Summary of Contents for AUTOLIFT ONDA OB Series

- Page 1 LIFT ONDA DEVICE ONDA OB Series ONDA OW Series ONDA OS Series MODELS ORIGINAL INSTRUCTIONS REVISION 2020 YEAR...

-

Page 2: Table Of Contents

Lift DEVICE GENERAL WARNINGS ONDA MODEL GENERAL WARNINGS ..........................3 MANUFACTURER............................3 MARKING ..............................3 IDENTIFICATION OF OPERATORS ......................4 STRUCTURE AND USE OF THE MANUAL ....................5 ATTACHMENTS LIST ..........................6 SAFETY – GENERAL RULES ........................7 GENERAL DESCRIPTION ........................9 COMPONENTS ............................ -

Page 3: General Warnings

DEVICE GENERAL WARNINGS ONDA MODEL MANUFACTURER AUTOLIFT SRL Via Trentin8 – 46020 Pegognaga (MN) - Italy Tel. +39 0376 550375 – info@autoliftsrl.com MARKING The lift device is manufactured in compliance with the relevant EC directives applicable on the date of entering the market. -

Page 4: Identification Of Operators

This applies also to any tampering or modifications by the operator of parts or components of the lift which no longer guarantee its safety and reliability for the transported persons. Autolift Srl declines all liability in the event of such situations. -

Page 5: Structure And Use Of The Manual

Before performing any operations on the lift, users and operators must carefully read the instructions given in this publication. In the event of doubt over the correct interpretation of the instructions, contact the AUTOLIFT srl technical department to obtain the required clarifications. -

Page 6: Attachments List

Lift DEVICE GENERAL WARNINGS ONDA MODEL THE INDICATIONS MARKED BY THIS SYMBOL REPRESENT A POTENTIAL HAZARD, WITH THE RISK OF PHYSICAL DANGER FOR THE USERS. THE INDICATIONS MARKED BY THIS SYMBOL ARE DEEMED PARTICULARLY IMPORTANT FOR THE OPERATION OF THE LIFT. THE INDICATIONS MARKED WITH THIS SYMBOL ARE IMPORTANT FOR COMMUNICATION BETWEEN THE MANUFACTURER AND THE USER. -

Page 7: Safety - General Rules

Examine the hydraulic lift carefully before each use. If there are any hazardous conditions or if you notice unusual noises or movements, do not use the lift and contact an Autolift agent or authorised workshop for the necessary inspections and repairs. - Page 8 Unauthorised persons must not stand nearby during the use of the lift, and must not stand between the vehicle and the platform, even for quick checks with the platform at a standstill. These checks and adjustments must be performed exclusively by authorised Autolift staff.

-

Page 9: General Description

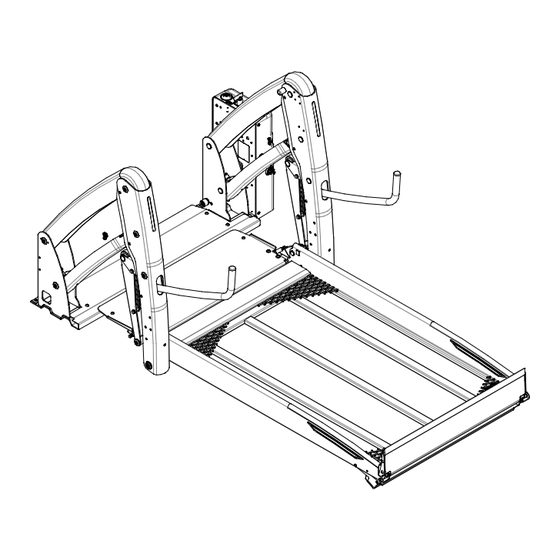

Lift DEVICE GENERAL DESCRIPTION ONDA MODEL COMPONENTS Vehicle fixing base Roll stop plate Lifting arms Handrails Hydraulic power unit Bridge plate Drive cylinders Safety microswitch and cam Platform Emergency devices The drawing shown represents all models: OB – OW - OS... -

Page 10: Dimensions

Lift DEVICE GENERAL DESCRIPTION ONDA MODEL DIMENSIONS... - Page 11 Lift DEVICE GENERAL DESCRIPTION ONDA MODEL...

- Page 12 Lift DEVICE GENERAL DESCRIPTION ONDA MODEL...

-

Page 13: Technical Data

Lift DEVICE GENERAL DESCRIPTION ONDA MODEL TECHNICAL DATA CARATTERISTICA OB 1350 OB 1402 Capacity Weight Power supply Volt 12/24 12/24 Max. pressure Platform 810x1350 910x1400 Max. overhang Aux emergency pump Airborne noise dB(A) < 70 < 70 CARATTERISTICA OW 1060 OW 1100 OW 1320 Capacity... -

Page 14: Field Of Use

Lift DEVICE FIELD OF USE ONDA MODEL INTENDED USE The lift is designed for installation on the loading floor of a vehicle designed for transportation of the disabled in wheelchairs, within the limits of the performances and capacities indicated in the technical characteristics. -

Page 15: Safety Devices

Lift DEVICE SAFETY DEVICES ONDA MODEL Handrail Bridge plate Roll stop plate Hydraulic power unit safety devices: a) Overload limit valve b) Anti-tipping pressure switch IT IS FORBIDDEN TO ELIMINATE, REMOVE OR TAMPER WITH THE EXISTING SAFETY SYSTEMS. The anti-tipping pressure switch prevents the platform from closing when occupied by a wheelchair. -

Page 16: Warning Signs

Lift DEVICE WARNING SIGNS ONDA MODEL THE LIFT HAS THE FOLLOWING MARKINGS Do not lubricate, clean or adjust the device while moving Do not remove the guards Risk of crushing Capacity, on three sides (only for Bsi PAS 12) IT IS FORBIDDEN TO TAMPER WITH/REMOVE THE MARKINGS. -

Page 17: Installation

Lift DEVICE INSTALLATION ONDA MODEL RECEIPT AND INSPECTION On receipt of the lift, you must perform the following inspections: Check that the supply corresponds to the specifications ordered and the transport document. Check that the packaging is intact and that no parts have been broken or damaged during transportation. -

Page 18: Transport

Lift DEVICE INSTALLATION ONDA MODEL TRANSPORT The lift must be transported using a vehicle (van, lorry, etc.) of an appropriate size and capacity. The lift is shipped by the manufacturer packaged in a cardboard box or wooden crate anchored to a wooden pallet. -

Page 19: Handling

Lift DEVICE INSTALLATION ONDA MODEL HANDLING The packaged lift must be handled by a transpallet, fork lift truck, etc. The means used for safe handling must have a load capacity suited to the load to be transported (see weight indicated in the Technical Data table). HANDLING STAFF MUST WEAR: SAFETY SHOES WITH STEEL TOE CAP AND NON-SLIP SOLES. -

Page 20: Installation On A Vehicle

Installation on a vehicle must be performed exclusively by Autolift staff or authorised installers. Autolift declines all liability to damage to persons, property or the machine due to installation on a vehicle not performed by authorised persons. Installation of the Lift Please remove the packaging film when the lift is still on the pallet. - Page 21 Lift DEVICE INSTALLATION ONDA MODEL Mark the position of the fixing bolts and move the lift forward inside the vehicle Make the holes in the floor for the bolts Please move the lift to its fixing position and complete the mechalical installation BEWARE Make sure that the fixing bolts don’t interfere with floor supports, suspensions supports or other important parts of the vehicle.

- Page 22 Together with the bolts please use nuts in nylon or nuts with suitable locking BEWARE Make sure that the fixing bolts don’t interfere with floor supports, suspensions supports or other important parts of the vehicle. Autolift is not responsible for an incorrect installation...

-

Page 23: Electric Installation

Lift DEVICE INSTALLATION ONDA MODEL ELECTRIC INSTALLATION Power wire Connect the power wire,(RED) from the power supply to the Plus pole (+) of the battery Connect a ground wire (BLACK) from the power supply to the minus pole (-) of the battery. The plus wire (RED)should be protected through a protective sheath (not supplied) and fixed to the vehicle through clamps. -

Page 24: Use

MODEL NORMAL USE The AUTOLIFT SKY electro-hydraulic lift control has a wired portable remote control, equipped with two push buttons indicating the two operating states. The fundamental purpose of the push-button panel is to control the four distinct lift operations (open - down - up - close) in just two control buttons. - Page 25 Lift DEVICE ONDA MODEL To raise the lift, press and hold down the button with the up arrow, in the upper part of the push-button panel. The anti-roll device rises automatically when the platform lifts off the ground. The lift stops automatically when it reaches the height of the floor of the vehicle.

-

Page 26: Use In Emergency Conditions

(1) in the manual pump housing (2). Move the handle up and down (3) to raise the platform up to the point of full closure. After the operation, replace the handle (1) in its fixing points and contact your Autolift Dealer or authorised converter. -

Page 27: Opening - Down

Lift DEVICE ONDA MODEL 7.2.2 OPENING - DOWN To open and lower the platform use the emergency knob (4) that is placed at the side of the hand pump To open and lower the platform turn anti-clockwise the emergency knob. After completing the operation , turn back the emergency knob in the original position. -

Page 28: Cleaning

Lift DEVICE CLEANING ONDA MODEL The lift must be cleaned by hand using a cloth soaked in non-aggressive detergent and then rinsed with a cloth dampened with water. DO NOT USE AGGRESSIVE DETERGENTS. DO NOT USE WATER JETS OR HOT WATER JET CLEANERS. -

Page 29: Adjustements

Lift DEVICE ADJUSTEMENTS ONDA MODEL SETTING OF THE FLOOR LEVEL The floor level stop position can be changed, repositioning the microswitch cams This adjustement will be executed this way: • Unlock fixing screw (1) • Rotate Cam • Tight fixing screw (1) PLATFORM “STOP”... -

Page 30: Maintenance

In the event of an immediate safety hazard, the user must place the lift out of use until the fault has been eliminated. Defects or damages must be reported to the manufacturer AUTOLIFT srl which will take any appropriate measures. -

Page 31: Frequency Of Controls

Lift DEVICE MAINTENANCE ONDA MODEL 10.2 FREQUENCY OF CONTROLS Frequency Operation Daily Monthly Yearly Frame check / Bridge and Rollstop and plates Operation check Controls check Oil level check Emergency devices check Plates and labels check ... -

Page 32: Demolition And Disposal

Lift DEMOLITION AND DEVICE DISPOSAL ONDA MODEL When disposing of the machine, comply with the procedures imposed by the law in force. Generally the machine should be disassembled to group homogeneous materials together. Specific materials such as lubricants, electrical / electronic components, must be disposed of according to specific laws. -

Page 33: Troubleshooting

Lift DEVICE TROUBLESHOOTING ONDA MODEL The troubleshooting table below helps to solve any operating failures. For any failure that is not listed below or that is due to machanical or hydraulic damage, please contact the nearest authorised service point. FAILURE MODE CAUSE SOLUTION Main power switch positioned on... - Page 34 Lift DEVICE TROUBLESHOOTING ONDA MODEL FAILURE MODE CAUSE SOLUTION Lowering valve emergency screw The platform does not rise Tight emergency screw not tight Lowering valve broken Replace the lowering valve Power pack starting relais broken Replace power pack starting relais Replace Hydraulic power pack Hydraulic power pack defective defective...

-

Page 35: Wiring Diagram

Lift DEVICE WIRING DIAGRAM ONDA MODEL... -

Page 36: Hydraulic Diagram

Lift DEVICE HYDRAULIC DIAGRAM ONDA MODEL... -

Page 37: Spare Parts

Lift DEVICE SPARE PARTS ONDA MODEL For spare parts, contact the Autolift Srl spare parts department by submitting the following form. - Page 38 SPARE PARTS REQUEST FORM FROM SPARE PARTS DEPARTMENT Fax +39 (0)376 553728 – mail: info@autoliftsrl.com DESCRIPTION PRIORITY URGENT NORMAL SHIPMENT PAYMENT DESTINATION SIGNATURE DATE...

Need help?

Do you have a question about the ONDA OB Series and is the answer not in the manual?

Questions and answers