Table of Contents

Summary of Contents for Gema HFF01

- Page 1 Rev. 00 1011 521 Operating instructions and spare parts list Powder hopper HFF01 Only the powdered foods approved by Gema and tested in connection with this product may be processed! Translation of the original operating instructions...

- Page 2 To the best of our knowledge and belief, the information contained in this publication was correct and valid on the date of issue. Gema Switzerland GmbH makes no representations or warranties with respect to the contents or use of this publication, and reserves the right to revise this publication and make changes to its content without prior notice.

-

Page 3: Table Of Contents

Product contamination through foreign matter ......... 17 Preparing for production ..................17 Operation ......................18 Manually filling the powder hopper ............... 18 Automatically filling the powder hopper ..............19 Ending production ....................19 Decommissioning / Storage Introduction ......................21 Table of contents • 3 HFF01... - Page 4 Requirements on personnel carrying out the work ........29 Disposal regulations ................29 Materials ....................29 Spare parts list Ordering spare parts ..................... 31 HFF01 ........................32 HFF01 – Spare parts .................... 33 Agitator unit ......................34 Agitator unit ......................35 Agitator drive......................36 Agitator drive......................37 Attachment Material declaration ....................

-

Page 5: About These Instructions

General information This operating manual contains all important information you will need to work with the HFF01. It will safely guide you through the start-up process and give you references and tips for the optimal use of your new powder coating system. -

Page 6: Presentation Of The Contents

Presentation of the contents Presentation of the contents Figure references in the text Presentation of the contents: figure references in the text Figure references are used as cross references in the descriptive text. Example: 6 • About these instructions HFF01... -

Page 7: Safety

If this product is to be used for other purposes or other substances outside of our guidelines then Gema Switzerland GmbH should be consulted. –... -

Page 8: Product-Specific Safety Information

The installation work to be done by the customer must be carried out according to local regulations. – It must be ensured, that all components are earthed according to the local regulations before start-up. For further security information, see the more detailed Gema safety regulations. 8 • Safety HFF01... -

Page 9: Product Description

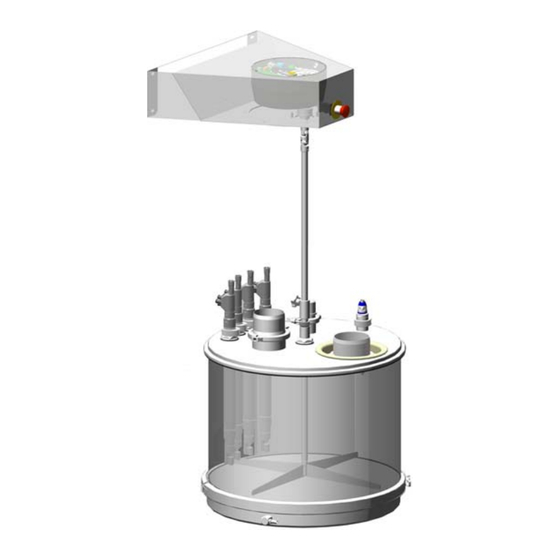

All materials meet the highest corrosion resistance and biocompatibility demands. Fig. 1: Powder hopper HFF01 The powder hopper is approved for the following zone if powder hoses with guide strips are applied and the earthing resistance is less than 1... -

Page 10: Reasonably Foreseeable Misuse

– Operation without the proper training Structure Overall view Fig. 2 Agitator drive Filler cap with nozzle Emergency STOP button Discharge shaft with rotors Connecting shaft Connection for fluidizing air Air mover connection Fluid plate Level detector 10 Connection 10 • Product description HFF01... -

Page 11: Technical Data

Rev. 00 02/17 Technical Data Technical Data Versions Versions The powder hopper is available in two versions. HFF01-60 HFF01-120 Content 60 dm³ 120 dm³ Number of injectors Pneumatic data Pneumatic data HFF01-60 HFF01-120 Air consumption fluid air ~ 8 Nm³/h ~ 11 Nm³/h... - Page 12 Rev. 00 02/17 12 • Product description HFF01...

-

Page 13: Assembly / Connection

Only locally authorized specialists may install and inspect the electrical elements of the machine. In the event of customizations, the wiring plan may differ. Connecting the pneumatic system The compressed air must be free of oil and water! Assembly / Connection • 13 HFF01... - Page 14 Rev. 00 02/17 14 • Assembly / Connection HFF01...

-

Page 15: Start-Up

Inserting the powder – Open the filler cap of the powder hopper. – Insert the powder Only fill the powder up to the half mark of the powder hopper to prevent fluidizing powder escaping from the lid. Start-up • 15 HFF01... -

Page 16: Set Fluidization

The operator has been told that he is responsible for instructing the personnel. Assembly and installation have been concluded in accordance with the operating manual. Electrical and mechanical safety equipment is in perfect working order. 16 • Start-up HFF01... -

Page 17: Operation

Start the machine. Start the fluidization process. After a prolonged shutdown of the system or before a product change, clean the interior powder hopper. Refer to chapter on "Cleaning the interior of the powder hopper" on page 25. Operation • 17 HFF01... -

Page 18: Operation

► Wear protective clothing and safety goggles! CAUTION Foreign objects. Contamination by foreign objects. ► Ensure that no foreign objects can fall into the powder hopper during manual filling! Open the filler cap (1) Insert the powder. Close the filler cap. 18 • Operation HFF01... -

Page 19: Automatically Filling The Powder Hopper

In the event of impurities, clean the powder hopper. – Clean the exterior of the powder hopper. – Clean the interior of the powder hopper. Refer to chapter on "Cleaning the interior of the powder hopper" on page 25. Operation • 19 HFF01... - Page 20 Rev. 00 02/17 20 • Operation HFF01...

-

Page 21: Decommissioning / Storage

The space requirements correspond to the sizes of the product. There are no special requirements concerning distance to neighboring equipment. Physical requirements Storage must be inside a dry building at a temperature between +5 – 50 °C. Decommissioning / Storage • 21 HFF01... -

Page 22: Shut-Down

Cleaning the interior of the powder hopper. Refer to chapter on "Cleaning the interior of the powder hopper" on page 25. Maintenance during storage Maintenance schedule No maintenance schedule is necessary. Maintenance works During long-term storage, periodically perform a visual check. 22 • Decommissioning / Storage HFF01... -

Page 23: Maintenance / Repairs

Lack of maintenance and a lack of ignition protection can lead to explosions. – Do not modify the machine. – Do not use potentially explosive products, operational material or cleaning liquids. – Maintain, clean and lubricate the machine correctly. – Only use original spare parts. Maintenance / Repairs • 23 HFF01... -

Page 24: Pressurized Pneumatics System

Cleaning intensity depends of the powder used. For optimal cleaning / sterilization results, we recommend dismantling the entire powder hopper into its dismantle components. ATTENTION Hopper components may be damaged during the cleaning process. – Please dismantle carefully to avoid damages! 24 • Maintenance / Repairs HFF01... -

Page 25: Cleaning The Interior Of The Powder Hopper

Daily maintenance – Clean the exterior of the powder hopper with a dry cloth – Check hose connections Wearing part Wearing parts replaced during maintenance can be individually purchased (refer to spare parts list). Maintenance / Repairs • 25 HFF01... - Page 26 Rev. 00 02/17 26 • Maintenance / Repairs HFF01...

-

Page 27: Fault Clearance

Only use original spare parts. Pressurized pneumatics system The pressurized pneumatics system may trigger dangerous situations. Disconnect the compressed air supply before working on the pneumatics system. Depressurize the pneumatics system. Secure the compressed air supply against reactivation. Fault clearance • 27 HFF01... -

Page 28: Faults

Free movement of Check the the agitator unit mechanical impaired operation of the agitator unit Compressed air not Connect device to Powder is not available compressed air fluidized Fluidizing air set too Set fluidizing air correctly 28 • Fault clearance HFF01... -

Page 29: Disposal

Requirements on personnel carrying out the work The disposal of the product is to be carried out by the owner or operator. When disposing of components that are not manufactured by Gema, the instructions in the respective manufacturer’s documentation must be observed. - Page 30 Rev. 00 02/17 30 • Disposal HFF01...

-

Page 31: Spare Parts List

When using the spare parts from other manufacturers the explosion protection is no longer guaranteed. If any damage is caused by this use all guarantee claims become invalid! ► Only original Gema spare parts should be used! Spare parts list • 31 HFF01... -

Page 32: Hff01

Rev. 00 02/17 HFF01 Connector 1014 919 Locking clip – 100 1015 532 Sealing ring – 100 1015 534 Connection – 40 1015 545 Locking clip – 40 1015 533 Level probe - complete 1015 115 Nozzle 1015 110 Rubber lid – Ø 200 mm 1014 889 Plug –... -

Page 33: Hff01 - Spare Parts

Rev. 00 02/17 HFF01 – Spare parts Fig. 3 Spare parts list • 33 HFF01... -

Page 34: Agitator Unit

1014 902 Universal joint 1014 928 Seal holder 1014 924 Connector 1014 929 Slip clutch 1015 116 1014 901 Connector 1015 321 Agitator motor - complete 393940 * Please indicate length # Wearing part 34 • Spare parts list HFF01... -

Page 35: Agitator Unit

Rev. 00 02/17 Agitator unit Fig. 4 Spare parts list • 35 HFF01... -

Page 36: Agitator Drive

267007 Cylinder screws 245321 Serrated washers 205885 Fuses – 2 AT 221872 Adapter cable for agitator unit connection 391905 Stuffing box 265780 Gasket for agitator motor 393924 * Please indicate length # Wearing part 36 • Spare parts list HFF01... -

Page 37: Agitator Drive

Rev. 00 02/17 Agitator drive Spare parts list • 37 HFF01... - Page 38 Rev. 00 02/17 38 • Spare parts list HFF01...

-

Page 39: Attachment

MVQ (silicone rubber) – refer to Manufacturer's Declaration of Conformity Stainless steel X5CrNi 18-10 (1.4301) POM C ELS – refer to Manufacturer's Declaration of Conformity Stainless steel X5CrNi 18-10 (1.4301) Stainless steel X5CrNi 18-10 (1.4301) Stainless steel X5CrNi 18-10 (1.4301) Attachment • 39 HFF01... -

Page 40: Material Declaration

Rev. 00 02/17 Material declaration Material declaration Fig. 6: Powder-contacting parts 40 • Attachment HFF01... - Page 41 Rev. 00 02/17 Index About these instructions ........5 Operation ............17 Disposal ............29 Storage .............. 5 Disposal regulations ......... 29 Index • 41 HFF01...

- Page 42 Rev. 00...

Need help?

Do you have a question about the HFF01 and is the answer not in the manual?

Questions and answers