Subscribe to Our Youtube Channel

Summary of Contents for GSi PNEG-1828

- Page 1 42' Dura-Lok Plank and Support Manual Owner’s Manual PNEG-1828 Version: 1.0 Date: 10-31-11 PNEG-1828...

- Page 2 All information, illustrations, photos, and specifications in this manual are based on the latest information available at the time of publication. The right is reserved to make changes at any time without notice. PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 3: Table Of Contents

42'-26" Monorail Spacing Layout ......................39 42' Split Floor Bundle Layout ......................40 42' Split Floor Plank Layout ......................... 41 42' Non-Split Floor Bundle Layout ....................... 43 42' Non-Split Floor Plank Layout ......................44 Chapter 7 Warranty ..............................47 PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 4: Chapter 1 Introduction

Should the equipment be abused, or modified to change its performance beyond the factory specifications, the warranty will become void and field improvements may be denied. PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 5: Chapter 2 Safety

CAUTION, used with the safety alert symbol, indicates a CAUTION hazardous situation which, if not avoided, could result in minor or moderate injury. NOTICE is used to address practices not related to NOTICE personal injury. PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 6: General Safety Statement

Personnel operating or working around equipment should read this manual. This manual must be delivered with equipment to its owner. Failure to read this manual and its safety instructions is a misuse of the equipment. PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 7: Safety Instructions

Keep hands, feet, and clothing away from rotating parts. Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any Maintain Equipment built-up grease, oil, and debris. and Work Area PNEG-1828 42' Dura-Lok Plank and Support Manual... - Page 8 A respirator may be needed to prevent breathing potentially toxic fumes and dust. Wear a hard hat to help protect your head. Hard Hat Wear appropriate fall protection equipment when working at elevations greater than six feet (6'). Fall Protection PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 9: Safety Sign-Off Sheet

All unqualified persons are to stay out of the work area at all times. It is strongly recommended that another qualified person who knows the shut down procedure be in the area in the event of an emergency. Date Employee Name Supervisor Name PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 10: Proper Storage Of Grain Bin/Silo Materials Prior To Construction

Sidewall bundles can also be stored on edge but must be secured so that they do not fall over and cause injury. If “white rust” or “wet storage stain” occurs, contact the manufacturer immediately about ways to minimize the adverse effect upon the galvanized coating. PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 11: Chapter 3 Decals

Use positive aeration system. Make sure all roof vents are open and unobstructed. Start roof fans when supply fans are started. Do not operate when conditions exist that may cause roof vent icing. DC-969 PNEG-1828 42' Dura-Lok Plank and Support Manual... - Page 12 3. Station another person outside the bin. 4. Avoid the center of the bin. 5. Wear proper breathing equipment or respirator. Failure to heed these warnings will result in serious injury or death. DC-GBC-1A PNEG-1828 42' Dura-Lok Plank and Support Manual...

- Page 13 4. See manufacturers instructions for proper use of factory supplied sidedraw (wall) discharge systems. Failure to heed these warnings could result in serious injury, death, structural damage or collapse of tank. DC-GBC-2A PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 14: Chapter 4 Monorail Installation

4. Monorail Installation Fan Placement Diagram For uniform air flow, place the fans in relation to the unloading tube as shown in Figure 4A. Floor planks should be perpendicular to the unloading tube. Figure 4A PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 15: Tie Bar Detail

3. Tie bars should overlap and connect each rail to the next rail. Tie bars should be located along each side of a rail splice and around the perimeter of the bin, no more than 6" from the end of the rail. (See Figure 4C.) Figure 4C Tie Bar Dimension Detail PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 16: Tie Strap Detail

2. Tie straps are to be located in the same places as a tie bar would be used. NOTE: Some tie straps will be used to support center well and intermediate well assembly. (See Figure 5F on Page 24 and Figure 5G on Page 25.) Figure 4D Strap Detail PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 17: Assembling Legs To Rail

3. The leg can then be pushed down into the rail until the tabs lock it into place. (See Figure 4E.) See chart on Page Spacing depends on eave height. Figure 4E Assembly Leg Rail PNEG-1828 42' Dura-Lok Plank and Support Manual... - Page 18 See Page 37 See Page 34 See Page 34 See Page 34 See Page 33 See Page 33 See Page 30 See Page 30 See Page 29 See Page 29 See Page 26 PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 19: Outer Perimeter Rail Details

Outer Perimeter Rail Details 3' Sections of monorail should be placed around the perimeter of the bin. Monorail legs for perimeter rails should be spaced 16" apart on center. (See Figure 4F.) Figure 4F PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 20: Splicing Rails

3. Fasten the rail to the leg with two (2) #10 self-drilling screws (splice locations only). (See Figure 4G.) Figure 4G PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 21: Chapter 5 Flooring - Planks

Use eight (8) screws at the end of the splice for each plank, four (4) on each side. (See Figure 5A below (See Figure 5B on Page 22.) Figure 5A Floor Splice Layout PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 22: Flashing Installation

Finger tighten the nuts. While holding flashing flat, fasten the flashing to the floor with sheet metal screws. Now tighten flashing nuts. PNEG-1828 42' Dura-Lok Plank and Support Manual... - Page 23 5. Flooring - Planks Flashing Installation (Continued) Figure 5D 2.66" Corrugation Figure 5E 4.00" Corrugation PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 24: Center Well Assembly Details

5. Flooring - Planks Center Well Assembly Details Figure 5F 42' Diameter Bin Center Well Position PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 25: Intermediate Well Assembly Details

5. Flooring - Planks Intermediate Well Assembly Details Figure 5G 42' Diameter Bin Intermediate Well Position PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 26: Chapter 6 Layouts

6. Layouts 42'-15" Rail Spacing Layout Figure 6A 42' Diameter 15" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 27: 42'-15" Monorail Spacing Layout

FL-404-15 15" Monorail Tie Bar 571.5 A-11.42MONO S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 383.54 A-3MONO FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" Figure 6B 42' Diameter Bin with 15" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 28: 42'-16" Monorail Spacing Layout

16" Monorail Tie Bar A-12.9MONO 358.14 358.14 FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" A-11.8MONO 586.74 S-280 #10-16 x 5/8" Zinc Self-Drilling Screw A-3MONO 393.7 Figure 6C 42' Diameter Bin with 16" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 29: 42'-16" Rail Spacing Layout

6. Layouts 42'-16" Rail Spacing Layout Figure 6D 42' Diameter 16" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 30: 42'-17" Rail Spacing Layout

6. Layouts 42'-17" Rail Spacing Layout Figure 6E 42' Diameter 17" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 31: 42'-17" Monorail Spacing Layout

17" Monorail Tie Bar A-12.3MONO 619.76 FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" A-9.25MONO 434.34 S-280 #10-16 x 5/8" Zinc Self-Drilling Screw A-3MONO 281.94 Figure 6F 42' Diameter Bin with 17" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 32: 42'-18" Monorail Spacing Layout

18" Monorail Tie Bar A-10.92MONO 332.74 332.74 FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" A-10.5MONO 487.68 S-280 #10-16 x 5/8" Zinc Self-Drilling Screw A-3MONO 320.04 Figure 6G 42' Diameter Bin with 18" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 33: 42'-18" Rail Spacing Layout

6. Layouts 42'-18" Rail Spacing Layout Figure 6H 42' Diameter 18" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 34: 42'-20" Rail Spacing Layout

6. Layouts 42'-20" Rail Spacing Layout Figure 6I 42' Diameter 20" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 35: 42'-20" Monorail Spacing Layout

20" Monorail Tie Bar 393.7 393.7 A-14MONO FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 640.08 A-12.92MONO S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 426.72 A-3MONO Figure 6J 42' Diameter Bin with 20" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 36: 42'-22" Monorail Spacing Layout

22" Monorail Tie Bar A-14.5MONO 401.32 401.32 FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" A-13.17MONO 647.7 S-280 #10-16 x 5/8" Zinc Self-Drilling Screw A-3MONO 441.96 Figure 6K 42' Diameter Bin with 22" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 37: 42'-22" Rail Spacing Layout

6. Layouts 42'-22" Rail Spacing Layout Figure 6L 42' Diameter 22" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

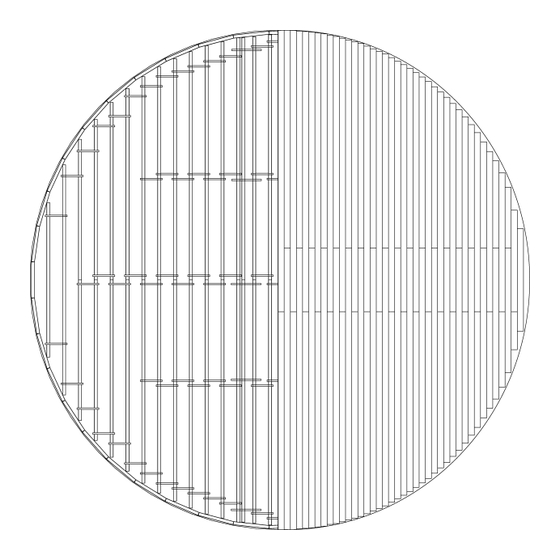

Page 38: 42'-26" Rail Spacing Layout

6. Layouts 42'-26" Rail Spacing Layout Figure 6M 42' Diameter 26" Rail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 39: 42'-26" Monorail Spacing Layout

26" Monorail Tie Bar A-12.33MONO 375.92 375.92 FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" A-11.58MONO 528.32 S-280 #10-16 x 5/8" Zinc Self-Drilling Screw A-3MONO 353.06 Figure 6N 42' Diameter Bin with 26" Monorail Spacing PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 40: 42' Split Floor Bundle Layout

7" plank to the next. The bundle is arranged so that the “A” plank is installed together with the “B” plank. 20'-4" Critical starting dimension for first plank Bundle A Bundle B Figure 6O 42' Split Floor Bundle Layout PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 41: 42' Split Floor Plank Layout

6. Layouts 42' Split Floor Plank Layout Figure 6P 42' Split Floor Plank Layout PNEG-1828 42' Dura-Lok Plank and Support Manual... - Page 42 520.7 17'-2" 523.24 23'-2" 706.12 23'-4" 711.2 17'-4" 528.32 17'-5" 530.86 23'-5" 713.74 23'-5" 713.74 17'-5" 530.86 17'-6" 533.4 23'-6" 716.28 23'-7" 718.82 17'-7" 535.94 17'-7" 535.94 23'-7" 718.82 23'-7" 718.82 17'-7" 535.94 PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 43: 42' Non-Split Floor Bundle Layout

7" plank to the next. The bundle is arranged so that the “A” plank is installed together with the “B” plank. 20'-4" Critical starting dimension for first plank Bundle A Bundle B Figure 6Q 42' Non-Split Floor Bundle Layout PNEG-1828 42' Dura-Lok Plank and Support Manual... -

Page 44: 42' Non-Split Floor Plank Layout

6. Layouts 42' Non-Split Floor Plank Layout Figure 6R 42' Non-Split Floor Plank Layout PNEG-1828 42' Dura-Lok Plank and Support Manual... - Page 45 36'-5" 1112.52 37'-2" 1132.84 37'-7" 1148.08 38'-2" 1163.32 38'-7" 1178.56 39'-2" 1193.8 39'-5" 1203.96 39'-8" 1214.12 40'-2" 1224.28 40'-3" 1229.36 40'-7" 1239.52 40'-8" 1244.6 40'-8" 1244.6 1249.68 41'-2" 1254.76 41'-2" 1254.76 41'-2" 1254.76 PNEG-1828 42' Dura-Lok Plank and Support Manual...

- Page 46 NOTES PNEG-1828 42' Dura-Lok Plank and Support Manual...

-

Page 47: Chapter 7 Warranty

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation) is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials or workmanship. - Page 48 Authorities having jurisdiction should be consulted before installations are made. GSI Group 1004 E. Illinois St. Assumption, IL 62510-0020 Phone: 1-217-226-4421 Fax: 1-217-226-4420 www.gsiag.com Copyright © 2011 by GSI Group Printed in the USA CN-205736...

Need help?

Do you have a question about the PNEG-1828 and is the answer not in the manual?

Questions and answers