Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Blastrac 500HSH

- Page 1 Operating manual 500HSH 500HSH Version 1.0 info@blastrac.eu...

-

Page 2: Ec Declaration Of Conformity

Operating manual 500HSH 2/20 EC DECLARATION OF CONFORMITY in accordance with Appendix II sub A of Directive 2006/42/EC BLASTRAC B.V. Utrechthaven 12 NL - 3433 PN NIEUWEGEIN Tel: 0031 (0)30 601 88 66 Fax: 0031 (0)30 601 83 33 Info@Blastrac.nl... -

Page 3: Table Of Contents

Operating manual 500HSH 3/20 Table of contents EC Declaration of Conformity 1. Introduction 2. Machine description 3. Safety Safety precautions Safety regulations Safety instructions 4. Initial operation Checkpoints of power supply Checkpoints of machine 5. Operating 6. Maintenance 7. Selection of abrasive 8. -

Page 4: Introduction

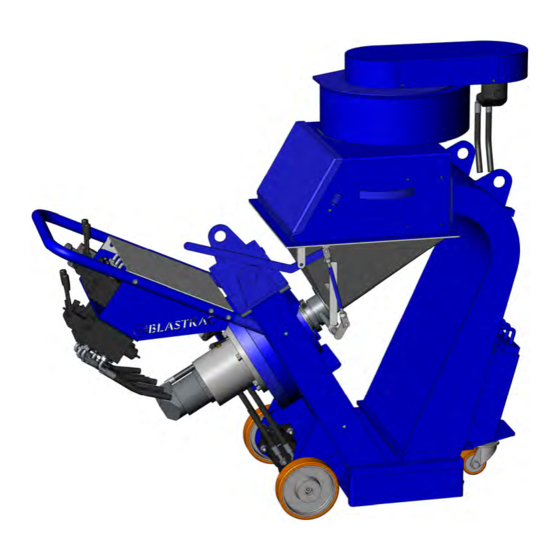

Only authorized and trained personnel may operate this machine. 2. Machine description The Blastrac blast cleaning machine 500HSH is a downward blasting machine with a closed abrasive circuit designed for the pre-treatment of horizontal surfaces. The bouncing impact of metallic abrasive onto the surface to be treated thoroughly removes surface contaminants, coats of paint, sealants and thin coatings. -

Page 5: Safety

Operating manual 500HSH 5/20 3. Safety Before operating the machine, the personnel must be familiar with the safety instructions given in this manual. Keep this manual near to the machine, so it can always be consulted. Safety precautions The surface to be treated must be swept clean to remove stones, screws etc. -

Page 6: Safety Instructions

The dust container / bag of the filter unit must be emptied regularly. Comply with the local waste treatment regulations considering the removed material. The weight of the 500HSH is 650 kg. By transport the machine with a crane or lift, use the lifting eyes of the machine. info@blastrac.eu... -

Page 7: Initial Operation

It is not permitted to use the machine if the machine safety is not according the checkpoints below. Checkpoints power supply Use the hydraulic hoses delivered by Blastrac BV. Hydraulic hoses must be fully unwind of them winches. ... -

Page 8: Operating

Operating manual 500HSH 8/20 5. Operating During operating the 500HSH, the following additional safety instructions must be followed closely. Before switch on Check the distance from brush sealing to the floor. This may be max. 1 mm. Fill the separator equally with the selected abrasive up to the bottom of the separator tray. -

Page 9: Maintenance

Store the cleaned machine in a dry room. Protect the hydraulic parts from moisture, heat dust and shocks. Remove the abrasive out of the abrasive storage hopper. All repair work has to be done by qualified Blastrac personnel, this guarantee a save and reliable machine. -

Page 10: Selection Of Abrasive

Operating manual 500HSH 10/20 7. Selection of abrasive Media nr. 2 Is often used when the surface is only subsequently sealed. creates fine profiles, e.g. on vacuum concrete and non-glazed tiles removes thin layers of rust on steel surfaces ... -

Page 11: Technical Data

(under load) Vibration level 1.23 RMS Allows >8 hrs. of working with the mentioned equipment without having to use anti vibration precaution measures. Dust hose Ø150 mm connection Design and specifications are subject to change without notice by Blastrac BV info@blastrac.eu... -

Page 12: Disassemble Procedure

Operating manual 500HSH 12/20 9. Disassemble procedure Disconnect all quick disconnect couplings and cover them with the red covers to protect the couplings against dirt. Return / Pressure Blastmotor Fan motor Right drive motor info@blastrac.eu... - Page 13 Operating manual 500HSH 13/20 Drain (fan) Pressure Return Drain Drain (blast motor) info@blastrac.eu...

- Page 14 Operating manual 500HSH 14/20 - Remove handle including hydraulic parts (M8 bolts) - Remove weights and weight bracket (M8 bolts) - Open the separator door; this give access to the nuts of the fan unit. Remove fan unit (4x M12 nut).

- Page 15 Operating manual 500HSH 15/20 - Remove the hopper (8x M8 bolts). Move the hopper out at the side of the shot valve handle. - Remove rebound (6x M8 bolt). info@blastrac.eu...

- Page 16 Operating manual 500HSH 16/20 - Remove the rebound (6x M8 bolt). Remove lute rests of the flanges. - Remove the top liner cover (8x M10 bolt). - Remove the top liner cover with a crowbar or a solid screwdriver. Remove lute rests.

- Page 17 Operating manual 500HSH 17/20 - Remove the cage - Remove the impeller bolt, M16 hexagon bolt - Remove the impellor - Through the opening of the blast housing: use a wooden or brass drift to tap out all six blades from the blast wheel towards the center of the blast wheel.

- Page 18 Operating manual 500HSH 18/20 - Mount the lifting tool bracket on the flange of the top liner cover - Put a strap on the blast wheel bearing housing and put the lifting tool on the lifting tool bracket. - Remove all bolts of the big flange what is mounted to the blast housing.

- Page 19 Operating manual 500HSH 19/20 The machine will now fit through a 24”-man hole. Before building up the machine clean the body and the blastwheel with air. Inspect the body, seals and brushes. Replace them when they are damaged or worn.

-

Page 20: Contact

Operating manual 500HSH 20/20 HEADQUARTER Blastrac BV The Netherlands Utrechthaven 12 NL - 3433 PN Nieuwegein Tel: 0031 (0)30 601 88 66 Fax: 0031 (0)30 601 83 33 info@blastrac.nl Blastrac United Kingdom Unit 2, Outgang Lane, Dinnington Sheffield, South Yorkshire GB –...

Need help?

Do you have a question about the 500HSH and is the answer not in the manual?

Questions and answers