Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Autool CT400

- Page 1 AUTOOL CT400 Injector Cleaner & Tester User Manual www.autooltech.com...

- Page 2 AUTOOL. The information contained herein is designed only for the use of this unit. AUTOOL is not responsible for any use of this information as applied to other units.

-

Page 3: Table Of Contents

Table of Contents Overview 1.1 Functions and features 1.2 Working environment and technical parameters Structure 2.1 Overview structure 2.2 Control panel Operation Procedures 3.1 Ultrasonic cleaning 3.2 Test functions Maintenance Precautions Warranty... -

Page 4: Overview

Overview 1.1 Functions and features This GDI Fuel Injector 6-cylinder Cleaner and Tester is a great upgrade, which adapts the latest GDI design. It not only can be used to clean and test the standard injectors, of note that it can carry out GDI injectors cleaning and tesst. It comes with multi voltages available for GDI injectors, which enables to adapt for different types of injector testing. -

Page 5: Working Environment And Technical Parameters

1.2 Working environment and technical parameters Working environment ● Power supply: AC 110/220V ±10% ● Frequency: 50-60HZ±0.5 ● Relative humidity: <85% ● Ambient temperature: 0℃~+40℃ ● External magnetic field strength: <400A/m ● No open flames are allowed around Technical parameter ●... -

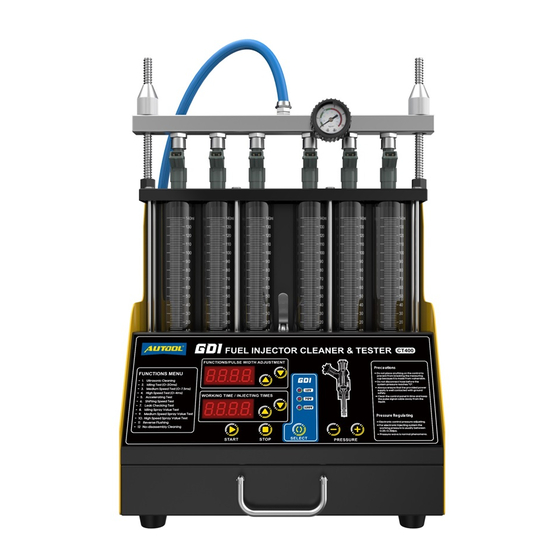

Page 6: Structure

Structure 2.1 Overview structure 1- Filling inlet; 2- Test tube; 3- Drain button; 4- Control panel; 5- Pulse signal cable; 6- Ultrasonic cleaning bath; 7- Power switch; 8- Power socket; 9- Pressure gauge; 10- Test liquid drain valve; 2.2 Control panel ●... -

Page 7: Operation Procedures

● Pressure increase adjustment button. ● Text description of function menu. How to use the drain button When performing work items 8, 9, and 10, press the button to close the drain valve. Then the oil injected by the fuel injectors is closed in the glass tube, so as to compare the amount of oil injected by each fuel injector. -

Page 8: Test Functions

time. (The system defaults to 10 minutes, if you need to modify the time, you can change it with the up and down keys) ● Press the run key, and the system starts to input pulse signals. When finished cleaning, take out the injectors from the ultrasonic tank. Wipe off the cleaning liquid with a soft cloth and prepare for the next operation. - Page 9 C. Install the fuel distributor assembly and the fuel injectors on the Top assem- bly plate and tighten and fix it with a fixed screw nut and a fixed screw sleeve. Get ready to test. D. Select 12v/70v/120v according to injector type. 3.2.2 Steps: Item 02 idle speed test: ●...

- Page 10 2)The system will automatically loop three times in a row to simulate the working conditions and fuel spraying amount of the fuel injectors when the engine is accelerating uniformly at 1,500 -15,000 rpm. 06 Various speed test: ● Press the item selection up and down keys to select the "06 Various speed est"...

-

Page 11: Maintenance

● Press the item selection up and down keys to select the "10 High-speed fuel injecting amount test" item. ● The rest of the operation steps are consistent with item 08. Notes: 1)Uniformity. This is for checking the uniformity carried out at various rpm. When the test liquid level is at 2/3 of the test tube, please pause or stop the machine to observe the uniformity of the injecting amount. -

Page 12: Precautions

can be blocked. Drain the test liquid by removing the level indicator on the left of the main unit. It is better to clean the fuel tank with a little test liquid before the tank is filled in with the new liquid. After cleaning, close the test liquid valve again and pour in new test liquid. -

Page 13: Warranty

● Man-made faults are not covered by the warranty. Disclaimer: All information, illustrations, and specifications contained in this manual, AUTOOL resumes the right of modify this manual and the machine itself with no prior notice. The physical appearance and color may differ from what is shown in the manual, please refer to the actual product. - Page 14 深 圳 市 偶 然 科 技 有 限 公 司 广东省深圳市宝安区北八路航城锦驰产业园 Shenhua Innovation Park, Baoan, Shenzhen, China www.autooltech.com aftersale@autooltech.com +86-400 032 0988 / +86-755-27807580...

Need help?

Do you have a question about the CT400 and is the answer not in the manual?

Questions and answers