Table of Contents

Advertisement

Quick Links

Thank you for purchasing a Shimaden PAC18A Series Single-Phase Thyristor Power Regulator.

After making sure the product fits the desired description, you should carefully read the instructions and get a good understanding of the contents before

attempting to operate the equipment.

Request

The instruction manual should be kept in a handy place where the end user can refer to it when necessary.

Preface

The instruction manual has been prepared for those involved in setup, wiring, operation or routine maintenance of PAC18A Series equipment.

The manual provides information concerning mounting, wiring and precautions when working with PAC18A Series equipment.

You should therefore keep it in a handy place to refer to when operating and handling the equipment.

Be sure to observe all precautions and adhere to the procedures provided in the manual.

Safety rules, precautions concerning equipment damage, additional instructions and notes are written based on the following headings.

Matters that could result in injury or death if instructions are not followed.

WARNING

Matters that could result in equipment damage if instructions are not followed.

CAUTION

additional instructions and notes

Note

PAC18A Series instrument is designed to control heater power, etc., used by industrial equipment. It should not be used for nuclear power generation, traffic

control, communications or medical equipment. You should either take appropriate safety measures or avoid using for control that could have a serious

effect on human life. The manufacturer shall not be liable for an accident that results if used without taking appropriate safety measures.

1. The power regulator should be used so the terminal elements in the control box, etc., are not touched by human beings.

2. The power regulator should not be used as a switch.

Even if output is zero, power is present in the capacitors and resistors of the output circuit, and could result in accident involving human life or serious

bodily injury due to electrical shock.

3. Radiation fins and chassis become extremely hot. Never touch the radiation fins or chassis. Doing so could result in burn injury.

4. Do not supply power when wiring. Doing so could result in electrical shock.

5. Do not touch terminal elements or other charged parts while conducting electricity. Also, do not introduce foreign objects or matter into the equipment.

If a foreign object or matter accidentally gets inside, be sure to turn off the power and make sure all is safe before introducing tools or your hands.

If there is danger of damage to any peripheral device or equipment due to failure of the power regulator, you should take appropriate safety measures such

as mounting a rapid fuse or overcurrent circuit breaker.

1. Concerning the

alert symbol on the power regulator's plate, a

The symbol is provided to prompt you to employ special care not to touch the device because doing so could result in electrical shock if parts that

conduct power are touched when power is present, or could result in burn injury if touched when hot, etc.

2. Provide a switch or breaker as a means of cutting off power for external power circuit connected to the power terminal of the device.

Mount a switch or breaker near the controller where the operator can get to it easily and label it as an electrical breaker for the device.

3. Be sure to securely fasten conductor cable connections before using.

Failure to do so could result in burning from overheating due to contact resistance.

4. Be sure power supply voltage and frequency do not exceed the rating.

5. Do not apply voltage/current other than rated input to the input terminal.

Doing so could shorten the life of the product or result in equipment failure.

6. Voltage/current of load connected to the output terminal should not exceed the rating.

Using voltage/current that exceeds the rating could shorten the life of the device by raising the temperature, and could result in equipment failure.

7. Be sure to mount the terminal cover that comes with the device after wiring.

8. The user should absolutely not modify or use the device in any way other than it was intended to be used.

9. To ensure safety and maintain the functions of this device, do not disassemble this device. If this device must be disassembled for replacement or repair,

contact your dealer.

10. Be sure to observe the notes and precautions provided in the manual to use the device safely and maintain its reliability.

Note: Shimaden shall bear no responsibility, monetarily or otherwise, for accident or damages caused by failure to observe warnings, notes and precautions

contained in the instruction manual.

PAC18A Series

Single-Phase Thyristor Power Regulator

Instruction Manual

WARNING

WARNING

CAUTION

CAUTION

alert symbol is printed on the label applied to the outer surface of the device.

- 1 -

MPA018A-E01-C

Jun. 2022

Advertisement

Table of Contents

Summary of Contents for Shimaden PAC18A Series

- Page 1 WARNING PAC18A Series instrument is designed to control heater power, etc., used by industrial equipment. It should not be used for nuclear power generation, traffic control, communications or medical equipment. You should either take appropriate safety measures or avoid using for control that could have a serious effect on human life.

-

Page 2: Table Of Contents

Contents 1. Introduction ......................... 3 12. Manual operation ....................14 1-1. Preliminary check ....................3 12-1. Manual operation.....................14 1-1-1. Specifications code check................ 3 13. Heater break alarm function ...................15 1-1-2. Accessories check ..................3 13-1. Heater break alarm function (current detection / alarm output function 1-2. -

Page 3: Introduction

Instruction manual: 1 CAUTION In the event you want to inquire about a product defect, missing accessory or other matter, please contact your nearest Shimaden agent. 1-2. Precautions when using Do not operate the front panel keys with hard or pointed objects. Always press the keys lightly with the tips of your fingers. -

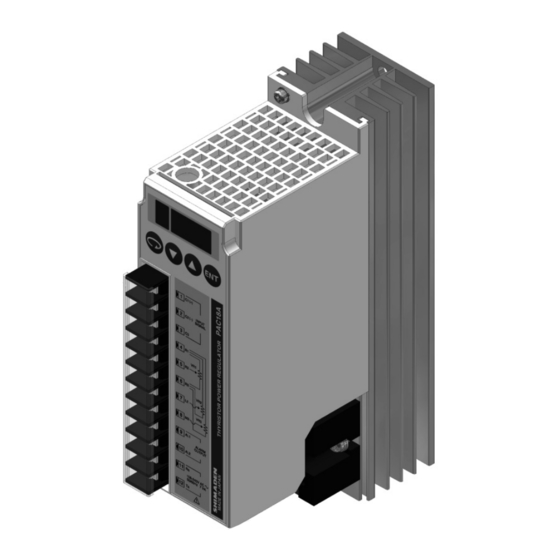

Page 4: Panel Part Names And Control Terminals

2. Panel part names and control terminals 2-1. Name and function of display and key operation sections C1(+) Voltage/ Control input terminal current C2(-) Contact input / external Contact control input terminal (Di) Display Status Parameter display display VR1, VR2 •... -

Page 5: External Dimensions / Terminal Dimensions / Weight

3. External dimensions / terminal dimensions / weight 20/30A Weight: Approx. 0.8 kg 5.5 notch 2-M4 12.5 Unit: mm 45/60A Weight: Approx. 1.8 kg 5.5 notch 2-M5 Unit: mm 80/100A Weight: Approx. 3.0 kg 2- 5.5 5.5 notch 2-M8 Unit: mm - 5 -... -

Page 6: Setup Location

4. Setup location The device is designed to be used under the following conditions. Observe the following environmental conditions when using: 1) Indoor use 2) Elevation: Max. 2000 m (see ‘15-2. Ambient temperature, elevation and load current.’) 3) Temperature range: -10 − 55°C (see ‘15-2. Ambient temperature, elevation and load current.’) 4) Humidity range: Max. -

Page 7: Terminal Arrangement And Wiring Example

6. Terminal arrangement and wiring example Control input terminal Control input External adjuster Control power 12 Ta supply input Main power supply / load 20/30A Terminal [80/100A Terminal] [45/60A Terminal] Screw diameter: R Power supply Screw diameter: Screw diameter: terminal 2-M4 2-M5 2-M8... -

Page 8: Control Input Signal Wiring

8. Control input signal wiring M3 screws are used for control signal terminals. Use the proper terminal and securely fasten the screws. Use wiring that conforms to crimping terminals. Control signal from the controller (4 – 20 mA, 1 – 5 V, 0 – 10 V, contact, etc.) enters the control input signal terminals (C1, C2, C3). Be careful of the polarity and make sure noise from strong electric circuits does not get into the wiring. -

Page 9: Alarm Function

10. Alarm function The alarm function consists of power failure, overcurrent, hardware error, heater break and input error. If an equipment error occurs, an alarm is output externally and is displayed on the front display (status display). In addition to input error, you can select key sequence ‘1-2 – 1-5’ for each alarm. When an error occurs and the key sequence ‘0-0. -

Page 10: Hardware Error (Current Detection / Alarm Output Function [Optional])

CAUTION Avoid conducting electricity with no load. If a hardware error alarm occurs even if a load is connected, repair is required. Contact your nearest Shimaden agent. 10-4. Heater break (current detection / alarm output function [optional] Function that detects load heater break. A heater break alarm occurs when the current drops below the preset heater break alarm current value. -

Page 11: Various Adjustment Functions

11. Various adjustment functions 11-1. Ramp higher limit (high power) Output is set to ramp higher limit (high power) by key sequence ‘1-7. Ramp higher limit selection’ or key input allocation is set by key sequence ‘1-8. Ramp higher limit setting’ (range: 0.1 - 100%). Because with ramp higher limit, maximum output is adjusted by control input signal being 100%, output ramp of the PAC18A is adjusted according to the control input signal. -

Page 12: Input Scaling

11-3. Input scaling You can set key sequence ‘1-13. Control input scale lower limit setting’ and ‘1-14. Control input scale higher limit setting.’ Setting below the lower limit value makes output 0% and setting above the higher limit value makes output 100%. Example: Input/output characteristics Example: Input/output characteristics according to scale lower limit setting... -

Page 13: Current Limit: Phase Control Only (Current Detection / Alarm Output Function [Optional])

11-5. Current limit: Phase control only (current detection / alarm output function [optional]) Function for limiting output current to within 0 – 120% of the device’s rated current. Limits current and protects the load if using loads with large inrush current such as pure metal heaters or lamp heaters. -

Page 14: Manual Operation

12. Manual operation The device is equipped with two modes of automatic operation by control input and manual operation (hereinafter referred to as “manual operation”): one by manual setting device and the other by key operation. If performing manual operation or deciding output characteristics by test operation, you can control output manually. Operation is set to automatic operation when shipped from the factory. -

Page 15: Heater Break Alarm Function

13. Heater break alarm function 13-1. Heater break alarm function (current detection / alarm output function [optional]) The heater break alarm is a function whereby an alarm is given to let you know when the heater is broken. The function is effective for preventing product defects and negative impact of insufficient power. -

Page 16: Key Sequence

14. Key sequence 14-1. Screen sequence Standard screens are indicated by and optional screens are indicated by Optional screens may not be displayed depending on the product specifications. press for 5 seconds or more. press for 2 seconds or more. press for 2 seconds or more. - Page 17 press for 2 seconds or more. press for 2 seconds or more. - 17 -...

-

Page 18: Monitor Screen Group

Standard screens are indicated by and optional screens are 0-1. Load current (current detection [optional]) Unit: A indicated by Displays load current value. Displayed when optional current detection Optional screens may not be displayed depending on the product is selected. specifications. -

Page 19: User Parameter Screen Group

1-6. Ramp lower limit setting Unit: % 14-3. User parameter screen group Sets allocation of output gradient lower limit (base power). The user can modify the control operation parameters. : Key input allocation You can obtain safer, more reliable control characteristics by various type of alarm output settings and settings such as overcurrent limit. -

Page 20: Initial Setting Screen Group

1-9. Variation limit slow-up Unit: Seconds 14-4. Initial setting screen group Current may change precipitously if amount of output varies dramatically Group of screens for setting operation conditions for the device. Must be while the power is on. Slow-up is provided to play the role of suppressing set in advance. -

Page 21: Manual Output Screen Group

2-4. Parameter initialize 14-5. Manual output screen group Resets initial settings screen group and user parameter group to default With manual operation, the desired operation amount is controlled manually. settings. With the heater break alarm function, there is an operation to set load When is displayed, executed by (device reboots after reset is... -

Page 22: Characteristics

15. Characteristics 15-1. Current capacity and heat value Voltage drop to thyristor device (0.9 – 1.3 V) is produced by current flowing to the thyristor. Voltage between thyristor device and accumulation of current (W) turn into Joule heat, resulting in rise in temperature of the thyristor device. Take heat dissipation and ventilation into account. Internal heat value (Conversion formula for calorific value : 860kcal = 1000W) Current capacity 100A... -

Page 23: Control Types And 5 Types Of Output Characteristics

15-4. Control types and 5 types of output characteristics This device enables you to switch your control type selection (2 types) according to load characteristics to either phase control by key operation (phase angle proportional output, voltage proportional output, voltage square [electric power] proportional output, current feedback [4 modes] or cycle calculation zero voltage switching control function [1 mode]). -

Page 24: Noise Countermeasures

The frequency of noise produced by the thyristor is distributed in a place below several megahertz, and the noise dampening effect of common commercially available noise filters is insufficient. Using noise filters specified by Shimaden can dampen this noise. Noise filter connection diagram... -

Page 25: Precautions When Using Transformer Load

17. Precautions when using transformer load Transformer usage objective 1) To match voltage when heater voltage differs from power supply voltage. 2) When it is necessary to insulate the heater circuit from the power supply. 3) To raise ground voltage resistance using a compound transformer when ground insulation deteriorates like vacuum equipment. 17-1. -

Page 26: Fuse / Heater Break Alarm Function

Rapid fuse and 45 / 60A QSF01G fuse holder set 80 / 100A QSF01H For information on rapid fuses, contact your nearest Shimaden agent. Connection diagram CAUTION Cut off the device’s power supply before replacing the rapid fuse. - 26 -... -

Page 27: Accessories (Sold Separately)

20. Accessories (sold separately) 20-1. External adjuster • Type : QSV003 • Specifications : Characteristics/resistance value: B 10kΩ Lead: Vinyl lead, 1 m, M3 crimp terminal Scale plate / knob: 1 each provided • External dimensions and panel cutout (unit: mm) Panel cutout M9 P0.75 t1.0... -

Page 28: Fuse Holder

20-3. Fuse holder 20/30A, 45/60A (Model: QSH002) • External dimensions (unit: mm) Insulation board (x 2) 2- 3.5 2-M6 80/100A (Model: QSH003) • External dimensions (unit: mm) - 28 -... - Page 29 21. Troubleshooting If a problem occurs while using the equipment, check it by using the following chart and contact your nearest Shimaden agent. Problem Place to inspect Measures to take No output. 1) Panel LED does not light. Check power. If power is not supplied, check out the power supply side.

-

Page 30: Common Specifications

• Data communication function Parameter setting function (optional) Reads/writes various types of parameters • Parameter setting function : Communication protocol: Shimaden protocol *No. of connections: 1 unit *Connection: Mini jack-plug *Communication speed: 9600 bps *No. of bits: 7 *Parity: Even *Stop bits: 1 (fixed) Writes various setting parameters;... - Page 31 □ Separately sold goods • Data communication adapter (Model: S5009 PAC data communications adapter) Connects with computer by USB cable; enables settings, setting value display, control input/output values display, and trend graph display • External adjuster : (Model: QSV003) B characteristics, 10kΩ, 3 lines •...

- Page 32 The contents of this manual are subject to change without notice. Temperature and Humidity Control Specialists Head Office: 2-30-10 Kitamachi, Nerima-ku, Tokyo 179-0081 Japan Phone: +81-3-3931-7891 Fax: +81-3-3931-3089 E-MAIL: exp-dept@shimaden.co.jp URL: http://www.shimaden.co.jp - 32 -...

Need help?

Do you have a question about the PAC18A Series and is the answer not in the manual?

Questions and answers