Advertisement

Quick Links

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1-520-882-6598 Fax +1-520-882-6599 email: pace@metallographic.com

Equipment Type:

Model:

Electrical Requirements:

Frequency:

Motor Horsepower:

Manual Revision Date:

Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

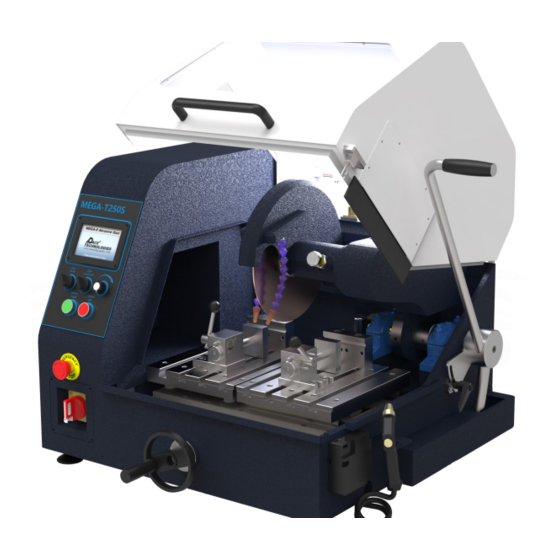

MEGA-T250S

Abrasive Cutter

250 mm (~10-inch)

Manual Abrasive Cut-off Machine

MEGA-T250S

208Y / 380 Volts (3-phase)

50/60 Hz

8.7 hp (6.5 kW/13 Nm)

(theoretical maximum) @ 380V 3-phase

March 25, 2022

I

M

NSTRUCTION

ANUAL

Web: https://www.metallographic.com

This instruction manual is

provided with each piece of

delivered equipment.

Advertisement

Summary of Contents for Pace Technologies MEGA-T250S

- Page 1 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 2 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 3 Terms and Conditions applying to all PACE Technologies Products 1. LIMITED WARRANTY AND DISCLAIMER: PACE Technologies Products are warranted for two years from the purchase date to be free from defects in material and workmanship under correct use, normal operating conditions, and proper application. PACE...

- Page 4 All Returns are subject to a restocking charge equal to 15% (fifteen percent) of the Invoice, unless the Goods are proved to be non-conformed by PACE Technologies. Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

-

Page 5: Table Of Contents

MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲... -

Page 6: Product Description

1.0 Product Description The MEGA-T250S is equipped with a powerful belt driven servo motor. In The MEGA-T250S is a manual wheel feed addition, the motor has an inductive brake or table feed abrasive cut-off machine for for faster stopping of the blade (approx. 2 cutting materials ranging from soft seconds). - Page 7 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 8 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 9 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 10 3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1-520-882-6598 Fax +1-520-882-6599 email: pace@metallographic.com Web: https://www.metallographic.com 1.3 Mechanical Schematic Note: Installation of the MEGA-T250S should be on a flat sturdy surface, with easy access to electrical connections. Please read this instruction manual carefully and follow all installation, operating and safety guidelines.

- Page 11 Measures WxHxD: Approx. 38 x 48 x 44-inch Weight: Approximately 425 lbs. 2.2 Shipping When moving crate, lift from bottom. To move MEGA-T250S use support bars provided with the machine. The MEGA-T250S is constructed of sensitive electronic and mechanical components. Do not drop.

- Page 12 3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1-520-882-6598 Fax +1-520-882-6599 email: pace@metallographic.com Web: https://www.metallographic.com 2.3 Installation Install unit carefully! Improper installation voids warranty. Main The MEGA-T250S should be placed on a flat stable surface. Power Connect coolant tank supply, drain and electrical connections.

- Page 13 Note: Inspect the operating voltage on the name plate. Electrical connection for external coolant supply: Power for recirculation system comes from the MEGA-T250S, Recommended Coolant: To minimize corrosion a coolant with a anti-corrosion additive or an oil emulsion coolant is recommended. Note: It is recommended that the coolant be changed every 50 cuts or every week, whichever occurs first.

-

Page 14: Safety Guidelines

Careful attention to this instruction manual and the recommended safety guidelines is essential for the safe operation of the MEGA-T250S. Proper operator training is required for the safe operation of the MEGA-T250S. Any unauthorized mechanical and electrical change, as well as improper operation, voids all warranty claims. - Page 15 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲ NSTRUCTION ANUAL 3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1-520-882-6598 Fax +1-520-882-6599 email: pace@metallographic.com Web: https://www.metallographic.com Recirculation tank The MEGA-T250S is equipped with a coarse filter to remove large particulate Electrical Pressure connection and broken blades...

- Page 16 3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1-520-882-6598 Fax +1-520-882-6599 email: pace@metallographic.com Web: https://www.metallographic.com 3.4 Safety Tests Examine and verify that the MEGA-T250S safety devices and operating performance are in good working condition prior to use. The following safety checks are...

-

Page 17: Start-Up And Operation

3601 E. 34th St. Tucson, AZ 85713 USA Tel. +1-520-882-6598 Fax +1-520-882-6599 email: pace@metallographic.com Web: https://www.metallographic.com 4.0 Start-up and Operation 4.1 General The MEGA-T250S is a manual wheel and manual table feed cutter. 4.2 Control Panel Information Screen Selector /... - Page 18 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 19 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 20 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 21 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 22 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

-

Page 23: Maintenance

5.0 Maintenance 5.1 Introduction The recommended maintenance for the MEGA-T250S includes the following: 1. Use an anti-corrosion cutting fluid such as the MAXCUT 2 cutting fluid. It is recommended that the cutting fluid be changed every 50 cuts or weekly for maximum effectiveness. -

Page 24: Trouble Shooting

MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲... -

Page 25: Cutting Basics

MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲... - Page 26 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 27 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

-

Page 28: Electrical Drawings

MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲... - Page 29 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...

- Page 30 MEGA-T250S Abrasive Cutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ▲...