Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Datalogic AREX 400

- Page 1 AREX™ 400 USER MANUAL InfraRed Fiber Laser Marker...

- Page 2 Electronic versions of this document may be downloaded from the Datalogic website (www.datalogic.com). If you visit our website and would like to make comments or suggestions about this or other Datalogic pub- lications, please let us know via the "Contact" page.

-

Page 3: Table Of Contents

TABLE OF CONTENTS PREFACE ........................V About this Manual ......................v Manual Conventions ..........................v Technical Support ......................vi Support Through the Website ......................vi Reseller Technical Support ........................ vi INTRODUCTION ......................1 General ........................... 1 Model Description ......................2 PRO Version ............................2 BASIC Version ............................2 CE Compliance ......................... - Page 4 CONTENTS F-Theta Scan Lens for Arex™ A20-X6X ...................29 F-Theta Scan Lens for Arex™ 130-X6X and 150-X6X ..............30 Green Spot ........................31 Connectors Specifications ....................32 Safety Circuit ............................. 32 Control rack back panel connector ..................32 Muting Device ..........................34 Command Box (Laser Control) ......................35 Control rack back panel connector ..................

- Page 5 UNDERSTANDING SLO: SAFE LASER OFF SAFETY CONSIDERATIONS ACCORDING TO EN ISO 13849-1:2008..................... 96 Machine Safety ......................96 Risk Assessment ......................96 Performance Level (PL) ....................98 Datalogic Laser Markers ....................98 SLO connection diagram ....................99 Safety Functions Of Arex™ 400 ..................100 Arex™ XXX-X5X ..........................100 Arex™ XXX-X6X ..........................100 Example 1 ............................101...

- Page 6 CONTENTS Direct viewing of the laser beam ....................108 Viewing of a laser reflected beam ....................109 Viewing of direct laser beam from a fiber output ................109 Viewing of scattered laser beam ....................109 N.O.H.D. determination and O.D. of protection goggles ........... 110 Accidental vision of the reflected laser radiation ................111 Filter scale index of the protection goggles ..................111 Eyes and skin risks .......................

-

Page 7: Preface

PREFACE ABOUT THIS MANUAL This User Manual (UM) is provided for users seeking advanced technical information, including connection, programming, maintenance and specifications. The Quick Refer- ence Guide (QRG) and other publications associated with this product can be down- loaded free of charge from the website listed on the back cover of this manual. Manual Conventions The following conventions are used in this document: The symbols listed below are used in this manual to notify the reader of key issues or... -

Page 8: Technical Support

PREFACE TECHNICAL SUPPORT Support Through the Website Datalogic provides several services as well as technical support through its website. Log on to ( www.datalogic.com For quick access, from the home page click on the search icon , and type in the name of the product you’re looking for. -

Page 9: Introduction

The operator is required to carefully read the section of the manual concerning safety instructions as well as the sections related to matters falling under her/his responsibility. Datalogic shall not be held responsible for any non-conforming use of laser marker of its manufacture. CAUTION BEFORE INSTALLING AND USING THE LASER MARKER, CAREFULLY READ THIS MANUAL. -

Page 10: Model Description

INTRODUCTION MODEL DESCRIPTION Arex™ 400 laser markers are described by their model number which indicates the char- acteristics listed in the diagram below. Not all combinations are available. For a com- plete list of combinations see the Models tab on the Product page of the website. AREX XXX-XXX Laser Type Power... -

Page 11: Ce Compliance

Datalogic commercial reference contacts. Since April 20th, 2016 the main European directives applicable to Datalogic products require inclusion of an adequate analysis and assess- ment of the risk(s). This evaluation was carried out in relation to the applicable points of the standards listed in the Declaration of Conformity. -

Page 12: Ul Compliance

INTRODUCTION UL COMPLIANCE Reading this manual prevents the operator from carrying out operations that could cause damage to himself or others. Follow-Up Service Procedure issued on 2019-03-26. AREX™ 400... -

Page 13: Laser Standards

Datalogic is available for providing to the customers all the information in its possession to help in complying with applicable standards. -

Page 14: Overview

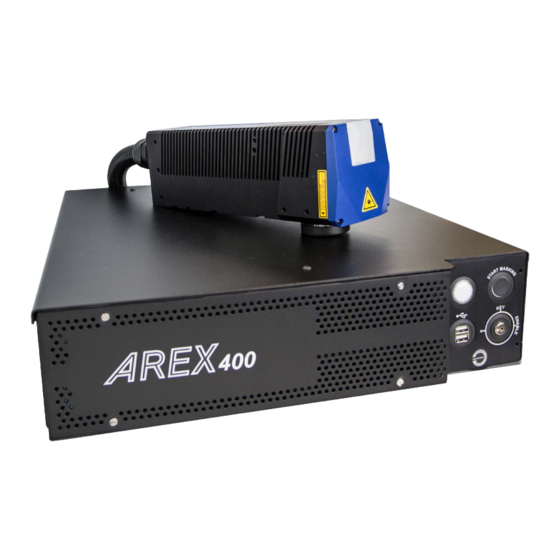

INTRODUCTION OVERVIEW The Fiber laser marker developed and manufactured by Datalogic employs the most advanced technologies with regards to the opto-mechanical parts, the electronic con- trol of laser beam power, communication and the overall safety of the entire marker. The Arex™ 400 laser marker features a control rack and a scan head. The control rack size is standard 19"... -

Page 15: Marking Software

Access to the internal parts of the laser marker is allowed only to authorized personnel, duly qualified and trained with regards to risks of optical and electrical nature. Datalogic declines any and all responsibility for work carried out on active parts by untrained or unauthorized personnel. -

Page 16: Installation

CHAPTER 2 INSTALLATION UNPACKING Control rack and scan head are joined by a connection cable 3 meters long, referred as Head Cable. Control rack and scan head are NOT separable. CAUTION Be extremely careful to not damage the connection cable between scan head and control rack. - Page 17 Carefully remove the laser marker from the packaging using both hands Figure 1: Unpacking Keep all packing materials until the laser has been inspected for completeness and dam- age. If something is missing or defective, call Datalogic (see “Technical Support” on page vi for contact details). USER MANUAL...

-

Page 18: Contents Of The Packaging

INSTALLATION CONTENTS OF THE PACKAGING Control Rack Scan Head Power Supply cables Rack Fixing Brackets Command Box Safety Circuit (Only for XXX-X6X models) MUTING DEVICE MUTING DEVICE Safety labels USB Recovery Disk Selector Keys VGA to DVI Adapter Scan Head Fixing Bracket Test report and sample test plate (Only for XXX-X6X models) Quick Reference Guide... -

Page 19: On Moisture Condensation

ON MOISTURE CONDENSATION ON MOISTURE CONDENSATION If the laser marker is brought directly from a cold to a warm location, moisture may con- dense inside or outside the laser product. This moisture condensation may cause a mal- function of the laser marker. Note on moisture condensation Moisture may condense when you bring the laser marker from a cold place into a warm place (or vice versa) and when you use the laser marker in a humid place. -

Page 20: Fixing And Positioning

INSTALLATION FIXING AND POSITIONING Fix the laser marker according to instructions shown in the figures. CAUTION It is mandatory to secure the laser marker before you start marking, since improper securing or positioning may cause serious damage. Do not secure the laser marker in a way other than the one described in the CAUTION figure. -

Page 21: Control Rack Installation

CONTROL RACK INSTALLATION CONTROL RACK INSTALLATION Horizontal installation The control rack must be positioned in a safe manner, following the recommendations below: Figure 2: Control rack horizontal positioning The control rack can be installed on a standard 19" rack cabinet using the fixing brackets supplied as a standard equipment with XXX-X6X models and as an accessory for XXX-X5X models (see "... - Page 22 INSTALLATION Using this position the fixing brackets are aligned with the console. Figure 4: Control rack fixing brackets mounting position 1 Using this position the fixing brackets are aligned with the frontal grid panel. Figure 5: Control rack fixing brackets mounting position 2 Use this position if you want to use a pre-existing integration for AREX™...

-

Page 23: Vertical Installation

CONTROL RACK INSTALLATION Vertical installation The control rack must be positioned in a safe manner, following the recommendations below. The feet must be removed from the bottom of the control rack and installed on the left side of the control rack using the appropriate fixing points. Tightening torque = 0.5 Nm. -

Page 24: Control Rack Mounting Screws Length

INSTALLATION Control rack mounting screws length To determine the length of the mounting screws, consider the thickness of the mount- ing plate and the thickness of the washer. Control rack 7 mm Mounting plate thickness Washer thickness M4 screw Figure 9: Length of mounting screws Mounting holes depth is =7mm. -

Page 25: Scan Head Installation

SCAN HEAD INSTALLATION The scan head can be installed in any orientation and must be fixed to a suitable base (not supplied by Datalogic) using the dedicated threaded holes and the high precisions slotted seats: Figure 10: Fixing points on scan head (bottom view) Mounting holes depth is =7mm. - Page 26 INSTALLATION A fixing bracket for scan head is provided to offer dedicated threaded holes designed to be fully compatible with Arex™ 3 products: Focusing Beam output Figure 11: Fixing points on scan head (back compatibility with Arex™ 3) If the scan head is mounted on an existing support suitable for Arex™ 3, the Arex™...

- Page 27 SCAN HEAD INSTALLATION It is also possible to mount the scan head sideways using dedicated threaded holes: Figure 12: Fixing points on scan head side All dimensions are in millimeters. NOTE USER MANUAL...

-

Page 28: Scan Head Mounting Screws Length

INSTALLATION Scan head mounting screws length To determine the length of the mounting screws, consider the thickness of the mount- ing plate and the thickness of the washer. Scan Head 4 mm Mounting plate thickness Washer thickness M5 screw Figure 13: Length of mounting screws Mounting holes depth is =4mm. -

Page 29: Installation Environment

INSTALLATION ENVIRONMENT INSTALLATION ENVIRONMENT Control rack The control rack must be installed in a suitable environment in order to allow proper air flow and correct housing of the cables. The control rack uses a forced air cooling system: an adequate air flow is necessary to guarantee its correct cooling. -

Page 30: Scan Head

INSTALLATION Scan Head The scan head must be installed in a suitable environment in order to allow proper air flow and correct housing of the cables. The scan head uses a passive air cooling system: an adequate air flow is necessary to guarantee its correct cooling. -

Page 31: Fume / Dust Extractor

FUME / DUST EXTRACTOR FUME / DUST EXTRACTOR During the marking process, dust and/or fume may be produced. It is important to use an adequate fume/dust extractor and/or air filtration (see “Fume Extractor” on page 82). Marking PVC (or other plastic material) can cause the release of chlorine gas which can be harmful to the laser operator and to the laser marker itself. -

Page 32: Technical Specifications

CHAPTER 3 TECHNICAL SPECIFICATIONS TECHNICAL CHARACTERISTICS AREX 400 MODELS A20-X6X 110-XXX 120-XXX 130-X6X 150-X6X ELECTRICAL SPECIFICATIONS Input Voltage (main power supply) V (AC) 100 to 240 @ 50-60 Hz Max. Input Current (main power supply) 3 - 1.25 4 - 1.7... - Page 33 TECHNICAL CHARACTERISTICS AREX 400 MODELS A20-X6X 110-XXX 120-XXX 130-X6X 150-X6X 17.5 Control Rack Weight 38.5 Control Rack IP Rating IP31 (in horizontal position, otherwise IP30) Forced Air Cooling Control Rack Cooling Rack fans: L10@40°C = 70000 h Laser source fans: L10@40°C = 65000 h...

-

Page 34: Product Description

TECHNICAL SPECIFICATIONS PRODUCT DESCRIPTION Control rack A description of the main parts of the control rack unit is provided here below: Figure 1: Control rack overview (front and back panels view) Front panel: 1. Status LED 2. Start Marking button 3. -

Page 35: Scan Head

PRODUCT DESCRIPTION Scan head A description of the main parts of the scan head unit is provided here below: Figure 2: Scan head overview (front, rear and bottom view) 1. Status LED 2. F-Theta Scan Lens 3. External Focus Beam connector 4. -

Page 36: Marking Area Specification

TECHNICAL SPECIFICATIONS MARKING AREA SPECIFICATION Datalogic provides a wide range of laser marker models with different F-Theta scan lenses configurations. These configurations are provided to best match customer needs regarding marking field size, working distance and power density. Contact Datalogic if other configurations are necessary. -

Page 37: F-Theta Scan Lens For Arex™ 110-Xxx And 120-Xxx

MARKING AREA SPECIFICATION F-Theta Scan Lens for Arex™ 110-XXX and 120-XXX The table below lists the standard F-Theta scan lenses currently available for Arex™ 110 120-XXX: XXX and F-Theta Scan Lens diameter M39 F-THETA SCAN LENS = 160S = 254S Working Distance (WD) 185 ±... -

Page 38: F-Theta Scan Lens For Arex™ 130-X6X And 150-X6X

TECHNICAL SPECIFICATIONS F-Theta Scan Lens for Arex™ 130-X6X and 150-X6X The table below lists the standard F-Theta scan lenses currently available for Arex™ 130- X6X and 150-X6X: F-Theta Scan Lens diameter M85 F-THETA SCAN LENS = 160L = 254L = 330L Working Distance (WD) -

Page 39: Green Spot

GREEN SPOT GREEN SPOT The Green Spot is an indicator integrated in the scan head able to provide a green visual feedback in the center of marking field area. Figure 4: Green Spot indicator DESCRIPTION CONFIGURATION The Green Spot indicator is not active (always OFF) The Green Spot is steady ON only when all these events are verified: •... -

Page 40: Connectors Specifications

TECHNICAL SPECIFICATIONS CONNECTORS SPECIFICATIONS Safety Circuit Control rack back panel connector Socket Sub-D, 15 pins, female. Figure 5: Safety Circuit connector, female panel plug (front view) SIGNAL TYPE DESCRIPTION Power Output Auxiliary 24V DC power supply RESERVED DO NOT CONNECT Power Output Auxiliary 24V DC power supply SAFETY_FDBK+... - Page 41 CONNECTORS SPECIFICATIONS Safety Circuit Electric Diagram for XXX-X6X models for XXX-X5X models Figure 6: Safety Circuit connector, electric diagram TECHNICAL CHARACTERISTICS Control Contacts 15 A for 20 ms Inrush current max. 5 mA to 6 A Switching current range ≤...

-

Page 42: Muting Device

TECHNICAL SPECIFICATIONS Muting Device Sub-D, 15 pins, male, with shell. Figure 7: Safety Circuit Muting Device provided Do not use the Safety Circuit Muting Device for external devices, since this will result in loss of the safety function of the machine to which this prod- uct is installed. -

Page 43: Command Box (Laser Control)

CONNECTORS SPECIFICATIONS Command Box (Laser Control) Control rack back panel connector Socket Sub-D, 25 pins, female. Figure 9: Command Box connector, female panel socket (front view) SIGNAL TYPE*** DESCRIPTION Output power 24V_ENABLE_B Auxiliary 24V DC power supply available for EXT_ENABLE_B (max 125mA) supply Secondary external ENABLE signal: EXT_ENABLE_B... -

Page 44: Muting Device

TECHNICAL SPECIFICATIONS SIGNAL TYPE*** DESCRIPTION Ground Ground reference This signal is used to know if the laser marker is ready to emit laser radia- tion: ENABLE_OUT Digital Output - ON when the laser marker is in READY state Depending on the configuration this signal can be used in different ways: - COMPATIBILITY: ON when a document or a sequence is running in AUTO MODE** or WORK MODE** independently from the laser marker state. -

Page 45: Axes (I/O Control)

CONNECTORS SPECIFICATIONS Axes (I/O Control) Control rack back panel connector Plug Sub-D, 25 pins, male. Figure 12: Axes connector, male panel plug (front view) SIGNAL** TYPE*** DESCRIPTION Output Power Auxiliary 24V DC power supply available for drive input logical HIGH (max EXT_24V supply 125mA) -

Page 46: Encoder

(*) see “Input/Output specifications” on page 41 Photocell Control rack back panel connector Socket, M12, 4 pins female. Recommended photocell: Datalogic S51-PA-5-B01-PK; Data- logic S15-PA-5-B01-PK or equivalent. See “Starter Kit for Marking On the Fly (MOF)” on page 81. Figure 14:Photocell connector, female panel socket (front view) -

Page 47: Device Port 1

CONNECTORS SPECIFICATIONS Device Port 1 Control rack back panel connector Plug, M12, 8 positions male. Figure 15: Device Port 1 connector, male panel plug (front view) SIGNAL TYPE* DESCRIPTION Power Output Auxiliary 24V DC power supply (15W max power) Ground Ground reference EXT_TRIG_#1 Digital Output... -

Page 48: Rs232 (Com3)

TECHNICAL SPECIFICATIONS RS232 (COM3) Control rack back panel connector Plug Sub-D, 9 pins, male. Figure 17: RS232 connector, male panel plug (front view) SIGNAL TYPE DESCRIPTION Input Data Carrier Detect Input Receive Data Output Transmit Data Output Data Terminal Ready Ground Ground reference Input... -

Page 49: Input/Output Specifications

INPUT/OUTPUT SPECIFICATIONS INPUT/OUTPUT SPECIFICATIONS Digital Input USING EXTERNAL POWER SUPPLY USING AUXILIARY POWER SUPPLY LASER MARKER SIDE USER SIDE LASER MARKER SIDE USER SIDE TECHNICAL CHARACTERISTICS Optocoupler Type 28 V DC Vmax 10 mA @ 24 V DC Imax ≥ 1ms (debounce) Pulse Width 0.0 V DC 0.0 V DC... -

Page 50: Laser Marker States

TECHNICAL SPECIFICATIONS LASER MARKER STATES Normal Operation States STATE DESCRIPTION STATUS LED This state occurs since the laser marker is SYSTEM BOOTING UP switched on until Laser Engine has been loaded and no errors occurred Blinking In this state the laser marker cannot emit IR lasers WAIT FOR START radiation and Aiming and Focus beam cannot be activated... -

Page 51: Error States

LASER MARKER STATES Error States STATE DESCRIPTION STATUS LED This state occurs if the laser marker detects an ERROR error that prevents normal operation Blinking SYSTEM ERROR DESCRIPTION This error rise if the INTERLOCK function is ON. To reset the error, set INTERLOCK ERROR INTERLOCK function to OFF and repeat the turning on sequence This error rise if the CONNECTOR_PRESENCE signal (pin 10 Com-... -

Page 52: Control The Laser Marker States

TECHNICAL SPECIFICATIONS Control the Laser Marker States The laser marker states can be controlled by: • Key Selector • Command Box connector Key Selector mode Controlling the laser marker states using the Key Selector on the control rack front panel requires that the input signals of the command box connector EXT_KEY, EXT_ENABLE_A and EXT_ENABLE_B are set to fixed HIGH level: COMMAND BOX INPUT... -

Page 53: Timing Diagrams

TIMING DIAGRAMS TIMING DIAGRAMS Turning On sequence user defined within 50ms within 50ms user defined typ 60s Figure 19: Turning On sequence timing diagram Marking control signals behavior Figure 20: Marking process timing diagram REF. NAME DESCRIPTION Minimum time duration that the START_MARKING signal must have Start Time in order to be accepted as a valid START_MARKING event Delay between the acceptance of the START_MARKING signal and the... -

Page 54: Sw_Ready Output Signal (Ready To Mark Mode)

TECHNICAL SPECIFICATIONS SW_Ready output signal (Ready to Mark mode) Figure 21: SW_Ready signal timing diagram Good\Bad output signal Bad marking event Figure 22: Good\Bad signal timing diagram System_Alarm output signal Error event Figure 23: System Alarm timing diagram AREX™ 400... -

Page 55: Marvis™ I/O Signals Behavior

TIMING DIAGRAMS MARVIS™ I/O signals behavior Figure 24: MARVIS™ I/O signals behavior Safety functions behavior Interlock behavior user defined within 50ms within 600ms Figure 25: Interlock behavior Laser_Stop behavior user defined within 50ms within 600ms Figure 26: Laser_Stop behavior USER MANUAL... -

Page 56: Green Spot Behavior

TECHNICAL SPECIFICATIONS Green Spot behavior System Ready to Mark mode Figure 27: Green Spot: System Ready to mark Marking Confirmation mode 0.1s to 5s Figure 28: Green Spot: Marking Confirmation MARVIS Verification mode 0.1s to 5s Figure 29: Green Spot: MARVIS™ Verification AREX™... -

Page 57: Axes I/O Signals Behavior

Read Verify Integrated Solution) feature to seamless interact with AutoID code reader for in-line validation of marked traceability codes. MARVIS™ connects Datalogic MATRIX™ N-series reader with the laser marker, enabling controlling from one single interface and enhancing individual products’ performances. - Page 58 TECHNICAL SPECIFICATIONS Advanced Editing Function • Easily create, import and edit texts, shapes and logos • One-click code generator for 1D and 2D symbologies • Object-related Property Browser for fast adjustment of Marker and Reader param- eters • Imports Bitmap and Vector files (DXF, DWG, PLT, PDF, AI, SVG, BMP, JPG, PNG and TIFF…) •...

- Page 59 LIGHTER™ SUITE MARKING SOFTWARE The programming language is ECMAScript (also called JavaScript). • Control the entire marking process • Create and fully customize marking lay- out and its content at runtime • Interact with local or centralized data- bases • Create alternative customized interfaces •...

-

Page 60: Set Up

CHAPTER 4 SET UP CONNECTIONS The laser marker connections are described here below. Follow the operations as described. Control rack and scan head are joined by a connection cable 3 meters long. Control rack and scan head are NOT separable. CAUTION Connecting Command Box connector The Command Box connector must always be inserted with properly signals provided in... -

Page 61: Connecting Safety Circuit Connector

CONNECTIONS Connecting Safety Circuit connector The Safety Circuit connector must always be inserted with properly signals provided in order to use the laser marker. The absence of such connector blocks the laser emission. Do not use the Safety Circuit Muting Device for external devices, since this will result in loss of the safety function of the machine to which this prod- uct is installed. -

Page 62: Connecting Power Supply Cable

SET UP Connecting Power Supply cable Connect the Power Supply cable using the cord retention system. The locking mechanism is released again by pressing the release lever. Thanks to its luminous bright yellow color, it is easily recognizable and distinguishes this system from conventional mains connections. NOTE Figure 3: Connecting Power Supply cable Connecting the Earth Ground... -

Page 63: Local Mode Control Connections

CONNECTIONS Local Mode Control connections To use the laser marker in “Local Mode Control” it is necessary to install a mouse, keyboard and monitor. Connect the monitor and input devices to laser marker as shown below: Figure 5: Connecting the mouse Figure 6: Connecting the keyboard USER MANUAL... - Page 64 SET UP Figure 7: Connecting the monitor Minimum monitor resolution 800 x 600 (VGA standard). NOTE AREX™ 400...

-

Page 65: Remote Mode Control Connection

CONNECTIONS Remote Mode Control connection To use the laser marker in “Remote Mode Control” it is necessary to connect a network cable: Figure 8: Connecting LAN port The LAN ports are configured by default with a fixed IP Address and Subnet Mask: - LAN 1 Default IP address: 192.168.1.10 NOTE... -

Page 66: F-Theta Scan Lens Protection Cap Removal

SET UP F-THETA SCAN LENS PROTECTION CAP REMOVAL Remove the F-Theta scan lens protection cap before marking operation: Figure 9: F-Theta scan lens protection cap removal Marking with the lens protection cap in place could result in damage to the laser marker. -

Page 67: Use And Operation

CHAPTER 5 USE AND OPERATION Before turning on the laser marker, be sure that the laser marker is connected as previ- ously described. Check the presence of: • Voltage power supply connection • Safety Circuit connection • Command Box connection Do not use the Safety Circuit Muting Device for external devices, since this will result in loss of the safety function of the machine to which this prod- uct is installed. -

Page 68: First Time Boot

USE AND OPERATION FIRST TIME BOOT The first time the laser marker is turned on after it has been unpacked, it warns that the operating system will be restarted within a few seconds. NOTE The CAUTION symbol advises you of actions that could damage equipment or property. -

Page 69: Turning On Sequence

TURNING ON SEQUENCE TURNING ON SEQUENCE The laser marker states can be controlled by: • Key Selector • Command Box connector Sequence using Key Selector Controlling the laser marker states using the Key Selector on the control rack front panel requires that the input signals of the command box con- nector EXT_KEY, EXT_ENABLE_A and EXT_ENABLE_B are set to fixed HIGH CAUTION level. - Page 70 USE AND OPERATION Rotate the key selector one-step to STANDBY position: Figure 3: Key selector in STANDBY position The status LED on the control rack and the status LED on the scan head are steady orange. The laser marker is in STANDBY SHUTTER CLOSED state. Figure 4: Standby Shutter closed state AREX™...

- Page 71 TURNING ON SEQUENCE Rotate the key selector one-step to LASER ON position: Figure 5: Key selector in LASER ON position The status LED on the control rack and status LED on the scan head will turn red. The laser marker is in READY state. Figure 6: Ready state USER MANUAL...

-

Page 72: Sequence Using Command Box

USE AND OPERATION Sequence Using Command Box Controlling the laser marker states using the Command Box connector on the control rack back panel requires that the Key Selector is set to fixed position LASER_ON. CAUTION Turn ON the main power supply switch in the back panel of the control rack. The laser marker turns on and goes in booting-up state. - Page 73 TURNING ON SEQUENCE The status LED on the control rack and status LED on the scan head will turn red. The laser marker is in READY state. Figure 9: Ready state USER MANUAL...

-

Page 74: Customize The Laser Marker Software

CHAPTER 6 CUSTOMIZE THE LASER MARKER SOFTWARE CHANGE O.S. LANGUAGE AND KEYBOARD LAYOUT The laser marker allows you to customize the operating system changing the language used in menus, dialogs and languages you can use to enter text and keyboard layout. In order to perform this setting it is necessary to connect mouse, keyboard and monitor to the laser marker (see "... - Page 75 CHANGE O.S. LANGUAGE AND KEYBOARD LAYOUT 3. Select Change display language: 4. In Keyboards and Languages select and choose the desired language. USER MANUAL...

- Page 76 CUSTOMIZE THE LASER MARKER SOFTWARE 5. Select Change keyboards to change your keyboard or input language: 6. Now select the default input languages and press OK: Default keyboard layouts are “US” and “IT”. Add a custom keyboard if nec- essary. NOTE 7.

- Page 77 CHANGE O.S. LANGUAGE AND KEYBOARD LAYOUT 8. A message advises you to restart or shutdown the operating system in order to permanently save data. Press OK: 9. Shut down the operating system in order to save the new settings: DO NOT turn OFF or UNPLUG the laser marker while Windows® is shutting down.

-

Page 78: Change The Lan Configuration And Ip Address

CUSTOMIZE THE LASER MARKER SOFTWARE CHANGE THE LAN CONFIGURATION AND IP ADDRESS The operating system allows you to change the LAN configuration and IP address. In order to perform this setting it is necessary to connect mouse, keyboard and monitor to the laser marker (see " Local Mode Control connections" on page 55 ). - Page 79 CHANGE THE LAN CONFIGURATION AND IP ADDRESS 4. In the Network and Sharing Center window select Change adapter settings: 5. In the Network Connections window double click on Local Area Connection icon: 6. In the Local Area Connection Properties window double click on Internet Proto- col Version 4 (TCP/IPv4) USER MANUAL...

- Page 80 CUSTOMIZE THE LASER MARKER SOFTWARE 7. In the Internet Protocol Version 4 (TCP/IPv4) Properties you can change the IP address and configuration: 8. Close all the open windows and double click on shortcut to save-data.bat icon in the Desktop window. 9.

-

Page 81: Change The Video Setting

CHANGE THE VIDEO SETTING CHANGE THE VIDEO SETTING The operating system allows you to change the Video setting. In order to perform this setting it is necessary to connect mouse, keyboard and monitor to the laser marker (see " Local Mode Control connections" on page 55 ). - Page 82 CUSTOMIZE THE LASER MARKER SOFTWARE 4. In the Screen Resolution window select the desired Screen resolution and Color quality: 5. Close all the open windows and double click on shortcut to save-data.bat icon in the Desktop window. 6. A message advises you to restart or shutdown the operating system in order to permanently save data.

-

Page 83: Remote Desktop Connection

REMOTE DESKTOP CONNECTION REMOTE DESKTOP CONNECTION To connect the laser marker to a remote Windows® based computer, follow these steps: 1. Turn on the laser marker 2. Make sure that both laser marker and remote computer are connected to the LAN 3. -

Page 84: Accessories

CHAPTER 7 ACCESSORIES The accessories listed here below are described for information purposes only, and are not necessarily included in the packaging. The minimum contents of the packaging include the main hardware, cables and keys. For additional information, please see "... -

Page 85: Remote Start Foot Switch

REMOTE START FOOT SWITCH REMOTE START FOOT SWITCH This accessory is used to provide the START_MARKING signal to the laser marker when the pedal is pressed by the operator. Figure 2: Remote Start Foot Switch (ordering no: 985350035) Refer to Remote Start Foot Switch instruction manual for more informa- tion. -

Page 86: Db25-To-Free Leads Cable

MARVIS™ ADD-ON MARVIS™ is the most advanced MARK and VALIDATE solution for traceability. The inno- vative Code Quality Training dramatically simplifies setup in a real production environ- ment. The MARVIS™ Add-on for AREX 400 includes: • MATRIX™ 300N reader •... -

Page 87: Marvis™ Mounting Bracket

MICROMETRIC DISTANCE SENSOR KIT MARVIS™ Mounting Bracket This accessory is used to properly fix the MATRIX™-N and the MARVIS™ LED Ring Light ID 50mm - White to the scan head in a MARVIS™ application (suitable for F160S and F254S F-Theta scan lens). Figure 6: MARVIS™... -

Page 88: M39 F-Theta Protective Cap

ACCESSORIES M39 F-THETA PROTECTIVE CAP Easy to install, easy to replace; simplifies preventive/periodic maintenance cleaning operation on F-Theta scan lens and allow no-stop operations. • Ensure complete IP64 protection • Protect expensive lens from dust and scratches • Suitable for 160S and 254S F-Theta scan lenses Figure 9: M39 F-Theta protective cap (ordering no. -

Page 89: Starter Kit For Marking On The Fly (Mof)

STARTER KIT FOR MARKING ON THE FLY (MOF) STARTER KIT FOR MARKING ON THE FLY (MOF) This accessory is used for the implementation of Marking on the Fly applications. The Kit includes: encoder, photocell, cables and plastic reflectors. Figure 10: Kit MOF (ordering no: 985330027) USER MANUAL... -

Page 90: Rack Handles

ACCESSORIES RACK HANDLES This accessory is used to easily fasten the control rack to the cabinet. The fixing brackets are equipped with handles for easier handling. Figure 11: Rack Handles (ordering no: 985350039) FUME EXTRACTOR This accessory is suitable for collecting and filtering dry and non combustible types of dust contained in non explosive air mixtures produced during laser marking. -

Page 91: Technical Support

The laser marker has seals in some areas. The seals must not be broken or removed for any reason. The sealed parts may be opened only and exclusively by Datalogic. Breaking these seals voids the warranty on the entire laser marker. -

Page 92: Maintenance

TECHNICAL SUPPORT MAINTENANCE The ordinary maintenance program of the laser marker includes only simple operations. Some operations consist in a mere “check” of the operating condition. The maintenance activities must be done in compliance with the legal directives regard- ing the safety rules during these operations. The following parts/functions have to be controlled periodically: COMPONENT TYPE OPERATION INTERVALS... -

Page 93: Air Filter Cleaning Procedure

MAINTENANCE Air filter cleaning procedure Procedure: • Turn off key switch on controller unit • Disconnect AC power cable • Untight grid panel screws and remove it • Remove filter Figure 2: Removal of air filter • Clean filter with compressed air or with neutral detergent and air-dry it •... -

Page 94: Troubleshooting

TECHNICAL SUPPORT TROUBLESHOOTING If a problem occurs during operation, first check the following troubleshooting. If you cannot fix the problem, contact Datalogic customer service (see “Technical Support” on page vi). Service Interface The laser marker is equipped with a Service Interface integrated in Lighter™ Laser Con- figuration - Service useful for service purpose. - Page 95 TROUBLESHOOTING LASER SOURCE INFO This counter is incremented every time the Laser source Temperature Error temperature is out of the operating temperature range This counter is incremented every time the External supply Power Supply Error voltage of the laser source is out of the specified range This counter is incremented every time the laser source Back Reflection Error detect an high optical power reflected back to the laser...

-

Page 96: List Of Warning And Error States

The temperature Blinking RED System Error Temperature error must not exceed the operative limit Scan Head Contact Datalogic Technical Support Connection error Check the temperature of the environment where the control Source Temperature rack is placed. The temperature... -

Page 97: List Of Problems Related To Laser Marker States

“Marking Area Specification” on page 28 Check that the laser parameters set in the layout are appropriate for the material to Incorrect laser parameters be marked. Contact Datalogic Technical Support Check the laser marker state is set to Incorrect laser marker state... - Page 98 TECHNICAL SUPPORT PROBLEM DESCRIPTION POSSIBLE CAUSE ACTION Check that the STOP_MARKING signal on STOP_MARKING signal is active the Command Box connector is not set to HIGH level - Check the START_MARKING signal on the Command Box connector (see “Com- mand Box (Laser Control)” on page 35). HIGH level pulsed signal start the marking Laser marker doesn't start to engrave process (refers to Lighter™...

- Page 99 TROUBLESHOOTING PROBLEM DESCRIPTION POSSIBLE CAUSE ACTION Check that the F-Theta scan lens protec- F-Theta Lens protection not removed tion has been removed The laser marker is provided with a sys- tem that prevent diode wear turning of the Aiming Beam Standby time expired diode when the Aiming Beam Standby time expired.

-

Page 100: Remote Assistance

TECHNICAL SUPPORT REMOTE ASSISTANCE The laser marker is equipped with a remote connection tool that can be used for diag- nostic purposes by Datalogic technical support. The laser marker must be connected to the Internet. NOTE AREX™ 400... -

Page 101: Labels

APPENDIX A LABELS LABELS LABEL DESCRIPTION Identification label Warning laser logotype Laser Label (scan head) for Arex™ A20-X6X models (*) Laser Label (scan head) for Arex™ 110-XXX/120-XXX/130- X6X and 150-X6X models (*) Aperture Label DANGER Label for non-interlock protective housing Caution, possibility of electric shock USB port MAC Address for XXX-X5X models... -

Page 102: Positioning Of External Labels

LABELS LABEL DESCRIPTION 0 - STAND BY - POWER ON STAND BY / POWER ON positions COMMAND BOX Command Box connector AXES (I/O) Control Axes connector SAFETY CIRCUIT Safety Circuit connector LAN port (LAN2 - LAN3 only for XXX-X6X models) RS232 RS232 port VGA port... -

Page 103: Positioning Of Labels On The Scan Head

SAFETY LABELS IN LOCAL LANGUAGES Positioning of labels on the scan head: Figure 2: External labels Scan Head location SAFETY LABELS IN LOCAL LANGUAGES The laser marker is provided by default with laser labels and labels for non-interlock protective housing in Chinese and English language already attached to the product. Additional labels in French, Swedish, German, Italian, Spanish and Korean languages are provided with the laser marker. -

Page 104: Understanding Slo: Safe Laser Off Safety Considerations According To En Iso 13849-1:2008

APPENDIX B UNDERSTANDING SLO: SAFE LASER OFF SAFETY CONSIDERATIONS ACCORDING TO EN ISO 13849-1:2008 MACHINE SAFETY The European Community Directives establish that industrial machinery should not present a risk for workers and operators. The manufacturers should retain full responsi- bility for certifying the conformity of their machinery to the provisions of Machine Directive. - Page 105 RISK ASSESSMENT RISK ASSESSMENT is based on a clear understanding of the machine limits and func- tions and the tasks that may be required to be performed at the machine throughout its life. During Risk Assessment all the Hazards must be identified and analyzed for all the pos- sible tasks of the machine (such as maintenance or cleaning).

-

Page 106: Performance Level (Pl)

The Machinery Directive 2006/42/UE, EN 13849-1 and EN ISO 11553-1 are NOT applica- ble to Datalogic Laser Markers. Datalogic, in order to help customers in their approval process, as a voluntary act, has applied in its laser marker, where possible, some points of above mentioned regula- tions. -

Page 107: Slo Connection Diagram

SLO CONNECTION DIAGRAM SLO CONNECTION DIAGRAM INPUT LOGIC OUTPUT SLO is one of the components of the Protective System and Equipment. SLO is intended to be used in combination with safety PLC or safety relays. USER MANUAL... -

Page 108: Safety Functions Of Arex™ 400

UNDERSTANDING SLO: SAFE LASER OFF SAFETY CONSIDERATIONS ACCORDING TO EN ISO 13849-1:2008 SAFETY FUNCTIONS OF AREX™ 400 Arex™ XXX-X5X SAFETY FUNCTION PHYSICAL INTERFACE Number of Channels: 1 SF.1: Enable Category: B Command Box no laser emission if “EXT_ENABLE_A or MTTFd: 3 to 10 years connector “EXT_ENABLE_B”... -

Page 109: Example 1

SAFETY FUNCTIONS OF AREX™ 400 Example 1 Risk Analysis of a fully automatic laser processing machine that operates only when pro- tection system is disengaged. • Operative cycle: 500 pcs/hour, 3 shifts (8h/shift) 350 days/year • Dedicated enclosures prevent laser emission also during parts loading/unloading •... -

Page 110: Example 2

UNDERSTANDING SLO: SAFE LASER OFF SAFETY CONSIDERATIONS ACCORDING TO EN ISO 13849-1:2008 Example 2 Risk Analysis of a fully automatic laser processing machine that operates only when pro- tection system is disengaged. • Operative cycle: 500 pcs/hour, 3 shifts (8h/shift) 350 days /year •... -

Page 111: Example 3

SAFETY FUNCTIONS OF AREX™ 400 Example 3 Risk Analysis of a manual loading laser processing machine. • Operative cycle: 500 pcs/hour, 1 shift (8h/shift) 250 days /year • Dedicated enclosures prevent laser emission during laser processing • An interlocked door is dedicated to part loading •... -

Page 112: Laser Safety

APPENDIX C LASER SAFETY The following information is provided in compliance with regulations set by Interna- tional Authorities, and it refers to proper use of the laser marker. It is crucial that you protect yourself against beams of reflected or direct light as they cause permanent damage to your skin. - Page 113 Staring directly at a laser beam may cause irreversible damage to your eyes. WARNING Wear safety goggles while using the laser marker. WARNING BEFORE INSTALLING AND USING THE LASER MARKER, CAREFULLY READ THIS MANUAL. NOTE USER MANUAL...

-

Page 114: Laser Radiation

LASER SAFETY LASER RADIATION Laser radiation is form of electromagnetic emission in the wavelength range from the ultraviolet (e.g. from excimer lasers), through visible (e.g. HeNe or Argon lasers) and near infrared (e.g. Yb Doped Fiber and ND:YAG DPSS lasers) up to long infrared (e.g. CO2 lasers). -

Page 115: Absorption Of Laser Radiation

ABSORPTION OF LASER RADIATION ABSORPTION OF LASER RADIATION Human tissues absorbs electromagnetic radiation in different ways depending on tissue characteristics and the wavelength of the radiation. Certain wavelengths may be trans- mitted or absorbed, in different levels, by the human tissue. In the specific case of the eye, the Cornea and Crystalline lens allows most of the radiation within the wavelength range of 400nm to 1400nm to pass a reach the retina (where are the vision sensors). -

Page 116: Classification And Danger Level

LASER SAFETY CLASSIFICATION AND DANGER LEVEL Regulations have established different classes of Lasers, based on their ability to cause human injury. These classes ranges from Class 1 (basically safe in all conditions) to Class 4 (dangerous in several conditions). Lasers that can produce risk to human being, not only from direct or reflected radiation but also from scattered radiation, belong to Class 4. -

Page 117: Viewing Of A Laser Reflected Beam

DEGREE OF RISK WITH RADIATION VIEWING CONDITIONS Viewing of a laser reflected beam This may occur when beam is reflected on a mirror surface. This type of viewing is as danger for human eye as direct viewing of the laser beam. Do not look to reflected laser beam. -

Page 118: Determination And O.d. Of Protection Goggles

LASER SAFETY N.O.H.D. DETERMINATION AND O.D. OF PROTECTION GOGGLES In order to determine the characteristics of the protection goggles, it is essential to determine the characteristics of the radiation, knowing its optical path, the dimensions of the beam and its divergence. Objective Beam-Exp Source... -

Page 119: Accidental Vision Of The Reflected Laser Radiation

EYES AND SKIN RISKS Accidental vision of the reflected laser radiation Assuming a direct exposure of 10 seconds at a nominal distance of 0.5 m (worst case considered), with the Arex™ 400 model using F-Theta scan lens 160 mm, it is possible to calculate the suitable optical density (O.D.) for safety goggles. -

Page 120: Other Risks

CAUTION Datalogic shall not be held liable for any damage caused by inadequate work from non-authorized personnel. Only Datalogic authorized personnel, who have been trained and instructed on the electrical and optical risks, is allowed to access the internal parts of the scan head. -

Page 121: Using Marking Software

APPENDIX D USING MARKING SOFTWARE HOW TO CREATE AND EDIT GRAPHICS LAYOUT This example considers that the laser marker is controlled in Key Selector mode (see “Key Selector mode” on page 44). NOTE In “WAIT FOR START” state, double click the Laser Editor icon to start the layout editor application. - Page 122 USING MARKING SOFTWARE Click on the Text String icon in the Object toolbar to add a string object to the layer: Objects toolbar: it allows adding objects to the cur- rent document Edit String properties such as value, font, style, etc. using the Properties browser: Properties browser: give information about...

-

Page 123: How To Test And Mark Layout

HOW TO TEST AND MARK LAYOUT HOW TO TEST AND MARK LAYOUT In “STANDBY SHUTTER CLOSED” state, press Limits All button in the Laser Toolbar to adjust the object position in the marking field: Limits function: displays the bounding box of the object(s) present in the document. - Page 124 USING MARKING SOFTWARE In “READY” state, adjust the Laser parameters using the Properties browser: Press the Send Marking button in the Laser Toolbar AREX™ 400...

-

Page 125: How To Use Command Box Signals To Mark Layout

HOW TO USE COMMAND BOX SIGNALS TO MARK LAYOUT HOW TO USE COMMAND BOX SIGNALS TO MARK LAYOUT Automate the marking process allowing documents to be marked using external START_MARKING and STOP_MARKING signals, which can be generated by PLC or other external devices. - Page 126 USING MARKING SOFTWARE Select the document from the list and click on the To Auto Mode button: Auto/Manual The laser marker is ready to mark the document using external START_MARKING and STOP_MARKING signals: Consult Lighter™ software user's manual for a proper use of the same. NOTE AREX™...

-

Page 127: Mopa Fiber Laser

Datalogic designates this region as the “Constant Average Power Region”. A characteristic of the Datalogic Arex™ A20-X6X laser marker is that user is allowed to operate the laser at pulse repetition frequencies that can be reduced down to 20kHz and up to 500kHz (depending on Pulse profile selected). - Page 128 MOPA FIBER LASER Thus, within the extended operating region below the transition frequency, the pulse energy/peak power will remain constant (as illustrated in the figure above). Datalogic designates this extended region as “Constant Energy/Peak Power Region”. This region is ideal for applications that require changing of the laser pulse frequency while keeping pulse energy or peak power constant.

-

Page 129: Pulse Profile

LASER MARKER OPERATIONS Pulse Profile Datalogic's Arex™ A20-X6X laser marker includes 8 factory preset pulse profiles, user select- able through software interface (see “Lighter™ Pulse Profile Configuration” on page 123). The following figures illustrates the typical pulse shape of these pulse profiles at 200 kHz fre- quency. - Page 130 MOPA FIBER LASER For the longer pulse profiles (above 20 ns), the pulse shape varies with pulse frequency and Power level. Below the pulse transition frequency (fT), the pulse profile shape will remain invariant, i.e., will not vary with pulse frequency, while above fT the shape will vary with pulse frequency.

-

Page 131: Lighter™ Pulse Profile Configuration

LIGHTER™ PULSE PROFILE CONFIGURATION LIGHTER™ PULSE PROFILE CONFIGURATION Creating a document with multiple objects using a single pulse profile You can create documents with multiple objects, using the same pulse profile. To accomplish this, create a new document: In the Property window, Laser section, select the Pulse Profile you want to use for the entire document: USER MANUAL... -

Page 132: Creating A Document With Multiple Objects Using Different Pulse Profiles

MOPA FIBER LASER Add the desired objects to the document using the Insert object toolbar: By default, the new objects use the same laser property as those set for the document. The new objects are shown in black color to indicate that their laser property are the same as those set for the document: Creating a document with multiple objects using different pulse pro- files... - Page 133 LIGHTER™ PULSE PROFILE CONFIGURATION By default, all the added objects use the same laser property as those set for the docu- ment. Select the object you want to change the Pulse Profile: In the Property window flag the Custom laser parameters property and select the desired Pulse Profile: The object will be shown in blue color to indicate that its laser property are different from those set for the document:...

-

Page 134: Marking Software Upgrade

APPENDIX F MARKING SOFTWARE UPGRADE HOW TO UPDATE THE MARKING SOFTWARE This document describes how to update the software version: 1. Close Lighter™ Laser Editor and Laser Engine (right-click on the icon in the tray bar and select QUIT QUIT) 2. - Page 135 HOW TO UPDATE THE MARKING SOFTWARE 4. Press I Agree to continue: 5. Check “I accept the terms of the License Agreement” and press Next to continue: 6. Choose the INTERCATIVE installation type and press Next to continue: USER MANUAL...

- Page 136 MARKING SOFTWARE UPGRADE 7. Choose the components to install and press Next to continue: 8. Do not change the destination folder and press Install to continue: 9. Press OK to uninstall the old Lighter™ Suite version AREX™ 400...

- Page 137 HOW TO UPDATE THE MARKING SOFTWARE 10. Press Next to continue: 11. Select the components of the old Lighter™ Suite version to remove and press Uninstall: 12. Wait until the unistallation is complete and press Close to continue: USER MANUAL...

- Page 138 MARKING SOFTWARE UPGRADE 13. Lighter Suite will be installed. Press Finish to complete the procedure: 14. Depending on whether the Lighter™ Suite update includes any control board updates different procedure should be followed: • Procedure with laser control board upgrade: - press OK to execute control board update - upon completion, a window informs the user that data is automatically saved in the operating system...

- Page 139 HOW TO UPDATE THE MARKING SOFTWARE - A window informs the user that data is automatically saved in the operating sys- - operating system will be restarted automatically within the next 10 seconds DO NOT turn OFF or UNPLUG the laser marker while Windows® is restart- ing! CAUTION - wait until the operating system is restarted automatically...

-

Page 140: Recover The Laser Marker

APPENDIX G RECOVER THE LASER MARKER OVERVIEW The laser marker is provided with an USB recovery disk (see “Contents of the packag- ing” on page 10) able to restore it to the factory settings. The USB recovery disk should be used if the Operating System is corrupted or disks are corrupted. - Page 141 HOW TO RECOVER THE LASER MARKER • Datalogic Recovery Disk procedure screen will appear: • Press ENTER key to continue • Choose RESTORE_DISK_C_PCM3365 to restore disk C: and press ENTER key • In the next screen, choose NANDrive or SATA_Flash as target disk and press ENTER key •...

- Page 142 RECOVER THE LASER MARKER • Select Start over and press ENTER key • Choose RESTORE_DISK_D_PCM3365 to restore disk D: and press ENTER key • In the next screen, choose SATA_SSD or SQF-xxxxx as target disk and press ENTER • In some cases you may be asked to confirm the operation. Press ENTER key to con- tinue •...

-

Page 143: Initialize The Hardware

HOW TO RECOVER THE LASER MARKER Initialize the Hardware • Turn ON the laser marker • A message will advise you that the operating system is initializing the new hard- ware • WAIT until the process is completed: • A message advise you that Windows will be automatically rebooted: DO NOT turn OFF or UNPLUG the laser marker while Windows®... -

Page 144: Customize The Marking Software

In order to work, the marking software must be customized with the cor- rect configuration file. If the Laser.inz file is not available or the origi- nal USB recovery disk was lost, contact Datalogic. See “Support Through NOTE the Website” on page vi. -

Page 145: Mechanical Drawings

APPENDIX H MECHANICAL DRAWINGS USER MANUAL... -

Page 146: Control Rack

MECHANICAL DRAWINGS CONTROL RACK Please refer to Datalogic website for detailed drawings. NOTE AREX™ 400... -

Page 147: Scan Head

SCAN HEAD SCAN HEAD Please refer to Datalogic website for detailed drawings. NOTE USER MANUAL... - Page 148 © 2018-2019 Datalogic S.p.A. and /or its affiliates • All rights reserved • Without limiting the rights under copyright, no part of this documentation may be repro- duced, stored in or introduced into a retrieval system, or transmitted in any form or by any means, or for any purpose, without the express written permission of Data- logic S.p.A.

Need help?

Do you have a question about the AREX 400 and is the answer not in the manual?

Questions and answers