Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Johnson Controls SABROE SAB 355 S

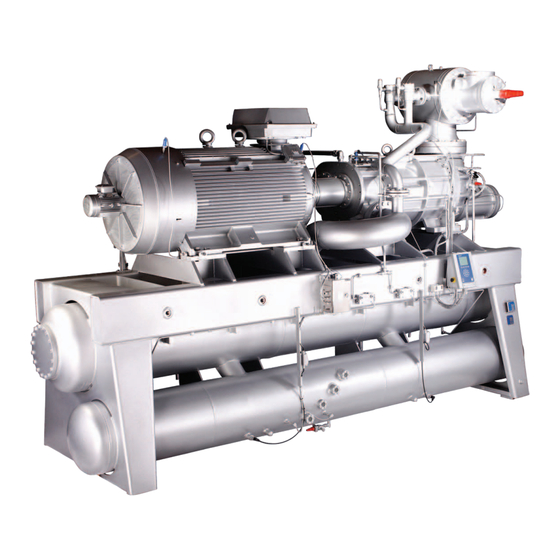

- Page 1 Operating manual SAB 355 (including ATEX) Screw compressor unit...

- Page 3 Manual for SAB 355 screw compressors Unit no. Compressor Compressor type Oil separator type OHU 7650/6050 OHU 6042/5030 Refrigerant R717 HFC/HCFC ____ Other: _________ Oil type Oil type: __________________ . Evap. temp. _______ . Cond. temp. _______ Control Unisab III None Other Single...

- Page 4 Vessel data Design pressure External surface Type [bar] Condenser Evaporator Liquid separator Oil separator Safety valve: Data for calculation of Oil cooler downstream line accord- ing to EN 13136 Economiser Other Pressure loss, if any, from safety valve to customer connection (based on design pressure) [bar] _____________ Safety valve type: Back-pressure dependent...

-

Page 5: Table Of Contents

Contents Introduction to operating manual ..........7 Compressor name, SABROE/Frick .......... 8 Amendments to the manual ............ 8 Safety precaution definitions used in this manual ....10 Requirements for competent persons ........10 Areas of application of screw compressor ....... 11 Application of the screw compressor ........ - Page 6 Demand pump oil system ............35 Compressor oil separation system ........35 6.10 Automatic oil return valve ............. 36 6.11 Cold-start system ..............37 6.12 Compressor hydraulic system ..........39 6.13 Volumizer volume ratio control ..........40 6.14 Compressor V increase ............

-

Page 7: Introduction To Operating Manual

It is important that the operating personnel familiarise themselves with the contents of this man- ual in order to ensure proper and efficient operation. Johnson Controls Denmark is not liable for damage occurring during the warranty period where this is attributable to incorrect operation. -

Page 8: Compressor Name, Sabroe/Frick

Introduction to operating manual Compressor name, SABROE/Frick The compressor in a SABROE SAB 355 screw compressor unit is manufactured by Frick. Below is indicated how the SABROE and Frick compressor names are made up and how they correspond to each other. SABROE name Frick name SAB 355 S... - Page 9 Copyright © Johnson Controls Denmark ApS This manual must not be copied without the written permission of Johnson Controls Denmark, and the contents must not be imparted to a third party nor be used for any unauthorised purpo- ses. Contravention will be prosecuted.

-

Page 10: Safety Precaution Definitions Used In This Manual

Introduction to operating manual Safety precaution definitions used in this manual Danger! Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. Warning! Indicates a potentially hazardous situation or practice which, if not avoided, will result in death or serious injury. -

Page 11: Areas Of Application Of Screw Compressor

However, check with the local authorities as exemptions to this rule may be granted. Warning! Johnson Controls Denmark is not liable for injuries to personnel or damage to equipment resulting from using the equipment for other purposes than the ones stated above. Operating manual- SAB 355 (including ATEX) 004059 en 2019.11... -

Page 12: Identification

Identification 3. Identification Identification All Johnson Controls Denmark equipment can be identified by one or several name plates as illus- trated in the following. Operating manual- SAB 355 (including ATEX) 12/63 004059 en 2019.11... -

Page 13: Unit/Pipe System Name Plate

Identification Unit/pipe system name plate Johnson Controls Denmark ApS 2516-343 Johnson Controls Denmark ApS 2516-342 Christian X's Vej 201 Christian X's Vej 201 8270 Højbjerg, Denmark 8270 Højbjerg, Denmark www.sabroe.com www.sabroe.com Refrigeration unit Year Refrigeration unit Year Type Type Scope... - Page 14 Identification The unit name plate is positioned on the frame and contains this information: Refrigeration unit No. Identification no. (serial no.) Year of manufacturing. Year Type Manufacturer's type designation. For EC PED/EAC approval: ‘Unit & Piping’ means that the CE/EAC mark applies to the complete unit including the piping system.

-

Page 15: Compressor Name Plate

Identification Compressor name plate Fig. 4: Compressor name plate Fig. 5: Refrigerant plates Note: The compressor is fitted with a name plate, Fig. 4, and one of the two refrigerant name plates shown in Fig. 5. The rotary screw compressor serial numbers contain the following information: Example: 10240A90000015Z. -

Page 16: Compressor Name Plate - Atex

Identification Compressor name plate - ATEX Fig. 6: Name plate for an ATEX compressor The ATEX compressor name plate contains this information: Manufacturer type designation. Model no. Manufacturer part number. Part no. Compressor manufacturing number. Serial no. Max. driver speed - rpm Maximum number of revolutions allowed. -

Page 17: Labelling Of Explosion-Proof Equipment

Identification Labelling of explosion-proof equipment ATEX: The compressor area of application is indicated next to the Ex-sign on the name plate. II 2 G T3/T4 Material group: II indicates that the equipment is suitable for use in industrial areas above ground. Material category: 2 indicates that the equipment is suitable for use in areas with possible occurrence of ex- plosive gasses. -

Page 18: Vessel Name Plate

Identification Vessel name plate Johnson Controls D e n m ar k ApS Johnson Controls Denmark ApS Christian X 's V e j 201 Christian X's Vej 201 2516-331 8 270 Højbj e rg, D e n m ark 8270 Højbjerg, Denmark www.sabro e .com... -

Page 19: Safety Precautions

Safety precautions 4. Safety precautions Signs All signs which may be found on your equipment are shown below. The number of signs, however, may vary from one product to another. High surface High voltage/ The compressor may be temperature Risk of electric shock High pressure top-heavy (about 70°C) -

Page 20: During Operation

Safety precautions General Use these precautions as a supplement to the safety precautions and warnings included in: • All other manuals pertaining to the compressor/unit. • Local, plant and shop safety rules and codes. • National safety rules and regulations. Read and understand all safety instructions before setting up, operating or servicing/performing maintenance on the compressor. -

Page 21: Safety During Maintenance And Service

Use the prescribed tools, and check that they are properly maintained and in good work- ing condition. In explosion-proof areas, use tools suited for this specific purpose. • Use only Johnson Controls Denmark original spare parts; other parts may impair the safety of the compressor/unit. •... -

Page 22: Electrical Installations

ATEX directive. If the installations are expanded or additional equipment is mounted, this must also be in conformity with the ATEX directive. For equipment not supplied by Johnson Controls Denmark, it is the contractor who is responsible for ensuring that the equipment is in conformity with the ATEX directive. -

Page 23: Purging A Refrigeration Plant

Safety precautions Purging a refrigeration plant Purging of air or other non-condensable gases is required in order to keep high system perform- ance and avoid corrosion of the equipment, which could endanger the safety of persons and equipment. When purging a refrigeration system, make sure to observe the following: •... - Page 24 Safety precautions Bans on GWP R404A/R507A and other refrigerants with a GWP over 2500 are banned from new stationary sys- tems after 2020. Existing systems can be serviced with reclaimed refrigerant until 2030, provided that proper-quality refrigerant is available. Read the local regulations. Labelling The unit must be fitted with a label (name plate).

-

Page 25: Sound And Noise Data

SAB 355 L SAB 355 E SAB 355 X Table 5: Noise data Noise data for other operating conditions can be provided by Johnson Controls Denmark on request. Note: • The actual SPL value on site will be between the stated SPL and SWL depending on the acoustic environment in the machine room. -

Page 26: Installation

ATEX directive. For equipment not supplied by Johnson Controls Denmark, it is the contractor who is responsible for ensuring that the equipment is in conformity with the ATEX directive. Specifically, the contractor is responsible for equalising potential differences on the compressor. -

Page 27: Operating Instructions

Operating instructions 6. Operating instructions Read chapter 4. Safety precautions carefully before operating the unit. Description of the unit Control system The compressor unit is controlled by an electronic control system. The control system is described in a separate manual, delivered with the unit. Principle drawing Fig. - Page 28 Operating instructions Fig. 10: Position of valves and components. Operating manual- SAB 355 (including ATEX) 28/63 004059 en 2019.11...

-

Page 29: General P&I Diagram

Operating instructions General P&I diagram Fig. 11: General P&I diagram, SAB 355 with oil cooler, dual oil filters and oil pump. Operating manual- SAB 355 (including ATEX) 004059 en 2019.11 29/63... - Page 30 Operating instructions Legend (Covers all P&I diagrams in this manual) Compressor Temperature switch high alarm Check valve Thermowell Discharge pressure Vi control Flow glass SB-2 Inlet bearing and balance piston Hand valve SB-3 Discharge bearings and seal Heater SC-1 Slide valve - unload Level glass SC-2 Slide valve - load...

-

Page 31: P&I Diagrams - Liquid Injection, Single And Dual Port

Operating instructions P&I diagrams - liquid injection, single and dual port Compressor Low Vi Tubing line Solenoid valve Motorised Strainer expansion Liquid refrigerant valve from receiver Liquid line Sight glass Fig. 12: P&I diagram - liquid injection, single port Compressor suction pressure Compressor Low Vi... - Page 32 Operating instructions Valve positions during operation Pos. no. Designation In-operation position Suction stop valve Open Open Stop valve after oil separator Change over valve Open to safety valve - no.1 or no.2 104 / PSV1 Safety relief valve (Closed) Fixed set point 105 / PSV 1 Safety relief valve (Closed) Fixed set point...

-

Page 33: Descriptions Of Main Components And Systems

Operating instructions Descriptions of main components and systems The screw compressor unit is an integrated system consisting of the following major subsystems: • Control system • Compressor • Compressor lubrication system • Compressor oil separation system • Compressor hydraulic system •... -

Page 34: Compressor Lubrication System

Operating instructions COMPRESSOR Fig. 14: Shaft rotation The compressor rotation is clockwise when facing the compressor drive shaft. See Fig. 14. The compressor must never be operated in reverse rotation as this will cause bearing damage. Compressor lubrication system The lubrication system on a screw compressor unit performs several functions: •... -

Page 35: Demand Pump Oil System

Operating instructions discharge pressure. During normal compressor operation, the compressor unit essentially oper- ates as its own oil pump. All oil entering the compressor is moved by the compressor rotors out the compressor outlet and back to the oil separator. For normal high-stage operation an oil pump is not required. -

Page 36: Automatic Oil Return Valve

Operating instructions 6.10 Automatic oil return valve 1: Inlet G1/4” 4: Stop valve, outlet side 2: Filter 5: Outlet G1/4” 3: Stop valve, inlet side 6: Sight glass Fig. 17 Note: Valve inlet and outlet are marked on the valve housing with "in" and “out”. Function The function of the automatic oil return valve, EVRB, is to return the separated oil in the fine sepa- rator to the compressor. -

Page 37: Cold-Start System

Operating instructions Fig. 18 Note: The sectional view shows the valve structure. Some of the internal oil channels are not visible. 6.11 Cold-start system The unit is equipped with a special "cold-start" discharge valve. This valve ensures a rapid devel- opment of oil pressure at initial start-up in order to lubricate the compressor without requiring an oil pump, even in cold ambient temperatures with all pressures equalised. - Page 38 Operating instructions side, these pressures will act across a piston inside the cold-start valve to partially overcome the spring force. When the differential pressure reaches and exceeds 2.0 bar [30 psi], the piston fully overcomes the spring force and powers the valve fully open for a very low operating pressure drop.

-

Page 39: Compressor Hydraulic System

Operating instructions 6.12 Compressor hydraulic system The compressor hydraulic system moves the movable slide valve (MSV) to load and unload the compressor. It also moves the movable slide stop (MSS) to increase or decrease the compressor’s volume ratio (Vi). The hydraulic cylinder located at the inlet end of the SGC compressor serves a dual purpose. It is separated by a fixed bulkhead into two sections. -

Page 40: Volumizer Volume Ratio Control

Operating instructions Booster compressor loading The compressor loads when the MSV solenoid valve, YY2, is energised, and oil flows from the oil manifold through the valve ports, P and B, to the cylinder port, SC2, and enters the loading side of the cylinder. -

Page 41: Compressor Oil Cooling Systems

Operating instructions 6.16 Compressor oil cooling systems The unit can be equipped with one of several systems for controlling the compressor oil tempera- ture. They are single or dual-port liquid injection and refrigerant-cooled (thermosyphon) or water-cooled oil coolers. Each system is automatically controlled, independent of compressor loading or unloading. -

Page 42: Balance Piston Pressure Regulator

Operating instructions separator takes more than 20-30 minutes to equalise to suction pressure after shutdown, NV-2 can be opened slightly. See Fig. 22. From separator cold-start valve Compressor end view For 8” and larger suction valve customer supplied line Fig. 22: Suction check valve by-pass Check valve CV-4 is installed on all units with suction pressure below atmospheric or installed with economiser option utilised on multiple compressor plants. -

Page 43: Low Ambient Temperature Operation

Operating instructions Pressure-regulating valve(A4ALE) To SB-2 From compressor compressor discharge or oil port manifold Solenoid valve Restriction orifice (pipe) From oil manifold Fig. 23: High-stage SB-2 oil supply line diagram (SAB 355 H only) 6.19 Low ambient temperature operation It is recommended that oil separators are insulated as a minimum requirement to preserve the heat generated by the oil heaters. -

Page 44: Initial Start-Up Procedure

Operating instructions Warning! On ATEX-executions, the limits in Table 7 must always be respected. Temp. class Max. surface Max. temperature of oil to Min. ignition temperature temp. shaft seal of oil 450°C 380°C 500°C 300°C 230°C 350°C 200°C 130°C 250°C 135°C 65°C 185°C... - Page 45 Operating instructions will give you a theoretical discharge temperature of the compressor. Once this temperature is known, you may adjust the hand expansion valve. The ideal discharge temperature is within +2.7°C or -2.7°C of the theoretical discharge temperature. Adjust the valve to achieve the theo- retical discharge temperature.

-

Page 46: Stopping Routine

Synthetic components in the compressor may deteriorate over time even if they are kept flooded with oil. A warm and dry environment is essential to minimise environmental and corro- sive damage. For further information, contact Johnson Controls Denmark. Operating manual- SAB 355 (including ATEX) 46/63... -

Page 47: Troubleshooting

Troubleshooting 7. Troubleshooting The tables below cover the most common problems. For detailed troubleshooting of the refrigera- tion plant, please refer to the manual of the plant or common refrigeration literature. Refrigeration plant, general issues Symptom Probable cause Solution Refrigeration load lower than com- Reduce compressor capacity. - Page 48 Troubleshooting Compressor unit, general issues Symptom Probable cause Solution Check main switch and fuses. Reset Electrical supply. emergency stop switch, etc. Register the alarm, correct if neces- Compressor cannot Alarm in control system. sary and reset (refer to the Control start manual).

- Page 49 Troubleshooting Compressor unit - oil separation Symptom Probable cause Solution Lower level by opening/adjusting Maintaining too high oil level. the oil return valve. Refrigerant carry-over or liquid in- Correct operation. Gradual oil loss with jection overfeeding. an oil level in the co- Loss of suction superheat.

- Page 50 Troubleshooting Compressor block Symptom Probable cause Solution Main oil injection valve may be Open valve. closed. Main oil injection valve may be open Adjust. too far. Bearing damage or excessive wear. Replace bearings. Excessive noise and Slide valve/slide stop out of calibra- Calibrate.

- Page 51 Troubleshooting Demand oil pump system (optional) Symptom Probable cause Solution Pump rotation. Check. Open valve. Service valves closed. Check pressure difference across Filter cartridges may be blocked. Pump will not pro- filters. Strainer may be blocked. duce enough oil Clean strainer. Oil pressure regulator set too low or pressure to start Readjust or repair.

-

Page 52: Maintenance Instructions

Motor lubrication and other routine maintenance tasks are usually based on running time. Please refer to 8.2: Maintenance intervals Table 13: Maintenance intervals. Major overhaul For major maintenance tasks such as compressor overhauls, contact Johnson Controls Denmark. Operating manual- SAB 355 (including ATEX) 52/63 004059 en 2019.11... -

Page 53: Maintenance Intervals

Maintenance instructions Maintenance intervals Table 13: Maintenance intervals Operating manual- SAB 355 (including ATEX) 004059 en 2019.11 53/63... -

Page 54: Monitoring Of Operation

Maintenance instructions Discharge flange to Suction flange Reference separator flange Compressor model designation Torque Torque model RWF II Bolt size Bolt size (ft-lb) (ft-lb) SAB 355 S SGC 3511 M24 x 3.0 M30 x 3.5 SAB 355 L SGC 3515 M24 x 3.0 M30 x 3.5 SAB 355 E... - Page 55 Maintenance instructions Checklist Checklist Checklist for commissioning of compressor, chiller and heat pump units Start-up log: Monitoring of operation at start-up Compressor serial no.: Date: Name: Compressor serial no.: Date: Name: Check before start-up Observation Value Read and understand all Sabroe manuals (compressor, Unisab, chiller, etc.) Operation time [hours ] Read and understand manuals for third party components (electric motors, valves,...

-

Page 56: Oil

The oil in the unit must be changed after a specific number of operating hours or when an oil anal- ysis shows that a change is required. We advise you to let Johnson Controls Denmark’s service organisation change the oil as it is rec- ommended to replace all filters in the unit at the same time. - Page 57 Maintenance instructions When the desired amount of oil has been charged to the unit, stop the pump and close the service valve, pos. 106. Open the ball valve, pos. 9, carefully to equalise the pressure. The hoses can now be dismantled.

-

Page 58: Motor

In connection with electric motors, it is absolutely essential to lubricate the bearings correctly and use the appropriate type of grease. Please refer to the motor manual and/or the motor name plate. Replacing motor bearings Please contact Johnson Controls Denmark’s service organisation. Operating manual- SAB 355 (including ATEX) 58/63 004059 en 2019.11... -

Page 59: Final Disposal

Final disposal 9. Final disposal Safety precautions Danger! Before dismantling the plant, read the safety precautions carefully. Dismantling a refrigeration unit to be scrapped must be carried out safely. Only competent refrigeration personnel must perform the dismantling as fundamental knowledge of refrigeration systems and the risks involved are required. -

Page 60: Compliance

10.1 Declaration of conformity Johnson Controls Denmark declares on the signed declaration of conformity that the unit is manu- factured and CE-marked in conformity with relevant directives and standards. The printed version of this operating manual, which is delivered with the unit, contains a trans- lated version of the declaration, however not filled in with the specific data for your unit. -

Page 61: Index

Index Amendments to the manual ......................8 ATEX ........................11, 17, 21, 43 Balance piston pressure regulator ....................42 Batteries ............................ 59 Booster applications ........................38 Booster compressor loading ....................... 40 Charging compressor ......................... 56 Cold-start system........................37 Combustion engines - application ....................11 Competent persons - requirements.................... - Page 62 Identification..........................12 Liquid injection adjustment ......................41 Logbook ............................. 54 Long-term storage ........................46 Low ambient temperature operation ..................43 Lubricating oil........................22, 56 Maintenance intervals ........................ 53 Maintenance of compressor unit....................52 Monitoring of operation ......................54 Motor lubrication ........................58 Noise data ..........................

- Page 63 Unit/pipe system name plate ..................... 13 Valve positions during operation ....................32 Vessel name plate ........................18 Vibration and noise........................20 Volumizer volume ratio control....................40 Operating manual- SAB 355 (including ATEX) 004059 en 2019.11 63/63...

- Page 64 Johnson Controls Denmark ApS SABROE Factory Christian X's Vej 201 ∙ 8270 Højbjerg Denmark Phone +45 87 36 70 00 Version 2 www.sabroe.com...

Need help?

Do you have a question about the SABROE SAB 355 S and is the answer not in the manual?

Questions and answers