Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Blue-White FLEXFLO A3 Series

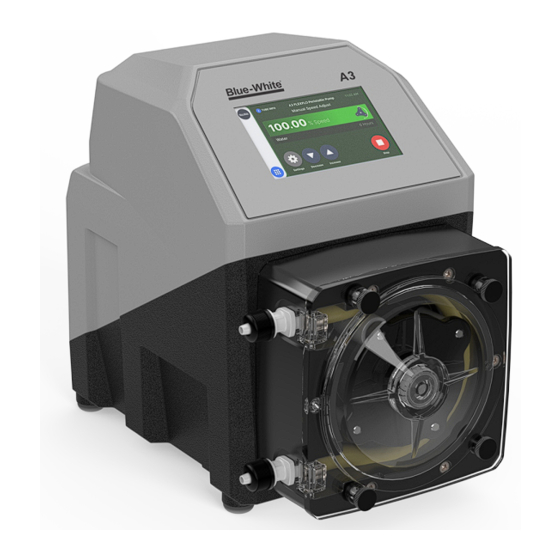

- Page 1 ® Peristaltic Metering Pump Series A3...

-

Page 2: Table Of Contents

Page 2 ® FLEXFLO A3 Introduction 10.0 Industrial Protocols What’s in the box 10.1 Control and Status Mapping for Profibus and EtherNet/IP Engineering Specifications Output vs fluid viscosity 10.2 Control and Status Mapping for Modbus Materials of Construction Wetted Components 10.3 EtherNet/IP Non-Wetted Components... - Page 3 ® Page 3 FLEXFLO A3 READ THE ENTIRE OPERATING MANUAL PRIOR TO INSTALLATION AND USE. +1 (714) 893 - 8529 sales@blue-white.com customerservice@blue-white.com 5300 Business Drive Huntington Beach, CA 92649...

- Page 4 Please Note: Your new pump has been pressure tested at the factory with clean water before shipping. You may notice trace amounts of clean water in the pre-installed tube assembly. This is part of our stringent quality assurance pro- gram at Blue-White Industries. For more information please visit us at: ww.blue-white.com For videos and tutorials please visit as at: https://www.blue-white.com/resources/videos...

-

Page 5: Introduction

® Page 5 Introduction FLEXFLO A3 What’s In The Box The following items are included with every A3 peristaltic metering pump: A3 Peristaltic Pump USB Flash Drive With Instruction Manual Standard Mounting Brackets Spare Tubing Tube Installation Tool Injection Fitting Suction Tubing Discharge Tubing Suction Strainer... - Page 6 Page 6 ® 2.0 Engineering Specifications FLEXFLO A3 125 psig (8.6 bar) Maximum Working Pressure (excluding pump tubes) NOTE: see individual pump tube assembly max. pressure ratings. 185 °F (85 °C) Maximum Fluid Temperature (excluding pump tubes) NOTE: see individual pump tube assembly max. temperature ratings. Ambient Operating Temperature 14 °F to 115 °F (-10 °C to 46 °C) Ambient Storage Temperature...

-

Page 7: 2.0 Engineering Specifications

® Page 7 2.0 Engineering Specifications FLEXFLO A3 OUTPUT VERSUS FLUID VISCOSITY Fluid viscosity and motor RPM both have an effect on fluid output. For your reference the charts below display the various tubes we offer and their output at different viscosities and different motor RPM. -

Page 8: Materials Of Construction

Page 8 ® Materials of Construction FLEXFLO A3 Non-Wetted Components Wetted Components... -

Page 9: Features

® Page 9 Features FLEXFLO A3 Agency Listings This pump is ETL listed to conforms to the following: UL Standard 778 as a motor operated water pump. CSA Standard C22.2 as process control equipment This pump complies to the Machinery Directive 2006/42/EC, BS, EN 60204-1, Low Voltage Directive 2014/35/EU BS EN 61010-1, EMC Directive 2014/30/EU, BS EN 50081-1/BS EN 50082-1. -

Page 10: Installation

Page 10 ® Installation FLEXFLO A3 CAUTION The pump should be serviced by qualified persons only. If equipment is used in a manner not specified in this manual, the protection provided by the equipment may be impaired. CAUTION Risk of chemical overdose. Be certain pump does not overdose chemical during backwash and periods of no flow in circulation system. -

Page 11: Mounting Dimensions

® Page 11 Installation FLEXFLO A3 Pump Dimensions Front View Side View Mounting Hole Spacings (for standard and extended type brackets) 2.5” (6.35 cm) A3 Series 8.25” (20.9 cm) Maximum bolt hole size 0.200” diameter (4 places) Bottom View Extended Brackets Stainless Steel extended brackets allow the pump to be securely mounted to most any surface;... -

Page 12: Input Power Connections

Page 12 ® Installation FLEXFLO A3 Input Power Connections WARNING Risk of electric shock – cord connected models are supplied with a grounding conductor and grounding-type attachment plug. To reduce risk of electric shock, be certain that it is connected only to a properly grounded, grounding-type receptacle. WARNING Electrical connections and grounding (earthing) must conform to local wiring codes. -

Page 13: Wiring Terminals And I/O Schematics

(+) POSITIVE FREQUENCY, AC SOURCE SINE WAVE, TTL, INPUT #2 CMOS (-) NEGATIVE INPUT: (+) POSITIVE RED (+) FVS SYSTEM BARE BLUE-WHITE (FLOW VERIFICATION INPUT #1 (-) NEGATIVE FVS SENSOR SENSOR) FV SENSOR ONLY SIGNAL BLACK (-) INPUT: (+) POSITIVE BLUE-WHITE... -

Page 14: Layout

Page 14 ® Layout FLEXFLO A3 HOME SCREEN LAYOUT Tube Info Pump Name Run Mode System Time Blue-White Icon Pump Status Rotation Direction Run Time / Chemical Name Revolution Counter Start/Stop App Drawer Run Status Settings Tube Calibration APP SCREEN LAYOUT... -

Page 15: M12 Connectors (A3V Only)

® Page 15 Layout FLEXFLO A3 M12 Connector Pump (Rear Upper Panel) Input Connector 2 Output Connector 1 Input Connector 1 Output Connector 2 Output Connector 4 Output Connector 3 IO Connection Pump (Rear Lower Panel) USB-C ON/OFF Ethernet Power Supply Profibus... -

Page 16: M12 Connectors Description (A3V Only)

Page 16 ® Layout FLEXFLO A3 M12 Connector M12 Input/Output Connector M12 Profibus Connector M12 Input Connector 1 Function Specifications Reference Remote Start/Stop No Voltage FVS (+) 15 VDC @ 60 mA Supply Power FVS Sensor FVS (-) DC GND (0 VDC) FVS Ground Input FVS (Signal) Input Signal... - Page 17 ® Page 17 Layout FLEXFLO A3 M12 Output Connector 3 Function Specifications Reference Not Used Not Used .8 Amp Max @ 30VDC N.O. Relay Out, N.O. Contact 1 Amp @ 125 VAC N.C. Relay Out, N.C. Contact Ground Relay Out, COM Contact M12 Output Connector 4 Function Specifications...

-

Page 18: Startup

Page 18 ® Startup FLEXFLO A3 Powering On The Pump The A3 is equipped with a rocker switch to power ON/OFF the pump. Ensure that the power cord is securely plugged into the corresponding power source before powering on the pump. “I”... -

Page 19: Welcome Screen

® Page 19 Startup FLEXFLO A3 Welcome Screen The first time the pump is powered on, or after a factory reset, the pump will boot up to the Welcome Screen. Follow the onscreen instructions to configure your A3 pump. Refer to section 11 of this manual to change any of these options after you have finished the initial configuration. -

Page 20: Input Setup

Page 20 ® Input Setup FLEXFLO A3 Manual Speed Adjust This input mode allows the user to set a specific speed and the pump will run at that speed until stopped. There are up and down arrows on the home screen to incrementally adjust the speed of the motor. -

Page 21: Ma Input

® Page 21 Input Setup FLEXFLO A3 4-20mA Input This input mode allows the user to set a range of mA input signals to a given motor speed, flow rate or rpm. Used to remotely control the pump with an incoming 4-20mA signal. Four points on the slope must be defined: 1) a low mA value 2) an output rate at the low mA value... -

Page 22: Frequency Input

Page 22 ® Input Setup FLEXFLO A3 Frequency Input This input mode is used to remotely control the pump with an incoming high speed frequency signal. Four points on the slope must be defined: 1) a low Hz value 2) an output rate at the low Hz value 3) a high Hz value 4) an output rate at the high Hz value Default settings:... -

Page 23: Pulse Input

® Page 23 Input Setup FLEXFLO A3 Pulse Input This input mode allows the user to trigger the pump to dispense a measured amount of chemical (Amount Per Trigger) over a specific period of time (Pump On Time), after a specific number of pulses (Pulses Count Trigger). -

Page 24: Remote Start/Stop

Page 24 ® Input Setup FLEXFLO A3 Remote Start/Stop This input mode is used to remotely start and stop the pump using a close=stop or open=stop signal. Primary Remote Switch - Used to Start/Stop the pump Secondary Remote Switch - Used in conjunction with a pressure switch or level switch Default settings: Disabled Dry Contact Closure (no voltage required) -

Page 25: Flow Verification Sensor (Fvs)

FVS requires a sensor that is connected to the inlet of the pump to monitor the fluid input. Blue-White offers two flow verification sensors: The S6A &... -

Page 26: Prime The Pump

Page 26 ® Input Setup FLEXFLO A3 Prime This mode allows the user to prime the pump at 100% motor speed for sixty seconds. After the prime is complete the pump will remain in this mode ready to be primed again. To exit: select another input method. -

Page 27: Manual Cycle Adjust

® Page 27 Input Setup FLEXFLO A3 Manual Cycle Adjust This input mode allows the user to run the pump at a set motor speed (Pump Speed) for a set amount of time (Duty Time) after which the pump will pause for a set amount of time (Cycle Time). -

Page 28: Dispensing

Page 28 ® Input Setup FLEXFLO A3 Dispensing This input mode allows the user to dispense a set amount of fluid (in milliliters) at a set rate (Motor % Speed). Default settings: Amount Per Dispense = 1,000 mL Motor % Speed = 50% To Enable Dispensing: Open the App Drawer Select Dispensing... - Page 29 ® Page 29 Output Setup FLEXFLO A3 Relay This feature is used to assign alarms to relay & contact closures One value to be defined: 1) Relay Output To Enable the Relay: Open the App Drawer Select Outputs Select Relay & Contacts Set Desired Values Confirm by pressing Save (refer to chart below)

-

Page 30: Output Setup

Page 30 ® Output Setup FLEXFLO A3 Frequency Output This output sends a configurable high speed frequency signal. This feature can be used to control other pumps (in sync / proportionally), data logging systems, and other external devices for plant automation. Four points on the slope must be defined: 1) a low Hz value 2) an output rate at the low Hz value... - Page 31 ® Page 31 Output Setup FLEXFLO A3 Set 4-20mA Output This output sends a configurable 4-20mA. This feature can be used to control other pumps (in sync / proportionally), data logging systems, and other external devices for plant automation. Four points on the slope must be defined: 1) a low mA value 2) an output rate at the low mA value 3) a high mA value...

-

Page 32: Relay & Contact Output

Page 32 ® Output Setup FLEXFLO A3 Relay & Contacts This feature is used to assign alarms to relay & contact closures Four values to be defined: 1) Contact #1 2) Contact #2 3) Contact #3 4) Relay Output To Enable Relay & Contacts: Open the App Drawer Select Outputs Select Relay &... -

Page 33: Industrial Protocols

® Page 33 10.0 Industrial Protocols FLEXFLO A3 10.1 Control and Status Mapping for Profibus and Ethernet/IP... -

Page 34: Control And Status Mapping For Modbus Tcp

Page 34 ® 10.0 Industrial Protocols FLEXFLO A3 10.2 Control and Status Mapping for Modbus TCP Holding Registers (PLC to Pump) - Pump Control Modbus Data Name Description Address Up to 2 decimal places, with most significant byte representing the whole number and least Motor Percent 0000 - 0001 significant byte... -

Page 35: Ethernet/Ip

® Page 35 10.0 Industrial Protocols FLEXFLO A3 10.3 EtherNet/IP This is used to configure the EtherNet/IP Three values to be defined: 1) IP Address 2) Subnet Mask 3) Gateway 4) Always on To Enable EtherNet/IP: Open the App Drawer Select Industrial Protocols Select EtherNet/IP Pump will go to home screen... -

Page 36: Modbus Tcp

Page 36 ® 10.0 Industrial Protocols FLEXFLO A3 10.4 Modbus TCP/IP This is used to configure the Modbus TCP/IP Three values to be defined: 1) IP Address 2) Subnet Mask 3) Gateway 4) Always on To Enable Modbus TCP: Open the App Drawer Select Industrial Protocols Select Modbus TCP/IP Pump will go to home screen... -

Page 37: Profibus

® Page 37 10.0 Industrial Protocols FLEXFLO A3 10.5 Profibus This is used to configure the Profibus Three values to be defined: 1) IP Address 2) Subnet Mask 3) Gateway 4) Always on To Enable Profibus: Open the App Drawer Select Industrial Protocols Select Profibus Pump will go to home screen... -

Page 38: Tubing

Page 38 ® 11.0 Tubing FLEXFLO A3 11.1 Tube Info This feature will display information regarding the tubing within the pump including: ! Tube type ! Tube installation date ! Tube run time ! Current maximum tube flow rate To View The Tube Info: Tap on the Tube Info text in the Tube info will be displayed Click “reset”... -

Page 39: Tube Calibration

® Page 39 11.0 Tubing FLEXFLO A3 11.2 Tube Calibration This feature allows the user to calibrate the pump’s indicated flow rate to the system To Calibrate Your Tube: On the home screen select the Enter values: Select Start to begin Calibration Icon !Pump Speed (% Speed) !Run Time (seconds) -

Page 40: Settings

Page 40 ® 12.0 Settings FLEXFLO A3 12.1 Pump Name This is to change the name of the pump that is displayed on the home screen. To Input Pump Name: Open the App Drawer Open Settings Open System Select “Pump Name” Enter desired Pump Name Confirm by pressing OK... -

Page 41: Unit Of Volume

® Page 41 12.0 Settings FLEXFLO A3 12.2 Unit of Volume This is to change the units of volume that is displayed. To Input Units of Volume: Open the App Drawer Open Settings Open System Select Unit of Volume Select desired Units of Volume Confirm by pressing OK Milliliters Ounces... -

Page 42: Unit Of Time

Page 42 ® 12.0 Settings FLEXFLO A3 12.3 Unit of Time This will change the Unit of Time that is displayed for the flow rate To Input Unit of Time: Open the App Drawer Open Settings Open System Select Unit of Time Select Desired Time Confirm by pressing OK !Minutes (mL &... -

Page 43: Chemical Name

® Page 43 12.0 Settings FLEXFLO A3 12.4 Chemical Name This is used to change the Chemical Name that is displayed on the home screen. To Input a Chemical Name: Open the App Drawer Open Settings Open System Select “Chemical Name” Enter desired Chemical Name Confirm by pressing OK... -

Page 44: Language

Page 44 ® 12.0 Settings FLEXFLO A3 12.5 Set Language This setting is used to change the system language. To Input a Language: Open the App Drawer Open Settings Open System Select Locale Select Desired Language Confirm by pressing OK !English !Deutch !Español... -

Page 45: Pump Rotation Direction

® Page 45 12.0 Settings FLEXFLO A3 12.6 Pump Rotation Direction This setting is used to change the rotational direction of pump. In most applications, the tube will fail by developing a small leak in the outlet side (pressure side) of the tube assembly. -

Page 46: System Time

Page 46 ® 12.0 Settings FLEXFLO A3 12.7 System Time This setting is used to change the local time that is displayed. To Input The System Time: Select the Time in the upper Select Desired Hour Select Desired Minute right hand corner Select AM or PM Confirm by pressing OK... -

Page 47: Passcode

Default settings: Pump will lockout after 30 seconds To Input a Passcode: Open the App Drawer Open Settings Open Passcode Enable Passcode Select User Passcode and Confirm by pressing Save create new a six digit code. Lost password? Email customerservice@blue-white.com to have your password reset... -

Page 48: Factory Reset

Factory Reset This setting is used to factory reset the pump. This will erase all of the configurations and restore the pump to it’s original configuration when it left Blue-White factory. To Conduct A Factory Reset: Open the App Drawer... -

Page 49: System

® Page 49 13.0 System FLEXFLO A3 13.1 SYSTEM INFORMATION This is to view the System Information Information to be displayed: !Pump Name !Model !Chemical Name !I/O Port Firmware Version !Firmware Version !Motor Firmware Version !System Build !Industrial Protocol Firmware Version !Manufactured Data &... -

Page 50: Firmware Update

Firmware Update ® To update the firmware for your pump you first need to download and install Blue-Central which is available at: https://www.blue-white.com/resources/ To Update The System Firmware: Plug pump into a computer via Select firmware tab and select The firmware upgrade box will ®... -

Page 51: Pump Maintenance

® Page 51 14.0 Pump Maintenance FLEXFLO A3 Always wear protective clothing, face shield, safety glasses and gloves when working on CAUTION or near your metering pump. Additional precautions should be taken depending on solution being pumped. Refer to MSDS precautions from your solution supplier. 14.1 Routine Inspection and Maintenance The pump requires very little maintenance. - Page 52 Page 52 ® 14.0 Pump Maintenance FLEXFLO A3 14.3 Removing Pump Head and Tubing The pump requires very little maintenance. However, the pump and all accessories should be checked weekly. This is especially important when pumping aggressive chemicals. Remove the Pump Head Cover by unscrewing the four Thumb Screws. Pull out the Pump Head Cover.

-

Page 53: Removing Pump Head And Tubing

® Page 53 14.0 Pump Maintenance FLEXFLO A3 14.5 Tube Replacement CAUTION Prior to service, pump clean water through the pump and suction / discharge line to remove chemical. CAUTION Always wear protective clothing, face shield, safety glasses and gloves when working on or near your metering pump. - Page 54 Page 54 ® 14.0 Pump Maintenance FLEXFLO A3 14.6 This pump is equipped with a Tube Failure Detecting System which is designed to stop the pump and provide an output alarm (see Output menu) in the event pump the tube should rupture and chemical enters the pump head.

-

Page 55: Tfd (Tube Failure Detection)

® Page 55 FLEXFLO A3 PAGE INTENTIONALLY LEFT BLANK... -

Page 56: Tube Replacement

Page 56 ® 15.0 Replacement Parts List FLEXFLO A3 15.1 Tube Replacement Spacer 90011-217 Complete Roller Assembly GE / GG / GH / GK / G2G A3-SGE-R ND / NF A3-SND-R TH / NKL A3-STH-R NGG / NH / NJ / NK / NHL /NEE / TK A3-SNGG-R Tubing (Reference Tubing Matrix) Pump Head Cover... -

Page 57: Tube Selection Matrix

® Page 57 15.0 Replacement Parts List FLEXFLO A3 15.2 Tube Replacement Tubing Inlet/Outlet Connection Size, Connection Type, Connection Material 3/8” OD x 1/4” ID Tube Compression Fitting, Natural PVDF (Kynar) 1/2” Male NPT Fitting, Natural PVDF (Kynar) 1/2” Hose Barb, Natural PVDF (Kynar), available for ND, NEE, NGG, and G2G only 1/2”... -

Page 58: Accessories

Page 58 ® 16.0 Accessories FLEXFLO A3 16.0 ACCESSORIES ® The following accessories are available for the A3 FLEXFLO Peristaltic Metering Pump. Please visit Blue- white.com for more information. All accessories are sold separately. KIT-M12 KIT-M12 WIRING INSTRUCTIONS DIAGRAM PIN # WIRE COLOR Kit contains: Two M12 PIN 1... - Page 59 ® Page 59 16.0 Accessories FLEXFLO A3 KIT-QBV Kit contains: One Quick Connect Inlet with .50” hose barb connection (assembled with FKM O-rings), One Quick Connect Inlet with .50” hose barb connection (assem- bled with FKM O-rings) and two #5 Clamps. *KIT-QBE for EP O-rings KIT-MVM Kit contains: One Tube Install Tool, One Foot Strainer, One injection valve...

- Page 60 Page 60 ® FLEXFLO A3 PAGE INTENTIONALLY LEFT BLANK...

-

Page 61: Warranty

Blue-White does not have the same degree of familiarity with the application that the customer/end user has. While Blue-White will honor all of its product warranties according to their terms and conditions, Blue- White shall only be obligated to repair or replace its defective parts or products in accordance with the associated product warranties. -

Page 62: Appendix A: Acronyms

Page 62 ® FLEXFLO A3 APPENDIX A: ACRONYMS Return Material Authorization °C Celsius Revolutions per minute °F Fahrenheit Steam-in-place Alternating current Solid state Unit of pressure TFD+ Enhanced Tube Failure Detection Clean-in-place TFE/P Tetrafluoroethylene propylene Centimeters Underwriters Laboratories Cash on Delivery United States Depth Volt... -

Page 63: Appendix B: Model Number Matrix

® Page 63 FLEXFLO A3 ® FLEXFLO Model Number ® FLEXFLO A3 Peristaltic Metering Pump Power Cord (operating voltage requirement 96VAC to 264VAC) 115V / 60HZ, power cord NEMA 5/15 plug (US) 230V / 60HZ, power cord NEMA 6/15 plug (US) 220V / 50HZ, power cord CEE 7/VII plug (EU) 240V / 50HZ, power cord AS 3112 plug (AU/New Zealand) 230V / 50HZ, power cord BS 1363 plug (UK) - Page 64 The WEEE marking applies only to countries within the European Union (EU) and Norway. Appliances are labeled in accordance with European Directive 2002/96/EC. Contact your local waste recovery agency for a Designated Collection Facility in your area. www.blue-white.com sales@blue-white.com customerservice@blue-white.com P.N.

Need help?

Do you have a question about the FLEXFLO A3 Series and is the answer not in the manual?

Questions and answers