Subscribe to Our Youtube Channel

Summary of Contents for Man D2842 LE602

- Page 1 Operating Instruction MAN Industrial Diesel Engines D2842 LE602/604/606/607 MAN Engines A Division of MAN Truck & Bus...

- Page 3 Operating Instruction MAN Industrial Diesel Engines D2842 LE602/604/606/607 51.99493-8344 “Translation of the original operating instructions” Version 03...

- Page 4 Subject to technical alterations in the interests of further development. The reprinting, reproduction or translation of this document, even in part, is not permitted without the written permission of MAN. All rights under the law relating to copyright are expressly reserved by MAN. © 2014 MAN Truck &...

-

Page 5: Table Of Contents

Contents Page Preface ................. Instructions . -

Page 6: Preface

It is imperative and in your own interest to entrust your MAN Local Service Centre with the removal of any disturbances and with the performance of checking, setting, and repair work. -

Page 7: Instructions

Instructions Important instructions which concern technical safety and protection of persons are emphasised as shown below. Danger: This refers to working and operating procedures which must be complied with in order to rule out the risk to persons. Caution: This refers to working and operating procedures which must be complied with in order to prevent damage to or destruction of material. -

Page 8: Nameplates

Nameplates In all your correspondence please always quote engine model, serial number and job number (Order num ber). For this reason it is advisable to read off the data from the engine type plates before putĆ ting the engine into operation and to enter them in the appropriate spaces. The engine type plates are on the crankcase. -

Page 9: Safety Regulations

D Do not touch the engine with bare hands when it is warm from operation - risk of burns. Ë Ë D Exhaust gases are toxic. Comply with the instructions for the installation of MAN Diesel engines which are to be operated in enclosed spaces. Ensure that there is adequate ventilation and air extraction. - Page 10 Safety regulations During maintenance and care D Always carry out maintenance work when the engine is switched off. If the engine has to be maintained while it is running, e.g. changing the elements of change-over filters, remember that there is a risk of scalding. Do not get too close to rotating parts.

- Page 11 If faults occur, find the cause immediately and have it eliminated in order to prevent more serious damage. Use only genuine MAN spare parts. MAN will accept no responsibility for damage resulting from the in stallation of other parts which are supposedly “just as good".

- Page 12 Safety regulations 3. Regulations designed to prevent pollution Engine oil and filter elements / cartridges, fuel / fuel filter D Take old oil only to an old oil collection point. D Take strict precautions to ensure that no oil or Diesel fuel gets into the drains or the ground. The drinking water supply could be contaminated.

- Page 13 Safety regulations 4. Notes on safety in handling used engine oil ∗ Prolonged or repeated contact between the skin and any kind of engine oil decreases the skin. Drying, ir ritation or inflammation of the skin may therefore occur. Used engine oil also contains dangerous substan ces which have caused skin cancer in animal experiments.

-

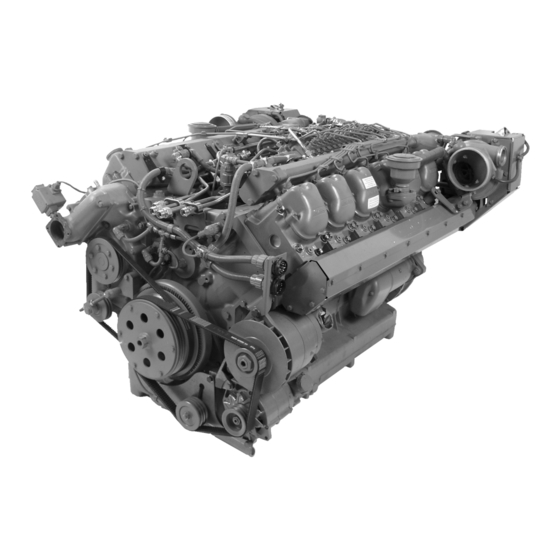

Page 14: Commissioning And Operation

Commissioning and operation Engine views D 2842 LE 602... - Page 15 Commissioning and operation (1) Turbocharger (2) Oil separator valve for crankcase breather (3) Exhaust manifold (4) Starter motor (5) Oil sump (6) Engine cranking device (7) Cooling water pipe (8) In take pipe (9) Injection pump (10) Alternator (11) Oil drain plug (12) Water pump (13) Oil dipstick (14) Oil filter...

-

Page 16: Engine Views D 2842 Le 604

Commissioning and operation Engine views D 2842 LE 604... - Page 17 Commissioning and operation (1) Oil separator valve for crankcase breather (2) Turbocharger (3) Exhaust manifold (4) Starter motor (5) Oil sump (6) Tension pulley (7) Water pump (8) Cooling water pipe (9) Injection pump (10) In take pipe (11) Alternator (12) Oil drain plug (13) Oil filler neck (14) Oil filter...

-

Page 18: Engine Views D 2842 Le 606

Commissioning and operation Engine views D 2842 LE 606... - Page 19 Commissioning and operation (1) Oil separator valve for crankcase breather (2) Turbocharger (3) Exhaust manifold (4) Starter motor (5) Oil sump (6) Tension pulley (7) Water pump (8) Cooling water pipe (9) Injection pump (10) In take pipe (11) Oil drain plug (12) Oil filter (13) Oil dipstick...

-

Page 20: Engine Views D 2842 Le 607

Commissioning and operation Engine views D 2842 LE 607... - Page 21 Commissioning and operation (1) Oil separator valve for crankcase breather (2) Turbocharger (3) Exhaust manifold (4) Starter motor (5) Oil sump (6) Tension pulley (7) Cooling water pipe (8) Injection pump (9) In take pipe (10) Oil drain plug (11) Water pump (12) Oil filter (13) Air compressor...

-

Page 22: First Commissioning

Fill the cooling system of the engine with a mixture of drinkable tap water and anti-freeze agent on the ethy lene glycole basis or anti-corrision agent. See Publication “Fuels, Lubricants and Coolants for MAN Diesel Engines". D Observe / adhere to vehicle manufacturer's filling specifications D Slowly pour in coolant (max. -

Page 23: Commissioning

Commissioning and operation Commissioning Before daily starting the engine, check fuel level, coolant level and engine oil level and replenish, if ne cessary. Caution: Use only approved fuels, lubricants etc. (see brochure “Fuels, lubricants etc."). Otherwise the liability for defects will become null and void! Checking oil level Check the oil level when the engine is horizontal, but only if at least 20 minutes have passed since the ma... -

Page 24: Starting

Commissioning and operation Starting Danger: Before starting make sure that no-one is in the engine's danger area. Caution: When starting do not use any additional starting aids (e.g. injection with starting pilot). Multi-engine systems start via an automatic start-stop system. This must fulfil the following functions: D Switch on EDC D Triggering of flame start system... -

Page 25: Operation Monitoring System

Commissioning and operation Operation monitoring system Caution: Do not overload the engine. Do not exceed the maximum permissible engine tilt. If faults occur, find their cause immediately and have them eliminated in order to prevent more serious damage! Monitor the oil pressure of the engine lubrication and coolant agent temperature during operations. If the monitoring equipment displays a drop in the pressure of lubrication oil or excess coolant temperature then the engine must be turned off immediately Shutting down... -

Page 26: Maintenance And Care

Maintenance and care Lubrication system Ensure outmost cleanliness when handling fuels, lubricants and coolants. Caution: se only approved fuels, lubricants etc. (see brochure “Fuels, lubricants etc."). Otherwise the liability for defects will become null and void! Refilling with oil Danger: The oil is hot-risk of scalding. - Page 27 Maintenance and care Filling with engine oil Caution: Do not add so much engine oil that the oil level rises above the max. marking on the dipstick. Overfilling will result in damage to the engine. Pour in fresh oil through oil filler neck (1). Ac cording to variant, this is either on the cylinder head cover or on the oil pan.

- Page 28 Maintenance and care Changing oil filter Renewal of filter cartridges D Allow the filter content to run off along drain plug. Use a vessel of sufficient size to ensure that the oil does not overflow Danger: The oil is hot and under pressure when the drain plug is opened.

-

Page 29: Fuel System

Maintenance and care Fuel system Fuel If Diesel fuel which contains moisture is used the injection system and the cylinder liners / pistons will be damaged. This can be prevented to same extent by filling the tank as soon as the engine is switched off while the fuel tank is still warm (formation of condensation is prevented). - Page 30 Maintenance and care Fuel filter Changing fuel filter Only when the engine is swiched off. D Loosen filter cartridge by means of tape wrench, unscrew it by hand and take it off D Moisten the seals on the new filter cartridge with fuel D Screw on the filter cartridges and tighten them vigorously by hand...

-

Page 31: Cooling System

Fill the cooling system of the engine with a mixture of drinkable tap water and anti-freeze agent on the ethy lene glycole basis or anti-corrision agent. See Publication “Fuels, Lubricants and Coolants for MAN Diesel Engines". Coolant must be poured in according to the vehicle manufacturer's filling specifications. -

Page 32: Air Filter

Maintenance and care Air filter An air filter is installed in the vehicle to purify the air for combustion. The intervals at which the air cleaner requires servicing depend on the specific operating conditions en countered. Clogged air filters may cause black smoke and reduce power. A check should be made from time to time to see that the fastening elements securing the air cleaner to the intake manifold seal the connection tightly. -

Page 33: V-Belts

Maintenance and care V-belts Checking condition D Check V-belts for cracks, oil, overheating and wear D Change demaged V-belts If, in the case of a multiple belt drive, wear or diffe ring tensions are found, always replace the com plete set of belts. Checking tension Use V-belt tension tester to check V-belt tension. - Page 34 Maintenance and care Tensioning and changing V-belt Crankshaft - water pump - tension pulley D Remove fixing bolts (1) D Remove lock-nut (2) D Adjust nut (3) until V-belts have correct tensions D Retighten lock-nut and fixing bolts To change the V-belt, turn back the setting nut and swivel the tension pulley inwards.

-

Page 35: Turbocharger

The water / air intercooler is part of the MAN delivery share and does not require any regular cleaning. Air / air intercooler systems are not part of the MAN delivery share. These are to be cleaned after liasing with the vehicle manufacturer, or according to amount of soiling. -

Page 36: Technical Data

Technical data Model D 2842 LE 602 Design V-form, 90° Cycle 4-stroke Diesel with turbocharger and intercooler Combustion system Direct injection Turbocharging Turbocharger with intercooler Number of cylinders Bore 128 mm Stroke 142 mm Swept volume 21 930 cm Compression ratio 16,5 : 1 Rating see engine nameplate... - Page 37 Technical data Engine lubrication Force feed Oil capacity in oil sump (litres) min. max. Shallow 35 l 50 l Oil change quantity (with filter) Shallow 53 l Oil pressure during operation (depending on oil must be monitored by oil pressure monitors / gau temperature, oil viscosity class and engine rpm) Oil filter...

- Page 38 Technical data Model D 2842 LE 604 Design V-form, 90° Cycle 4-stroke Diesel with turbocharger and intercooler Combustion system Direct injection Turbocharging Turbocharger with intercooler Number of cylinders Bore 128 mm Stroke 142 mm Swept volume 21 930 cm Compression ratio 16,5 : 1 Rating see engine nameplate...

- Page 39 Technical data Engine lubrication Force feed Oil capacity in oil sump (litres) min. max. Shallow 35 l 50 l Oil change quantity (with filter) Shallow 53 l Oil pressure during operation (depending on oil must be monitored by oil pressure monitors / gau temperature, oil viscosity class and engine rpm) Oil filter...

- Page 40 Technical data Model D 2842 LE 606 Design V-form, 90° Cycle 4-stroke Diesel with turbocharger and intercooler Combustion system Direct injection Turbocharging Turbocharger with intercooler Number of cylinders Bore 128 mm Stroke 142 mm Swept volume 21 930 cm Compression ratio 16,5 : 1 Rating see engine nameplate...

- Page 41 Technical data Engine lubrication Force feed Oil capacity in oil sump (litres) min. max. Shallow 35 l 50 l Oil change quantity (with filter) Shallow 53 l Oil pressure during operation (depending on oil must be monitored by oil pressure monitors / gau temperature, oil viscosity class and engine rpm) Oil filter...

- Page 42 Technical data Model D 2842 LE 607 Design V-form, 90° Cycle 4-stroke Diesel with turbocharger and intercooler Combustion system Direct injection Turbocharging Turbocharger with intercooler Number of cylinders Bore 128 mm Stroke 142 mm Swept volume 21 930 cm Compression ratio 16,5 : 1 Rating see engine nameplate...

- Page 43 Technical data Engine lubrication Force feed Oil capacity in oil sump (litres) min. max. Shallow 35 l 50 l Oil change quantity (with filter) Shallow 53 l Oil pressure during operation (depending on oil must be monitored by oil pressure monitors / gau temperature, oil viscosity class and engine rpm) Oil filter...

-

Page 44: Maintenance Chart

Maintenance chart ALWAYS COMPLY WITH SAFETY REGULATIONS Maintenance cycles * Maintenance jobs Check coolant level and oil level in engine Check air filter contamination Change engine oil (see also page 43) Change oil filter cartridge (see also page 43) Clean fuel strainer Draining fuel filter / condensation (earlier if severe operating condi... - Page 45 400 h 400 h 602 / 604 / 606 / 607 *) See Publication “Fuels, Lubricants and Coolants for MAN Diesel Engines". Note: D Use only approved engine oils D Where Diesel fuels with a sulphur content greater than 1% are used, the oil change intervals are to be...

-

Page 46: Troubleshooting Table

Troubleshooting table Fault Engine does not start, or starts only with difficulty Engine starts but does not reach full speed or stalls Engine idles out of true when warm, misfiring Engine speed fluctuates during operation Power output unsatisfactory Coolant temperature too high, coolant being lost Lube oil pressure too low Lube oil pressure too high Black smoke accompanied by loss of power... - Page 47 Troubleshooting table Fault Engine does not start, or starts only with difficulty Engine starts but does not reach full speed or stalls Engine idles out of true when warm, misfiring Engine speed fluctuates during operation Power output unsatisfactory Coolant temperature too high, coolant being lost Lube oil pressure too low Lube oil pressure too high Black smoke accompanied by loss of power...

-

Page 48: Index

Index Air filter ........Maintenance and care . - Page 50 MAN Truck & Bus AG Vogelweiherstraße 33 90441 Nuremberg Germany man-engines@man.eu www.man-engines.com MAN Truck & Bus – a member of the MAN Group...

Need help?

Do you have a question about the D2842 LE602 and is the answer not in the manual?

Questions and answers

PRIMARY PUMP

The primary pump for the MAN D2842 LE602 is an in-line injection pump.

This answer is automatically generated