Table of Contents

Advertisement

Quick Links

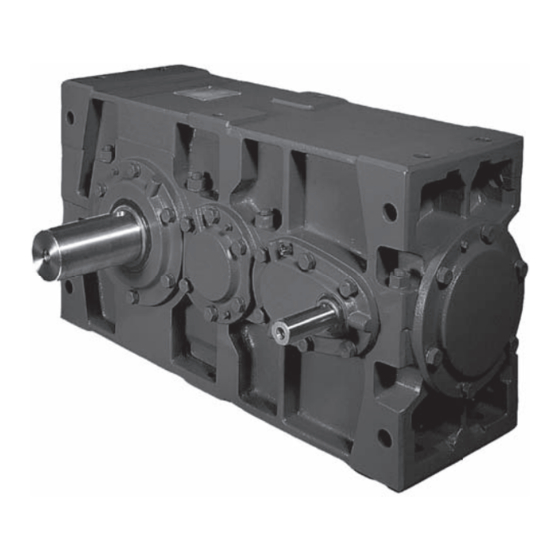

PARAMAX

M Series

CAUTION

These products should be handled, installed, and maintained by trained technicians.

Carefully read the maintenance manual before use.

Oil is removed from these products before shipment. Supply oil according to the

maintenance manual before operation.

A copy of this maintenance manual should be sent to the actual user.

This maintenance manual should be kept by the user for future reference.

®

Maintenance Manual

No.GM0102E-6

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Sumitomo Drive Technologies PARAMAX M Series

- Page 1 PARAMAX ® M Series CAUTION These products should be handled, installed, and maintained by trained technicians. Carefully read the maintenance manual before use. Oil is removed from these products before shipment. Supply oil according to the maintenance manual before operation. A copy of this maintenance manual should be sent to the actual user.

-

Page 3: Introduction: Safety Precautions

Introduction: Safety Precautions Carefully read this maintenance manual and all accompanying documents before use (installation, operation, ● maintenance, inspection, etc.). Thoroughly understand the machine, information about safety, and all precautions for correct operation. After reading, retain this manual for future reference. Pay close attention to the "DANGER"... -

Page 4: Table Of Contents

Introduction: Reading the Maintenance Manual, Table of Contents This is a maintenance manual for Paramax M Series. Please refer to Motor Maintenance Manual (No. MM1001E) for unit with motor. Contents Introduction : Safety Precautions …………………………………………………………………………………… Introduction: Reading the Maintenance Manual, Table of Contents ………………………………………………... -

Page 5: Inspection Upon Delivery

1. Inspection Upon Delivery CAUTION ● Unpack the unit after verifying that it is positioned right side up; otherwise, personal injury may result. ● Verify that the unit received matches your order. Installing an incorrect product may result in personal injury or damage to the equipment. - Page 6 1. Inspection Upon Delivery 1-2 Nomenclature Symbol meanings are shown below. Please confirm that the nomenclature matches the order. In case of special type, it may not be shown below. ANCV Series Shaft arragement Nominal reducion ratio M Series Type Size Auxiliary type (Model) Auxiliary type (Mounting)

-

Page 7: Storage

2. Storage If this product is not for immediate use, note the following points when storing. 2-1 Storage Location Store the product indoors in a clean, dry location. Do not store outdoors. Store in a location that is free of moisture, dust, extreme temperature changes, corrosive gas, etc. -

Page 8: Transport

3. Transport DANGER Do not stand directly under a unit suspended by a crane or other lifting mechanism; otherwise, personal ● injury, or death may result. CAUTION Exercise ample care so as not to drop the unit. ● When a hanging bolt or hole is provided, be sure to use it. After mounting a unit to a machine, do not hoist the entire machine using the hanging bolt or hole;... -

Page 9: Installation

4. Installation CAUTION Do not use the products for purposes other than those shown on the nameplate or in the ● manufacturing specifications; otherwise, electric shock, personal injury, or damage to the equipment may result. Do not place flammable objects around the reducer; otherwise, fire may result. ●... -

Page 10: Connecting To Machinery

5. Connecting to machinery CAUTION Confirm the rotation direction before connecting to the driven machine. Incorrect rotation direction ● may cause personal injury or damage to the equipment. Remove the key temporarily attached to the output shaft when the reducer operates alone; otherwise, ●... -

Page 11: Operation

6. Operation DANGER Do not approach or touch rotating parts (output shaft, etc.) during operation; otherwise loose ● clothing may become caught in these rotating parts and cause serious injury or death. CAUTION Do not put fingers or foreign objects into the opening of reducer; otherwise, electric shock, personal ●... -

Page 12: Daily Maintenance And Inspection

7. Daily Inspection and Maintenance DANGER Do not approach or touch any rotating parts (output shaft, etc.) during run-time maintenance or ● inspection of the unit; otherwise loose clothing may become caught in these rotating parts and cause serious injury or death. When shutdown inspection is conducted to check the tooth surface, make sure to stop the motor and ●... - Page 13 7. Daily Inspection and Maintenance DANGER For equipment with a motorized oil pump, run the pump prior to starting the reducer. Start motor of re- ● ducer after lubricant has circulated through the bearings; otherwise, the damage to the equipment may result.

- Page 14 7. Daily Inspection and Maintenance (3) Lubricant selection Refer to Table 7-5 to select appropriate oil viscosity. Table 7-6 shows recommended lubricants. Table 7-5 Oil Viscosity Ambient temperature °C -10 to 16 10 to 50 ISO*/AGMA VG68/2EP VG150/4EP * : Viscosity at ISO 40°C (mm Table 7-6 Recommended Lubricant Viscosity Classification...

- Page 15 7. Daily Inspection and Maintenance (6) Fill/Drain Grease • Except for some models, bearings are grease lubricated. Verify the number and locations of the grease fittings. • Grease is supplied before shipment. For grease supply after starting operation, supply necessary amount according to the following table 7-7.

- Page 16 7. Daily Inspection and Maintenance 7-4 Parts Maintenance To increase the reducer's service life, overhaul and replace below items every 3 to 5 years. Please contact factory for overhaul. Replacement parts ■ Bearing, oil seal, nilos ring, collar, key, shim, packing, retaining ring or visible gauge ■...

-

Page 17: Troubleshooting

8. Troubleshooting CAUTION Identify any abnormalities during operation and take appropriate corrective action outlined in this ● maintenance manual. Do not operate the unit until corrective action has been taken. Refer to Table 8-1 whenever the reducer is operating abnormally and take the appropriate corrective action im- mediately . -

Page 18: Construction Drawing

9. Construction Drawings 9-1 Construction Drawings (Parallel Shaft) Table 9-1 Parts List Part Name 10 11 12 13 Dip Stick Housing Bearing Helical Gear Oil Seal High Speed Shaft 10 Collar 11 Bearing 12 Nilos-ring 13 Key 14 Helical Pinion 15 Helical Gear 16 Intermediate shaft 17 Key... - Page 19 9. Construction Drawings 9-2 Construction Drawings (Right Angle Shaft) Table 9-3 Parts List Part Name Dip Stick Bearing Helical Gear Bearing Helical Pinion Shaft Bearing Intermediate shaft 10 Spiral Bevel Gear 11 Bearing 12 Bearing 13 Oil Seal 14 Bevel Pinion Shaft 15 Collar 16 Nilos-ring 17 Helical Pinion...

-

Page 20: Oil Quantity

10. Oil Quantity Table 10-1 N Type Oil Quantity Unit: Liter Double reduction Triple reduction Quadruple reduction Parallel shaft Right angle shaft Parallel shaft Right angle shaft Parallel shaft Right angle shaft Size Horizontal Vertical Horizontal Vertical Horizontal Vertical Horizontal Vertical Horizontal Vertical... -

Page 21: Oil Filler And Drain Plug Locations

11. Oil filler and Drain Plug Locations 11-1 Horizontal Oil Filler PlugOil Filler/Vent Plug PlugOil Filler/Vent Plug Oil Filler PlugOil Filler/Vent Plug Dip Stick Dip Stick Dip Stick Drain Plug Drain Plug Drain Plug Fig.11-1 N Type A-G Size Fig.11-2 N Type K-L Size Fig.11-3 D Type A-G Size 11-2 Vertical PlugOil Filler/Vent Plug PlugOil Filler/Vent Plug Oil Filler PlugOil Filler/Vent Plug Dip Stick Dip Stick... -

Page 22: Warranty

12. Warranty The scope of our product warranty is limited to our manufacturing range. Warranty The product warranty period is 18 months after delivery, 18 months after shipment of the product Period from the seller, or 12 months from product commissioning, whichever is first. In the event that any problem or damage to the product arises during the “Warranty Period”... - Page 24 Worldwide Locations Korea U.S.A Austria Sumitomo (SHI) Cyclo Drive Germany GmbH Sumitomo (SHI) Cyclo Drive Korea, Ltd. (SCK) Sumitomo Machinery Corporation of America (SCG) (SMA) Room #913, Royal Bldg, Saemunan-ro 5 gil 19, 4200 Holland Blvd. Chesapeake, VA 23323, U.S.A. SCG Branch Austria Office Jongro-gu, Seoul, Korea 03173 TEL (1)757-485-3355...

Need help?

Do you have a question about the PARAMAX M Series and is the answer not in the manual?

Questions and answers