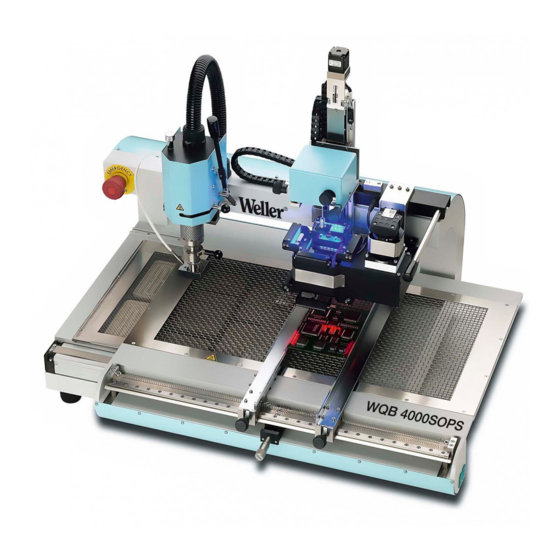

Weller WQB 4000SOPS Operating Instructions Manual

Bga / qfp rework system

Hide thumbs

Also See for WQB 4000SOPS:

- Operating instructions manual (66 pages) ,

- Quick starter manual (9 pages) ,

- Operating instructions manual (64 pages)

Summary of Contents for Weller WQB 4000SOPS

- Page 1 BGA / QFP Rework System WQB 4000SOPS Operating Instructions GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 2 1 Table of contents GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 3 7.4.1 Soldering profile bar graph ..................33 7.4.2 Input boxes for process parameters ................33 7.4.3 Display LEDs for process step ...................34 7.4.4 Saving and loading parameter blocks / profiles ............35 7.4.5 Soldering / desoldering functions - runtime:..............35 7.4.6 Reinitialisation ......................36 7.4.7 Language selection ....................36 7.4.8 Celsius / Fahrenheit ....................36 7.4.9 Process documentation ....................36 7.6.1 Gradient ........................38...

- Page 4 Have your soldering tool repaired in an electrical service centre......42 8.1.23 Do not work on electrically live parts..............42 8.1.24 Do not connect combustible gases.................42 ® 8.1.25 Use with other WELLER devices................42 8.1.26 Observe the safety regulations applicable to your work area........42 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 5 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 6 2 Identification Product brand and type designation Product version GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 7 Declaration of Conformity GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 8 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

-

Page 9: Product Description

3 Product description General functions, area of application, intended use GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com... - Page 10 Basic device Soldering head GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 11 Insertion head Camera and split optical unit Bottom heater PCB holder GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 12 Dimensions and weight Specifications on current, gas and compressed air supply 3.10 PC system requirements WIN 2000 SP4 WIN XP SP2, WIN Vista 32-Bit Win 7 32-Bit & 64-Bit GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 13 3.11 Noise Emission 3.12 Ambient conditions 3.13 Safety information GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 14 4 Definitions 5 Transport and storage GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 15 Unpacking Safe disposal of the packaging material GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 16 Preparatory task for installation Scope of supply 4000SOPS Control software GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 17 Assembly Compress Nitrogen (N GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 18 5.5.1.1 Assembly 10 x zoom lens 5.5.1.2 Storing and protecting during interruption of normal usage Repacking to prevent damage during transport GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 19 Location of Operating Instructions 6 Operating Instructions Commissioning / restarting This procedure is necessary every time the device is restarted! GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 20 Software Installation Registration with Administrator rights is mandatory! The device must not be disconnected To avoid installation conflicts, older software versions should be deinstalled. Especially the SILABS USB driver should be removed GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 21 STEP 1 Installation of the SILABS USB drivers SILABS GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 22 STEP 2 Installation of the uEye Camera driver GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 23 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 24 STEP 3 Installation of DirectX 9 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 25 STEP 4 Installation of the Weller WQB4000 Control software GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 26 Change of the settings of the CPU idle states If you are experiencing performance issues with uEye cameras, please try to change the settings of the CPU idle states. Start the “IDS Camera Manager”. You find this Program in: Start menu/ids/IDS Camera Manager Open the “Additional functions”...

- Page 27 Installation of the firmware updater The installation of the firmware updater is not necessary for correct operation of the device; installation of this software is therefore only recommended if required. Uninstall Back up your parameter blocks or measurement data files before you uninstall the program from your system.

- Page 28 6.10 Program Start 6.11 Checking the split optical unit Placement Important. Following this, the vacuum pick-up alignment must not be changed! GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 29 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

-

Page 30: Operation

7 Operation Layout and function of operator interface Standard buttons: GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com... - Page 31 Placement 7.3.1.1 Control unit LED Illumination 7.3.1.2 Camera screen and zoom GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 32 7.3.1.3 Camera settings 7.3.1.4 Placement / Z-axis drive 7.3.1.4.1.1 Automatic Mode 7.3.1.4.2 Standard mode GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 33 Soldering 7.4.1 Soldering profile bar graph 7.4.2 Input boxes for process parameters GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 34 7.4.3 Display LEDs for process step GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 35 7.4.4 Saving and loading parameter blocks / profiles By loading a parameter block and saving under another name, changed / separate parameter blocks can be created. 7.4.5 Soldering / desoldering functions - runtime: GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 36 7.4.6 Reinitialisation 7.4.7 Language selection 7.4.8 Celsius / Fahrenheit 7.4.9 Process documentation GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 37 Print Function GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 38 Special functions 7.6.1 Gradient During application of Gradient mode, operation is always carried out with nozzle pre- heating and the nozzle is already lowered above the component prior to process start. Nozzle pre-heating (Standby Nozzle) is therefore always activated. 7.6.2 Teach-in GlobalTestSupply www.

- Page 39 7.6.2.1 Automatic Teach-in 7.6.2.2 Manual Teach-In GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 40 Other functions 7.7.1 Operating the soldering head and insertion head 7.7.2 Component placement GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

-

Page 41: Maintenance And Cleaning

8 Maintenance and cleaning Safety measures 8.1.1 The mains cable must only be inserted in the approved power sockets or adapters. 8.1.2 Keep your work area tidy and in proper order. 8.1.3 Take surrounding factors into consideration. 8.1.4 Protect yourself against electric shocks. 8.1.5 Keep children away from work area. - Page 42 8.1.22 Have your soldering tool repaired in an electrical service centre. 8.1.23 Do not work on electrically live parts. 8.1.24 Do not connect combustible gases. ® 8.1.25 Use with other WELLER devices. 8.1.26 Observe the safety regulations applicable to your work area. GlobalTestSupply www.

- Page 43 Maintenance and cleaning by users GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 44 Cleaning agents Troubleshooting, fault status diagnosis and repair GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 45 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 46 Possible faults Fault Cause Remedy GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 47 9 Optional modules and extras, specifications 10 Maintenance and cleaning 10.1 Maintenance cycles for safe operation 10.2 Customer Service address Weller Tools GmbH 10.3 Repacking GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 48 10.4 Calibration GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 49 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 50 Camera settings GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 51 11 List of spare parts and consumables 11.1 Electrical system 11.2 Pneumatics 11.3 Optical system GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 52 11.4 Hot air nozzles Article No. Nozzle housing, inside Nozzle housing, outside GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 53 12 De-commissioning the product 13 Warranty GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 54 14 Figures GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 55 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 56 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 57 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 58 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 59 15 Circuit diagrams GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 60 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 61 17 Index GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 62 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 63 Parameter block GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

- Page 64 WIN 2000 SP4 WIN Vista 32-Bit WIN XP SP2 GlobalTestSupply www. .com Find Quality Products Online at: sales@GlobalTestSupply.com...

Need help?

Do you have a question about the WQB 4000SOPS and is the answer not in the manual?

Questions and answers