Table of Contents

Summary of Contents for Dorner ERT 150

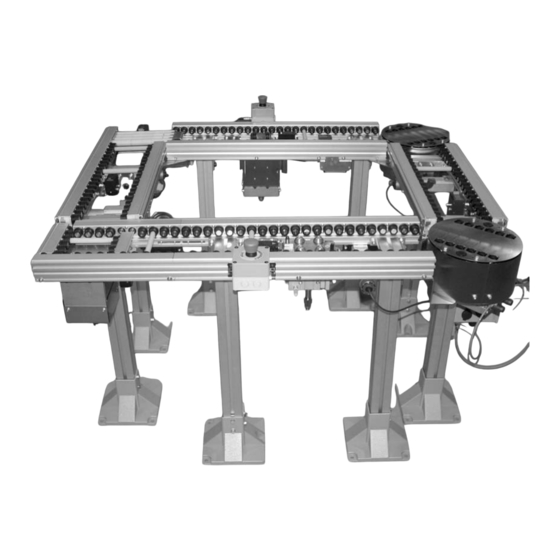

- Page 1 ® 150 Pallet System Stations & Accessories Installation, Maintenance & Parts Manual For other service manuals visit our website at: www.dornerconveyors.com/manuals-literature Record Conveyor Serial Number Here 851-961 Rev. A...

-

Page 2: Table Of Contents

Simplified Installation ..........24 Post Support Stand ............74 Full Installation Steps..........24 Sprocket Removal Tool..........75 Pneumatic and Control Logic Suggestions ....26 Return Policy..............76 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 3: Introduction

DO NOT operate equipment manual with the Performance Parts Kits logo without guards. Dorner reserves the right to make changes at any time Upon receipt of shipment: without notice or obligation. • Compare shipment with packing slip. Contact factory regarding discrepancies. -

Page 4: Warnings − General Safety

A WARNING The safety alert symbol, black triangle with white exclamation, is used to alert you to potential personal injury hazards. Dorner cannot control the physical A DANGER installation and application of conveyors. Taking protective measures is the responsibility of the user. -

Page 5: Specifications

Lift and Transfer Station Document Language ER3 T M D C N G S Controller Type Speed Guarding Pallet Sensor Option Orientation Direction Flow Option Length Width Document Language ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 6: Torque Specifications

6 mm 56.0 Nm 8 mm 97.5 Nm 6 mm 48.0 Nm 5 mm 35.0 Nm (496 in lbs) (863 in lbs) (425 in lbs) (310 in lbs) ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 7: Installation

(Figure 4, item 2). Figure 4 Figure 1 Attach sensor (Figure 2, item 1) to conveyor with screw (Figure 2, item 2). Figure 2 Figure 4 Figure 2 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 8: Pallet Stops

(Figure 8, item 2) on the opposite side of the pallet Figure 6 stop. Figure 8 Figure 8 Tighten screws to secure bracket back onto pallet stop. Figure 6 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 9: Pneumatic And Control Logic Suggestions

Figure 11 Figure 9 Attaching and Operations of Pneumatics Connect the solenoid to the stop. Dorner fittings (Figure Figure 11 10, item 1) accept 1/4" outside diameter tubing standard • On an in–frame stop, two bottom (Figure 12, item 1) and (Figure 10, item 2). -

Page 10: Lift And Locate Station

(Figure 14, item 1) in inner T–slot on both sides of the conveyor. Figure 14 Figure 16 Install pallet stop (Figure 16, item 4) at leading end. (Refer to “Pallet Stops” starting on page 8.) Figure 14 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 11: Guard Kit Removal (If Equipped)

18, item 2), and four screws (Figure 18, item 3) from the top of the guard (Figure 18, item 4). Figure 20 Figure 18 Figure 20 Figure 18 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 12: Pneumatic And Control Logic Suggestions

Figure 23 Attaching and Operations of Pneumatics Remove guarding, if equipped. Connect the 3–port, 2–way solenoid valve to the stop. Dorner fittings (Figure 24, item 1) accept 1/4" outside diameter tubing standard (Figure 24, item 2). Figure 24 Figure 21... -

Page 13: Sensor Installation And Basic Logic

25, item 1) in plate (Figure 25, item 2) and to the (Figure 26, item 2) sensor brackets can be used to mount a lowest port (Figure 25, item 3) on the lift. Dorner 12 mm barrel proximity sensor (Figure 26, item 3). -

Page 14: Lift And Transfer Station

Join conveyor frames (Figure 29, item 1) and install conveyor tie brackets (Figure 29, item 2) in bottom slots (Figure 29, item 3) on both sides of the conveyor. Figure 29 Figure 31 Figure 29 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 15: Guard Kit Removal (If Equipped)

(Figure 35, item 2) onto lift cylinder. Figure 35 Figure 32 Remove two screws (Figure 33, item 1) and remove side guard (Figure 33, item 2). Figure 33 Figure 35 Figure 33 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 16: Stroke Adjustment

Turn large nut (Figure 39, item 2) clockwise or counterclockwise to raise or lower (Figure 39, item 3) pallet assembly as needed. Tighten jam nut against large nut to secure position. Figure 37 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 17: Pneumatic And Control Logic Suggestions

Figure 43 Connect Port 2 (Figure 41) of the 5 port, 2 way solenoid to the upper port (Figure 43, item 2) on the lift. Dorner fittings accept 1/4" outside diameter tubing standard. • The lift raises when air is supplied to the lowest port of the lift and the upper port is allowed to exhaust. -

Page 18: Lift And Rotate Station

(Figure 45, item 1) in inner T–slot on both sides of the conveyor. Figure 45 Figure 47 Install pallet stop (Figure 47, item 4) at leading end. (Refer to “Pallet Stops” starting on page 8.) Figure 45 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 19: Rotation Adjustment

Figure 51 Figure 48 Figure 49 Figure 51 Rotation Adjustment Loosen nuts (Figure 52, item 1) with an open–end wrench. Figure 52 Figure 49 Figure 52 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 20: Guard Kit Removal (If Equipped)

Lower cylinder guard (Figure 54, item 2) from around counterclockwise to raise or lower (Figure 56, item 3) cylinder assembly. pallet assembly as needed. Tighten jam nut against large nut to secure position. ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 21: Pneumatic And Control Logic Suggestions

(Figure 61, item 4) in plate (Figure 61, item 2) and to the upper port (Figure 61, item 5) on the lift. Dorner fittings accept 1/ 4" outside diameter tubing standard. • The lift raises when air is supplied to the lowest port of the lift and the upper port is allowed to exhaust. -

Page 22: Sensor Installation And Basic Logic

Connect Port 4 (Figure 59) of the 5–port 2–way Figure 64 solenoid t to the left port (Figure 62, item 1) of the rotator. Dorner fittings accept 1/4" outside diameter tubing standard. Figure 62 Figure 64 • Use proximity sensor to detect pallet located at the stop. - Page 23 Figure 68 Install sensor(s) (Figure 67, item 1) (provided by Figure 69 others) into slots (Figure 67, item 2) in sensor bracket. Figure 67 Figure 69 Figure 67 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 24: Simplified Installation

Figure 71 Figure 73 Figure 71 Connect transfer conveyor with connecting brackets (Figure 71, item 2). Install and connect pneumatic solenoids (Figure 71, item 3), provided by others. ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 25 Remove shims (Figure 75, item 1) from bottom of brackets (Figure Figure 77 75, item 2) and place between brackets and module. Figure 75 Figure 77 Figure 75 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 26: Pneumatic And Control Logic Suggestions

Rotation Adjustment To adjust counterclockwise rotation, loosen right side Recommended Pneumatics nut (Figure 80, item 1) with an open–end wrench. Dorner recommends using a 5–port 2–way solenoid valve Figure 80 (Figure 78) to operate the Rotating Actuator. Figure 78 Figure 78... -

Page 27: Pallet Pusher

Simplified Installation Install and adjust Pusher module (Figure 83, item 1). Figure 83 Figure 85 Figure 83 Connect transfer conveyor with connecting brackets (Figure 83, item 2). ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 28: Guard Kit Removal (If Equipped)

(Figure 86, item 1) on To adjust outward stroke distance (limit), loosen jam nut the pallet pusher. Dorner fittings accept 1/4" outside (Figure 88, item 1) from stud (Figure 88, item 2) on diameter tubing standard. -

Page 29: Preventive Maintenance And Adjustment

(Figure 92, item 2) and remaining conveyor components. Figure 92 Figure 90 Replace worn or damaged parts. Installation is the reverse of removal. Figure 92 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 30: Lift And Locate Station

Remove optional guarding that secures cylinder guard (Figure 94, item 1) over cylinder assembly. See “Guard Kit Removal (If Equipped)” on page 11. Figure 94 Figure 96 Figure 94 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 31 Disconnect upper (Figure 100, item 1) and lower (Figure 100, item 2) hoses from fittings on lift cylinder (Figure 100, item 3). Figure 100 Figure 98 Figure 100 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 32: Lift And Transfer Station

Remove two screws (Figure 104, item 1) securing bracket (Figure 104, item 2) to lift and transfer station (Figure 104, item 3). Figure 104 Figure 102 Figure 104 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 33 (Figure 106, item 2). Figure 108 Figure 106 Figure 106 Figure 108 NOTE Be sure to mark lower and upper hoses and there locations to aid in reinstalling. ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

- Page 34 10. Remove lift and transfer section and cylinder (Figure cylinder (Figure 110, item 2). 112, item 1) from bracket (Figure 112, item 2) on Figure 110 conveyor. Figure 112 Figure 110 Figure 112 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A...

- Page 35 14. Remove two fittings (Figure 116, item 1) from cylinder. 12. Remove two socket head screws (Figure 114, item 1) securing cylinder to conveyor frame. Figure 116 Figure 114 Figure 116 Figure 114 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 36: Lift And Rotate Station

Disconnect both hoses (Figure 120, item 1) from fittings on rotate cylinder (Figure 120, item 2). Figure 120 Figure 120 Figure 118 Lower cylinder guard (Figure 118, item 2) from around cylinder assembly. ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 37 (Figure 126, item 2). Figure 126 Figure 122 Remove two socket head screws (Figure 123, item 1) from the top of rotate cylinder. Figure 123 Figure 126 Figure 123 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 38: Turn And Transfer

Remove four screws (Figure 130, item 1) that secure the two pallet guides (Figure 130, item 2) and top plate (Figure 130, item 3). Figure 130 Figure 128 Figure 130 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 39: Guarding Removal

Disconnect both hoses (Figure 134, item 1) from guard. fittings on turn and transfer assembly cylinder (Figure Figure 132 134, item 2). Figure 134 Figure 132 Figure 134 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. - Page 40 Loosen two screws (Figure 138, item 1) on sensor bracket (Figure 138, item 2), so the bracket is no longer secured. Figure 138 Figure 138 Figure 136 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A...

- Page 41 (Figure 143, item 1). Figure 142 Figure 139 Tap roller shaft assembly (Figure 140, item 1) to remove (Figure 141). Figure 140 Figure 142 Figure 143 Figure 140 Figure 143 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 42: Drive Motor Replacement

When reassembling, make sure there is a gap Figure 147 (Figure 145, item 1) between the gear and the U frame. Figure 145 Figure 147 Figure 145 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 43 Remove four screws (Figure 151, item 3) holding hex posts (Figure 151, item 4) onto motor. 10. Replace worn or damaged parts. 11. Installation is the reverse of removal. ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

-

Page 44: Cylinder Replacement

Remove turn and transfer assembly (Figure 153, item 1) from cylinder (Figure 153, item 2). Figure 153 Figure 155 Replace worn or damaged parts. Installation is the reverse of removal. Figure 153 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 45: Pallet Pusher

159, item 3). Figure 159 Figure 156 Remove screw (Figure 157, item 1) on both ends and remove cover (Figure 157, item 2). Figure 157 Figure 159 Figure 157 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 46: Gear, Roller, And Roller Shaft Replacement

(Figure 161, item 2). onto conveyor frame. Figure 161 Figure 161 Rotate and remove side cover (Figure 162, item 1) from conveyor frame Figure 162 Figure 164 Figure 162 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 47 (Figure 166, item 2) on roller shaft. Figure 167 Figure 166 Remove two screws (Figure 168, item 1) securing roller plate (Figure 168, item 2) on assembly. Figure 168 Figure 166 Figure 168 ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp.

- Page 48 13. Repeat for removing remaining gears and rollers, as remove rollers (Figure 170, item 2) from rod. necessary. 14. Replace worn or damaged parts. Figure 170 15. Installation is the reverse of removal. Figure 170 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A...

-

Page 49: Notes

Notes ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 50: Service Parts

Service Parts NOTE For replacement parts other than those shown in this section, contact an authorized Dorner Service Center or the factory. Key Service Parts and Kits are identified by the Performance Parts Kits logo . Dorner recommends keeping these parts on hand. - Page 51 WWW = Pallet width reference: 160, 200, 240, 280, 320 LLL = Pallet length reference: 160, 200, 240, 280, 320 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 52: Bottom Sensor

960816MFY Flanged Hex Head Cap Screw, M8 x 16 mm Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 53: Side Sensor

960816MFY Flanged Hex Head Cap Screw, M8 x 16 mm Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 54: Light Load Pallet Stop

M8 x 16 mm 920640M Socket Head Screw, M6–1.00 x 40 mm Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... -

Page 55: Standard Load Pallet Stop

960816MFY Flanged Hex Head Cap Screw, M8 x 16 mm Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 56: Low Height Lift And Locate

Service Parts Low Height Lift and Locate ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 57 WWW = Pallet width reference: 160, 200, 240, 280, 320 LLL = Pallet length reference: 160, 200, 240, 280, 320 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 58: Lift And Locate For Pallets 160 X 160, 160 X 240, 200 X 200, And 240 X 160

Service Parts Lift and Locate for Pallets 160 x 160, 160 x 240, 200 x 200, and 240 x 160 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 59 WWW = Pallet width reference: 160, 200, 240 LLL = Pallet length reference: 160, 200, 240 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 60: Lift And Locate For Pallets 240 X 240, 240 X 320, 280 X 280, 320 X 240 And 320 X 320

Service Parts Lift and Locate for Pallets 240 x 240, 240 x 320, 280 x 280, 320 x 240 and 320 x 320 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 61 WWW = Pallet width reference: 240, 280, 320 LLL = Pallet length reference: 240, 280, 320 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 62: Lift And Transfer For Pallets 160 X 160, 160 X 240, 200 X 200, 240 X 160, And 240 X 240

Service Parts Lift and Transfer for Pallets 160 x 160, 160 x 240, 200 x 200, 240 x 160, and 240 x 240 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 63 LLL = Pallet Length Reference: 160, 200, 240 16 mm Service parts can be obtained through your distributor or directly FASN–M8 Square Nut from Dorner Mfg. Corp. (800) 397-8664 or 400429-WWW U-Plate customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 64: Lift And Transfer For Pallets 240 X 320, 280 X 280, 320 X 240 And 320 X 320

Service Parts Lift and Transfer for Pallets 240 x 320, 280 x 280, 320 x 240 and 320 x 320 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 65 LLL = Pallet Length Reference: 240, 280, 320 FASN–M8 Square Nut Service parts can be obtained through your distributor or directly 400430-B Bottom Plate from Dorner Mfg. Corp. (800) 397-8664 or 400536-WWW Cylinder Mount customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A...

-

Page 66: Lift And Rotate For Pallets 160 X 160, 160 X 240, And 200 X 200

Service Parts Lift and Rotate for Pallets 160 x 160, 160 x 240, and 200 x 200 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 67 WWW = Pallet width reference: 160, 200, 240 LLL = Pallet length reference: 160, 200, 240 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 68: Lift And Rotate For Pallets 240 X 160, 240 X 240, 240 X 320, 280 X 280, 320 X 240 And 320 X 320

Service Parts Lift and Rotate for Pallets 240 x 160, 240 x 240, 240 x 320, 280 x 280, 320 x 240 and 320 x 320 ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 69 WWW = Pallet width reference: 160, 200, 240 LLL = Pallet length reference: 160, 200, 240 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 70: Turn And Transfer

Service Parts Turn and Transfer ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 71 WWW = Pallet width reference: 160, 200, 240, 280, 320 LLL = Pallet length reference: 160, 200, 240, 280, 320 Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev.

-

Page 72: Pallet Pusher

Service Parts Pallet Pusher ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. 851-961 Rev. A... - Page 73 33:1, RPM = 17.6-176 Service parts can be obtained through your distributor or directly 826-987 Motor, Speed = 25 Mpm, Gear Ratio = from Dorner Mfg. Corp. (800) 397-8664 or 27:1, RPM = 21.5-215 customerservice@dorner.com 826-988 Motor, Speed = 37 Mpm, Gear Ratio = 18:1, RPM = 31.7-317...

-

Page 74: Post Support Stand

400278 Top Plate Service parts can be obtained through your distributor or directly FATB-20 Twist-In Stud, M8 x 20 mm from Dorner Mfg. Corp. (800) 397-8664 or 990812M Lock Nut, M8 customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories Dorner Mfg. Corp. -

Page 75: Sprocket Removal Tool

Sprocket Removal Tool Item Part Number Description 400571 Sprocket Removal Tool Service parts can be obtained through your distributor or directly from Dorner Mfg. Corp. (800) 397-8664 or customerservice@dorner.com ERT® 150 Pallet System Stations & Accessories 851-961 Rev. A Dorner Mfg. Corp. -

Page 76: Return Policy

Return Policy Returns must have prior written factory authorization or they will not be accepted. Items that are returned to Dorner without authorization will not be credited nor returned to the original sender. When calling for authorization, please have the following information ready for the Dorner factory representative or your local distributor: Name and address of customer.

Need help?

Do you have a question about the ERT 150 and is the answer not in the manual?

Questions and answers