Table of Contents

Advertisement

Quick Links

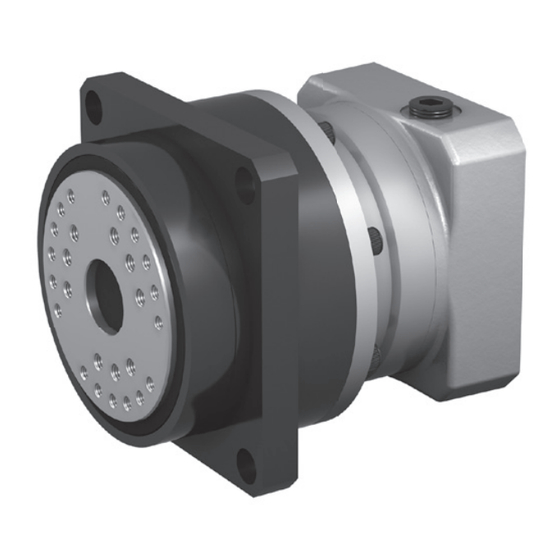

Planetary Gear Reducer

for Servo Motor

IB Series

P1 Type

PK1 Type

P2 Type

P Type

L Type

<Note>

■ This product should be handled by only those who have been trained for the work.

Please read this manual carefully before use.

■ Deliver this manual to the customer who will actually use the product.

■ This instruction manual should be carefully stored.

Maintenance Manual

No.ZM2003E-6

Advertisement

Table of Contents

Summary of Contents for Sumitomo Drive Technologies IB Series

- Page 1 Planetary Gear Reducer for Servo Motor IB Series P1 Type PK1 Type P2 Type P Type L Type <Note> ■ This product should be handled by only those who have been trained for the work. Please read this manual carefully before use. ■ Deliver this manual to the customer who will actually use the product. ■ This instruction manual should be carefully stored. Maintenance Manual No.ZM2003E-6...

-

Page 3: Introduction 】 Safety Precautions

【 Introduction 】 Safety Precautions • C arefully read this maintenance manual and all accompanying documents before use (installation, operation, maintenance, inspection, etc.). Thoroughly understand the machine, information about safety, and all precautions for correct operation. Maintain this manual for future reference. • Pay particular attention to the "DANGER" and "CAUTION" warnings regarding safety and proper use. Improper handling may result in physical damage, serious personal injury and/or death. Improper handling may result in physical damage and/or personal injury. Matters described in may lead to serious danger depending on the situation. Be sure to observe important matters described herein. DANGER ● T ransport, installation, plumbing, wiring, operation, maintenance and inspections should be handled by properly trained technicians; otherwise, electric shock, injury, fire, or damage to the equipment may result. ● I n the case of maintenance with disassembly, please contact our local subsidiary nearest to you. ● W hen the unit is to be used in a system for transport of human beings, a protective device should be installed. There is a risk of personal injury or damage to the equipment due to runaway or falling. -

Page 4: Table Of Contents

【 Contents 】 Contents 【 Introduction 】 Safety Precautions ………………………………………………………………… 1 【 Contents 】 ………………………………………………………………………………………… 2 【 1 】 Inspection Upon Delivery ……………………………………………………………………… 3 【 2 】 Storage ………………………………………………………………………………………… 5 【 3 】 Transportation ………………………………………………………………………………… 6 【 4 】 Installation ……………………………………………………………………………………… 7 【... -

Page 5: Inspection Upon Delivery

【 1 】 Inspection Upon Delivery CAUTION ● Unpack the unit after verifying that it is positioned right side up; otherwise, injury may result. ● V erify that the unit received is in fact the unit ordered. When a different unit is installed, injury or damage to the equipment may result. ● Do not remove the nameplate. Upon delivery and receipt of the reducer check the following. If a nonconformity or problem is found, contact our nearest agent, distributor, or sales office. [1] Do the items on the nameplate conform to what was ordered? [2] Were there any parts that were broken during transport? [3] Are all bolts and nuts tightened firmly? 1-1 How to Refer to the Nameplate There are two main types of nameplates: type 1 and type 2. Representative examples are shown below. Please observe them by type. When making an inquiry, advise us of the [1] Nomenclature and [2] Serial No. ■ Nameplate Type 1: P1, PK1, P2, P Type [1] Nomenclature [2] Serial No. - Page 6 【 1 】 Inspection Upon Delivery 1-3 Nomenclature The meanings of the symbols are as follows. Verify that the nomenclature matches that of the order. A N F X P120 2R LD Model Symbol Output Shaft Geometry IB Series Solid shaft (keyless) Solid shaft (with key) Flange shaft Note: L type does not have Output Shaft Direction this symbol. Can be mounted in either direction Mounting Method Special Specification Motor Flange Code Standard Flange Various Blank specifications mounting Note: L type does not have this Special symbol.

-

Page 7: Storage

【 2 】 Storage When storing reducers for any extended period of time, consider the following important points. 2-1 Storage Location Store the unit indoors in a clean dry location. Do not store the unit outdoors or in locations where there is excessive moisture, dust, severe temperature change, corrosive gas, etc. 2-2 Storage Period • Storage period should be less than 1 year. • Standard Rust Prevention Specifications External rust prevention S tandard specification is no coating. The unit is packaged with volatile rustproof paper, however, the surface condition should be checked for rust on the machined surfaces every 6 months after shipment. When long-term storage is necessary, rust prevention such as application of rust prevention oil should be performed. -

Page 8: Transportation

【 3 】 Transportation DANGER ● D o not stand directly under a unit suspended by a crane or other lifting mechanism; otherwise, injury or death may result. CAUTION ● E xercise ample care so as not to drop or tip over the unit during transportation. ● W hen lifting the unit using eye bolts in the threaded holes provided on the main unit, refer to the package, exterior drawings, catalog, etc., and do no lift a unit that is heavier than the rated load of the eye bolts; otherwise, the falling/tumbling of the unit or damage to the lifting devices may cause personal injury or equipment damage. ● A fter the unit has been mounted in the machine, avoid lifting the entire machine with using the eye bolts; otherwise, it may result in injury or damage to the equipment due to the unit falling or tipping over, or due to failure of the eye bolts. -

Page 9: Installation

【 4 】 Installation CAUTION ● D o not use the unit for a purpose other than that indicated on the nameplate or in the manufacturing specifications; otherwise, injury or damage to the equipment may result. ● D o not place any object that will hinder ventilation around the reducer; otherwise, the cooling effect is reduced, possibly leading to fire or burns due to excessive heat built-up. ● A bsolutely do not stand on or hang from the unit; otherwise, injury or damage to the equipment may result. ● D o not touch the keyways of the unit with bare hands; otherwise, injury may result. ● W hen the unit is used in food processing applications, machines for cleanroom and so on, vulnerable to oil contamination, install an oil pan or other such device to cope with grease leakage due to breakdown or failure; otherwise, grease leakage may cause failure of the unit, etc. 4-1 Place of Installation Ambient temperature 0 to 40°C ( Start failure may occur depending on the speed and torque of the motor in use, so consult us if the reducer will be used at about 0°C.) Ambient humidity... -

Page 10: Mounting The Servo Motor

【 5 】 Mounting the Servo Motor 5-1 P1, PK1, P2, P Type The product has a special shaft coupling between the reducer gear and the motor so that a non-straight motor shaft such as key-or D-shape-cut shafts can be accommodated. Assemble the motor in the following steps from (1) to (8): (In the case of a key-slotted shaft, remove the key before assembly). (1) Wipe rustproofing or other oils from the motor shaft surface. (2) Place the reducer on an appropriate work surface with the coupling [3] facing straight up. (3) Remove the plug [1] from the setting hole. (4) M anually align the components so that the coupling tightening bolt [2] can be tightened from the setting hole [1]. (5) I nsert the motor shaft into the center hole of the coupling [3]. Press the shaft straight into the coupling, and engage the joint between the motor and the adapter plate [4]. P2 Type with flange plate, set the flange plate [5] between motor and adapter plate [4]. A fter fitting the spigot of the flange plate [5] and adapter plate [4], insert motor shaft into the center hole of the coupling [3], press in vertically and fit the spigot of the motor and the flange plate [5]. (6) Lock the motor and the adapter plate [4] together by tightening the motor mounting bolt. (7) T ighten the coupling tightening bolt [2] from the setting hole using a torque wrench. Tighten to the appropriate torque value shown on Table 5-1 and 5-2. (8) Reinstall the plug [1] from the setting hole. Table 5-1 Bolt Tightening Torque (P1, PK1, P Type) Table 5-2 Bolt Tightening Torque (P2 Type) Tightening Coupling Hole Tightening... - Page 11 【 5 】 Mounting the Servo Motor 5-2 L Type The product has a shaft coupling between the reducer gear and the motor. Assemble the motor in the following steps from (1) to (9). (1) Wipe rustproofing or other oils from the motor shaft surface. (2) Place the reducer on an appropriate work surface with the oldham’s coupling facing straight up. (3) A lign the oldham’ coupling boss 1 [5], spacer [4], and oldham’ coupling boss 2 [2] straight and push in so that the claws of the boss engage sufficiently. (4) Remove the plug [3] from the setting hole. (5) M anually align the components so that the coupling tightening bolt [1] can be tightened from the setting hole [3]. (6) I nsert the motor shaft into the center hole of the oldham’ coupling boss 2 [2] . Press the shaft straight into the coupling, and engage the joint between the motor and the adapter plate [6]. (7) Lock the motor and the adapter plate [6] together by tightening the motor mounting bolt. (8) T ighten the coupling tightening bolt [1] from the setting hole using a torque wrench. Tighten to the appropriate torque value shown on Table 5-3. (9) Reinstall the plug [3] from the setting hole. Table 5-3 Bolt Tightening Torque (L Type) Tightening Bolt Tightening Torque Coupling Hole Diameter 1.67Nm CCZ18 3.92Nm CCZ25 7.35Nm CCZ35...

-

Page 12: Coupling With Other Machines

【 6 】 Coupling with Other Machines CAUTION ● C onfirm the direction of rotation before coupling with the driven machine; otherwise, injury or damage to the equipment may result. ● W hen the product is to run on its own without being connected to other devices, remove the key from the output shaft in advance. Otherwise, the key may fly off the shaft and cause personal injury. ● Provide a cover etc. so that the rotating part cannot be touched; otherwise, injury may result. ● W hen coupling the reducer with a load, check that the centering, belt tension, parallelism of the pulleys, etc. are within the specified limits. When the unit is directly coupled with another machine, check that the direct coupling accuracy is within the specified limits. When a belt is used for coupling the unit with another machine, check the belt tension. Correctly tighten bolts on the pulley and coupling before operation; otherwise, injury may result because of misalignment. 6-1 Checking the Rotation Direction (1) P1, P2, P, L Type Verify that the rotation direction is the same as that of the input shaft. - Page 13 【 6 】 Coupling with Other Machines 6-2 Mounting a Connecting Element • W hen installing a connecting element, be careful not to impact the shaft or apply an excessive amount of thrust load. Bearing damage or collar disengagement may be caused. • I nstallation by shrink fit or shaft end thread engagement is recommended. (1)When Using a Coupling Make sure that the alignment errors (A, B and X) illustrated in Figure 6.1 are not greater than the specification values shown in Table 6-1. Table 6-1 F lexible Coupling Alignment Errors 0.1 mm or manufacturer- A Size Tolerance specified value 0.1 mm or manufacturer- B Side Tolerance specified value Manufacturer-specified Dimension X value Figure 6-1 (2) When Using a Chain/Sprocket or Gear Coupling • I n the case of chain-based coupling, make sure that the tensioned chain angle is at the right angle to the shaft.

-

Page 14: Operation

【 7 】 Operation DANGER ● D o not touch rotating parts (output shaft, etc.) during operation; otherwise, loose clothing caught in these rotating parts may result in serious injury. CAUTION ● D o not put fingers or foreign object into the opening of the reducer; otherwise, injury or damage to the equipment may result. ● T he reducer will become very hot during operation. Do not touch or come in contact with the unit; otherwise, burns may result. ● I f anomaly occurs during operation, stop operation immediately; otherwise, injury may result. ● D o not operate the unit in excess of the rated load level; otherwise, injury or damage to the equipment may result. 7-1 Check Before Operation After installation, check the following items before starting operation. -

Page 15: Daily Inspection And Maintenance

【 8 】 Daily Inspection and Maintenance DANGER ● D o not come close to or touch any rotating parts (output shaft, etc.) during maintenance or inspection of the unit; otherwise, loose clothing caught in these rotating parts may result in injury or death. CAUTION ● D o not put fingers or foreign object into the opening of the reducer; otherwise, injury or damage to the equipment may result. ● T he reducer will become very hot during operation. Do not touch the unit with bare hands; otherwise, burns may result. ● I dentify and provide appropriate corrective action in a timely fashion and according to this maintenance manual if any abnormal operating characteristics are observed. Do not operate the unit corrective action has been taken. ● D o not use damaged reducers; otherwise, injury or damage to the equipment may result. ● W e can not assume any responsibility for damage or injury as a result of an unauthorized modification by a customer. - Page 16 【 8 】 Daily Inspection and Maintenance 8-1 Daily Inspection To ensure proper and continued optimum operation, use table1 to perform daily inspections. All of the answers should be "No." Table 8-1 Daily Inspection Inspection Item Details of Inspection Noise Is there abnormal sound? Is there sudden change in sound? Vibration Is vibration abnormally large? Does vibration change suddenly? Is the surface temperature abnormally high? Does the surface Surface temperature temperature rise suddenly? Is there any grease leakage from the gears? Is there any rust on the Grease leakage sliding surface of the oil seal? Installation bolts Have any of the installation bolts become loose? Chain Timing belt Is the chain or timing belt loose? • I f any abnormal condition is observed during the daily inspection, remedy the situation by referring to 9, “Troubleshooting” (page 15. If the abnormal condition still persists, contact our local subsidiary nearest to you.

-

Page 17: Troubleshooting

【 9 】 Troubleshooting If any abnormal condition is observed in or related to this unit, promptly remedy the situation by referring to Table 9-1. If the abnormal condition still persists, contact our local subsidiary nearest to you. Table 9-1 Troubleshooting Condition Possible causes Control The motor runs when without load, Unit damaged due to gear Contact our local subsidiary but the output shaft does not turn overloading etc. Cannot run fast and Reduce the load to the Unit overloaded becomes overheated specification level The key is not fitted Fit the key Stops Bearing is burned Contact our local subsidiary Runs in the reverse direction Control setup error Change the control setup Reduce the load to the Unit overloaded specification level Ambient temperature at the use Improve ventilation location is too high Tue unit becomes excessively heated Bearing damaged Contact our local subsidiary... -

Page 18: Structural Drawing

【 10 】 Structural Drawing 10-1 Structural Drawing (P1 Type) 9 10 11 12 13 14 15 Figure 10-1 P1 Type Double-reduction (example: ANFX-P120N) Table 10-1 Main Components (P1 Type) Part Number Description Output shaft Oil seal Bearing of output Sun gear of output Planetary gear of output Casing with internal gear Sun gear of input Planetary gear of input Internal gear of input Joint cover Oil seal Input shaft bearing Coupling Adaptor plate Motor (Provided by the user) - Page 19 【 10 】 Structural Drawing 10-2 Structural Drawing (PK1 Type) Figure 10-2 PK1 Type Triple-reduction (example: ANFX-PK120N) Table 10-2 Main Components (PK1 Type) Part Number Description Part Number Description Output shaft Casing Oil seal Bearing Bearing of output Intermediate Shaft Sun gear of output Spiral bevel gear Planetary gear of output Pinion shaft Casing with internal gear Bearing Sun gear of input Cover (Casing) Planetary gear of input Oil seal Internal gear of input Input shaft bearing Adaptor (Casing) Coupling Oil seal Adaptor plate O-ring Motor (Provided by the user) Bearing...

- Page 20 【 10 】 Structural Drawing 10-3 Structural Drawing (P2 Type) 9 10 11 12 13 14 15 Figure 10-3 P2 Type Double-reduction (example: ANFX-P250F) Table 10-3 Main Components (P2 Type) Part Number Description Output shaft Oil seal Main bearing Sun gear of output Planetary gear of output Casing with internal gear Sun gear of input Planetary gear of input Internal gear of input Joint cover Oil seal Input shaft bearing Coupling Adaptor plate Motor (Provided by the user)

- Page 21 【 10 】 Structural Drawing 10-4 Structural Drawing (P Type) 9 10 11 12 13 14 Figure 10-4 P Type Double-reduction (example: ANFX-P20N) Table 10-4 Main Components (P Type) Part Number Description Output shaft Oil seal Main bearing Sun gear of output Planetary gear of output Casing with internal gear Sun gear of input Planetary gear of input Internal gear of input Joint cover Input shaft bearing Oil seal Coupling Motor (Provided by the user)

- Page 22 【 10 】 Structural Drawing 10-5 Structural Drawing (L Type) Figure 10-5 L Type Double-reduction (example: ANFJ-L40) Table 10-5 Main Components (L Type) Part Number Description Slow speed shaft Case Slow speed shaft bearing Secondary sun gear Secondary planetary shaft Secondary planetary gear Inner gear Primary planetary shaft Primary planetary gear Primary sun gear Cover High speed shaft bearing Adaptor plate Coupling Motor (Provided by the user)

-

Page 23: Warranty

【 11 】 Warranty The scope of warranty of our delivered products is limited only to what we manufactured. Warranty (period and contents) The warranty period for the Products shall be 18 months after the shipment of the Products Warranty from the seller's works or 12 months from the Products coming into operation, whether Period comes first. In the event that any problem or damage to the Product arises during the“Warranty Period”from defects in the Product whenever the Product is properly installed and combined with the Buyer's equipment or machines, maintained as specified in this manual, and properly operated under the conditions described in this manual, or as otherwise agree upon in writing between the Seller and the Buyer or its customers; the Seller will provide, Warranty at its sole discretion, appropriate repair or replacement of the Product without charge at a Condition designted facility, except as stipulated in the“Warranty Exclusions”as described below. However, if the Product is installed or integrated into the Buyer's equipment or machines, the Seller shall not reimburse the cost of : removal or re-installation of the Product or other incidental costs related thereto, any lost opportunity, any profit loss or other incidental or consequential losses or damages incurred by the Buyer or its customers. Notwithstanding the above warranty, the warranty as set forth herein shall not apply to any problem or damage to the Product that is caused by: 1. installation, connection, combination or integration of the Product in or to the other equipment or machine that is rendered by any person or entity other than the Seller ;... - Page 24 【 MEMO 】...

- Page 25 【 MEMO 】...

- Page 26 【 MEMO 】...

- Page 28 Worldwide Locations U.S.A Austria Korea Sumitomo Machinery Corporation of America Sumitomo (SHI) Cyclo Drive Germany GmbH Sumitomo (SHI) Cyclo Drive Korea, Ltd. (SCK) (SMA) (SCG) Royal Bldg. 19 Rm. 913, 5 Saemunan-ro 5-Gil Jongro-Gu SCG Branch Austria O ce 4200 Holland Blvd. Chesapeake, VA 23323, U.S.A. Seoul, Korea 03173 Gruentalerstraße 30A, 4020 Linz, Austria TEL (1)757-485-3355...

Need help?

Do you have a question about the IB Series and is the answer not in the manual?

Questions and answers