Summary of Contents for SCHUNK VERO-S NSL mikro 50-13

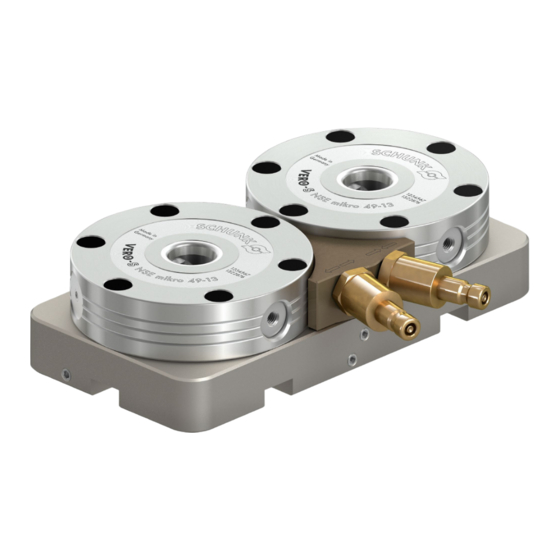

- Page 1 Translation of the Original Operating Manual VERO-S clamping station NSL mikro 50-13 Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 General ........................5 1.1 About this manual ....................5 1.1.1 Presentation of Warning Labels ..............5 1.1.2 Applicable documents ................... 6 1.2 Sizes .......................... 6 1.3 Warranty ........................6 1.4 Scope of delivery ...................... 6 1.4.1 Accessories .................... - Page 4 Table of Contents 5 Maintenance and care ..................... 28 5.1 Ambient conditions and operating conditions ............28 5.2 Control of proper function ..................29 5.3 Leak test ........................30 6 Troubleshooting ...................... 31 7 Parts list ........................32 8 Drawings ......................... 33 9 Declaration of Incorporation ...................

-

Page 5: General

General General About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Applicable Documents

• Catalog data sheets of standard products used * • Assembly and Operating Manual for VERO-S quick-change pallet system mikro 49-13 * The documents marked with an asterisk (*) can be downloaded on our homepage schunk.com Sizes This manual applies to the following sizes: Clamping stations •... -

Page 7: Accessories

General 1.4.1 Accessories (see catalog or data sheets when ordering separately) • Clamping pallets type PAL mikro • Clamping pallets type SPA mikro 10, SPB mikro 10, SPC mikro • Protection cover type SDE mikro 01.00|NSL mikro 50-13 1425873|en... -

Page 8: Basic Safety Notes

Basic safety notes Basic safety notes Personnel qualification Inadequate qualifications of the personnel If the personnel working with the product is not sufficiently qualified, the result may be serious injuries and significant property damage. • All work may only be performed by qualified personnel. •... -

Page 9: Intended Use

SCHUNK. Spare parts Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. 01.00|NSL mikro 50-13 1425873|en... -

Page 10: Environmental And Operating Conditions

Basic safety notes Environmental and operating conditions Required ambient conditions and operating conditions Incorrect ambient and operating conditions can make the product unsafe, leading to the risk of serious injuries, considerable material damage and/or a significant reduction to the product's life span. •... -

Page 11: Notes On Safe Operation

Basic safety notes Notes on safe operation Incorrect handling of the personnel Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. • Avoid any manner of working that may interfere with the function and operational safety of the product. -

Page 12: Disposal

Basic safety notes 2.11 Disposal Handling of disposal The incorrect handling of disposal may impair the product's safety and cause serious injuries as well as considerable material and environmental harm. • Follow local regulations on dispatching product components for recycling or proper disposal. 2.12 Fundamental dangers General... -

Page 13: Protection During Commissioning And Operation

Basic safety notes Incorrect lifting of loads Falling loads may cause serious injuries and even death. • Stand clear of suspended loads and do not step into their swiveling range. • Never move loads without supervision. • Do not leave suspended loads unattended. 2.12.2 Protection during commissioning and operation Falling or violently ejected components... -

Page 14: Notes On Particular Risks

Basic safety notes 2.12.4 Notes on particular risks DANGER Risk of fatal injury from suspended loads! Falling loads can cause serious injuries and even death. • Stand clear of suspended loads and do not step within their swiveling range. • Never move loads without supervision. •... - Page 15 Basic safety notes WARNING Risk of injury when the clamping pin axis is being used in a horizontal position or during overhead applications, resulting in the device or pallet falling down. • Use a crane or a transport truck when transporting. •...

- Page 16 Basic safety notes CAUTION There is a risk of limbs being crushed by moving parts during manual loading and unloading and during the clamping procedure. • Do not reach into the clamping pin holder. • Use loading devices. • Wear protective gloves. CAUTION Danger due to pneumatic exhaust noises.

-

Page 17: Technical Data

Technical data Technical data Designation NSL mikro 50-13-V10 NSL mikro 50-13-2 1358958 1358959 Holding force (M3 / M4)* 3 / 5 kN 6 / 10 kN Pull-in force without 0.5 kN 1.0 kN turbo Pull-down force with 1.5 kN 3.0 kN turbo Repeat accuracy <... -

Page 18: Assembly

Assembly Assembly General Installation Notes The clamping pins are available as accessories and are suitable for transporting the clamping station. The eye bolts can be screwed into the internal threads of the clamping pins. The quick-change pallet modules of the clamping station are unlocked with compressed air to insert the clamping pins. -

Page 19: Aligning The Clamping Station

Assembly Aligning the clamping station The clamping station can be aligned with loose T-nuts along an aligning groove on the machine table. At least two T-nuts offset lengthwise are provided and their size is matched to the aligning groove on the machine table. The T-nuts are not included in the scope of delivery of the clamping station. - Page 20 Assembly Compliance For the sake of conformity, clamping pins with positioning accuracy in one direction (SPB mikro 10) should be used for clamping modules within a clamping station or multiple interlinked clamping stations that are more than 160 mm apart or that do not show a positioning tolerance of ±0.01 mm.

- Page 21 Assembly Clamping areas for mounting using cylindrical clamp blanks NSL mikro 50-13-V10 NSL mikro 50-13-2 A / B / C D / E / F Cylindrical clamp blanks are versatile fastening elements The mounting holes are machined by the customer Flexible mounting options for common slot spacings of the machine tables 01.00|NSL mikro 50-13 1425873|en...

-

Page 22: Assembly And Connections

Assembly 4.3.1 Assembly and connections Clamping station NSL 50-13-V10 T-slot holder (4x) for alignment on the machine table Bearing surface of the four BRR mikro 17 clamp blanks for fastening the clamping station to the machine table. Short taper segment for position orientation of the clamping pallet Measure of clearance for IXB V10 PAL mikro in the clamping pallet Air connection for "Open module"... - Page 23 Assembly Clamping station NSL mikro 50-13-2 T-slot holder (6x) for alignment on the machine table Bearing surface of the four BRR mikro 17 clamp blanks for fastening the clamping station to the machine table Air connection for "Open module" with M6 connection thread Air connection for "Turbo function"...

-

Page 24: Unlocking Connection

Assembly 4.3.2 Unlocking connection When the unlocking connection of the clamping station is actuated with compressed air, all of the modules are unlocked simultaneously. Clamping pallets, devices and workpieces can be inserted in and removed from the clamping station. 4.3.3 Turbo connection The clamping station comes with a turbo connection as standard. -

Page 25: Screw Tightening Torques

This is why only screws of strength class 12.9 may be used. • Only original SCHUNK clamping pins may be used. • If the clamping pins are to be used in customer-owned devices, the customer must provide sufficiently dimensioned threaded holes or a sufficiently thick mounting material. - Page 26 Assembly The clamping pins can be attached to the workpiece or pallet in two different ways. Preference should be given to the left mounting option in the illustration "Mounting the clamping pins". With this variant, if there is a module failure then the device or pallet can be removed after disassembling the clamping pins.

- Page 27 Assembly Usage/arrangement of the different types of clamping pins 01.00|NSL mikro 50-13 1425873|en...

-

Page 28: Maintenance And Care

If a pneumatic clamping module has to be disassembled, send the module to SCHUNK for repair. The rear cover of the clamping module is spring preloaded and must only be removed and installed using a special installation tool by trained specialist personnel and in line with the appropriate removal and installation manual. -

Page 29: Control Of Proper Function

Maintenance and care • Check the clamping stations at regular intervals (at least every two weeks or after 1000 clampings). The system is functioning correctly if the clamping slides move smoothly at minimum system pressure (5 bar) and open completely. •... -

Page 30: Leak Test

Maintenance and care Leak test As part of a leak test, the air and plug-in connections and the entire clamping station are tested for leaks. Leaks must be sealed, for example at the plug-in connections or at the set-screws for the duct closure. Defective components must be replaced with new parts. -

Page 31: Troubleshooting

Install maintenance unit with oiler with oiled compressed air Defective air connections Check air supply A component is broken (e.g. due to Replace the module or send it to SCHUNK for overloading) repair Excess tensile load on clamping pins Reduce support weight... -

Page 32: Parts List

Parts list Parts list Item Designation (piece) (piece) Base plate VERO-S NSE mikro 49-13-V10 VERO-S NSE mikro 49-13 Connecting strip Sealing nipple Locking screw O-ring Ø 2 x 1 Fastening screw Locking coupling 10** Cylindrical clamp blanks BRR mikro 17 Parts list key contained in NSL mikro 50-13-V10 (ID 1358958) contained in NSL mikro 50-13-2 (ID 1358959) -

Page 33: Drawings

Drawings Drawings Wearing parts; replacement is recommended when maintenance is performed Parts are unassembled on delivery For scope of delivery of quick-change pallet system, see parts list in NSE mikro 49-13 operating manual 01.00|NSL mikro 50-13 1425873|en... - Page 34 Drawings Wearing parts – replacement is recommended when maintenance is performed Parts are unassembled on delivery For scope of delivery of quick-change pallet system, see parts list in NSE mikro 49-13 operating manual 01.00|NSL mikro 50-13 1425873|en...

-

Page 35: Declaration Of Incorporation

Declaration of Incorporation in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of the Council on machinery. Manufacturer/ H.-D. SCHUNK GmbH & Co. Spanntechnik KG Distributor Lothringer Str. 23 D-88512 Mengen We hereby declare that on the date of the declaration the following partly completed machine complied with all basic safety and health regulations found in the directive 2006/42/EC of the European Parliament and of the Council on machinery. -

Page 36: Annex To Declaration Of Incorporation

Annex to Declaration of Incorporation Annex to Declaration of Incorporation according 2006/42/EG, Annex II, No. 1 B 1.Description of the essential health and safety requirements pursuant to 2006/42/EC, Annex I that are applicable and that have been fulfilled with: Product designation Clamping station VERO-S Type designation NSL mikro 50-13-V10, NSL mikro 50-13-2... - Page 37 Annex to Declaration of Incorporation Risks due to other hazards 1.5.1 Electricity supply 1.5.2 Static electricity 1.5.3 Energy supply other than electricity 1.5.4 Errors of fitting 1.5.5 Extreme temperatures 1.45.6 Fire 1.5.7 Explosion 1.5.8 Noise 1.5.9 Vibrations 1.5.10 Radiation 1.5.11 External radiation 1.5.12 Laser radiation...

Need help?

Do you have a question about the VERO-S NSL mikro 50-13 and is the answer not in the manual?

Questions and answers