Summary of Contents for SCHUNK SVP-2

- Page 1 Translation of the original manual Assembly and Operting Manual Clamping Device SVP-2 Polygonal Clamping System...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Fastening the clamping device onto a work bench .......... 13 Assembly of the length adjustment.............. 13 Operation ....................... 15 Reduction insert and toolholder................. 15 Notes on clamping and unclamping .............. 17 TRIBOS pressure table .................. 19 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 4 7.10 Oil leaking out of the clamping device ............... 28 Maintenance ...................... 29 Care and storage .................... 29 Maintenance and service ................... 29 Transport and disposal.................... 30 Transport ...................... 30 Disposal ...................... 30 10 Short manual ...................... 31 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

-

Page 5: General

Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. CAUTION Material damage! Information about avoiding material damage. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 6: Applicable Documents

• Protective cover for TRIBOS clamping device SVP-2/2D (ID number: 9935548) • Length adjustment LMG-M (ID number: 0201961) • Stacker (ID number: 0211768) • Protective cover for Stacker (ID number: 9937963) 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 7: Basic Safety Notes

Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 8: Environmental And Operating Conditions

The incorrect handling of disposal may impair the product's safety and cause serious injuries as well as considerable material and environmental harm. • Follow local regulations on dispatching product components for recycling or proper disposal. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 9: Fundamental Dangers

Insert the toolholder till the stop into the reduction insert and • position correctly (via the flattened areas). Insert the reduction insert till the stop into the clamping • device. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 10 A too low minimum clamping depth causes loss of accuracy and torque at the toolholder. Observe minimum clamping depth of the tool, • See Assembly and Operating manual Toolholder. ✓ 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

-

Page 11: Technical Data

3.2 Position of the type plate Type plate 3.3 Content of the type plate Product designation and Id-No. Id-No. Type plate Consecutive No. Construction date Technical data 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

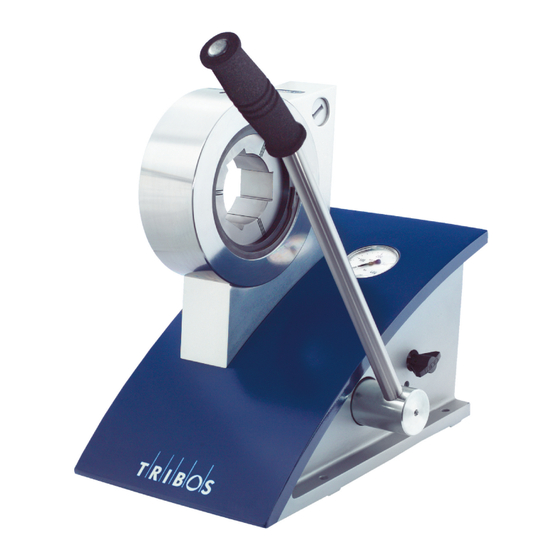

Page 12: Design And Description

Through bore for fastening 4.2 Description • Clamping device for a safe and quick tool change. • With the clamping device clamp TRIBOS tools quickly and evenly. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 13: Assembly And Settings

• 1 Caliper gauge (1) • 2 Measuring legs (2) • 2 Brackets for the measuring pins (3) • 2 Knurled screws (4) • 1 Safety pin (5) 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 14 To determine the zero point of the caliper gauge, swivel up the Ø two measuring arms and slide towards one another. Set the caliper gauge´s display to zero (see illustration). 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

-

Page 15: Operation

Material damage due to exceeding the permissible pressure! Too high pressure causes deformation of the toolholder and loss of function. Observe the pressure specifications of the toolholder. • 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 16 To unclamp the device, open the pressure release valve. Ø The reduction insert with the toolholder can be removed from ✔ the clamping device. The toolholder is now ready for use. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

-

Page 17: Notes On Clamping And Unclamping

• Sometimes, the tool shanks are marked. These markings are often "wrapped". This impairs the insertion of the TRIBOS toolholder or even makes an insertion impossible. In this case, re-move the wrapping. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 18 If the degree of hardness or stiffness should be lower, the compression joint is not properly covered and therefore results a reduced force transmission of the clamping system. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

-

Page 19: Tribos Pressure Table

Operation 6.3 TRIBOS pressure table Generally the following applies: Observe TRIBOS pressure table 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 20: Troubleshooting

Too much pressure could have been aligned with the segment). applied to toolholder/reduction insert causing constant deformation. TRIBOS toolholder not turned to right- hand stop. Turn TRIBOS toolholder to right-hand stop 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 21 Keep clamping area clean at the outer diameter. It must be possible to insert the reduction insert properly. Stickers or the like on the clamping area. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

-

Page 22: Tool Shank Can Only Be Partially Inserted Into The Toolholder

Bad quality of tool shank e.g. it may have Check tool shank. a slightly conical shape. Use tool shank with tolerance h6. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 23: Tool Cannot Be Removed From The Toolholder

Actuate clamping device on release pressure for the toolholder. Drive out the tool shank using a hammer and a suitable drift punch. Clean clamping bore and clamp new tool. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 24: Tool Shank Can Be Inserted Outside The Pressure Range If Slight Pressure Is Applied

(> h6). 7.6 Clamping device does not build up pressure Possible cause Corrective action Close Open Hydraulic valve on pump housing is open. Close hydraulic valve. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 25: Torque / Clamping Force / Holding Force Too Low

Lubricant film on tool shank and/or on De-grease and clean clamping area and tool clamping area. shank. Toolholder and tool were inserted with Adjust cutting data/cutting values. wrong (too high) cutting data. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 26: Concentricity Errors On The Clamped Tool

Tool shank not fully cylindrical. Use fully cylindrical tool shanks. Minimum shank clamping depth was not Observe minimum shank clamping depth (see observed. operating manuals TRIBOS polygonal toolholder). 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 27: Svp-2 Clamping Device Does Not Reach Required Pressure

Retighten screw connections, refill with oil if Screw connection necessary and vent clamping device Care and storage 29]. Filter screw Screw connection Oil leakage at TRIBOS pressure body (screw connection, terminal block) 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 28: Oil Leaking Out Of The Clamping Device

7.10 Oil leaking out of the clamping device Possible cause Corrective action Replace seal. send the clamping device to SCHUNK for inspection/repair Oil leakage at pressure body (seal) 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 29: Maintenance

Service and repair work should only be carried out in accordance with the service instructions by qualified personnel. This includes SCHUNK service technicians or qualified technicians trained by SCHUNK. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 30: Transport And Disposal

The use of unsuitable means of transport can cause injuries. Use suitable means of transport. • 9.2 Disposal For proper disposal, return the clamping device to SCHUNK. 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... -

Page 31: Short Manual

Short manual 10 Short manual 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021... - Page 32 03.00 | Clamping Device SVP-2 | Assembly and Operting Manual | en | 0289021...

Need help?

Do you have a question about the SVP-2 and is the answer not in the manual?

Questions and answers