Table of Contents

Advertisement

Quick Links

●

Please read this instruction manual carefully before using this product,

especially the section describing safety.

●

Retain this instruction manual with the product for further consultation

whenever necessary.

Discontinue

INSTRUCTION MANUAL

PILOT TYPE 3,5 PORTS

ELECTRIC-MAGNETIC

VALVE

MN3GD/E1-SERIES

MN3GD/E2-SERIES

MN4GD/E1-SERIES

MN4GD/E2-SERIES

Block manifold type

SM-P00037-A

2ND EDITION

Advertisement

Table of Contents

Summary of Contents for CKD MN3GD/E1 Series

- Page 1 Discontinue SM-P00037-A INSTRUCTION MANUAL PILOT TYPE 3,5 PORTS ELECTRIC-MAGNETIC VALVE MN3GD/E1-SERIES MN3GD/E2-SERIES MN4GD/E1-SERIES MN4GD/E2-SERIES Block manifold type ● Please read this instruction manual carefully before using this product, especially the section describing safety. ● Retain this instruction manual with the product for further consultation whenever necessary.

- Page 2 Pneumatic or water control circuit Electric control that controls the above It is important to select, use, handle, and maintain the product appropriately to ensure that the CKD product is used safely. Observe warnings and precautions to ensure device safety.

- Page 3 If any failure for which CKD CORPORATION is recognized to be responsible occurs within the above warranty period, a substitute or necessary replacement parts shall be provided free of charge, or the product shall be repaired free of charge at the plant of CKD CORPORATION. However, the guarantee excludes following cases: ①...

- Page 4 Discontinue UNPACKING (Chapter 3.) Bags containing solenoid valves should be opened only when you ! CAUTION CAUTION : : : : CAUTION CAUTION are ready to connect the valves to the pipes immediately afterward. ・If bags are opened before the valves are ready to be connected to the pipes, the entry of foreign matter from the piping ports could cause the solenoid valves to fail or malfunction.

- Page 5 Discontinue PIPING (Section 4.3.) a) Observe the recommended tightening torque when connecting ! CAUTION CAUTION CAUTION CAUTION : : : : pipes. Observing the recommended tightening torque prevents air leakage and damage to the screw threads. To prevent damage to the screw threads, first use your hand to lightly tighten the screw and then use a tool to tighten the screw to the recommended torque.

- Page 6 Discontinue MANUAL OPERATION (Section 5.2.) a) After using the manual override, be sure to reset the manual ! WARNING WARNING WARNING WARNING : : : : override to the original (OFF) position before resuming the operation of the device. b) Before using the manual override, make sure that nobody is present near the cylinder to be activated.

- Page 7 Discontinue ELECTRIC CIRCUIT (Section 5.4.) a) Check for the presence of any current leak from the external ! CAUTION CAUTION : : : : CAUTION CAUTION control device because it may cause malfunction. When a programmable controller or a similar control device is used, a current leak may prevent the normal returning of the valve when the solenoid is de-energized.

- Page 8 Discontinue ADDITIONAL INSTALLATION OF A VALVE UNIT TO A REDUCED WIRING TYPE MANIFOLD (Section 6.3.) When disassembling or assembling the manifold, perform it after ! WARNING WARNING WARNING WARNING : : : : reading the Instruction Manual carefully and with full understanding of its contents.

-

Page 9: Table Of Contents

Discontinue INDEX MN3GD/E1 , MN3GD/E2 MN4GD/E1 , MN4GD/E2 Pneumatic 3,5-port solenoid valve Instruction Manual No. SM-P00037-A PRODUCT·····························································································9 PORT INDICATION AND SI UNIT SYSTEM Port indication ··············································································12 Conversion between SI unit and conventional unit ·····················12 UNPACKING ·······················································································13 INSTALLATION Installation environment·······························································14 Installation····················································································15 Piping ···························································································16 Wiring···························································································19 PROPER OPERATION... -

Page 10: Product

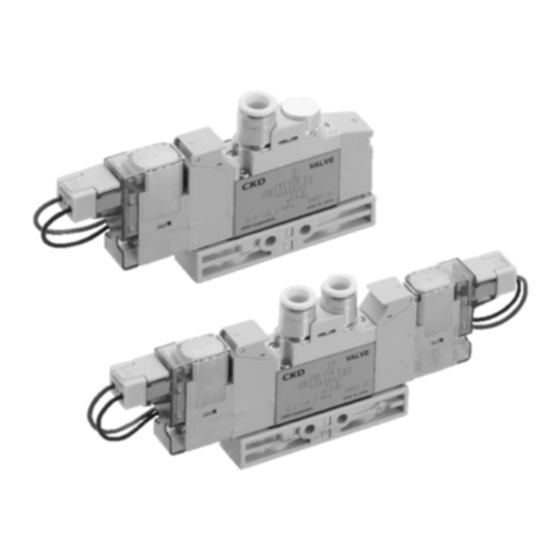

Discontinue 1 PRODUCT 1. PRODUCT base porting type body porting type Individual wiring type manifold Individual wiring type manifold Mix - manifold 18.D-sub connector(T30) 19.Flat cable type(T50) 21.Common terminal stand block(T11) 20.Common terminal stand block(T10) Push-in fitting type M3 thread type [SM-P00037-A] -9-... - Page 11 Discontinue 1 PRODUCT 1) Solenoid valve individual Parts name Explanation Lead wire No specification about the polarities. The green power indicator light on the top surface is lit when the power is Electric component cover surplied to the coil. (With E-type and A-type connectors only.) Coil assembly It varies depending on electric wire connection type and voltage.

- Page 12 Discontinue 1 PRODUCT 3)Wiring block Parts name Explanation D sub-connector type(T30) 18-1 D-sub 25-pin connector Combines the manifold valve control terminals. 18-2 Connector lock screw Locks the mating connector (M2.6). Loosened to allow changing the direction for leading out the connected cable; 18-3 Lock screw tightened to lock the direction.

-

Page 13: Port Indication And Si Unit System

Discontinue SI UNIT 2. PORT INDICATION AND SI UNIT SYSTEM 2.1 Port Indication Each piping port is marked with ISO and JIS conformable piping port indication codes. Application Supply port Output port Output port Exhaust port Exhaust port Installing position of the solenoid valve is free. The position of the 4(A) and 5(R1) ports for 4G series are in reverse with 2(B) and 3(R2) ports respectively, compared with the 4K series. -

Page 14: Unpacking

Discontinue 3 UNPACKING 3. UNPACKING Bags containing solenoid valves should be opened only when you ! CAUTION CAUTION CAUTION CAUTION : : : : are ready to connect the valves to the pipes immediately afterward. If bags are opened before the valves are ready to be connected to the pipes, the entry of foreign matter from the piping ports could cause the solenoid valves to fail or malfunction. -

Page 15: Installation

Discontinue 4 INSTALLATION 4. INSTALLATION If you have to use the product under conditions that are different ! CAUTION CAUTION : : : : CAUTION CAUTION from the specified conditions or if you intend to use the product for a special application, be sure to consult us about the product specifications before using the product. -

Page 16: Installation

Discontinue 4 INSTALLATION 4.2 Installation When installing a solenoid valve unit, never attempt to hold it in ! WARNING WARNING WARNING : : : : WARNING position by means of the pipes connected to it. ・ Fix the solenoid valve by applying the mounting screws and/or mounting plate to the solenoid valve. -

Page 17: Piping

Discontinue 4 INSTALLATION 4.3 Piping a) Observe the recommended tightening torque when connecting ! CAUTION CAUTION CAUTION CAUTION : : : : pipes. Observing the recommended tightening torque prevents air leakage and damage to the screw threads. To prevent damage to the screw threads, first use your hand to lightly tighten the screw and then use a tool to tighten the screw to the recommended torque. - Page 18 Discontinue 4 INSTALLATION 4.3.1 Seal material When using seal material, take care to avoid getting it in the pipes or overflowing on the exterior surface of the pipes. ●Seal Material (Paste or liquid) ●Seal Tape (Correct) (Incorrect) (Correct) (Incorrect) When applying fluororesin sealing tape to the screw threads, wind the tape two or three times around the threads but leave the one or two threads at the pipe end uncovered.

- Page 19 Discontinue 4 INSTALLATION 4.3.6 Pipe connections (1) Tubes to be used For use with solenoid valves with push-in joints, select tubes of the type specified by us: Soft nylon tubes (F-1500 Series) Urethane tubes (U-9500 Series) (2) For installation at a site that has spatters in the air, select incombustible tubes or metal pipes. (3) For a piping used for both hydraulic and pneumatic controls, select a hydraulic hose.

-

Page 20: Wiring

Discontinue 4 INSTALLATION 4.4 Wiring When carrying out electrical connections, please perform ! WARNING: : : : WARNING WARNING WARNING disassembling and assembling work after reading the Instruction Manual carefully and with full understanding of its contents. ・ Your understanding of the structure of solenoid valve and its operation principle is required in order to secure the safety. - Page 21 Discontinue 4 INSTALLATION 4.4.2 How to use A-connector The A-connector is dedicated for the reduced wiring manifold, and is connected from the bottom. The same precaution as when using the E-connector is required when installing and removing the socket. When mounting and dismounting a socket, exercise the same caution as that when using E-type connectors.

- Page 22 Discontinue 4 INSTALLATION 4.4.4 How to use DIN terminal box 1) Disassembling Disassembling Loosen the screw (1), and pull the cover (2) in the direction of screw (1). The connector will come off the coil assembly (12). Pull the screw (1) out of the cover (2). There is a notch (9) (next to GDSN mark) on the bottom of the terminal block (3).

- Page 23 Discontinue 4 INSTALLATION 4.4.5 Common terminal stand type: Wiring style T10/T11 1) Points requiring your attention with common terminal stand type (T10/T11): (1) The internal common wiring for common terminal stand type has already been made. So, please unify the power source of manifold. In case of a PC output unit of independent contact point type, apply a common wiring at the contact point.

- Page 24 Discontinue 4 INSTALLATION 3) Wiring style T10 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 25 Discontinue 4 INSTALLATION Wiring style T11 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 26 Discontinue 4 INSTALLATION 4.4.6 D sub-connector type : The connector for the T30 1) T30 connector The connector for the T30, which is usually called the D sub-connector, is widely used in FA and OA equipment. The 25P type, in particular, is the connector specified in the RS232C standard for use in personal computer communication.

- Page 27 Discontinue 4 INSTALLATION 4) Wiring style T30 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 28 Discontinue 4 INSTALLATION 5) Connection to PLC The common wiring has been internally done on the manifold side. Since the electromagnetic valve has no polarity, it can be connected to either the NPN output or PNP output of the DC output unit of the PLC. Wire each unit in the following manner.

- Page 29 Discontinue 4 INSTALLATION 7) CKD cable specifications (CKD cables of the following models can be used) (Note 1) (Note 2) Model CABLE Note 1: Connecting method on the user side Note 2: Cable length L Cutting only With round crimp terminal for M3.5 screws...

- Page 30 Discontinue 4 INSTALLATION 4.4.7 Flat cable type : The connector for the T50 1) Flat cable connector The connector used in the T50 complies with the MIL standard (MIL-C-83503). Its flat-cable press-connection design makes wiring work easy. Pin numbers may differ from one PC manufacturer to another, but their functions are the same.

- Page 31 Discontinue 4 INSTALLATION 4) Wiring style T50 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 32 Discontinue 4 INSTALLATION 5) Power supply The terminal stand is designed to accept power supplied from an external source when such outside power supply is needed. Supply the power to the wiring block or the input/output unit in the manner as shown in the following drawings.

- Page 33 Discontinue 4 INSTALLATION 4.4.8 Flat cable connector type : The connector for the T51/T52/T53 Cautions regarding the connector type (T51/T52/T53) (1) The order of signals in the PLC output unit should match the order of signals in the solenoid valve system.

- Page 34 Discontinue 4 INSTALLATION Wiring style T51 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 35 Discontinue 4 INSTALLATION Wiring style T52 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 36 Discontinue 4 INSTALLATION Wiring style T53 Maximum number of manifold station varies depending on the model. Please check the specifications for each model. Note) Valve No. 1a, 2a, 2b , etc. the numbers indicate the 1st station and 2nd station respectively, and alphabet (a) means the solenoid on a-side and (b) means the solenoid on b-side respectively.

- Page 37 Discontinue 4 INSTALLATION 6) Connection to PLC The common wiring has been internally done on the manifold side. Since the electromagnetic valve has no polarity, it can be connected to either the NPN output or PNP output of the DC output unit of the PLC. Wire each unit in the following manner.

- Page 38 Discontinue 4 INSTALLATION 8) Cable The system uses flat cables or slender multi-conductor cables. As these cables have fine core wires, it should be checked that they have enough mechanical strength and electric capacity. Make sure to make a rounded corner (R) when bending the flat cable. The cable has large electric resistance (AWG28, approx.

- Page 39 Discontinue 4 INSTALLATION [SM-P00037-A] -38-...

-

Page 40: Proper Operation

Discontinue 5 OPERATION 5. PROPER OPERATION 5.1 Description of operation Valve operation 1) Description of Operation diagram (4GD2 series as an example) operation De-energized. (As shown in the diagram) 1(P) 2(B) 4(A) 5(R1) N4G**10 Single Energized 1(P) 4(A) 2(B) 3(R2) SOL a is energized 1(P) 4(A) 2(B) 3(R2) - Page 41 Discontinue 5 OPERATION Description of Operation diagram (4GD2 series as an example) operation De-energized. (As shown in the diagram) 4(A) 5(R1) N3GD*10 Normally Energized closed 1(P) 4(A) De-energized. (As shown in the diagram) 1(P) 2(B) N3GD*110 Normally Energized opened 2(B) 3(R2) De-energized.

- Page 42 Discontinue 5 OPERATION 2) Manifold operation The main and pilot exhaust gases are collected in the manifold base and discharged from the exhaust port. 3) Prevention of malfunction A PR check valve is provided as a standard option. An exhaust malfunction prevention valve is provided when optionally selecting the symbol H.

-

Page 43: Manual Operation

Discontinue 5 OPERATION 5.2 Manual operation a) Once the manual operation device has been operated, ! WARNING WARNI NG: : : : WARNI WARNI always return it to its origin (initial position), and then start the operation of the device. b) Before starting the manual operation, make sure that no one is around the cylinder to be operated. -

Page 44: Air Quality

Discontinue 5 OPERATION (2) Push and lock operation Push the manual device and turn it 90 in the direction indicated by an arrow. Even though the manual device is released, the manual operation is not cancelled. 5.3 Air quality a) Do not supply air other than the compressed air. !... -

Page 45: Electric Circuit

Discontinue 5 OPERATION 5.3.4 Contaminant Always use compressed air without oxidized oil content, tar, and/or carbon of the air compressor. (1) If oxidized oil content, tar, and/or carbon enter the inside of the pneumatic device and they are solidified, the resistance of the sliding part is increased, causing a malfunction. (2) If oxidized oil content, tar, and/or carbon are mixed with the lubricant, the sliding part of the pneumatic device is worn out. -

Page 46: Maintenance

Discontinue 6 MAINTENANCE 6. MAINTENANCE 6.1 Periodic inspection Before providing a maintenance service, cut the power and the ! WARNING RNING: : : : RNING RNING supply of compressed air and confirm the absence of residual pressure. ・The above is required to ensure safety. Regularly perform the daily and periodic inspections to correctly !... -

Page 47: Disassembly And Reassembly

Discontinue 6 MAINTENANCE 6.2 Disassembly and reassembly Before providing maintenance service, cut the power and the supply ! WARNING: : : : WARNING WARNING WARNING of compressed air and confirm residual pressure is released. ・The above is required to ensure safety. Regularly perform the daily and periodic inspections to correctly !... -

Page 48: Additional Installation Of A Valve Unit

Discontinue 6 MAINTENANCE 6.2.3 Replacement of cartridge joint Before changing the push-in joint size, check the proper work steps. If the cartridge joint is not mounted correctly or if the mounting screw is tightened insufficiently, this may cause air leak. 1) Direct piping (D) type (1) Remove the mounting screws. - Page 49 Discontinue 6 MAINTENANCE 6.3.1 Block manifold disassembly drawing Example of disassembly: MNGB1 for specifications of D-sub connector right side wiring 6.3.2 Access to electric component board [SM-P00037-A]...

- Page 50 Discontinue 6 MAINTENANCE 6.3.3 Installation of an Additional Valve Block 1) Loosen the DIN rail set screw of the retainer(See assembly drawing). 2) Open the wiring cover. 3) Pull the connecting key of the place for installation of an aditional valve block until a click is heard, and then disconnect blocks.

- Page 51 Discontinue 6 MAINTENANCE 6.3.4 Connection procedure of electric circuit board Connector and valve's compatibility on electric circuit board may differ depending on reduced wiring specifications (T10, T11, T30, T50, T51, T52, T53, T6*, T7*). When wiring the connector, always confirm the connector No.

- Page 52 Discontinue 6 MAINTENANCE Electric circuit board assembly Compatibility with valves [SM-P00037-A]...

-

Page 53: Trouble Shooting

Discontinue TROUBLE SHOOTING 7. TROUBLE SHOOTING TROUBLE SHOOTING Motion troubles Suspected cause Remedies No electric signals Turn on the power Damage to signal wiring system Repair the control circuit Excessive fluctuating range of current or Reaffirm the power capacity. Does not actuate voltage (within ±10% of voltage fluctuation) The circuit is not wired correctly... -

Page 54: Product Specifications And How To Code Model Numbers

Discontinue 8 HOW TO ORDER 8. PRODUCT SPECIFICATIONS AND HOW TO CODE MODEL NUMBERS 8.1 Product specifications 1) Common specifications Model number MN4G1・MN4G2 Item Working fluid Compressed air Operation method Pilot operated type Valve structure Soft spool valve Min. working pressure MPa Max. - Page 55 Discontinue 8 HOW TO ORDER Response time Item Two 3 -port valves built-in Response Single time 2-position - - Double [ms] ABR port 3-position connection Values include the light surge suppressor. Response time is the value at an air supply of 0.5 MPa, 20℃, and oil-free. Changes based on pressure and quality of oil.

- Page 56 Discontinue 8 HOW TO ORDER 5) Weight Valve 3GA1 3GA2 4GA1 4GA2 4GB1 4GB2 grommet lead wire E-connector EJ-connector - - - DIN terminal box 2-position - - grommet lead wire - - E-connector - - EJ-connector - - - -...

- Page 57 Discontinue 8 HOW TO ORDER MN4G2 Block Weight Model Specification N3GD210-C8-3 N3GD2110-C8-3 Direct ported N4GD210-C8-3 Individual wiring N4GD220-C8-3 N4GD230-C8-3 N3GD2660-C8-3 N4GE210-C8-3 Base ported N4GE220-C8-3 Individual wiring N4GE230-C8-3 N3GE2660-C8-3 Valve block with valve N3GD210-C8-A2N-3 N3GD2110-C8-A2N-3 Direct ported N4GD210-C8-A2N-3 Reduced wiring N4GD220-C8-A2N-3 N4GD230-C8-A2N-3 N3GD2660-C8-A2N-3 N4GE210-C8-A2N-3...

-

Page 58: How To Code Model Numbers

Discontinue 8 HOW TO ORDER 8.2 How to code model numbers Individual wiring manifold; body porting Manifold model no. MN4GD1 3 port manifold model no. MN3GD1 Discrete valve block with solenoid valve N4GD1 Discrete valve block with 3 port solenoid valve N3GD1 Discrete valve for base installation 4GD1... - Page 59 Discontinue 8 HOW TO ORDER (A) Model No. N N N N N N N N N N N N N N N N 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 G G G G G G G G G G G G G G G G...

- Page 60 Discontinue 8 HOW TO ORDER Individual wiring manifold; sub-base porting Manifold model no. MN4GE1 3 port manifold model no. MN3GE1 Discrete valve block with solenoid valve N4GE1 Discrete valve block with 3 port solenoid valve N3GE1 Discrete valve for base installation 4GE1 (A) Model No.

- Page 61 Discontinue 8 HOW TO ORDER (A) Model No. N N N N N N N N N N N N N N N N 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 G G G G G G G G G G G G G G G G...

- Page 62 Discontinue 8 HOW TO ORDER Reduced wiring manifold; body porting Manifold model no. MN4GD1 3 port manifold model no. MN3GD1 Discrete valve block with solenoid valve N4GD1 Discrete valve block with 3 port solenoid valve N3GD1 Discrete valve for base installation 4GD1 (A) Model No.

- Page 63 Discontinue 8 HOW TO ORDER (A) Model No. N N N N N N N N N N N N N N N N 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 G G G G G G G G G G G G G G G G...

- Page 64 Discontinue 8 HOW TO ORDER Reduced wiring manifold; body porting; serial transmission Manifold model no. MN4GD1 T6A0 3 port manifold model no. MN3GD1 T6A0 Discrete valve block with solenoid valve N4GD1 Discrete valve block with 3 port solenoid valve N3GD1 Discrete valve for base installation 4GD1 Discrete 3 port valve for base installation...

- Page 65 Discontinue 8 HOW TO ORDER (A) Model No. N N N N N N N N N N N N N N N N 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 G G G G G G G G G G G G G G G G...

- Page 66 Discontinue 8 HOW TO ORDER Reduced wiring manifold; sub-base porting Manifold model no. MN4GE1 3 port manifold model no. MN3GE1 Discrete valve block with solenoid valve N4GE1 Discrete valve block with 3 port solenoid valve N3GE1 Discrete valve for base installation 4GE1 (A) Model No.

- Page 67 Discontinue 8 HOW TO ORDER (A) Model No. N N N N N N N N N N N N N N N N 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 G G G G G G G G G G G G G G G G...

- Page 68 Discontinue 8 HOW TO ORDER Reduced wiring manifold; sub-base porting; serial transmission Manifold model no. MN4GE1 T6A0 3 port manifold model no. MN3GE1 T6A0 Discrete valve block with solenoid valve N4GE1 Discrete valve block with 3 port solenoid valve N3GE1 Discrete valve for base installation 4GE1 (A) Model No.

- Page 69 Discontinue 8 HOW TO ORDER (A) Model No. N N N N N N N N N N N N N N N N 3 3 3 3 3 3 3 3 4 4 4 4 4 4 4 4 G G G G G G G G G G G G G G G G...

- Page 70 Discontinue 8 HOW TO ORDER 8.3 Option 1) Explanation of option ・With check valve: Symbol “H” Refer to 5.1 section. To prevent malfunction due to introduction of back pressure, a gasket with a malfunction prevention valve can be selected. ・Ozone and coolant proof : Symbol “A” Set it if the coolant flows in the valve.

-

Page 71: Accessories

Discontinue 8 HOW TO ORDER 8.4 Accessories 1) Mounting rail All the angular corners are rounded. The mounting rail is cut at a mounting pitch of 12.5 mm. (pitch) Silencer Model SLW-H6 SLW-H8 SLW-H10 Blank plug Model GWP4-B GWP6-B 12.5 GWP8-B GWP10-B 18.5... -

Page 72: Kit Parts

Discontinue 8 HOW TO ORDER 8.5 Kit parts Commodity Model Part name 4G-Wiring type - Option - COIL - Voltage 1: AC100V 3: DC24V 4: DC12V Blank : standard type Coil assembly A : Ozone-resistant Blank : Grommet lead wire E* : E-type connector E*J : EJ-type connector A2N : A-type connector... - Page 73 Discontinue 8 HOW TO ORDER Masking plate kit Model name Model Description 1 Masking plate, 4G1-MP 1 Gasket, 2 Mounting screws 1 Masking plate, 4G2-MP 1 Gasket, 2 Mounting screws, 2 PR check valve 4) Selecting the expansion socket assembly Calculate distance W between the expansion location and wiring block (Fig), and select the appropriate cable length from Table.

- Page 74 Discontinue 8 HOW TO ORDER 5) supply spacer Valve model No. supply spacer model no. GWS6 Descriptions Sy mbol (A) supply spacer model no. ● ● (B) Port size Note 1 Note 1 Blank M5 (4G1), Rc thread (4G2) ● ● GWS4 4 joint ●...

- Page 75 Discontinue 8 HOW TO ORDER 11) Mounting screw for coil assembly (One set: 10 screws) Model Description 4G-COIL-SET-SCREW 10 Mounting screws (for 5 units) 12) Serial transmission slave unit Wiring type Model Description T6A0 4G-OPP3-0A T6A1 4G-OPP3-1A T6C0 4G-OPP3-0C T6C1 4G-OPP3-1C T6E0 4G-OPP3-0E...

Need help?

Do you have a question about the MN3GD/E1 Series and is the answer not in the manual?

Questions and answers