 95193 with 0.030 Restrictor Hex Nut 5/16”-18UNC 9394-004 Poly Clamp Pair 9003816 Flat Washer 2"...

-

Page 112: Pto Assembly Shearbolt Clutch

— Parts Parker 1042 PTO Assembly Shearbolt Clutch Please visit www.unverferth.com/parts/ for the most current parts listing. 1 3/4-20 Spline Shown Optional 1 3/8-21 Spline Shown 5-38... -

Page 113: Shear-Bolt Clutch

— Parts Parker 1042 PTO Assembly Shearbolt Clutch Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. NOTES PTO Assembly Complete 9004767 1 3/4-20 Spline PTO Assembly Complete 9004766 1 3/8-21 Spline (optional) End Yoke / Overrunning Clutch... -

Page 114: Pto Assembly Friction Clutch

— Parts Parker 1042 PTO Assembly Friction Clutch Please visit www.unverferth.com/parts/ for the most current parts listing. Optional 1 3/4-20 Spline Shown Optional 1 3/8-21 Spline Shown ITEM DESCRIPTION PART NO. NOTES PTO Assembly Complete 9004769 1 3/4-20 Spline PTO Assembly Complete... -

Page 115: Friction Clutch

1 for specific clutch information. — Parts Parker 1042 Friction Clutch Assembly Please visit www.unverferth.com/parts/ for the most current parts listing. NOTE: The clutch is preset at the factory and should not require adjustment. See Section 1 for specific clutch information. -

Page 116: Shear-Bolt Clutch

— Parts Parker 1042 Shear Bolt Clutch Please visit www.unverferth.com/parts/ for the most current parts listing. • USE GENUINE OEM REPLACEMENT PART. Incorrect part may cause shear function to oc- cur too soon causing inconvenience or too late resulting in damage to driveline and auger components. -

Page 117: 45 Degree Gear Box

— Parts Parker 1042 45 Degree Gear Box Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Gear Box, Complete 9002812 Includes Items 1 thru 17 Shaft, Input 9001131 1.8:1 Gear Shaft, Output 9001132 1.8:1 Gear... -

Page 118: Driveline U-Joint Assembly

— Parts Parker 1042 Driveline U-Joint Assembly Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Complete U-Joint Assembly 95012 Yoke 95010 Grease Zerk, 1/4-28 UNF 91160 Yoke, 1-3/8-6 Spline 95011 Quick Disconnect Pin Kit 92362 Cross &... - Page 119 — Parts Parker 1042 Notes Please visit www.unverferth.com/parts/ for the most current parts listing. 5-45...

-

Page 120: Video System Option

— Parts Parker 1042 Video System Option Please visit www.unverferth.com/parts/ for the most current parts listing. 5-46... - Page 121 — Parts Parker 1042 Video System Option Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM PART NO. DESCRIPTION NOTES 265770 Video System Kit for Front View Includes Items 1,3,4,5,6,7,8 9004506 Additional Camera for Rear View Includes Items 6 & 7...

- Page 122 MANUALS\\2007593//June 2018-0//March 2019-1/MARCH 2020-2//MAY 2022-3...

Need help?

Do you have a question about the PARKER 1042 and is the answer not in the manual?

Questions and answers