Summary of Contents for Man D2848 LE201

- Page 1 Operating Instructions MAN Industrial Diesel Engines D2848 LE201/203/211/213 D2840 LE201/203/211/213 D2842 LE201/203/211/213 51.99493-8509 “Translation of the original operating instructions”...

-

Page 2: Information And Copyright

Information and Copyright Subject to technical alterations in the interests of further development. Reprinting, copying or translation, even of extracts, is not allowed without written permission from MAN. All rights under the copyright law are strictly reserved by MAN. © 2011 MAN Truck &... -

Page 3: Table Of Contents

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Table of Contents Information and Copyright ............. . . - Page 4 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Table of Contents Design and Function ............. .

- Page 5 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Table of Contents Operation ............... . .

- Page 6 ........10.4.1 Commissioning of Preserved Engines according to MAN-Werknorm M 3059 .

-

Page 7: Preface

Use only genuine MAN spare parts and accessories or those approved by MAN. Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines. A particular concern of MAN is to improve environmental protection. This begins with the development and design of our engines. -

Page 8: Key To Symbols

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Foreword 1.2 Key to Symbols Warnings Warnings are identified in these Operating Instructions with symbols. These warnings are pre ceded by signal words that express the magnitude of the risk. Always heed these warnings and act prudently to prevent accidents, injuries and property damage. -

Page 9: Limitation Of Liability

MAN and the law applicable at the time of contracting arrangements. 1.4 Copyright Please handle these Operating Instructions as confidential. They are only to be used by the persons work ing with the engine. Transfer to a third party without explicit written permission from MAN is strictly prohib ited. NOTE! The information, texts, drawings, illustrations and other depictions are all protected by copy... -

Page 10: Spare Parts

Use only genuine MAN spare parts and accessories or those approved by MAN. Only MAN approved genuine spare parts have been tested by us and thus suitable for use in our engines. Spare parts and accessories must either be MAN genuine parts or parts that have been specifically ap... -

Page 11: Warranty Terms

Valid are the commitments agreed upon in the delivery contract and the General Terms and Conditions of MAN and the law applicable at the time of contracting arrangements. Failure to observe these Operating Instructions and any accompanying supplier operating instructions leads to the loss of warranty claims. -

Page 12: General Safety Instructions

This engine is built solely to drive power generators on land. Any other use is considered as "not intended". MAN is not liable for any damage resulting from use that is not intended. The risk is entirely borne by the operator. -

Page 13: Contents Of The Operating Instructions

MAN. If changes are made without the written consent of MAN, the guarantee or warranty obligation for MAN is not longer valid for damage and defects, which are based on these unauthorised changes. Furthermore MAN assumes no liability for any damage caused as a result of unauthorised changes. -

Page 14: Personnel Requirements

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.5 Personnel Requirements 2.5.1 Qualifications WARNING! Risk of injury caused by insufficient qualifications! Improper handling can result in significant personal injury and property damage For this reason: S Specific activities must only be performed by those persons who are named in the re... -

Page 15: Personal Protective Equipment

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.6 Personal Protective Equipment Wearing personal protective equipment is necessary to minimise the health risks when working. SThe required personal protective equipment for the relevant job must always be worn while working. -

Page 16: Specific Dangers

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.7 Specific Dangers The following section describes residual risks which have been identified. S Observe the safety instructions listed here and the warnings in the other chapters of these instructions in order to reduce health hazards and avoid dangerous situations. - Page 17 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions Exhaust gases WARNING! Risk of health hazard caused by exhaust gases! Leaks in the exhaust system can cause dangerous exhaust gases to leak into the engine room. For this reason: S Ensure sufficient ventilation.

- Page 18 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions Hot Surfaces CAUTION! Risk of burns caused by hot surfaces! Contact with hot components can cause burns. For this reason: S When performing any work in the vicinity of hot components always wear protective cloth...

-

Page 19: Safety Equipment

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.8 Safety Equipment The operator must have the following safety equipment in place: Before the engine is placed into operation, install the emergency-off equipment and connect it into the safety chain of the system. -

Page 20: Conduct In Dangerous Situations And When Accidents Occur

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.9 Conduct in Dangerous Situations and When Accidents Occur Preventative Measures S Always be prepared for an accident! S Keep first aid equipment (first aid kit, blankets, etc.) and fire extinguishers at hand. -

Page 21: Signs

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.10 Signs The following symbols should be installed in the immediate vicinity of the hazard area. WARNING! Risk of injury caused by illegible symbols! Stickers and symbols can become dirty or made otherwise illegible in the course of time! For this reason: S Always keep the safety, warning and operational signs in good legible condition. -

Page 22: Environmental Protection

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 General Safety Instructions 2.11 Environmental Protection CAUTION! Environmental hazard caused by incorrect handling! Incorrect handling of environmentally hazardous substances, especially when incorrectly disposed of, can cause considerable damage to the environment. For this reason: S Always heed the information below. -

Page 23: Engine Model Plate

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Engine Model Plate Engine Model Plate For all communications please always give the en gine model (3), engine number (4) and work num ber/job number (5). For this reason before the engine is commis... -

Page 24: Explanation Of The Motor-Nr./Engine-No. (Engine Identification Number)

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Engine Model Plate 3.1 Explanation of the Motor-Nr./Engine-No. (Engine Identification Number) Motor-Nr./Engine-No. Class identifier (assignment) Model number according to index of model codes 1234 Day of assembly (plant internal) Assembly order (sequence number on day of assembly) 3.2 Explanation of Model Designation... -

Page 25: Design And Function

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Design and Function Design and Function 4.1 Engine, General The 8, 10 and 12-cylinder engines described here are liquid-cooled, 4-cycle diesel engines with turbochar ging and charge air cooling. Engine Monitoring Monitoring of the engine is made through various sensors. The sensors are designed, for example, as rpm and temperature sensors, which report the various operating conditions of the engine to the engine control unit. -

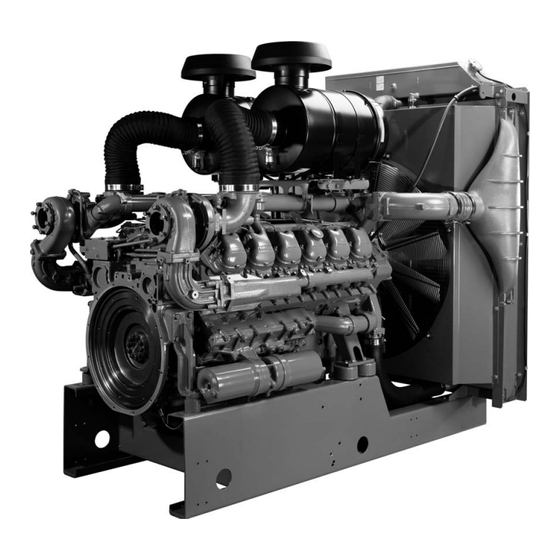

Page 26: Engine Views

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Design and Function 4.2 Engine Views 4.2.1 Front Left View (1) Fan (2) Alternator (3) Oil filler neck (4) Turbocharger (5) Starter (6) Exhaust pipe (7) Tensioning pulley Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. -

Page 27: Rear Right View

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Design and Function 4.2.2 Rear Right View (8) Crankcase breather (9) Combustion air line from charge air cooler (10) Combustion air line to charge air cooler (11) Coolant pump (12) Tensioning pulley (13) Oil drain plug... -

Page 28: Transport, Packaging And Storage

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Transport, Packaging and Storage Transport, Packaging and Storage It is absolutely necessary to observe the “Assembly Instructions” for the installation and commissioning of a new or reconditioned engine. NOTE! Installation and commissioning is only to be made by the employees of the manufacturer of the entire system or by manufacturer authorised personnel. - Page 29 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Transport, Packaging and Storage Off-Centre Point of Gravity WARNING! Risk of injury caused by falling or tipping packages! Packages can have a centre of gravity that is off-centre. If the lifting equipment is not hooked up properly, these packages could tip over and fall causing serious injuries.

-

Page 30: Transport Inspection

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Transport, Packaging and Storage 5.3 Transport Inspection Check the delivery for missing items and for damage from transport. If external signs of transport damage are apparent: S Do not accept delivery or only accept under written protest. -

Page 31: Transport

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Transport, Packaging and Storage 5.4 Transport Lifting Points There are 2 lifting lugs (1) and (2) for the crane installed on the engine. WARNING! Risk of death caused by the load falling! During lifting operations, loads can fall down. This can cause serious injury and even death. - Page 32 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Transport, Packaging and Storage Transport with Crane The engine can be transported with a crane under the following conditions. S The crane and the lifting equipment must be designed for the weight of the engine.

-

Page 33: Packaging

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Transport, Packaging and Storage 5.5 Packaging Packaging The individual packages are packed in accordance with the expected conditions of transport. The purpose of the packaging is to protect the components from transport damage, corrosion and other damage. -

Page 34: Installation And Commissioning

S Safety Shoes S Safety Gloves 6.2 Safety Instructions Personnel S The installation and commissioning may only be performed by MAN employees or by MAN-trained quali fied personnel. WARNING! Danger caused by faulty installation and commissioning! Installation and commissioning require trained qualified personnel with sufficient experi... -

Page 35: Installation - Engine

6.3.2 Engine Model Plate Data Please always specify the engine model, engine number and order number when corresponding with MAN, see page. For this reason, before commissioning the engine, read off the data from the engine model plate and enter it into the Engine Model Plate chapter, see page 25. -

Page 36: Commissioning

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Installation and Commissioning 6.4 Commissioning Do not run new or reconditioned engines during the first operating hours above 3/4 load. However, make sure to vary the engine speed. After this time period the engine can be slowly brought up to full power. -

Page 37: Filling Coolant

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Installation and Commissioning 6.4.2 Filling Coolant NOTE! Do not let coolant drip or leak out while filling. Do not let coolant leak out onto the ground or into bodies of water. Otherwise, the environment will be damaged. -

Page 38: Filling Engine Oil

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Installation and Commissioning 6.4.3 Filling Engine Oil IMPORTANT! Termination of liability for material defects by use of non-approved fluids and lubric ants! Liability of material defects is terminated if non-approved fluids and lubricants are used. -

Page 39: Operation

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation Operation 7.1 Prerequisite Before starting any work read and observe the General Safety Instructions and the safety information in this chapter. Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage. -

Page 40: Preparations Before Operation

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation 7.3 Preparations before Operation DANGER! Danger caused by damaged engines! Damaged engines can be dangerous to persons. For this reason: S Check engine for damage and leaks before each operation. S Do not operate engine if damage is found. -

Page 41: Checking Coolant

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation 7.3.2 Checking Coolant WARNING! Risk of scalding! The cooling system is under pressure and the coolant is hot. For this reason: S Let engine cool down first 1. Remove cap (1). 2. Check coolant level. -

Page 42: Refilling Coolant

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation 7.3.3 Refilling Coolant NOTE! Do not let coolant drip or leak out while refilling. Do not let coolant leak out onto the ground or into bodies of water otherwise this will cause damage to the environment. -

Page 43: Checking Engine Oil Level

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation 7.3.4 Checking Engine Oil Level NOTE! Check the oil level when the engine is horizontal and only after at least 20 minutes have passed since the engine was switched off. 1. Pull out oil dipstick (1). -

Page 44: Refilling Engine Oil

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation 7.3.5 Refilling Engine Oil IMPORTANT! Termination of liability for material defects by use of non-approved fluids and lubric ants! Liability of material defects is terminated if non-approved fluids and lubricants are used. For this reason: S Only use approved fluids and lubricants (see “Fluids and Lubricants ..."... -

Page 45: Operation

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Operation 7.4 Operation 7.4.1 Monitoring Operation IMPORTANT! Do not overload engine. If faults occur, investigate and solve them immediately to prevent major damage from oc curring! The engine oil pressure is monitored during its operation. -

Page 46: Maintenance And Care

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Maintenance and Care 8.1 Prerequisite Before starting any work read and observe the General Safety Instructions and the safety information in this chapter. Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage. -

Page 47: Maintenance Schedule

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care IMPORTANT! Termination of liability for material defects by use of non-approved fluids and lubric ants! Liability of material defects is terminated if non-approved fluids and lubricants are used. For this reason: S Only use approved fluids and lubricants (see “Fluids and Lubricants ..."... -

Page 48: Maintenance Work

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 8.4 Maintenance Work 8.4.1 Engine Oil Change WARNING! Risk of scalding! Engine oil is hot. For this reason: S Only touch the oil drain screws using protective gloves NOTE! The oil filter elements are to be changed out at every engine oil change. - Page 49 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Drain engine oil - with hand vane pump Drain engine oil with engine at operating temperature. NOTE! Use a container with sufficient ca pacity to change oil (at least 100 litres). This ensures that oil will not overflow.

- Page 50 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Change oil filter elements - on switchable oil filters IMPORTANT! A continuous operation (both halves of the filter Engine damage! switched on) Danger of blocked oil supply. For this reason: Right side...

- Page 51 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Change oil filter elements - on dual horizontal oil filters NOTE! Use a container with sufficient ca pacity to change oil (at least 10 litres). This ensures that oil will not overflow.

- Page 52 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Change oil filter elements - on dual vertical oil filters NOTE! Use a container with sufficient ca pacity to change oil (at least 10 litres). This ensures that oil will not overflow.

- Page 53 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Change oil filter elements - single oil filter NOTE! Use a container with sufficient ca pacity to change oil (at least 10 litres). This ensures that oil will not overflow. 1. Remove oil drain screw (1) from oil filter bowl (2) and completely drain engine oil.

- Page 54 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Filling Engine Oil IMPORTANT! Termination of liability for material defects by use of non-approved fluids and lubric ants! Liability of material defects is terminated if non-approved fluids and lubricants are used.

- Page 55 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Check Engine Oil Level NOTE! Check the oil level when the engine is horizontal and only after at least 20 minutes have passed since the engine was switched off. 1. Pull out oil dipstick (1).

-

Page 56: Cleaning Fuel Prefilter

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 8.4.2 Cleaning Fuel Prefilter DANGER! Fire hazard caused by uncontrolled fuel leakage When opening the fuel system, fuel can leak out uncontrolled. For this reason: S Work carefully. S Do not spill any fuel. -

Page 57: Changing Fuel Filter

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 8.4.4 Changing Fuel Filter DANGER! Fire hazard caused by uncontrolled fuel leakage When opening the fuel system, fuel can leak out uncontrolled. For this reason: S Work carefully. S Do not spill any fuel. - Page 58 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Fuel filter - dual filter, switchable IMPORTANT! A continuous operation (both halves of the filter Engine failure! switched on) Danger of fuel supply blockage. For this reason: Right side S Leave the oil flow lever set to...

-

Page 59: Bleeding The Fuel System

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 8.4.7 Bleeding the Fuel System DANGER! Fire hazard caused by uncontrolled fuel leakage When opening the fuel system, fuel can leak out uncontrolled. For this reason: S Work carefully. S Do not spill any fuel. -

Page 60: Changing Coolant

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 8.4.8 Changing Coolant Drain coolant WARNING! Risk of scalding! The cooling system is under pressure and the coolant is hot. For this reason: S Let engine cool down first NOTE! Do not let coolant spill while draining. Do not let coolant leak out onto the ground or into bodies of water otherwise this will damage the environment. - Page 61 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 4. Open drain screw in crankcase (4) and in oil cooler housing (5). 5. Drain coolant. 6. Reinstall screw plug. 7. Fill/bleed cooling system. Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

- Page 62 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Refilling Coolant NOTE! Do not let coolant spill while refilling. Do not let coolant leak out onto the ground or into bod ies of water otherwise this will damage the environment.

-

Page 63: Changing V-Belt

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care 8.4.9 Changing V-Belt Check condition of V-belt If any wear is detected or if, on multi-belt systems, the belts have different tensions, the entire poly- V-belt set is always to be exchanged. - Page 64 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Set tension and change V-belts Alternator - top 1. Loosen mounting bolt (1) 2. Loosen jam nut (2) 3. Set adjustment nut (3) until belt has the correct tension 4. Retighten jam nut and mounting bolt To change belt loosen adjustment nut (3) and swi...

- Page 65 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Maintenance and Care Crankshaft - Coolant pump - Tensioner pulley 1. Loosen mounting bolt (1). 2. Turn adjustment screw (2) clockwise until belt has the correct tension 3 Retighten mounting nuts (1) To change the belt, turn adjustment screw (2) counter clockwise.

-

Page 66: Faults

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Faults Faults The following chapter describes the possible faults which can occur and the work to correct them. For those faults that cannot be rectified by the following information, contact the manufacturer of the entire system or MAN. -

Page 67: Fault Table

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Faults 9.3 Fault Table The “Remedy” column is only filled in when it is not clear from the "probable cause" what needs to be done Fault Possible cause Remedy D Fuel tank empty Engine does not start... - Page 68 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Faults Fault Possible cause Remedy D Not enough fuel in tank Engine speed fluctua D Air in fuel system tions during operation D Tachometer faulty D Injectors faulty D Too much power is demanded from the...

- Page 69 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Faults Fault Possible cause Remedy D Engine cold Lube-oil pressure too D Selected oil viscosity is inappropriate for D See "Fluids and Lubricants..." high ambient temperature (too thick) D Oil pressure indicator faulty D Safety valve in oil circuit faulty (does not...

- Page 70 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Faults Fault Possible cause Remedy D Engine not at correct operating tempe D Let engine warm to operating Engine knocking rature temperature before running at full load D Check thermostat D Valve clearance not OK...

- Page 71 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Faults Starter Fault Possible cause Remedy (This column is only filled in when it is not clear from the "probable cause" what needs to be done) To be repaired by a vehicle elec trician or by the manufacturer...

-

Page 72: Decommissioning And Recommissioning

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Decommissioning and Recommissioning Decommissioning and Recommissioning 10.1 Prerequisite Before starting any work read and observe the General Safety Instructions and the safety information in this chapter. Strictly observe these instructions and act prudently to avoid accidents, personal injury and property damage. -

Page 73: Temporary Decommissioning Of Engines

Decommissioning and Recommissioning 10.3 Temporary Decommissioning of Engines Temporary anticorrosion protection according to MAN works norm M 3069 is required for engines which are to be put out of service depending on the duration. The works norm can be obtained from our After-Sales Service department Nuremberg works. -

Page 74: Recommissioning Of Decommissioned Engines

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Decommissioning and Recommissioning 10.4 Recommissioning of Decommissioned Engines 10.4.1 Commissioning of Preserved Engines according to MAN-Werknorm M 3059 1. Remove external preservation. Never use a high pressure cleaner for this. 2. Remove caps from intake and exhaust openings. -

Page 75: Technical Data

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data Technical Data 11.1 Dimensions and Weights 11.1.1 D2848 LE201/203/211/213 Specification Value Unit Weight (dry) 1250 1850 1400 1700 11.1.2 D2840 LE201/203/211/213 Specification Value Unit Weight (dry) 1480 2125 1600 1826 11.1.3 D2842 LE201/203/211/213... -

Page 76: Engine Data

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data 11.3 Engine Data 11.3.1 D2848 LE201/203/211/213 Model D 2848 LE 201 / 203 / 211 / 213 Design V 90_ Operating Principle 4-cycle diesel engine with turbocharging and charge air cooling Combustion system... - Page 77 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data D 2848 LE 211 1500 rpm , continuous 1800 rpm, continuous D 2848 LE 213 1500 rpm , continuous 1800 rpm, continuous Engine lubrication Force feed lubrication Oil capacity in oil sump (litres) min.

-

Page 78: D2840 Le201/203/211/213

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data 11.3.2 D2840 LE201/203/211/213 Engine model D 2840 LE 201 / 203 / 211 / 213 Design V 90_ Operating Principle 4-cycle diesel engine with turbocharging and charge air cooling Combustion system Direct injection... - Page 79 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data D 2840 LE 211 1500 rpm , continuous 1800 rpm, continuous D 2840 LE 213 1500 rpm , continuous 1800 rpm, continuous Engine lubrication Force feed lubrication Oil capacity in oil sump (litres) min.

-

Page 80: D2842 Le201/203/211/213

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data 11.3.2 D2842 LE201/203/211/213 Engine model D 2842 LE 201 / 203 / 211 / 213 Design V 90_ Operating Principle 4-cycle diesel engine with turbocharging and charge air cooling Combustion system Direct injection... - Page 81 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Technical Data D 2842 LE 211 1500 rpm , continuous 1800 rpm, continuous D 2842 LE 213 1500 rpm , continuous 1800 rpm, continuous Engine lubrication Force feed lubrication Oil capacity in oil sump (litres) min.

-

Page 82: Declaration Of Incorporation

MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Declaration of incorporation Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters. - Page 83 MAN Industrial Diesel Engines D2848/40/42 LE201/203/211/213 Declaration of incorporation Carefully read the Operating Instructions before starting any work! This is especially valid for the chapter on General Safety Instructions and the safety instructions in each of the chapters.

Need help?

Do you have a question about the D2848 LE201 and is the answer not in the manual?

Questions and answers

i want to see primary pump on the engine

The primary pump on the MAN D2848 LE201 engine is the high-pressure pump, which is fed by flange-mounted delivery pumps. It is part of the high-pressure fuel system. To view the pump, you need to locate the fuel system components on the engine. The front left view of the engine includes key components like the fan, alternator, oil filler neck, turbocharger, starter, exhaust pipe, and tensioning pulley. Carefully reading the operating instructions, especially the general safety instructions, is essential before starting any work on the engine.

This answer is automatically generated