Table of Contents

Advertisement

Quick Links

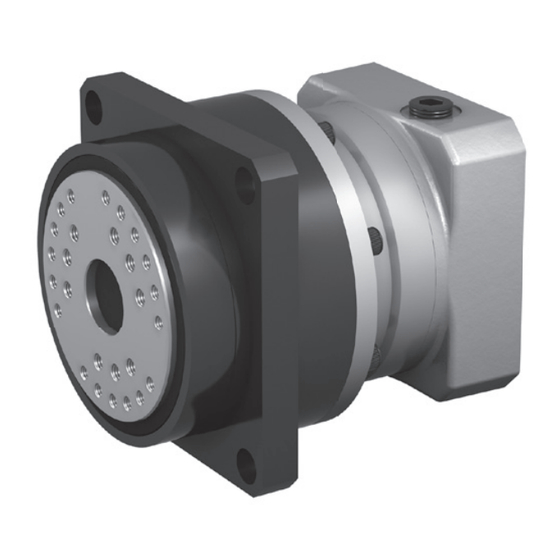

Planetary Gear Reducer

for Servo Motors

IB Series

P1 Type

PK1 Type

P2 Type

P Type

L Type

《CAUTION》

■ This product should be handled by only those who have been trained for the work.

Carefully read the maintenance manual before use.

■ Deliver this manual to the customer who will actually use the product.

■ This maintenance manual should be kept by the user for future reference.

Maintenance Manual

No.ZM2003E-7

Advertisement

Table of Contents

Summary of Contents for Sumitomo Drive Technologies IB Series

- Page 1 Planetary Gear Reducer for Servo Motors IB Series P1 Type PK1 Type P2 Type P Type L Type 《CAUTION》 ■ This product should be handled by only those who have been trained for the work. Carefully read the maintenance manual before use. ■ Deliver this manual to the customer who will actually use the product. ■ This maintenance manual should be kept by the user for future reference. Maintenance Manual No.ZM2003E-7...

-

Page 3: Instruction: Safety Precautions

Introduction: Safety Precautions - Carefully read this maintenance manual and all accompanying documents before use (installation, operation, maintenance, inspection, etc.). Thoroughly understand the machine, information about safety, and all precautions for correct operation. Maintain this manual for future reference. - Pay particular attention to the "DANGER" and "CAUTION" warnings regarding safety and proper use. Improper handling may result in physical damage, serious personal injury ... -

Page 4: Table Of Contents

Contents Contents Instruction: Safety Precautions …………………………………………………………………… 1 Contents …………………………………………………………………………………………… 2 1. Receiving Inspection …………………………………………………………………………… 3 2. Storage …………………………………………………………………………………………… 5 3. Transport ………………………………………………………………………………………… 6 4. Installation ………………………………………………………………………………………… 7 5. Mounting the Servo Motor ……………………………………………………………………… 8 6. Coupling with Other Machines ………………………………………………………………… 11 7. -

Page 5: Receiving Inspection

[2] Serial No. [1] Nomenclature [2] Serial No. Figure 1-2 Nameplate (type 2) 1-2 Checking Lubrication Method IB Series is a grease-lubricated unit. Grease is injected into the unit components before shipment so that no further lubrication is necessary during use. - Page 6 Symbol meanings are shown below. Please confirm that the nomenclature matches your order. A N F X P120 2R LD Model Symbol Output Shaft Geometry IB Series Solid Shaft (Keyless) Solid Shaft (With Key) Flange Shaft Note: L type does not have Output Shaft Direction this symbol.

-

Page 7: Storage

2. Storage If this product is not for immediate use, note the following points when storing it. 2-1 Storage Location Store the unit indoors in a clean and dry location. Do not store the product outdoors. Store it in a location that is free of moisture, dust, extreme temperature changes, corrosive gases, etc. -

Page 8: Transport

3. Transport DANGER Do not step under a unit suspended by a crane or other lifting mechanism for transport; otherwise, injury or death may result. CAUTION When hanging bolts or holes are provided, be sure to use them. After mounting the unit to a machine, do not hoist the entire machine by using the hanging bolts or holes;... -

Page 9: Installation

4. Installation CAUTION Do not use the unit for a purpose other than that indicated on the nameplate or in the manufacturing specifications; otherwise, injury or damage to the equipment may result. Do not place any object that will hinder ventilation around the reducer. Insufficient ventilation can cause excessive heat that may result in burns or fire. -

Page 10: Mounting The Servo Motor

5. Mounting the Servo Motor 5-1 P1, PK1, P2, P Type The product has a special shaft coupling between the reducer and the motor so that shaft with keyway or D shaft other than straight shaft can be accommodated. Attaching the motor in the following steps from (1) to (8): (In the case of a shaft with keyway, remove the key before assembly). - Page 11 5. Mounting the Servo Motor Table 5-1 Bolt Tightening Torque (P1, PK1, P Type) Table 5-2 Bolt Tightening Torque (P2 Type) Tightening Coupling Hole Tightening Coupling Hole Tightening Bolt Tightening Bolt Torque Diameter Torque Diameter 1.67Nm Ø 6-8 35Nm Ø 24-35 3.92Nm Ø...

- Page 12 5. Mounting the Servo Motor 5-2 L Type The product has a shaft coupling between the reducer and the motor. Assemble the motor in the following steps from (1) to (9). (1) Wipe rustproofing or other oils from the motor shaft surface. (2) Place the reducer on an appropriate working table with the oldham’s coupling facing straight up.

-

Page 13: Coupling With Other Machines

6. Coupling with Other Machines CAUTION Confirm the direction of rotation before coupling with the driven machine. Incorrect rotation direction may cause personal injury or damage to the equipment. When operating the product alone (uncoupled), remove the key that is temporarily attached to the output shaft;... - Page 14 6. Coupling with Other Machines 6-2 Mounting a Connector - When installing a connector, do not apply impact or excessive axial load to the shaft. The bearing could be damaged, or the collar could come off. - Shrinkage fit is recommend. (1)When Using a Coupling The alignment accuracy (A, B, X) in Figure 6-1 should be no greater than that shown in Table 6-1.

-

Page 15: Operation

7. Operation DANGER Do not touch rotating parts (output shaft, etc.) during operation; otherwise, loose clothing caught in these rotating parts may result in serious injury. CAUTION Do not put fingers or foreign object into the opening of the reducer; otherwise, injury or damage to the equipment may result. -

Page 16: Daily Inspection And Maintenance

8. Daily Inspection and Maintenance DANGER Do not come close to or touch any rotating parts (output shaft, etc.) during maintenance or inspection of the unit; otherwise, loose clothing caught in these rotating parts may result in injury or death. CAUTION Do not put fingers or foreign object into the opening of the reducer;... - Page 17 8. Daily Inspection and Maintenance 8-1 Daily Inspection Be sure to perform daily inspection according to Table 8-1. Lack of inspections is a source of trouble. Table 8-1 Daily Inspection Inspection Item Details of Inspection Noise Is there abnormal sound? Is there sudden change in sound? Vibration Is vibration abnormally large? Does vibration change suddenly? Is the surface temperature abnormally high? Does the surface...

-

Page 18: Troubleshooting

9. Troubleshooting If any abnormal condition occurs, refer to Table 9-1 and promptly take appropriate measures. If these actions do not solve the issue, immediately contact the nearest authorized maintenance shop. Table 9-1 Troubleshooting Condition Possible causes Control The motor rotates without a load Unit damaged due to gear Confer with authorized but the output shaft does not... -

Page 19: Structural Drawing

10. Construction Drawing 10-1 Construction Drawing (P1 Type) 9 10 11 12 13 14 15 Figure 10-1 P1 Type Double-reduction (example: ANFX-P120N) Table 10-1 Main Components (P1 Type) Part Number Description Output shaft Oil seal Main bearing Sun gear of output Planetary gear of output Casing with internal gear Sun gear of input... - Page 20 10. Construction Drawing 10-2 Construction Drawing (PK1 Type) Figure 10-2 PK1 Type Triple-reduction (example: ANFX-PK120N) Table 10-2 Main Components (PK1 Type) Part Number Description Part Number Description Output shaft Casing Oil seal Bearing Bearing of output Intermediate Shaft Sun gear of output Spiral bevel gear Planetary gear of output Pinion shaft...

- Page 21 10. Construction Drawing 10-3 Construction Drawing (P2 Type) 9 10 11 12 13 14 15 Figure 10-3 P2 Type Double-reduction (example: ANFX-P250F) Table 10-3 Main Components (P2 Type) Part Number Description Output shaft Oil seal Main bearing Sun gear of output Planetary gear of output Casing with internal gear Sun gear of input...

- Page 22 10. Construction Drawing 10-4 Construction Drawing (P Type) 9 10 11 12 13 14 Figure 10-4 P Type Double-reduction (example: ANFX-P20N) Table 10-4 Main Components (P Type) Part Number Description Output shaft Oil seal Main bearing Sun gear of output Planetary gear of output Casing with internal gear Sun gear of input...

- Page 23 10. Construction Drawing 10-5 Construction Drawing (L Type) Figure 10-5 L Type Double-reduction (example: ANFJ-L40) Table 10-5 Main Components (L Type) Part Number Description Slow speed shaft Case Slow speed shaft bearing Secondary sun gear Secondary planetary shaft Secondary planetary gear Inner gear Primary planetary shaft Primary planetary gear...

-

Page 24: Warranty

11. Warranty The scope of warranty of our delivered products is limited only to what we manufactured. Warranty (period and description) Warranty The warranty period applies only to new products and represents 18 months after the shipment or 12 months after the actual operation, whichever is shorter. Period If the product failed within the warranty period, during which despite a proper mounting, connection and maintenance &... - Page 25 MEMO...

- Page 26 MEMO...

- Page 28 Worldwide Locations U.S.A Austria Korea Sumitomo Machinery Corporation of America Sumitomo (SHI) Cyclo Drive Germany GmbH Sumitomo (SHI) Cyclo Drive Korea, Ltd. (SCK) (SMA) (SCG) Royal Bldg Room #913, 19, Saemunan-ro 5-gil, SCG Branch Austria O ce 4200 Holland Blvd. Chesapeake, VA 23323, U.S.A. Jongno-gu, Seoul, 03173, Korea Gruentalerstraße 30A, 4020 Linz, Austria TEL (1)757-485-3355...

Need help?

Do you have a question about the IB Series and is the answer not in the manual?

Questions and answers