Renkforce FDM 3D Printer Pro 6+ Operating Instructions Manual

Hide thumbs

Also See for FDM 3D Printer Pro 6+:

- Quick start manual (2 pages) ,

- User manual (27 pages) ,

- Safety instruction (8 pages)

Table of Contents

Advertisement

Quick Links

Bedienungsanleitung

FDM 3D Drucker Pro 6+

Best.-Nr. 2583518

Operating Instructions

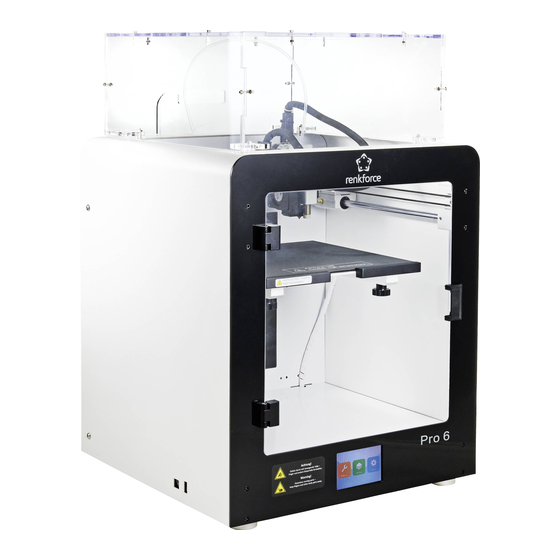

FDM 3D Printer Pro 6+

Item No. 2583518

Lesen Sie vor dem Gebrauch die Sicherheitshinweise die dem Produkt

beiliegen

Read the safety instructions supplied with the product before using

Befolgen Sie diese Anleitungen, um eine sichere und

ordnungsgemäße Verwendung zu gewährleisten.

For safe and proper use, follow these instructions

Advertisement

Table of Contents

Summary of Contents for Renkforce FDM 3D Printer Pro 6+

- Page 1 Bedienungsanleitung Lesen Sie vor dem Gebrauch die Sicherheitshinweise die dem Produkt beiliegen FDM 3D Drucker Pro 6+ Read the safety instructions supplied with the product before using Best.-Nr. 2583518 Operating Instructions FDM 3D Printer Pro 6+ Item No. 2583518 Befolgen Sie diese Anleitungen, um eine sichere und ordnungsgemäße Verwendung zu gewährleisten.

-

Page 2: Table Of Contents

1 Table of contents Introduction ....................3 13 Filaments ....................21 Up-to-date operating instructions ..............3 13.1 Changing filaments ................21 Intended use ....................3 14 Cleaning .....................22 Delivery content ...................4 14.1 Cleaning the printer ................22 Description of symbols .................4 14.2 Cleaning the magnetic mat ..............22 7.1 Printer ....................5 14.3 Cleaning the nozzle ................22 7.2 Print head ....................6... -

Page 3: Introduction

2 Introduction 4 Intended use Dear customer, The product is a 3D printer. Thank you for purchasing this product. The product is not designed for use in the food and medical industries. If there are any technical questions, please contact: www.conrad.com/contact The product is intended for indoor use only. -

Page 4: Delivery Content

5 Delivery content 6 Description of symbols Printer The following symbols are on the product/appliance or are used in the text: Housing For safe and proper use, follow these instructions. Keep them for future Magnetic mat reference. Spool holder Filament tube The symbol warns of hazards that can lead to personal injury. -

Page 5: Printer

7 Operating elements 7.1 Printer ② ⑦ ④ ⑤ ③ ⑥ ① 1 Touch screen 4 Print head 7 USB-A port 2 USB-B port 5 Cooling fan 3 Print bed 6 Power inlet with power switch... -

Page 6: Print Head

7.2 Print head 1 Nozzle 6 Object fan 2 Heat block of hotend 7 Extruder fan 3 Heater and NTC 8 Cover of extruder 4 Filament feed tube 5 Heatsink... -

Page 7: Print Bed

7.3 Print bed 1 Print bed 3 Leveling screw 2 Magnetic mat 4 Heating panel... -

Page 8: Touch Screen Menus

8 Touch screen menus 8.2.2 Manual interface In the menu Manual you can manually steer the print head along The touch screen is on when the power supply is the X, Y, and Z-axis. connected. Do not touch the screen with sharp ob- jects. - Page 9 8.2.3 Preheating 8.2.4 Filament In the menu Preheat you can set print bed and extruder tempera- In the menu Filament you can control the loading and unloading of tures. filaments. Temperature 27/0 Temperature Bed Temp 28/0 Stop Heatbed 28/0 Unload Load Extruder Extruder...

-

Page 10: Print Menu

8.3 Print menu 8.2.5 Fan control In the menu Fan you can adjust fan parameters. In the menu Print you select print files for printing. 8.3.1 Print file selection E1(%) Extruder fan in % B(%) Object fan in % A Navigate menu C Print files B Return to previous menu item A Decrease air flow... - Page 11 8.3.2 Print control 8.3.3 Print parameters In the print parameters menu you can set parameters for print jobs. A Stop printing F Elapsed time B Print speed G Print bed temperature C Pause printing H Nozzle temperature D Remaining time I Print job progress bar E Adjust print parameters A Set object fan parameters...

-

Page 12: Installation

9 Installation 9.3.1 Installing the spool holder 9.3.2 Installing the filament tube 1. Insert the filament tube in the feeder. 2. Insert the filament tube into the extruder. -

Page 13: Power Supply

10 Power supply 11 Before printing Before you can print you must 10.1 Connecting to power calibrate the print bed 1. Connect the mains cable to the power inlet on the printer. load the filament 2. Connect the mains cable to a suitable mains outlet. 11.1 Calibrating the print bed 10.2 Switching on/off Calibrate the print bed before you use the printer for the first time, after transporting... - Page 14 11.1.1 Using “Auto-levelling” to level the print bed Use “Auto-levelling” to level the print bed automatically. “Auto-levelling” will attempt to level the print bed with high precision and is only useful for making fine adjustments to the print bed. Insert the print bed and magnetic mat. Open the menu Tools.

- Page 15 11.1.2 Calibrating the Z-offset CAUTION By calibrating the Z-offset you set the distance between the nozzle and the print bed. Hot print bed Z-offset calibration is followed by “Auto-levelling”. Touching hot print bed can cause burns Let cool down before touching Insert the print bed and magnetic mat.

- Page 16 Touch the distance increment 0.1 mm Activate the Z-offset calibration with the Slide one sheet of A4 paper (80 g) slider. to activate it. between the nozzle and the print bed. Touch the button Leveling to start Confirm the Z-offset calibration. Slide the paper back and forth while repeatedly touching the button to lift “Auto-levelling”.

- Page 17 11.1.3 Levelling the print bed manually You level the print bed manually to prepare it for “Auto-levelling”. Manual levelling must always be followed by Z-offset calibration and “Auto-levelling”. Insert the print bed and magnetic mat. Open the menu Tools. Open the menu Manual. Activate the Z-offset calibration.

- Page 18 Level each of the four indicated calibration points individually. Slide the paper back and forth while repeatedly touching the button to lift the print bed up. As soon as you notice slight resistance between nozzle, paper, and print bed Touch the buttons to navigate the extruder to each calibration point.

-

Page 19: Loading Filament

11.2 Loading filament Open the menu Tools. Open the menu Filament. Touch the temperature display to preheat Cut the filament at an angle and then feed it the extruder. into the feeder. Touch the button E1 Load to load the Touch the button Stop as soon as molten filament flows from the nozzle. -

Page 20: Printing

12 Printing 12.4 Removing printed models 12.1 Printing from USB memory stick CAUTION 1. Save the print file that contains the model to the supplied USB memory stick. Hot print bed 2. Connect the USB memory stick to the USB-A port on the printer. Touching hot print bed can cause burns 3. -

Page 21: Filaments

13 Filaments 13.1 Changing filaments If you want to use a different filament, you must first unload the current filament and then load the new filament. Open the menu Tools. Open the menu Filament. Touch the temperature display to preheat Touch the button E1 Unload to unload the extruder. -

Page 22: Cleaning

14 Cleaning 14.4 Cleaning the inside of the nozzle Clean the inside of the nozzle if residue obstructs the filament flow. 14.1 Cleaning the printer CAUTION Important: – Do not use aggressive cleaning agents, rubbing alcohol or other chemical solu- Hot nozzle and molten filament tions. -

Page 23: Cleaning The Extruder

15 Maintenance 14.5 Cleaning the extruder 15.1 Calibrating the Z-sensor CAUTION Calibrate the Z-sensor after replacing the nozzle or the hotend. The calibration of the Hot nozzle and molten filament Z-sensor directly affects the precision of the “Auto-levelling” function. 1. Disconnect the power supply. Touching hot nozzle or molten filament can cause burns 2. -

Page 24: Replacing The Fuse

16 Storage 15.2 Replacing the fuse 1. Remove the mains cable from the power inlet on the printer. 1. Disconnect the power supply. 2. Pry open the fuse box. See Fig. 4. 2. Unload the filament. 3. Remove the blown fuse. 3. -

Page 25: Troubleshooting

17 Troubleshooting Problem Possible solution No power supply. Check mains connection. Display does not switch on. Check fuse. Replace fuse if blown. Filament snaps. Check that filament spool turns freely. Check if filament is trapped on the way from spool to extruder. Too little filament is extruded. -

Page 26: Disposal

18 Disposal 19 Declaration of Conformity (DOC) Conrad Electronic SE, Klaus-Conrad-Straße 1, D-92240 Hirschau hereby declares that This symbol must appear on any electrical and electronic equipment placed this product conforms to the 2014/53/EU directive. on the EU market. This symbol indicates that this device should not be dis- Click on the following link to read the full text of the EU declaration of conformity: posed of as unsorted municipal waste at the end of its service life. -

Page 27: Technical Data

20 Technical data 20.4 Wi-Fi module Wi-Fi frequency range ....2412 - 2472 MHz (802.11b/g/n20) 20.1 Power supply Wi-Fi transmission power ..... 802.11b : 10.91 dBm 802.11g : 11.98 dBm Input voltage ......... 100 – 240 V/AC, 50 – 60 Hz 802.11n-HT20: 13.04 dBm Power consumption ...... - Page 29 Dies ist eine Publikation der Conrad Electronic SE, Klaus-Conrad-Str. 1, D-92240 Hirschau (www.conrad.com). Alle Rechte einschließlich Übersetzung vorbehalten. Reproduktionen jeder Art, z. B. Fotokopie, Mikroverfilmung, oder die Erfassung in elektronischen Datenverarbeitungsanlagen, bedürfen der schriftlichen Genehmigung des Herausgebers. Nachdruck, auch auszugsweise, verboten. Die Publikation entspricht dem technischen Stand bei Drucklegung. Copyright 2022 by Conrad Electronic SE.

Need help?

Do you have a question about the FDM 3D Printer Pro 6+ and is the answer not in the manual?

Questions and answers