Table of Contents

Advertisement

Quick Links

Thank you very much for purchasing this product.

• To ensure correct and safe usage with a full understanding of this product's performance, please be sure to read through this manual com-

pletely and store it in a safe location.

• Unauthorized copying or transferal, in whole or in part, of this manual is prohibited.

• The specifications of this product and the contents of this operation manual are subject to change without notice.

• The operation manual and the product have been prepared and tested as much as possible. If you find any misprints or errors, please

inform us.

• Roland DG Corporation assumes no responsibility for any direct or indirect loss or damage that may occur through use of this product,

regardless of any failure to perform on the part of this product.

• Roland DG Corporation assumes no responsibility for any direct or indirect loss or damage that may occur with respect to any article made

using this product.

FA02621

R1-211008

http://www.rolanddg.com/

Copyright © 2021 Roland DG Corporation

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Roland VersaSTUDIO BN-20A

- Page 1 • Roland DG Corporation assumes no responsibility for any direct or indirect loss or damage that may occur through use of this product, regardless of any failure to perform on the part of this product. • Roland DG Corporation assumes no responsibility for any direct or indirect loss or damage that may occur with respect to any article made using this product.

-

Page 2: Table Of Contents

Basic Information ...................... 6 Introduction ......................... 7 Part Names ........................7 Roland BN-20A System Configuration..................9 How to Open the BN-20 Driver's Printing Preferences Screen...............10 How to Open the Utility Window / Exit the Utility ................11 How to Open the Utility Window..................11 Starting from the Windows start menu ..................11... - Page 3 Contents Setting of Dry Time ......................53 Resetting All Adjustments to Factory Default Values ..............55 Maintenance ................... 56 Introduction ......................57 Important Notes on Handling and Use ..................58 Automatic Maintenance Function: Points to Note ..............58 Maintenance Schedule ......................58 When Not in Use for a Prolonged Period .................58 Checking Ink Levels and Replacing ....................60 Checking Ink Levels ......................60 How to Replace Ink Cartridges ....................61...

- Page 4 Contents Media Feed Problems ....................86 The Media Jams ........................87 Is the media warped or wrinkled? ..................87 Media Wrinkles or Shrinks ......................88 Is the media loaded and set up straight and securely? ..............88 Was loaded media allowed to stand for some time? ..............88 Was the media loaded while the heater was hot? ..............88 Is the temperature of room too low? ..................88 Is the humidity of the room too high? ..................88...

- Page 5 Contents [Crop mark detection could not be started.] / [Crop marks were not found. Output will be canceled.] ..........................105 [The operation has been stopped to prevent the print heads from drying out. Turn the printer off.] . 105 [Motor error] ......................

-

Page 6: The Basics

The Basics... -

Page 7: Basic Information

Basic Information Introduction ....................7 Part Names ..................7 Roland BN-20A System Configuration ............9 How to Open the BN-20 Driver's Printing Preferences Screen ........10 How to Open the Utility Window / Exit the Utility..........11 How to Open the Utility Window ..............11 Starting from the Windows start menu ............11... -

Page 8: Introduction

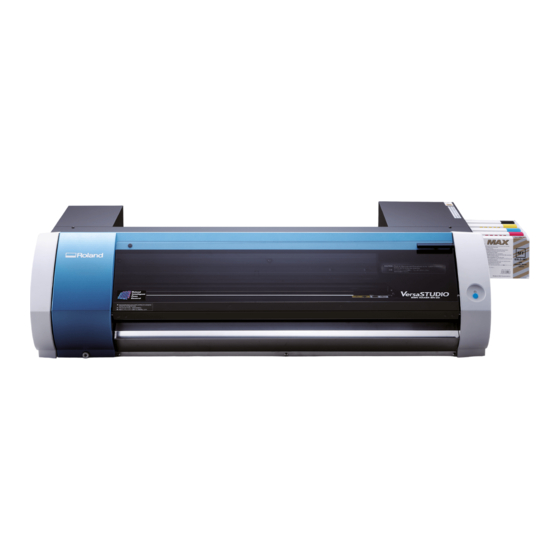

Introduction Part Names Front Name Function overview Remove when performing manual head cleaning. Maintenance cover P. 70 "Manual Cleaning" Open the cover to load media; in general use, always keep the Front cover cover closed. Print-head carriage The print heads and blade are inside this section. [POWER] key This switches the printer on and off. - Page 9 Introduction Rear Name Function overview Loading lever You operate this when you load media. USB connector Main power switch Power-cord connector Use this guide when loading media. This guide is on the "Left" Left media guide when viewing the printer from the front. Use this guide when loading media.

-

Page 10: Roland Bn-20A System Configuration

Introduction Roland BN-20A System Configuration "VersaWorks 6" is written as "VersaWorks" in this manual. System Configuration Output is available in the following combinations. • Commercial application software + BN-20 driver • Commercial application software + VersaWorks + BN-20 driver MEMO When you use VersaWorks, the BN-20 driver's Printing Preferences become invalid. -

Page 11: How To Open The Bn-20 Driver's Printing Preferences Screen

Move the mouse to the lower right corner to display Charm and click [Settings]. c. Click [Control Panel]>[View devices and printers]. Right-click the [Roland BN-20] icon, and then click Printing Preferences. The BN-20 driver's Printing Preferences screen opens. Basic Information... -

Page 12: How To Open The Utility Window / Exit The Utility

How to Open the Utility Window / Exit the Utility How to Open the Utility Window Click the Utility icon on the task tray. (Or, right-click the , and then click [View/Hide].) The Utility window is displayed. MEMO Utility is resident software Utility is “resident software”... -

Page 13: How To Start The Versaworks

How to Start the VersaWorks Windows 10 From the start menu, click [VersaWorks]>[VersaWorks]. Windows 8.1 1. Click on the [Start] screen. 2. From the [Apps] screen, click [VersaWorks]>[VersaWorks]. RELATED LINKS ・ https://downloadcenter.rolanddg.com/VersaWorks6 Basic Information... -

Page 14: How To Open The Bn-20 Driver / Versaworks Help

How to Open the BN-20 Driver / VersaWorks Help BN-20 driver Open the BN-20 driver's Printing Preferences screen, and then click [Help]. RELATED LINKS ・ P. 10 "How to Open the BN-20 Driver's Printing Preferences Screen" VersaWorks Start VersaWorks, and then click [Help]>[Show Help] from the menu. Windows 10 From the start menu, click [VersaWorks]>[VersaWorks Help]. - Page 15 How to Open the BN-20 Driver / VersaWorks Help RELATED LINKS ・ P. 12 "How to Start the VersaWorks" Basic Information...

-

Page 16: About The Media Used

• Sheet media: Any media that is not wound on to a paper tube, e.g. standard size paper sheets For both roll and sheet media, different types of paper can be selected according to the purpose. For details contact your media supplier. Media can also be purchased from the Roland DG Corp. website. RELATED LINKS ・... -

Page 17: Four Different Output Methods

Four Different Output Methods The following four output methods are available for this machine. Printing by using ink. It is also called "Printing Only" as well to distinguish from "Printing and Printing (Only) Cutting." Cutting by using cutter such as for cutting seal. It is also called "Cutting Only" as well to distin- Cutting (Only) guish from "Printing and Cutting."... -

Page 18: Basic Operations

Basic Operations Switching Power On and Off ................18 Precautions When Operating the Power Supply ..........18 Switching the Power On .................18 Switching the Power Off (Sub-power Off) ............19 About Sleep Mode (Power-Saving Mode) ............19 Printing....................20 Step 1: Loading Media ................20 Step 2: Bidirectional Adjustment .............27 Step 3: Printing Tests and Normal Cleaning ..........29 Step 4: Calibrate Sheet Feeding Amount ............31 Step 5: Starting Print Output ..............32... -

Page 19: Switching Power On And Off

Switching Power On and Off Precautions When Operating the Power Supply IMPORTANT Make sure that the main power is on at all times Never switch the main power off. Continuous power on allows the automatic maintenance function to work periodi- cally. -

Page 20: Switching The Power Off (Sub-Power Off)

Switching Power On and Off Switching the Power Off (Sub-power Off) Procedure When output is completed, press and hold down the [POWER] key for one second or more. When the [POWER] key light is off, the power is off. Push the loading lever backward. Even if you are not going to switch the power off when the machine is not in use, make sure the loading lever is moved to the rear. -

Page 21: Printing

Printing This section describes operations when printing only. Refer to "Cutting / Printing and Cutting(P. 38)" "Performing Printing and Cutting Separately(P. 46)" Step 1: Loading Media Loading roll media Procedure Move the left media guide to the left edge. Push the loading lever ( ) backward. Move the left media guide ( ) to the left. - Page 22 Printing Load the roll media onto the media bar. Install the roll media so there is no gap between it and the media flange. MEMO Place the fixed media flange at th e bottom, so that the media feeds in a clockwise direction when looking from above.

- Page 23 Printing Pass the media through the printer. Pull the media straight to keep it taut, and let it pass beneath the media clamps ( ). Not OK Do not move the pinch roller by hand. Use the media guide to move the CAUTION pinch roller.

- Page 24 Printing Close the front cover ( ). Pull the loading lever ( ) forward. Pull the loading lever forward to start initial operation. When the [POWER] key indicator changes from flashing to steady, initial operation is complete. Basic Operations...

- Page 25 Printing Loading Sheet Media Procedure Move the left media guide to the left edge. Push the loading lever ( ) backward. Move the left media guide ( ) to the left. Install the cut media. Move the media to the right, and apply it to the right media guide. Slide the left media guide and apply it to the media.

- Page 26 Printing Not OK Do not move the pinch roller by hand. Use the media guide to move CAUTION the pinch roller. Moving the pinch roller by force may result in injury. As shown in the figure, pass the media under the front cover and pull the media out the other side. Start initial operation.

- Page 27 Printing Basic Operations...

-

Page 28: Step 2: Bidirectional Adjustment

Printing Step 2: Bidirectional Adjustment Perform adjustment in the following situations. You do not need to perform adjustment in other situa- tions. Go to "Step 3: Printing Tests and Normal Cleaning(P. 29)" • When using this machine for the first time •... - Page 29 Printing VersaWorks : How to Perform Bidirectional Printing In VersaWorks, the bidirectional printing is performed when "draft" is selected in printing quality. For how to set the printing quality, see [Output Settings]>[Setting the Printing Quality] in Help of Versa- Works. Procedure Open the Utility window.

-

Page 30: Step 3: Printing Tests And Normal Cleaning

Printing Step 3: Printing Tests and Normal Cleaning Procedure Open the Utility window. P. 11 "How to Open the Utility Window / Exit the Utility" Click [Check Nozzle Condition]. Click [Test Print]. The test pattern is printed. Follow the on-screen instructions and check for dot drop-out. •... - Page 31 Printing To check for nozzle clogging again If the nozzle clogging is not fixed, perform [Normal Cleaning] again. For information about [Medium Cleaning] and [Powerful Cleaning], refer to the following topic. RELATED LINKS ・ P. 68 "Medium and Powerful Cleaning" Basic Operations...

-

Page 32: Step 4: Calibrate Sheet Feeding Amount

Printing Step 4: Calibrate Sheet Feeding Amount Procedure Open the Utility window. P. 11 "How to Open the Utility Window / Exit the Utility" Click [Calibrate Sheet Feeding]. Click [Test Print]. The test pattern is printed. Read the on-screen instructions and then enter a value in the [New Value] box. Click [Apply]. -

Page 33: Step 5: Starting Print Output

Printing Step 5: Starting Print Output Procedure Prepare the print data. Output the print data. • When outputting from commercial application software for creating drawings Refer to the documentation supplied with your application software. • When outputting from VersaWorks Refer to the [VersaWorks Help]>[Basic Operations for Output]. Cut the media when outputting is complete. -

Page 34: About The Output-Start Location

About the Output-Start Location The output-start location is always the point shown in the figure below. Print area Right pinch roller Print start position Blade protector 1.4 mm 5 mm Basic Operations... -

Page 35: Stopping Print Output

Stopping Print Output To stop output on the printer side Procedure Press and hold down the [POWER] key for one second or more during output. Output stops. You cannot resume output from the stop point. Press the [POWER] key to turn the machine on. This operation does not cancel standby output data on the computer. - Page 36 Stopping Print Output Click [Printers]>[Cancel All Documents]. Depending on the computer data transfer status, it may be too late to cancel output. In this case, you need to cancel output from the printer. Basic Operations...

-

Page 37: Fully Utilizing The Machine

Fully Utilizing the Machine... -

Page 38: Optimizing The Output Quality

Optimizing the Output Quali- Cutting / Printing and Cutting ................38 Adjusting cutting .................38 Accurately Adjusting the Cutting-in Amount..........40 Adjusting printing and cutting ..............41 Creating Data for Cutting / Printing and Cutting..........42 Cautionary note on making output with cutting ..........45 Performing Printing and Cutting Separately ............46 To Perform Printing and Cutting Separately..........46 Media Sizes Allowing Automatic Crop Mark Detection........46 Printing with Crop Marks ................47... -

Page 39: Cutting / Printing And Cutting

Cutting / Printing and Cutting Adjusting cutting Adjust the cutting conditions to obtain beautiful razor sharp cut lines. Making adjustments to suit the media thickness. Procedure Load the media to be cut. P. 20 "Step 1: Loading Media" Open the Utility window. P. - Page 40 Cutting / Printing and Cutting [Cut Times] The number of times to cut the same location. If it is impossible to cut even if you adjust the cut force and cut speed, increase the cut times. (Default setting: 1) Check item Result Setting item Adjustment...

-

Page 41: Accurately Adjusting The Cutting-In Amount

Cutting / Printing and Cutting Accurately Adjusting the Cutting-in Amount When you want to perform accurate and fine adjustment of the cutting-in amount ( ), such as when cutting media with thin backing paper, you can obtain good results by adjusting the tip of the blade. Turn the cap portion of the blade holder to adjust the amount of blade extension. -

Page 42: Adjusting Printing And Cutting

Cutting / Printing and Cutting Adjusting printing and cutting When printing and cutting at the same time, adjust and align the printing and cutting positions. De- pending on the media thickness, sometimes printing and cutting positions are very slightly out of align- ment. -

Page 43: Creating Data For Cutting / Printing And Cutting

Cutting / Printing and Cutting Creating Data for Cutting / Printing and Cutting When using VersaWorks, refer to the [VersaWorks Help]. When using application software to create drawings Verified application software • Adobe Illustrator : after CS6 • CorelDRAW : after X3 1. - Page 44 Cutting / Printing and Cutting Enter values for [Red], [Green], and [Blue]. The BN-20 driver identifies the color specified using the values entered here as the cutting line, and outputs the color. Optimizing the Output Quality...

- Page 45 Cutting / Printing and Cutting 2. Creating print data Procedure Create the print data using application software for creating drawings. MEMO Set the Document Color Mode to [RGB]. The color (RGB value) specified as the cutting line may change be- cause CMYK is converted to RGB when outputting in CMYK mode.

-

Page 46: Cautionary Note On Making Output With Cutting

Cutting / Printing and Cutting Cautionary note on making output with cutting Points to Note when Cutting Only For roll media, let the media hang down to the rear before outputting. When using the roll media and only performing cutting, let the media hang down to the rear of the machine. -

Page 47: Performing Printing And Cutting Separately

Performing Printing and Cutting Separately To Perform Printing and Cutting Separately You can remove the printed media and then reload it and perform cutting. (Example: Perform lamination or other processing after printing, then reload the media and perform cutting.) Then, carry out alignment to prevent misalignment of the printing results and the cut lines. Perform this adjustment in the next Procedure. -

Page 48: Printing With Crop Marks

Performing Printing and Cutting Separately Printing with Crop Marks This section describes how to specify settings when using the BN-20 driver. When using VersaWorks, re- fer to the [VersaWorks Help]. Procedure Display the BN-20 driver's Printing Preferences screen. P. 10 "How to Open the BN-20 Driver's Printing Preferences Screen" Select [CropMark] on the [Printer Adjustment] tab. - Page 49 Performing Printing and Cutting Separately : Align point Ⓑ : Base point IMPORTANT Alignment marks and symbols drawn using a graphics program cannot be used as crop marks. Optimizing the Output Quality...

-

Page 50: Aligning Automatically And Cutting

Performing Printing and Cutting Separately Aligning Automatically and Cutting This section describes how to make settings when using the BN-20 driver. When using VersaWorks, refer to the [VersaWorks Help]. Procedure Print with a crop mark, and then reload the media that was removed. Points for Media Setting Place the crop marks ( ) on the blade protector ( ). - Page 51 Performing Printing and Cutting Separately IMPORTANT Before you start cutting, check that media size in the [Settings] tab of Printing Preferences Screen is the same as the size used for printing. When you perform cutting, set the same media size as the printing. If not, misalignment between the printing results and the cut lines might occur.

-

Page 52: Crop Cut Adjustment

Performing Printing and Cutting Separately Crop Cut Adjustment Depending on the composition of the media, the positioning of printing and cutting may be misaligned even when you're using crop marks. Make corrections for misaligned printing and cutting for the media you're using. -

Page 53: Utility : Other Function

Utility : Other Function Performing Various Adjustments Through a Sequence of Operations You can perform various output adjustments through a sequence of operations by clicking [Adjust All] on the [Adjustment] tab. The adjustment method is the same as when adjusting settings individually. When you click [Adjust All], adjustment information is displayed. -

Page 54: Setting Of Dry Time

Move the mouse to the lower right corner to display Charm and click [Settings]. c. Click [Control Panel]>[View devices and printers]. Right-click the [Roland BN-20] icon, and then click [Printing preferences]. The BN-20 driver’s Printing preferences screen opens. Set the drying time. - Page 55 Utility : Other Function When you make output from VersaWorks You can set the dry time in VersaWorks as well. For information on its setting method, refer to [Versa- Works Help]. IMPORTANT When you set the dry time in VersaWorks, if [Use Printer Settings] is set, 0 is set to the dry time. You should note that the setting in the BN-20 driver is not reflected.

-

Page 56: Resetting All Adjustments To Factory Default Values

Utility : Other Function Resetting All Adjustments to Factory Default Values Click [Factory Reset] in the [Option] tab of Utilities, and you can reset all the settings in utilities to the initial settings. Click [Factory Reset], and the message shown in the figure is displayed. Click [Yes] to reset the set- tings. -

Page 57: Maintenance

Maintenance... -

Page 58: Introduction

Introduction Important Notes on Handling and Use...............58 Automatic Maintenance Function: Points to Note...........58 Maintenance Schedule................58 When Not in Use for a Prolonged Period............58 Checking Ink Levels and Replacing..............60 Checking Ink Levels ................60 How to Replace Ink Cartridges ..............61 Introduction... -

Page 59: Important Notes On Handling And Use

If you know that you will not use the machine for a prolonged period, follow the procedure below to replace the drain cartridge. For information about purchasing drain cartridges, contact your author- ized Roland DG Corp. dealer. IMPORTANT Do not reuse drain cartridges. Doing so makes it impossible to manage the amount of discharged fluid, which may overflow. - Page 60 Important Notes on Handling and Use RELATED LINKS ・ P. 64 "Replacing the Waste Cartridge" Introduction...

-

Page 61: Checking Ink Levels And Replacing

Checking Ink Levels and Replacing Checking Ink Levels Ink levels can be checked in the Ink tab of the Utility window. A simple bar scale indicates the level of ink in each cartridge. Percentage values also indicate the level of ink remaining. When the cartridge is removed, [No Cartridge] is displayed. -

Page 62: How To Replace Ink Cartridges

Checking Ink Levels and Replacing How to Replace Ink Cartridges When ink runs out, a warning beep is heard and printing is temporarily suspended. Pull out the empty cartridge and insert a new one. Then printing resumes. The precipitation of the ingredients in the ink disables printing in normal color. So that the ink mixes well, shake each ink cartridge 50 times (about 20 seconds) horizontally with a stroke length of around 5 cm (1.97 in.) from each end of the ink cartridge before inserting it. -

Page 63: Regular Maintenance

Regular Maintenance Daily Maintenance ..................63 Maintenance of Ink Cartridges ..............63 Cleaning ...................63 Replacing the Waste Cartridge ..............64 Care and Maintenance of the Print Heads ............66 Periodical Cleaning Maintenance..............67 About Periodical Cleaning Menus ..............67 Medium and Powerful Cleaning ..............68 Manual Cleaning ..................70 When Manual Cleaning Is Necessary ............70 Manual Cleaning Method ................71 Regular Maintenance... -

Page 64: Daily Maintenance

Daily Maintenance Maintenance of Ink Cartridges The ink ingredients have a tendency to separate and settle. Allowing the ink to stand can cause the settled material to harden, resulting in malfunction or other problems. So that the ink mixes well, periodically shake each ink cartridge 50 times (about 20 seconds) horizon- tally with a stroke length of around 5 cm (1.97 in.) from each end of the ink cartridge before reinsert- ing it. -

Page 65: Replacing The Waste Cartridge

Daily Maintenance Replacing the Waste Cartridge When the waste cartridge is filled with waste fluid, the Utility window automatically opens and dis- plays a message in the Status column that prompts the replacement of the cartridge. Follow the mes- sage's instructions and prepare a replacement waste cartridge or replace the cartridge. Remove the waste cartridge after the message appears in the Utility window. - Page 66 Never attempt to incinerate discharged fluid or discard it with ordinary trash. Also, do not dispose of it in sewer systems, rivers, or streams. Doing so may have an adverse impact on the environment. To purchase a waste cartridge, contact your authorized dealer or Roland DG. Regular Maintenance...

-

Page 67: Care And Maintenance Of The Print Heads

P. 67 "Periodical Cleaning Maintenance" * Print heads are consumable parts and subject to wear. Depending on the frequency of use, periodical replacement is required. Please order them directly from us or your authorized Roland DG Corp. deal- Regular Maintenance... -

Page 68: Periodical Cleaning Maintenance

Periodical Cleaning Maintenance About Periodical Cleaning Menus There are four levels of cleaning for this machine. Perform the appropriate level of cleaning in accord- ance with the ink type, the cleaning period, and the machine condition. When using ECO-SOL MAX/ECO-SOL MAX 2 ink Carry out a printing test. -

Page 69: Medium And Powerful Cleaning

Periodical Cleaning Maintenance Medium and Powerful Cleaning If dot drop-out is still found after Normal Cleaning, carry out the more powerful [Medium Cleaning] 2 or 3 times. If the condition is still not improved, carry out the even stronger [Powerful Cleaning] MEMO Each level of cleaning consumes more ink than the previous level. - Page 70 Periodical Cleaning Maintenance • Nozzle is clogged -> Proceed to Procedure 5 • Nozzle is not clogged -> Click [Close] to finish Select [Medium Cleaning] and click [Go]. Medium cleaning starts. To check for nozzle clogging again. If the nozzle condition is not fixed by [Medium Cleaning], perform [Powerful Cleaning]. MEMO If after several times of Powerful Cleaning, nozzle clogging is still found, perform [Manual Cleaning].

-

Page 71: Manual Cleaning

Roland DG Corp. dealer. • Print heads are consumable parts. Depending on the frequency of use, periodical replacement is required. Please order them directly from us or your authorized Roland DG Corp. dealer. RELATED LINKS ・ P. 74 "Replacing the Wiper"... -

Page 72: Manual Cleaning Method

• Only use the included cleaning sticks. Any other tool, e.g. cotton bud or similar is not designed for this task and will become fluffy and damage the heads. Please order cleaning sticks directly from us or your authorized Roland DG Corp. - Page 73 Manual Cleaning Carry out test printing and check the result. Use the cleaning functions and perform cleaning several times if needed. RELATED LINKS ・ P. 29 "Printing Tests and Normal Cleaning" Regular Maintenance...

-

Page 74: Replacing Consumable Parts

Replacing Consumable Parts Replacing Parts for Maintenance ..............74 Replacing the Wiper ................74 Replacing the Felt Wiper................75 Replacing the Cutter Blade ..............76 Replacing Consumable Parts... -

Page 75: Replacing Parts For Maintenance

To purchase a wiper, contact us directly or your authorized Roland DG Corp. dealer. When the warning alarm sounds during replacing the wiper An alarm sounds about 30 minutes after the start of the operation. -

Page 76: Replacing The Felt Wiper

Utility icon on the computer task tray, it is time to replace the wiper with a new one. To purchase a felt wiper, contact us directly or your authorized Roland DG Corp. dealer. When the warning alarm sounds during replacing the felt wiper An alarm sounds about 30 minutes after the start of the operation. -

Page 77: Replacing The Cutter Blade

Replacing Parts for Maintenance Replacing the Cutter Blade When the cutter blade is blunt, the edge is chipped, or the cutting quality has deteriorated, replace with a new cutter blade. Be sure to perform operations as specified by the instructions, and never touch WARNING any area not specified in the instructions. - Page 78 Replacing Parts for Maintenance Replace the blade. Press the pin (A). Remove the old blade (B). Install a new blade (C). Support the screw from below and insert the blade holder. Failure to do this may adversely affect the cutting quality. Firmly tighten the screw.

- Page 79 Replacing Parts for Maintenance Make adjustments for cutting. RELATED LINKS ・ P. 38 "Adjusting cutting" Replacing Consumable Parts...

-

Page 80: Troubleshooting Methods

Troubleshooting Methods. -

Page 81: Output Quality Problems

Output Quality Problems Printed results are coarse or contain horizontal stripes..........81 Do the print heads show nozzle clogging? ............81 Have you carried out[Calibrate Sheet Feeding] ? ..........81 Have you carried out [Bidirectional adjustment] ? ........81 Is the temperature of the room too low?.............81 Is the printer installed in a level and stable location? ........81 Is the printer installed in a location out of direct sunlight? .......81 Is the media loaded and set up correctly? ...........81... -

Page 82: Printed Results Are Coarse Or Contain Horizontal Stripes

Printed results are coarse or contain horizontal stripes Do the print heads show nozzle clogging? Carry out a printing test and make sure no nozzle clogging occurs. If nozzle clogging is present, per- form head cleaning. RELATED LINKS ・ P. 29 "Printing Tests and Normal Cleaning" ・... -

Page 83: Colors Are Unstable Or Uneven

Colors are unstable or uneven Did you shake the ink cartridges gently before installing them? Shake new cartridges gently before you install them. So that the ink mixes well, periodically shake each ink cartridge 50 times (about 20 seconds) horizontally with a stroke length of around 5 cm (1.97 in.) from each end of the ink cartridge before reinserting it. -

Page 84: The Media Becomes Soiled When Printed

The media becomes soiled when printed Are the print heads dirty? The following may cause ink to drip on the media during printing. • Buildup of fibrous dust (lint) around the heads. • Ink transferred to the heads due to rubbing against the media. If this happens, perform manual head cleaning. -

Page 85: Cutting Is Misaligned Or Skewed

Cutting is misaligned or skewed Is the media loaded and set up correctly? If the media is not loaded and set up correctly, or media feed is not smooth, cutting may be adversely affected. Make sure the media is loaded and set up correctly. RELATED LINKS ・... -

Page 86: The Printed Surface Is Damaged When Cutting

The printed surface is damaged when cutting Does the tip of the blade holder cap scrap the printed surface? The tip of the blade holder cap may scrape, and soil or damage the printed surface. If this happens, increase the amount of blade extension. RELATED LINKS ・... -

Page 87: Media Feed Problems

Media Feed Problems The Media Jams..................87 Is the media warped or wrinkled? .............87 Media Wrinkles or Shrinks ................88 Is the media loaded and set up straight and securely? ........88 Was loaded media allowed to stand for some time?........88 Was the media loaded while the heater was hot?...........88 Is the temperature of room too low?............88 Is the humidity of the room too high?............88 Is the using media deflected? ..............88... -

Page 88: The Media Jams

The Media Jams If an error message is displayed because the media has jammed, immediately correct the problem. Failure to do so may damage the print heads. RELATED LINKS ・ P. 105 "Error Messages" Is the media warped or wrinkled? Many factors can cause warping or wrinkling. -

Page 89: Media Wrinkles Or Shrinks

Media Wrinkles or Shrinks Is the media loaded and set up straight and securely? Feed is not smooth when the media is not straight or is tensioned unevenly on the left and right. Re- load the media. RELATED LINKS ・ P. 20 "Loading Media" Was loaded media allowed to stand for some time? Media may shrink or wrinkle if it is heated for an extended time. -

Page 90: Media Feed Is Not Straight

Media Feed Is Not Straight Is the media loaded and set up straight and securely? Feed is not smooth when the media is not straight or is tensioned unevenly on the left and right. Re- load the media. RELATED LINKS ・... -

Page 91: Media Feed Is Not Smooth

Media Feed Is Not Smooth Do the media strike some other object? Make sure the media do not touch anything else. This may affect output, even when feed appears to be smoothly. RELATED LINKS ・ P. 20 "Loading Media" Is the media too thick? Media that is too thick may not only cause unstable feed, but may scrape the print heads, resulting in malfunction. -

Page 92: Machine Problems

Machine Problems The Print Heads Stop Moving................92 What to Do First ..................92 If the print-head carriage move to the standby ..........92 The Printer Unit Doesn't Run................94 Is the power switched on? ..............94 Does the [POWER] key stay steadily lighted? ..........94 Is the [POWER] key flashing? ..............94 Is the cover open? ................94 Has ink run out? ..................94... -

Page 93: The Print Heads Stop Moving

If the print-head carriage move to the standby If the heads still do not move after "What to Do First" is performed, carry out the following emergency response measure, then contact your authorized Roland DG Corp. dealer. Procedure Switch off the main power and open the front cover. - Page 94 The Print Heads Stop Moving Gently apply pressure from the right side to make sure the print heads don't move to the left. If the print heads move to the left, again move them slowly by applying pressure from the left side and make sure they lock in place.

-

Page 95: The Printer Unit Doesn't Run

The Printer Unit Doesn't Run Is the power switched on? Switch on the printer's main power, then press the [POWER] key and make sure the key lights up. Does the [POWER] key stay steadily lighted? Output is not performed when [POWER] key does not stay steadily lighted. After the media is loaded, pull the loading lever. -

Page 96: Are Two Or More Machines Connected To A Single Computer

The Printer Unit Doesn't Run Are two or more machines connected to a single computer? The utility cannot control more than one machine at the same time. Never connect two or more in- stances of this machine to a single computer. Is the temperature of the room too low? This machine does not complete startup until the heater reaches the specified temperature, and does not accept any operation. -

Page 97: Driver Problems

Driver Problems Installation is impossible ................97 Windows 10 ..................97 Windows 8.1 ..................97 Uninstalling the Driver.................99 Windows 10 ..................99 Windows 8.1 ..................99 Driver Problems... -

Page 98: Installation Is Impossible

Installation is impossible If installation quits partway through, or if the wizard does not appear when you make the connection with a USB cable, take action as follows. Windows 10 Procedure If the [Found New Hardware] appears, click [Cancel] to close it. Right-click the Start menu, and then click [Device Manager]. - Page 99 Installation is impossible Install the driver again according to "Preparation Before Use.” Driver Problems...

-

Page 100: Uninstalling The Driver

Uninstalling the Driver When uninstalling the driver, perform following operation. IMPORTANT If the driver is uninstalled without following the procedure given below, there is a possibility that it might not be able to be re-installed. Windows 10 Procedure Before you start uninstallation of the driver, unplug the USB cables from your computer. Log on to Windows as “Administrator”... -

Page 101: Important Notes When Performing Output From General Application

Important Notes When Per- forming Output from General Application Important Notes When Performing Output from Adobe Illustrator ......101 Important Notes When Performing Output from CorelDRAW ........102 Important Notes When Performing Output from General Application... -

Page 102: Important Notes When Performing Output From Adobe Illustrator

Important Notes When Performing Output from Adobe Illustrator MEMO These are cautionary notes on making output from Adobe Illustrator using the BN-20 driver. They are not applied when VersaWorks is used. When you want to print in metallic color and when you want to perform cutting, clear the [Print As Bitmap] checkbox in the [Print] dialog box. -

Page 103: Important Notes When Performing Output From Coreldraw

Important Notes When Performing Output from CorelDRAW MEMO These are cautionary notes on making output from CorelDRAW using the BN-20 driver. They are not applied when VersaWorks is used. Set the document's color mode to [RGB]. If you select CMYK mode, the CMYK values will be converted to RGB values when the output is generated.In this case, it may not be possible to perform cutting because the color specified for the driver as the cutting line and the color output from CorelDRAW differ. -

Page 104: Handling Messages And Error Messages

Handling Messages and Error Messages Messages ....................104 [XX ink : Shake the cartridge well] ............104 [The Waste cartridge is full.] ............... 104 [Replace the wiper.] ................104 [Replace the felt wiper.]..............104 [The connection to the printer has been released.] ........104 [Clean the printer manually.] ............... -

Page 105: Messages

Messages These are the main messages that appear in the Utility window to prompt correct operation. They do not indicate any error. There are other messages that appear in the Utility window. Follow the dis- played prompts and take action accordingly. [XX ink : Shake the cartridge well] Remove the ink cartridge that is indicated in *** and shake it well. -

Page 106: Error Messages

If the troubleshooting information dis- played in the Utility window or action described here does not correct the problem, or if an error mes- sage not described here appears, contact your authorized Roland DG Corp. dealer. [The pinch roller position is incorrect.] The media size is not acceptable for this machine, and thus the position of the pinch roller is not cor- rect. -

Page 107: [Waste Cartridge Is Estimated To Be Full]

Error Messages Operation cannot be continued. By following the messages displayed in the Utility window, remove the media, close the front cover, and then hold down the [POWER] key to switch the sub power off. This error may be caused by such factors as an incorrect loading of the media, a media jam, or an opera- tion that pulls the media with excessive force. -

Page 108: [No Sheet Is Present.]

Error Messages [No sheet is present.] Output is attempted but it fails because no media is present. Set up the media. [Printing cannot continue because the end of the sheet was detected. Print- ing will be canceled.] Printing is stopped because the trailing edge of the media is detected. When the trailing edge of the media is detected, output is cancelled. -

Page 109: Appendix

Appendix... -

Page 110: Operations When Moving The Unit

Operations When Moving the Unit Preparing to Move the Machine..............110 Procedures from Preparing to Move Through Reinstalling........111 Operations When Moving the Unit... -

Page 111: Preparing To Move The Machine

What is needed One piece of unused cleaning cartridge for AQUEOUS PIGMENT ink Three pieces of dummy cartridges Contact your authorized Roland DG Corp. dealer with regard to items that need to be purchased sepa- rately. IMPORTANT Make sure to use a cleaning cartridge corresponding to ink type. -

Page 112: Procedures From Preparing To Move Through Reinstalling

Procedures from Preparing to Move Through Re- installing Procedure Open the Utility window. P. 11 "How to Open the Utility Window / Exit the Utility" In the [Option] tab, click [Head Wash]. Carry forward the work by following the instructions displayed on the screen. Do not switch off power during operation until the work is completed. -

Page 113: Main Specifications

Main Specifications Printing Area ..................113 Maximum Area .................. 113 Maximum Area When Using Crop Marks ............. 114 About the Blade..................115 Dimensional Drawing ................. 116 Specifications ..................117 Main Specifications... -

Page 114: Printing Area

Printing Area Maximum Area The printing or cutting area along the horizontal plane (the direction in which the carriages move) is determined by the position of the pinch rollers. Printing or cutting area Left side pinch roller Left side pinch roller Printing or cutting coordinates origin Max. -

Page 115: Maximum Area When Using Crop Marks

Printing Area Maximum Area When Using Crop Marks Printing or cutting area Maximum area Crop mark 12.5 mm (0.49 in.) 10 mm (0.39 in.) Main Specifications... -

Page 116: About The Blade

About the Blade The cutting conditions and the service life of the blade change according to the media and the operat- ing environment, even when you're using identical blades. The service life also differs according to the type of blade. A rough guide is shown below. Blade Media Blade force... -

Page 117: Dimensional Drawing

Dimensional Drawing Unit: mm Main Specifications... -

Page 118: Specifications

Colors Four colors (cyan, magenta, yellow, and black) Printing resolution (dots per inch) Maximum 1,440 dpi Cutting blade Type Roland CAMM-1 series compatible Blade offset 0.25 mm (9 mil) Cutting speed 1 to 15 cm/s Blade force 30 to 300 gf Software resolution (when cutting) 0.025 mm/step... - Page 119 • 487 to 515 mm (19.2 to 20.3 inch) The length of printing or cutting is subject to the limitations of the program. • Media type: Media specified by Roland DG Corp. • Temperature: 25 °C (77 °F), humidity: 50% •...

Need help?

Do you have a question about the VersaSTUDIO BN-20A and is the answer not in the manual?

Questions and answers