Summary of Contents for Sleipner SH400

- Page 1 Installation Guide For Hydraulic Thruster Models SH400 DOCUMENT ID: SLEIPNER AS 6074 REVISION: P.O. Box 519 DATE: N-1612 Fredrikstad 2021 Norway LANGUAGE: www.sleipnergroup.com...

-

Page 2: Table Of Contents

Pre-delivery Checklist ..................................23 Service and Support................................... 24 Product Spare Parts and Additional Resources ..........................24 Warranty Statement .................................... 24 Products SM908041 | SH400/300TC-BA23 - SH400 Tunnel thruster, BA23 Sleipner Motor AS P.O. Box 519, Arne Svendsensgt. 6-8 N-1612 Fredrikstad, Norway MC_0020... -

Page 3: Responsibility Of The Installer

Sleipner products. If you are interfacing the S-Link™ bus by agreement with Sleipner through a designated Sleipner supplied interface, you are still required to install at least one original Sleipner control panel to enable efficient troubleshooting if necessary. -

Page 4: Thruster Measurements

Thruster Measurements MC_0195 *400 Measurement Measurement description code mm inch Internal tunnel diameter 11.81 Motor Height 14.02 Width 10.16 Length 10.16 Water Depth 17.72 Minimum tunnel length 14.57 TL (recommended) Recommended tunnel length 21.65 T (min) Minimum tunnel wall thickness 0.39 T (max) Maximum tunnel wall thickness... -

Page 5: Thruster Specifications

Thruster Specifi cations MC_0196 Description * 400 Light duty thrust up to (kg * lbs) 400 kg * 882 lbs Heavy duty thrust up to (kg * lbs) 400 kg * 882 lbs Typical Boat Size (m * ft) 18m - 33m * 75ft - 110ft Propulsion System Twin Counter Rotating Power (kw * Hp) - Page 6 USG-PSI 14.4 2118 16.46 2843 18.57 3553 L/min -Bar 43.5 50.2 54.2 USG-PSI 11.49 2828 13.26 3771 14.32 4380 SH400 L/min -Bar 52.3 60.4 67.5 BA23 USG-PSI 13.82 2364 15.96 3162 17.83 3945 L/min -Bar 44.7 51.6 56.2 USG-PSI 11.81 2726 13.63...

-

Page 7: Technical Requirements / Hydraulic Hose Connections To Motor

07.03.2014 07.03.2014 Hyd. motor 16 ccm Copyright All rights reserved Copyright All rights reserved Title Title Hyd. motor 16 ccm Hyd. motor 16 ccm SLEIPNER MOTOR AS Part nr Weight Size Scale Edition Sheet SLEIPNER MOTOR AS SLEIPNER MOTOR AS... -

Page 8: Positioning Of The Tunnel / Thruster

Positioning of the tunnel / thruster MC_0003 Aim to install the thruster as far forward as possible (1) Due to the leverage effect around the boats’ pivot point. The distance difference from the boat pivots’ point to the thruster will determine the amount of real rotation power for the boat. -

Page 9: Tunnel Length

Tunnel Length MC_0003 Optimal tunnel length Achieving the correct tunnel length depends on many factors from the hull type, operation and environmental conditions. Tunnels should avoid being longer than 4 x the tunnel diameter as this will reduce thruster performance. (NB: Installing long length tunnels can flex/ bend over time and may require additional support. -

Page 10: Tunnel Installation In Sailboats

Tunnel installation in Sailboats MC_0003 Some sail boats have a flat bottom and shallow draft in the bow section. This can make installing the thruster as far forward from the boats main pivot point diffi cult. (Fig. 1). However, it is possible to install a tunnel thruster in most sail boats, even when the hull does not directly support the fi tting of a tunnel. Instead fi... -

Page 11: Water Deflection

Water Deflection MC_0003 A possible problem in sail boats or fast powerboats is that a non-rounded surface can generate drag from the back face of the tunnel, as it creates a “flat” area facing the flow of water. This problem can be solved in two different ways, depending on what is possible or easier to perform. The best solution which generally reduces the most drag is to make a recess in the hull at the back of the tunnel. -

Page 12: Tunnel Ends

Tunnel Ends MC_0003 Rounded tunnel ends will maximise thrust and minimise noise and cavitation. For best performance round the tunnel connection to the hull-side as much as possible. The minimum rounding has a radius of 10% of the diameter of the tunnel. -

Page 13: Tunnel Installation

Tunnel Installation MC_0003 IMPORTANT We recommend that a professional does the fi breglass, steel or aluminium fi tting of the tunnel. These instructions are only general instructions and do not explain in any way the details of fi breglass work. Problems caused by faulty installation of the tunnel, are the installers full responsibility. - Page 14 Tunnel Installation MC_0003 With tunnel installed and cast. Round the edges with a radius of 10% of the tunnel diameter. For steel/ aluminium hulls make a slope with a length of 10-15% of the tunnel diameter. (NB: If this is not possible, round the tunnel end as much as possible.) Additionally cast two layers on the outside of the tunnel/ hull in a 10cm area Follow the same method if making the deflector/ spoiler.

-

Page 15: Stern Tunnel Installation

Stern Tunnel Installation MC_0003 For Stern Thruster installation please refer to the supplied manual in your Sleipner product delivery Installation Guide Stern Thruster SLEIPNER AS DOCUMENT ID: P.O. Box 519 REVISION: DATE: N-1612 Fredrikstad Norway www.sleipnergroup.com LANGUAGE: SH 400 6074... -

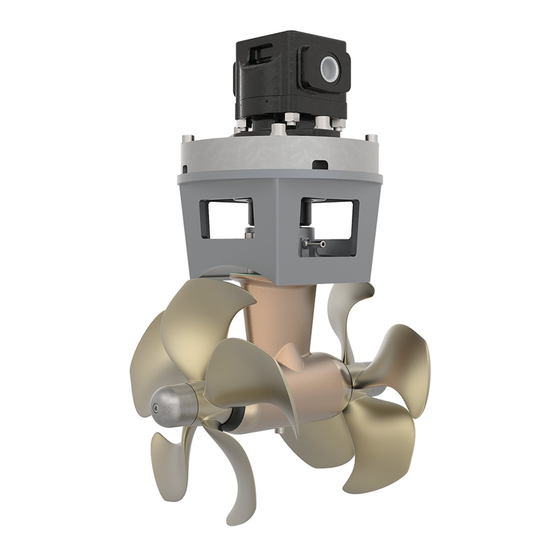

Page 16: Gear Leg & Motor Bracket Installation

Gear Leg & Motor Bracket Installation MC_0001 ! Please refer to the graphic for special considerations relating to your model ! Mark the tunnel centreline and the boat’s centreline. (NB: Install the gear leg and propeller as shown above for the thrust direction to correspond with the control panel. -

Page 17: Propeller Installation

Propeller Installation MC_0022 ! Please refer to the graphic for special considerations relating to your model ! Rotate the propeller shaft, so the propeller key is on top. Remove the tape holding the propeller key in its recess on the propeller shaft. Insert the propeller onto the propeller shaft until the propeller key aligns into the slot/ groove in the propeller. -

Page 18: Motor Installation

Motor Installation MC_0109 ! Please refer to the graphic for special considerations relating to your model ! Install the motor onto the motor bracket ensuring the couplings are engaged together correctly (top and bottom). (NB: The motor can be placed in all directions on the motor bracket. -

Page 19: Oil Tank Installation

Oil Tank Installation MC_0023 ! Please refer to the graphic for special considerations relating to your model ! Install the oil tank above the waterline by at least 20% of the distance from the waterline to the centre of the tunnel. This ensures enough overpressure for the oil in the gear leg. -

Page 20: Crossover Valve

Crossover Valve Crossover valve must be mounted as close as possible to the motor SH 400 1/2” valve SH 700, 1000, 1400 1” valve Valve coil w/ connector MG_0341 SH 400 6074 2021... -

Page 21: S-Link System Description

MC_0120 S-Link is a CAN-based control system used for communication between Sleipner products installed on a vessel. The system uses BACKBONE Cables as a common power and communication bus with separate SPUR Cables to each connected unit. Units with low power consumption are powered directly from the S-Link bus therefore one power cable must be connected to the BACKBONE Cable through a T-Connector. -

Page 22: Control Panel Installation

Control Panel Installation MC_0398 For Control Panel installation please refer to the supplied manual in your Sleipner product delivery Installation Guide Control Panel SLEIPNER AS DOCUMENT ID: P.O. Box 519 REVISION: DATE: N-1612 Fredrikstad Norway www.sleipnergroup.com LANGUAGE: SH 400 6074... -

Page 23: Pre-Delivery Checklist

Checklist for Hydraulic Thrusters MC_0049 ..Propeller is fastened correctly to the shaft... Propeller turns freely in tunnel... Lower-unit is fi lled with gear oil... Oil-drain screw is tightened and the copper seal is present... The anode holding screw is tightened well with thread glue... -

Page 24: Service And Support

10. This warranty gives you specific legal rights, and you may also have other rights which vary from country to country. Patents MC_0024 At Sleipner we continually reinvest to develop and offer the latest technology in marine advancements. To see the many unique designs we have patented visit our website www.sleipnergroup.com/patents SH 400... - Page 25 Notes MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................SH 400 6074 2021...

- Page 26 Notes MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................SH 400 6074 2021...

- Page 27 Notes MC_0037 ..............................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................................SH 400 6074 2021...

- Page 28 © Copyright Sleipner Motor AS, 2021 The information given in the document was correct at the time it was published. However, Sleipner Motor AS can not accept liability for any inaccuracies or omissions it may contain. Continuous product improvement may change the product specifi...

Need help?

Do you have a question about the SH400 and is the answer not in the manual?

Questions and answers