Table of Contents

Advertisement

Quick Links

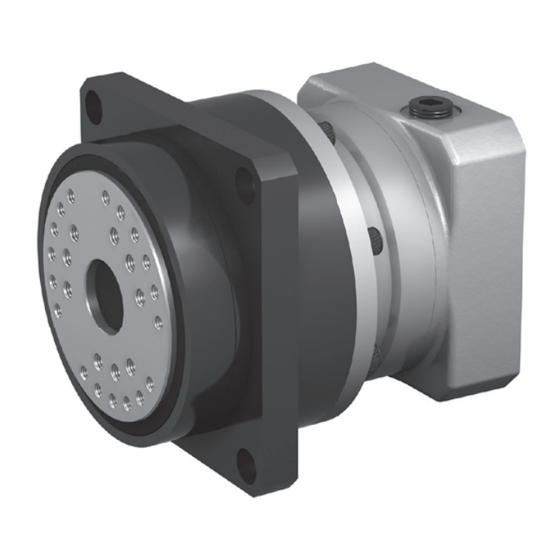

MC DRIVE

IB

Series

Speed Reducer for Servo Motors

Speed reducer should be handled, installed and maintained by trained

technicians. Carefully read the maintenance manual before use.

A copy of this maintenance manual should be sent to the actual user .

This maintenance manual should be maintained by the user.

Maintenance Manual ZM2003E

ZM2003E-3.0

-3

2006.1

Advertisement

Table of Contents

Summary of Contents for Sumitomo Drive Technologies IB Series

- Page 1 MC DRIVE Series Speed Reducer for Servo Motors Speed reducer should be handled, installed and maintained by trained technicians. Carefully read the maintenance manual before use. A copy of this maintenance manual should be sent to the actual user . This maintenance manual should be maintained by the user.

- Page 2 Safety and Other Precautions ● Carefully read this maintenance manual and all accompanying documents before use (installation, operation, maintenance, inspection, etc.). Thoroughly understand the machine, information about safety, and all precautions for correct operation. Maintain this manual for future reference. ●...

-

Page 3: Table Of Contents

CONTENTS 1. Inspection Upon Delivery..............13 2. Storage....................15 3. Transport.................... 15 4. Installation................... 16 5. Coupling with Other Machines............17 6. Operation.................... 18 7. Daily Inspection and Maintenance............19 8. Instructing Motor Installation............... 10 9. Construction Drawing................. 14 10.Backlash..................... 18 11.Warranty..................... -

Page 4: Inspection Upon Delivery

• When making an inquiry, advise us of 1 the type of reducer and 2 serial No. 1—2) Lubrication Method Since all MC drive IB series adopt grease lubrication, grease has been loaded on shipping from factory. Put units into operation as they are. - Page 5 1—3) Nomenclature of Reducer ● Type M, L, K MC Drive IB Series A N F SVLB 29 Ratio Specification Suffix SV:Backlash 3min. SVLB:Backlash 0.5min. Type and Frame Size Input Connection Type M J:Adaptor plate(without motor) JM:With motor Mounting F:F flange...

-

Page 6: Storage

2. Storage When storing reducers for any extended period of time, consider the following important points. 1) Storage Location — Store the unit in a clean, dry place indoors. • Avoid storage outdoors or in places with humidity, dust, sudden temperature change, or corrosive gas. -

Page 7: Installation

4. Installation CAUTION ● Do not use the reducer for purpose other than those shown on the rating plate or in the manufacturing specification; otherwise, electric shock, injury, or damage to the equipment may result. ● Do not place any object that will hinder ventilation around the reducer; otherwise, the cooling effect is reduced, possibly leading to fire or burns due to excessive heat built-up. -

Page 8: Coupling With Other Machines

5. Coupling with Other Machines CAUTION ● Confirm the direction of rotation before coupling the unit with the driven machine. Difference in the direction of rotation may cause injury or damage to the equipment. ● When operating the reducer alone (uncoupled), remove the key that is temporarily attached to the output shaft;... -

Page 9: Operation

(2) When Using a Chain Sprocket and Gear • The chain tension angle should be perpendicular to the shaft. • Refer to the chain catalog for the chain tension. • Select sprockets and gears whose pitch diameter are three times the shaft diameter or geater. -

Page 10: Daily Inspection And Maintenance

7. Daily Inspection and Maintenance DANGER ● Do not approach or touch any rotating parts (output shaft, etc.) during maintenance or inspection of the unit; otherwise, loose clothing caught in these rotating parts may result in injury or death. CAUTION ●... -

Page 11: Instructing Motor Installation

8. Instructing Motor Installation 1) Type M · L — This is the construction anyone can connect with motor because the coupling is used at the shaft coupling part between reducer and motor. Assemble them as the following instruction. (1) Put the reducer on the proper table so that the slow speed shaft is facing down. (2) Put hub(1), spacer, and hub(2) of the coupling which are equipped with the input shaft of the reducer in order, and push them until clicks of the hub are engaged enough. - Page 12 2) Type K — Because the special coupling is used at the coupling part between reducer and motor, it is possible to install either straight shaft, shaft with key groove, or D-cut shaft. Install it as the following instruction. (1) Set the coupling unified with primary sun gear into motor shaft. Set the tip of sun gear from the motor flange side for size in the table 5.

- Page 13 Motor Fastening bolt Coupling Primary sun gear Slow speed end cap High speed shaft shield Primary planetary gear Fig. 6 Motor Installation Drawing Table 5 Motor power Frame Reduction Designated Motor power Frame Reduction Designated size ratio size size ratio size ±...

- Page 14 3) Type P, P1 — Either straight type, shaft with keyway, or D shaft may be attached to the motor shaft, because special coupling is used for shaft connection part of reducer and motor. Follow the process below from (1) through (7) for assembly. (Remove key while assembly for shaft with keyway.) (1) Place reducer on an appropriate worktable with output shaft on the bottom side.

-

Page 15: Construction Drawing

9. Construction Drawing 1) Type M — As shown in Fig.8, this construction has two stages reduction structure with spur gear and two pairs of gear train for the clockwise and the counterclockwise directions are combined. Fig. 8 Type M Construction Drawing Part No. - Page 16 2) Type L — As shown in Fig.9, this is simple planetary gearing mechanism and has four gears at each stage. Two of them are for clockwise and the others for counterclockwise. This is the power transmitting mechanism. Fig.9 Type L Construction Drawing Part No.

- Page 17 3) Type K — As shown in Fig.10, this is simple planetary gearing mechanism and has four gears at each stage. Two of them are for clockwise and the others for counterclockwise. This is the power transmitting mechanism. Fig. 10 Type K Construction Drawing Part No.

- Page 18 4) Type P — 9 10 11 12 13 14 Fig. 11 Type P Construction Drawing Part No. Part name Output shaft Oil seal Bearing Sun gear Planetary gear Casing with internal gear Sun gear Planetary gear Internal gear Bracket Bearing Oil seal Coupling...

-

Page 19: Backlash

5) Type P1 — 9 10 11 12 13 14 15 Fig. 12 Type P1 Construction Drawing Part No. Part name Output Shaft Oil Seal Bearing of Output Sun Gear of Output Planetary Gear of Output Casing with Internal Gear Sun Gear of Input Planetary Gear of Input Internal Gear of Input... -

Page 20: Warranty

11. Warranty The scope of our warranty for our products is limited to the range of our manufacture. Warranty (period and contents) The warranty period for the Products shall be 18 months after the Warranty commencement of delivery or 18 months after the shipment of the Products Period from the seller's works or 12 months from the Products coming into operation, whether comes first.

Need help?

Do you have a question about the IB Series and is the answer not in the manual?

Questions and answers