Advertisement

Quick Links

Installation - Operation - Parts

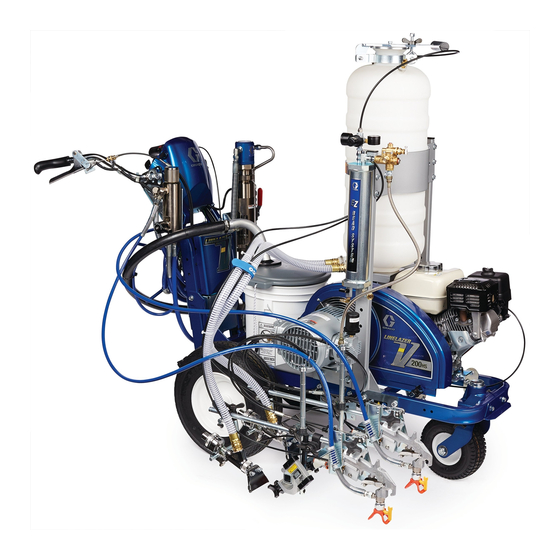

Complete Pressurized Bead System for

LineLazer 200HS/DC/MMA and LineLazer

250SPS/DC/MMA

Models:

25R268 1-Gun LL200

25R270 1-Gun LL250

25R267 2-Gun LL200

25R269 2-Gun LL250

80 psi (.55 MPa, 5.5 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in the striper manual. Be familiar

with the controls and the proper usage of the equipment. Save

these instructions.

- For professional use only -

HS/MMA

SPS/MMA

HS/DC/MMA

SPS/DC/MMA

Related Manual

Bead Gun Kit

LLIV 200HS Repair

LLV 200HS/DC Repair and Parts

LLV 200MMA Operation, Repair, Parts 3A6466

250DC Repair

332230T

EN

332226

311021

3A3390

334053

Advertisement

Need help?

Do you have a question about the LineLazer 200HS and is the answer not in the manual?

Questions and answers