Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Schaeffler DuraSense

- Page 1 Schaeffler DuraSense User manual...

- Page 3 It records the current running behaviour of the carriage, evaluates and visualises the data, and enables automated lubrication. With two operating modes, Schaeffler DuraSense can be used to provide lubrication in accordance with requirements and to monitor an existing central lubrication system. The system enables lubricant savings and the avoidance of unplanned machine downtimes.

-

Page 4: Table Of Contents

Download.................. 17 Service Setup Tool (SST) Start screen................17 General settings ................ 18 Commissioning Preparation ................19 Connecting setup software SST to the PPU ......... 19 Configuration ................21 Reference run ................24 Threshold values ............... 26 BA 60 Schaeffler Technologies... - Page 5 Technical data and Voltage supply................34 accessories Connection to the controller (PLC) ..........35 Connection to sensors .............. 36 Ethernet connection..............37 Fieldbus connections (Profinet IRT) ........... 38 Technical data Schaeffler DuraSense......... 39 Appendix EU Declaration of Conformity Schaeffler Technologies BA 60...

-

Page 6: About The User Manual Symbols

Unauthorised modifications to or improper use of the device are not permitted. Schaeffler accepts no liability in these cases. General safety guidelines Usage Schaeffler DuraSense may only be used to analyse and monitor Schaeffler monorail guidance systems. for the intended purpose Schaeffler DuraSense may only be used in an industrial environment. -

Page 7: Selection And Qualification Of Operating And Commissioning Personnel

Selection and qualification Schaeffler DuraSense may only be fitted and commissioned by qualified personnel. of operating and Qualified personnel: commissioning personnel ■ are authorised to fit Schaeffler DuraSense by the machine manufacturer or operator ■ have all the necessary knowledge ■... -

Page 8: Safety Regulations

If Schaeffler DuraSense is operated outside these limits, the device may be destroyed. Do not carry out repairs on a damaged Schaeffler DuraSense device. Arrange to have any necessary repairs carried out by Schaeffler. Only use Schaeffler DuraSense with the lubricants approved for this product, see page 29. - Page 9 Suitable personal protective equipment must be worn for all work. Schaeffler DuraSense must be placed in a voltage-free state before starting maintenance and repair work. If any safety devices must be removed during maintenance or repair, these must be refitted once the work is complete and their function must be checked.

-

Page 10: Scope Of Delivery

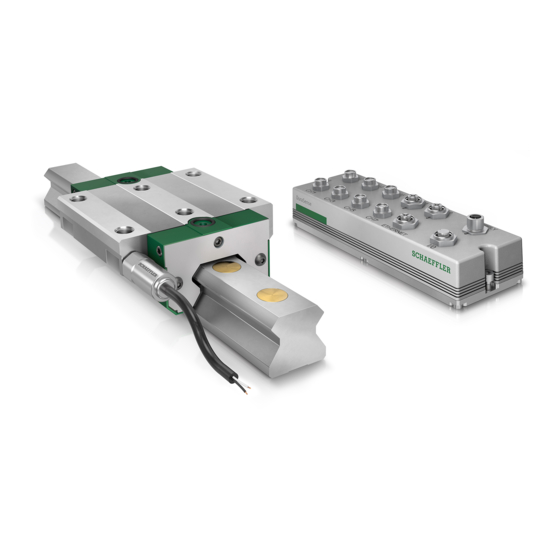

Observe the guidelines regarding the required plugs and cables, see page 34. Description Function Schaeffler DuraSense is a sensor-based system for analysing and monitoring the lubrication status of Schaeffler monorail guidance systems. The system consists of a sensor for measuring vibrations, a pre- processing unit (PPU), a carriage prepared for fitting the sensor and a guideway. - Page 11 ■ monitoring of the lubrication status and lubrication circuit, see page 11 All of the interfaces required to operate Schaeffler DuraSense are integrated in the PPU. All inputs and outputs are located on the top of the housing. The lubrication status of up to 7 carriages (CH1 to CH7) can be monitored with a PPU.

-

Page 12: Operating Modes

Lubrication appropriate to The lubrication intervals are controlled by the signals from requirements Schaeffler DuraSense. When the set threshold value is reached, the PPU sends a signal to the machine controller that can be used to initiate a relubrication impulse. - Page 13 Monitoring The lubrication intervals are stipulated by the customer, for example of the lubrication status and by means of time or distance control. Schaeffler DuraSense is used lubrication circuit for monitoring here. The system determines and outputs the current lubrication parameter (SKW).

-

Page 14: Output Signals

Schaeffler DuraSense Output signals Digital When the lubrication parameter reaches the preset threshold value, the output signal changes from 0 V to 24 V or from 24 V to 0 V, depending on the setting. Analogue The calculated lubrication parameter is output using an output signal in each case in the range from 4 mA to 20 mA. -

Page 15: Measurement Runs

The measurement runs provide the data for determining the lubrication parameter. Note For measurement runs with acceleration components, please consult Schaeffler. Storage Conditions for storing Schaeffler DuraSense: ■ storage temperature: –25 °C to +70 °C ■ store in original packaging only Schaeffler Technologies... -

Page 16: Mounting Plug And Cable

Schaeffler DuraSense Mounting Plugs and cables To connect the sensor and pre-processing unit (PPU), plugs and cables are required, which are not included in the scope of delivery: Taking account of the scope of delivery, see page 8, check which plugs and cables you require in addition to the components included in the delivery. -

Page 17: Preparing To Fit The Sensor Using A Retrofit Adapter (Optional)

Once the adhesive connection has set, a sensor can be mounted on the adapter piece. Carriage Guideway Retrofit adapter Figure 6 Carriage with retrofit adapter Schaeffler Technologies BA 60... -

Page 18: Fitting The Sensor

Schaeffler DuraSense Fitting the sensor The sensor is fitted as follows: Attach the plug to the sensor cable to connect to the PPU. Observe the information on cables and plugs, see page 34 onwards. Screw the sensor into the thread provided on the carriage or into the thread of the retrofit adapter using a tightening torque of 5 Nm. -

Page 19: Setup Software Download

Service Setup Tool (SST) commissioning and servicing. Following setup, Schaeffler DuraSense will run in normal operation without setup software SST. Download The setup software SST for Schaeffler DuraSense is available to download from Schaeffler under the following link: ■ https://www.schaeffler.de/std/1F7D Start screen After starting setup software SST, the start screen appears. -

Page 20: General Settings

Schaeffler DuraSense Components of the start screen General settings Restarting the PPU Connection status between PPU and Windows PC Main menus: – [ Overview start screen – [ Data Acquisition recording and display of measured values, e.g. for the definition of threshold values –... -

Page 21: Commissioning Preparation

IP address. Download the Service Setup Tool (SST) software from the Schaeffler homepage to the Windows PC, see page 17. Connect the Windows PC to the PPU using an Ethernet cable. For details on the Ethernet connection, see page 37. - Page 22 Schaeffler DuraSense Under [ Enter network interface ], select the Ethernet connection that is set on the Windows PC, Figure 11. Click [ Refresh List ] to view all available PPUs. Alternatively, you can also enter the IP address of the PPU manually.

-

Page 23: Configuration

Read Config from PPU ] button is used for this purpose. Once the configuration has been changed, it must be saved in the PPU. The [ Write Config to PPU ] is used for this purpose. Figure 12 Configure Schaeffler Technologies BA 60... - Page 24 Schaeffler DuraSense Device settings The settings in the [ Common Settings ] area apply to the entire PPU and affect all channels: Perform the settings required for your particular application, see table and Figure 13. Setting options under Field...

- Page 25 Device Family Monorail guidance system type Design Size Monorail guidance system size Version Monorail guidance system version Design Model Carriage design Lubrication Type ] Lubricant Variant Filter parameter set for determining the lubrication parameter (standard = 0) Schaeffler Technologies BA 60...

-

Page 26: Reference Run

Schaeffler DuraSense Figure 15 Channel Configuration (screenshot) Saving the configuration Write settings to PPU: ] button, Figure 15, Now select the [ Write Config to Device to save the selected settings on the PPU. Reference run The reference run is carried out as follows: ] tab, Figure 16. - Page 27 If it is too high, the reference run must be carried out at a slower rate. This may necessitate exceeding or falling below the recommended velocity for a reference run, see page 12. Figure 17 Result of the reference run Schaeffler Technologies BA 60...

-

Page 28: Threshold Values

Schaeffler DuraSense Threshold values The system suggests threshold values based on the results of the reference runs, Figure 17, page 25. These must be verified for each active channel and adjusted if necessary, Figure 18 and Figure 19, page 27: ... - Page 29 Transfer the suggested threshold value to the machine controller, taking note of the following recommendation. Channel selection and input fields for adjusting the threshold values Figure 19 Output Configuration for analogue output signal (screenshot) Schaeffler Technologies BA 60...

-

Page 30: Operation

Only increase the reference value following careful investigation and observe the actual lubricant consumption. Operation Schaeffler DuraSense can also be operated in the following modes: ■ lubrication appropriate to requirements, see page 10 ■ monitoring of the lubrication status and lubrication circuit,... -

Page 31: Lubrication Parameter

When operation is resumed, the lubrication parameter will return to the level reached prior to the stoppage after a short period of operation. Operating temperature The permissible operating temperature is 0 °C up to +60 °C. Schaeffler Technologies BA 60... -

Page 32: Leds On Ppu

Catalogue PF 1, Monorail guidance systems Download at: https://www.schaeffler.de/std/1F7E Permissible indirect process All indirect process materials that come into contact with Schaeffler DuraSense must first be checked for compatibility with the materials materials used with Schaeffler DuraSense, see table, page 39. BA 60... -

Page 33: Troubleshooting And Rectification

] tab, Figure 22. Select the [ Select the [ Read Log ] tab. Check the displayed error code, see table, page 32, and carry out the corrective actions listed. Figure 22 (example) Schaeffler Technologies BA 60... - Page 34 Schaeffler DuraSense Error codes Error text Error description Corrective actions Bias Voltage Bias voltage too Check sensor cable. Threshold Violation. low or too high; Check shielding (on sensor Over Voltage/ Open possible causes: cable, sensor plug and Circuit: Please check ■...

-

Page 35: Dismounting

■ is malfunctioning ■ was exposed to conditions that contravene storage or operating specifications Disposal Schaeffler DuraSense components contain electrical and electronic parts that must be properly disposed of as electrical waste. Schaeffler Technologies BA 60... -

Page 36: Technical Data And Accessories

Ensure that plugs, cables and the respective transitions are correctly shielded. Voltage supply The connector and cable for the PPU voltage supply are not included in the Schaeffler DuraSense scope of delivery. Connector Connector requirements: ■ M12, A-coded, 4 pins ■... -

Page 37: Connection To The Controller (Plc)

Connection to the controller The plug and cable for connecting the PPU and PLC are not included in the Schaeffler DuraSense scope of delivery. (PLC) Plug Plug requirements: ■ M12, A-coded, 12 pins ■ protection type IP67 ■ shielded Pin assignment... -

Page 38: Connection To Sensors

Connection to sensors The plugs for connecting the sensors to the PPU are not included in the Schaeffler DuraSense scope of delivery. Each sensor has a 2 m cable, which can be shortened or extended to a maximum length of 5 m by the customer if required. -

Page 39: Ethernet Connection

Ethernet connection The plugs and cable for the Ethernet connection between the Windows PC and PPU are not included in the Schaeffler DuraSense scope of delivery. Plug Plug requirements: ■ (for connection with PPU) M12, D-coded, 4 pins ■ protection type IP67 ■... -

Page 40: Fieldbus Connections (Profinet Irt)

Schaeffler DuraSense Fieldbus connections The plug and cable for a fieldbus connection of the PPU (version PPU.DSE07-C-A-AA) and PLC are not included in the (Profinet IRT) Schaeffler DuraSense scope of delivery. Plug Plug requirements: ■ M12, D-coded, 4 pins ■... -

Page 41: Technical Data Schaeffler Durasense

Technical data Description Value Unit Schaeffler DuraSense Storage temperature –25 to +70 °C Operating temperature 0 to +60 °C Output Analogue 4 to 20 Digital 0 to 24 Mass Sensor (incl. 2 m cable) Sensor dimensions Diameter Length Sensor cable... -

Page 42: Appendix Eu Declaration Of Conformity

Schaeffler DuraSense Appendix EU Declaration of Conformity Figure 28 EU Declaration of Conformity BA 60 Schaeffler Technologies... - Page 44 This publication supersedes all deviating infor- mation from older publications. Printing, including excerpts, is only permitted with our permission. Technical support: © Schaeffler Technologies AG & Co. KG www.schaeffler.de/en/technical-support BA 60 / 01 / en-GB / DE / 2022-04...

Need help?

Do you have a question about the DuraSense and is the answer not in the manual?

Questions and answers